Patents

Literature

48results about How to "Out of operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

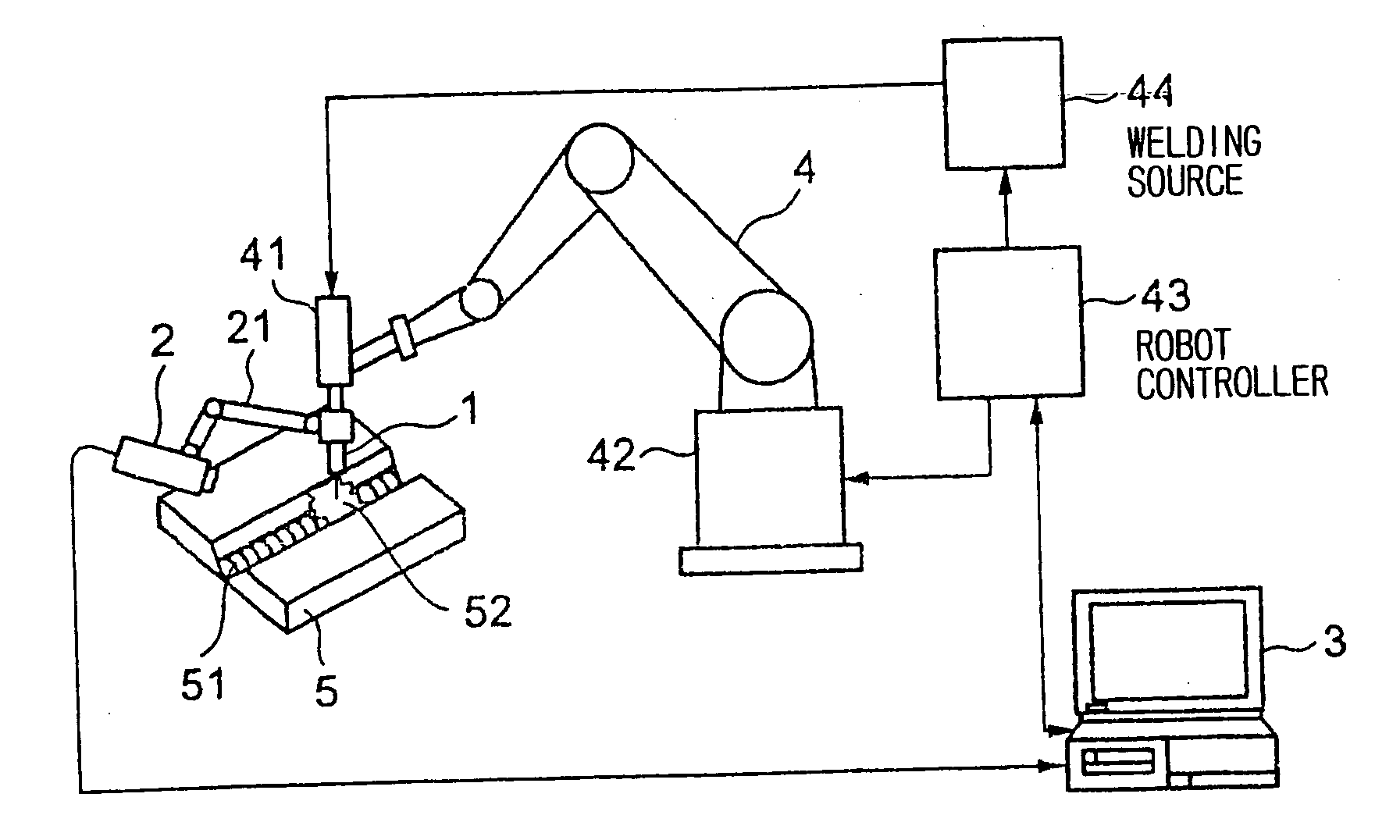

