Covalent organic framework with triphenylphosphine as skeleton, preparation method and application thereof

A covalent organic framework, triphenylphosphine technology, applied in the preparation of organic compounds, carbon-based compound preparation, organic chemistry and other directions, can solve the problems of the reusability and stability of small molecule catalysts need to be improved, and achieve improved Catalytic activity and reusability, cheap and easy availability of raw materials and solvents, enhanced interaction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

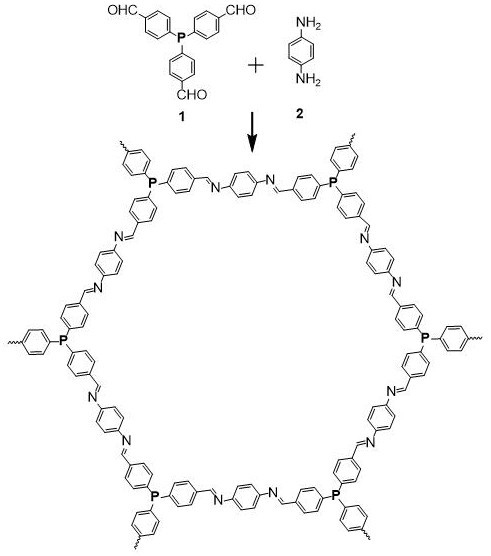

[0032] Example 1: A method for preparing a covalent organic framework with triphenylphosphine as a skeleton, the steps are as follows:

[0033] S1: Take 0.17mmol of triphenylphosphinetrialdehyde 60mg, 0.25mmol of p-phenylenediamine 28mg, add 10ml into a glass tube with a body length of 18cm and a neck length of 9cm, add 0.14ml of mesitylene and 0.42ml of 1,4-dioxine For six rings, after ultrasonically dispersing the raw materials evenly, add 0.35ml of 6mol / L acetic acid, and continue ultrasonically dispersing to form suspension A.

[0034] S2: The suspension A was frozen in liquid nitrogen, vacuumized, and degassed three times in sequence. Under the vacuum state, the glass tube was baked and sealed with a flame gun, and placed in a 120°C oven for 3 days. After cooling, the crude product was obtained.

[0035] S3: Roughly washed with N,N-dimethylformamide, then Soxhlet extracted with tetrahydrofuran and chloroform for 12 hours, and vacuum-dried at 65°C for 12 hours to obtain 6...

Embodiment 2

[0037] Example 2: A method for preparing a covalent organic framework with triphenylphosphine as a skeleton, the steps are as follows:

[0038] S1: Take 0.17mmol of triphenylphosphinetrialdehyde 60mg, 0.25mmol of p-phenylenediamine 28mg, add 10ml into a glass tube with a body length of 18cm and a neck length of 9cm, add 0.28ml of tert-butanol and 0.28ml of o-dichlorobenzene, and ultrasonically After the raw materials are evenly dispersed, add 0.35ml of 6mol / L acetic acid, and continue ultrasonic dispersion to form suspension A.

[0039] S2: The suspension A was frozen in liquid nitrogen, vacuumized, and degassed three times in sequence. Under the vacuum state, the glass tube was baked and sealed with a flame gun, and placed in a 120°C oven for 3 days. After cooling, the crude product was obtained.

[0040] S3: Suction filtration and washing with N,N-dimethylformamide, Soxhlet extraction with tetrahydrofuran and chloroform for 12 hours, and vacuum drying at 65°C for 12 hours t...

Embodiment 3

[0042] Example 3: The application of a covalent organic framework with triphenylphosphine as a skeleton (hereinafter referred to as Phos-COF) in the controllable preparation of metal nanoparticles, the specific preparation steps are as follows:

[0043] S1: Take 40mg of Phos-COF and 4mg of potassium tetrachloropalladate (K 2 PdCl 4 ), added to a 20ml reaction flask, added 4.8ml of methanol, and stirred at room temperature for 24 hours to form a suspension A.

[0044] S2: Vacuum the suspension A into a paste, then add 3.8ml of methanol to disperse, add 15mg of sodium borohydride (NaBH 4) in 1ml of methanol, stirred for 30 minutes to obtain a crude product.

[0045] S3: The crude product was centrifuged three times with methanol and dichloromethane at 10,000 rpm respectively, and the insoluble matter was collected and vacuum-dried at 65° C. for 12 hours to obtain 39 mg of a brown powder solid, with a yield of 94%.

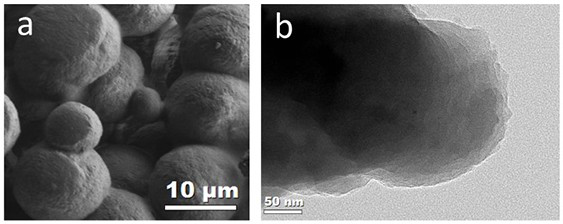

[0046] Transmission electron microscope of the Pd nanopartic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com