Hindered-phenol-modified montmorillonite damping agent and production method and application thereof

A technology of hindered phenol and montmorillonite, applied in the field of damping materials, can solve the problems that the damping performance and mechanical properties cannot meet the actual needs, and can not broaden the effective damping temperature range of rubber, etc., and achieve excellent damping performance and mechanical properties, wide effective Effect of damping temperature range and improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

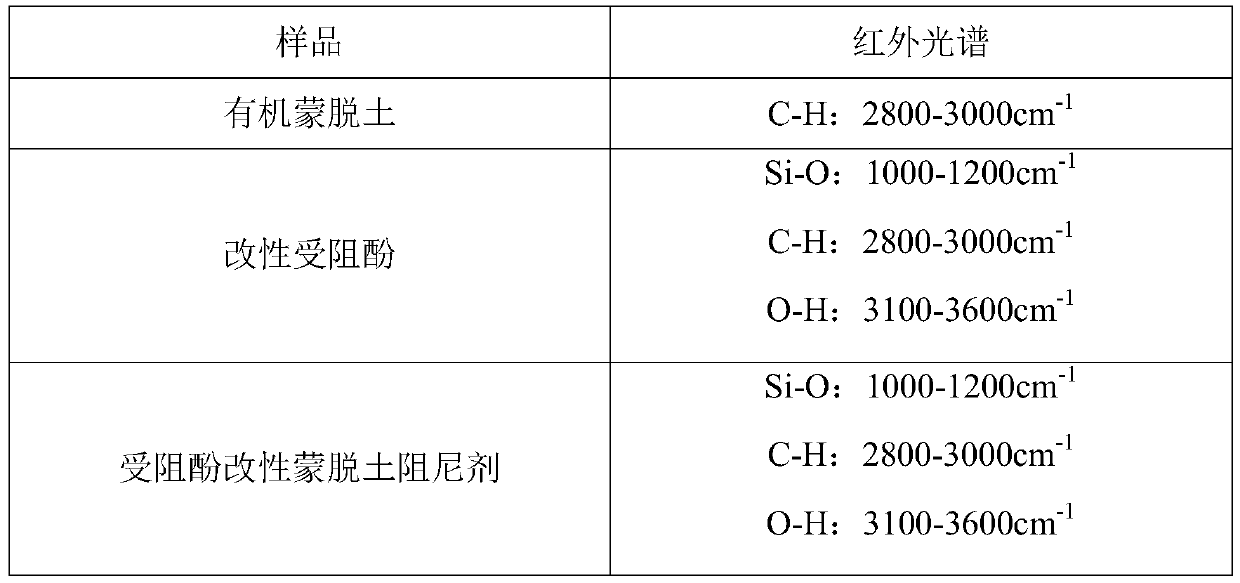

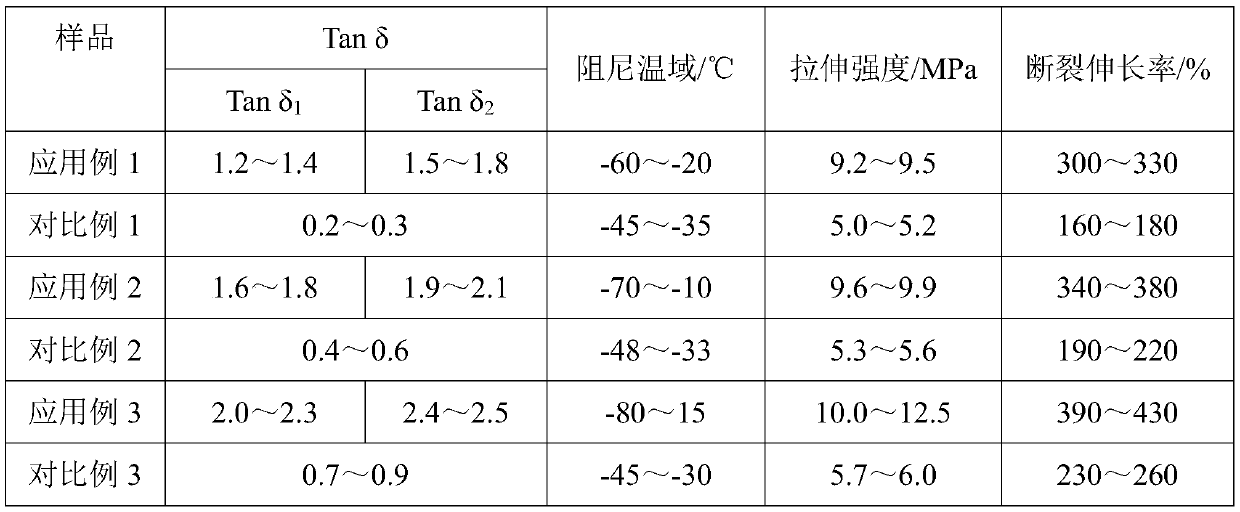

Examples

Embodiment 1

[0050] a) Inorganic montmorillonite is added to water, the mass ratio of water and inorganic montmorillonite is 5:1, and it is prepared into montmorillonite suspension; hexadecyl ammonium bromide is dissolved in water, water and hexadecane The mass ratio of alkyl ammonium bromide is 100:1, is mixed with alkyl quaternary ammonium salt aqueous solution; 10g montmorillonite suspension is mixed with 30g alkyl quaternary ammonium salt aqueous solution, then stirred and reacted at 70 ℃ for 6 hours, and ended the reaction , filter the reaction solution, wash the filter cake with deionized water until no bromide ions exist in the washing solution, then dry the resultant at 100°C to obtain organic montmorillonite;

[0051] b) dissolving 2,6-di-tert-butylphenol in xylene to prepare a 10wt% hindered phenol xylene solution; dissolving sodium methoxide in methanol to prepare a 6wt% sodium methoxide solution; anhydrous and oxygen-free Under the conditions, the hindered phenol xylene solution,...

Embodiment 2