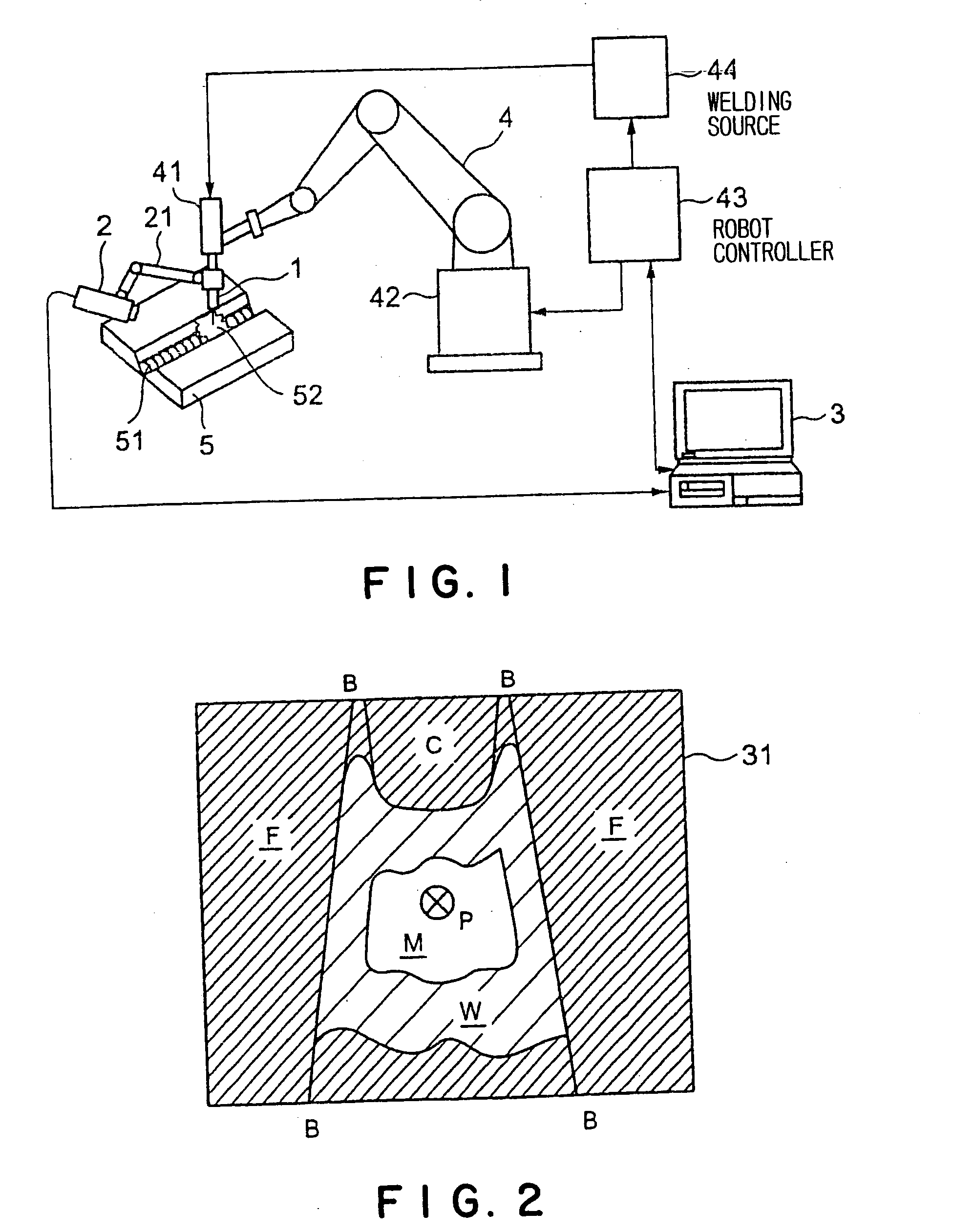