[0061] a) Inorganic montmorillonite is added to water, the mass ratio of water and inorganic montmorillonite is 8:1, and it is prepared into montmorillonite suspension; hexadecyl ammonium bromide is dissolved in water, water and hexadecane The mass ratio of ammonium bromide is 100:2, and it is prepared into an aqueous solution of alkyl quaternary ammonium salt; 10g of montmorillonite suspension is mixed with 40g of aqueous alkyl quaternary ammonium salt, then stirred and reacted at 75°C for 5 hours, and the reaction is terminated , the reaction solution was filtered, and the filter cake was washed with deionized water until no bromide ions existed in the washing solution, and then the resultant was dried at 110° C. to obtain organic montmorillonite;

[0062] b) dissolving 2,6-di-tert-butylphenol in xylene to prepare a 20wt% hindered phenol xylene solution; dissolving sodium methoxide in methanol to prepare a 7wt% sodium methoxide solution; anhydrous and oxygen-free Under the c...

Embodiment 3

[0072] a) Inorganic montmorillonite is added to water, the mass ratio of water and inorganic montmorillonite is 10:1, and it is prepared into montmorillonite suspension; hexadecyl ammonium bromide is dissolved in water, water and hexadecane The mass ratio of alkylammonium bromide is 100:3, and it is prepared into an aqueous solution of alkyl quaternary ammonium salt; 10g of montmorillonite suspension is mixed with 50g of aqueous alkyl quaternary ammonium salt, then stirred and reacted at 80°C for 4 hours, and the reaction is terminated , the reaction solution was filtered, and the filter cake was washed with deionized water until no bromide ions existed in the washing solution, and then the resultant was dried at 120° C. to obtain organic montmorillonite;

[0073] b) dissolving 2,6-di-tert-butylphenol in xylene to prepare a 30wt% hindered phenol xylene solution; dissolving sodium methoxide in methanol to prepare an 8wt% sodium methoxide solution; anhydrous and oxygen-free Unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com