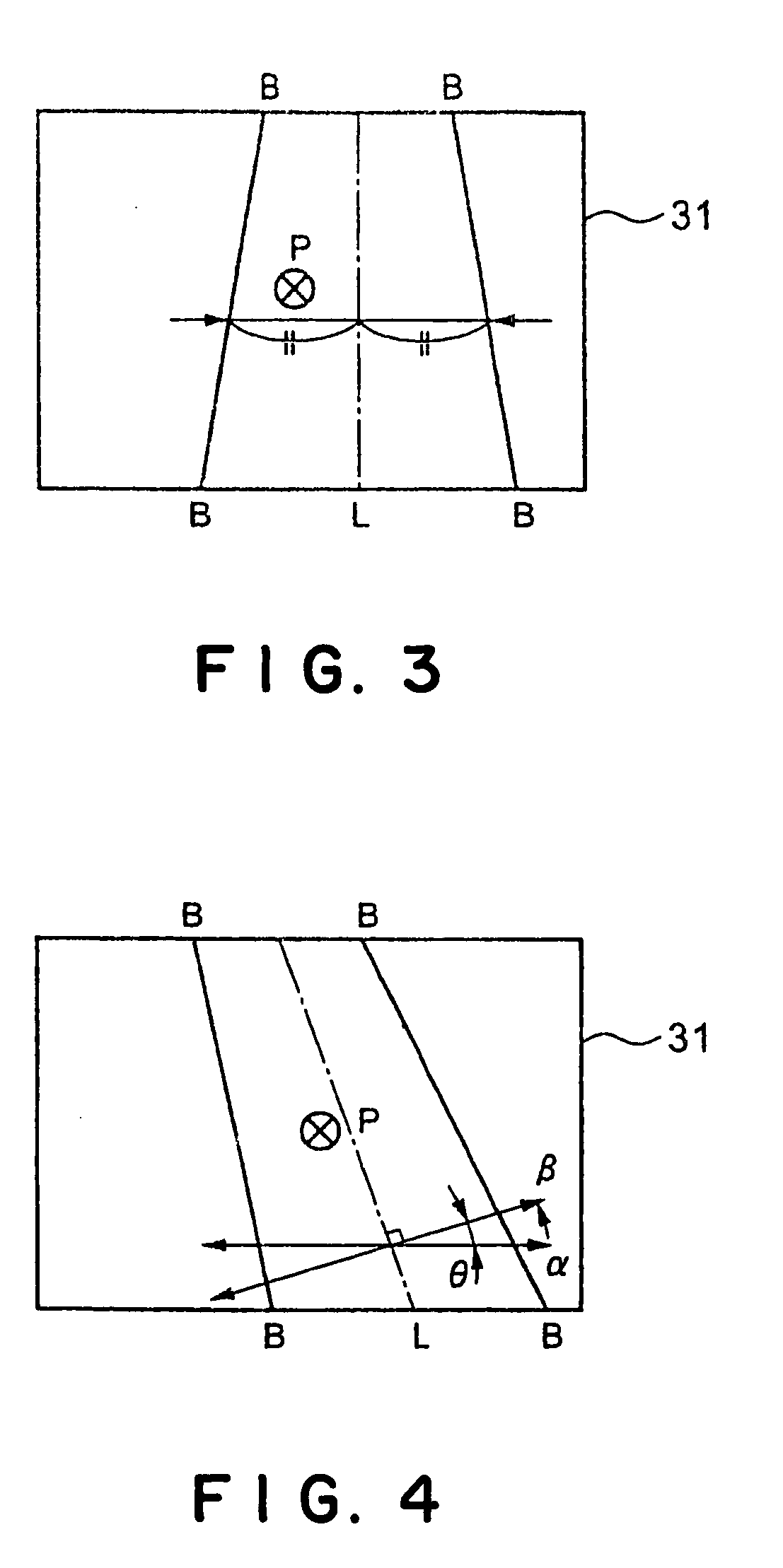

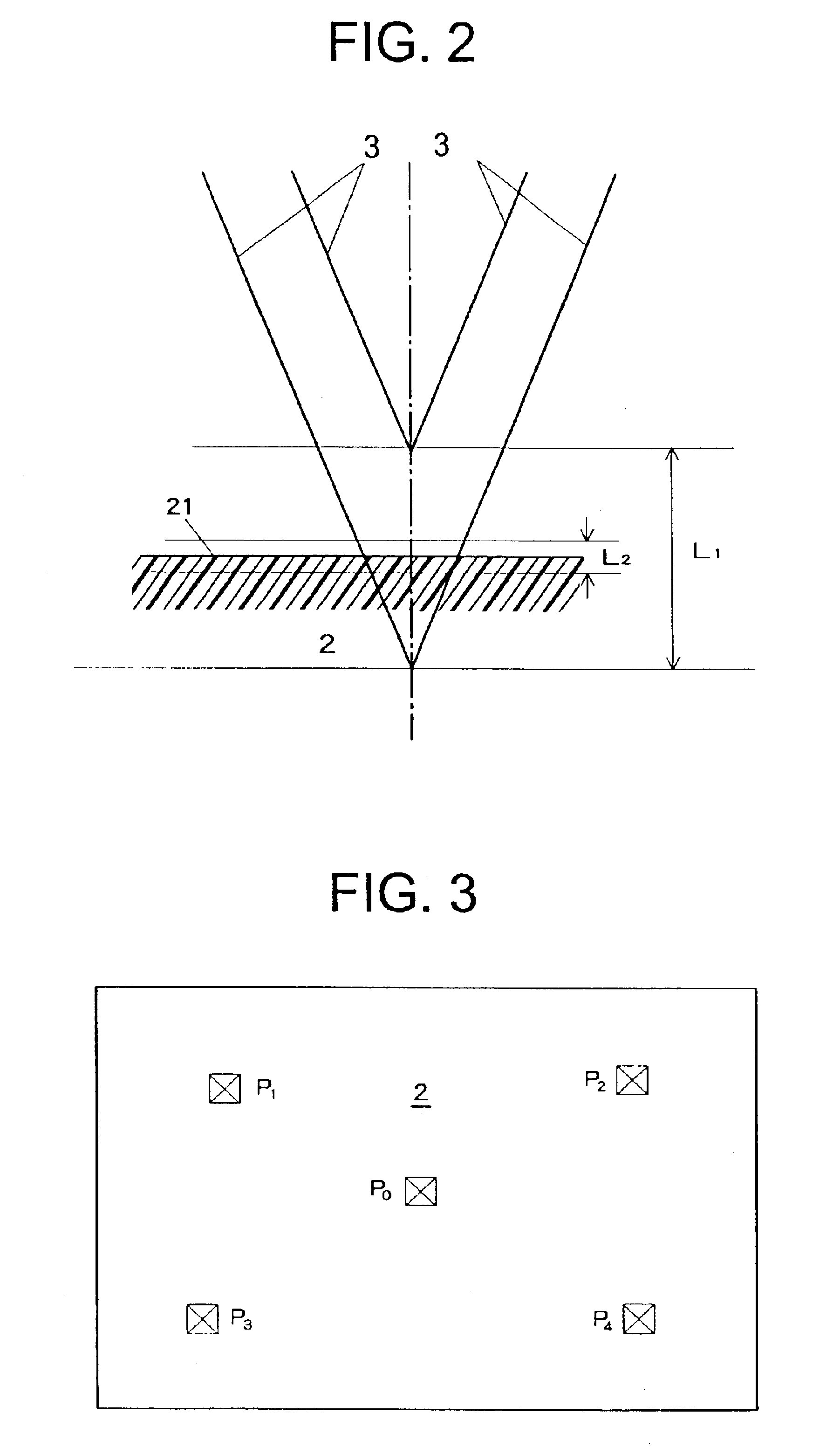

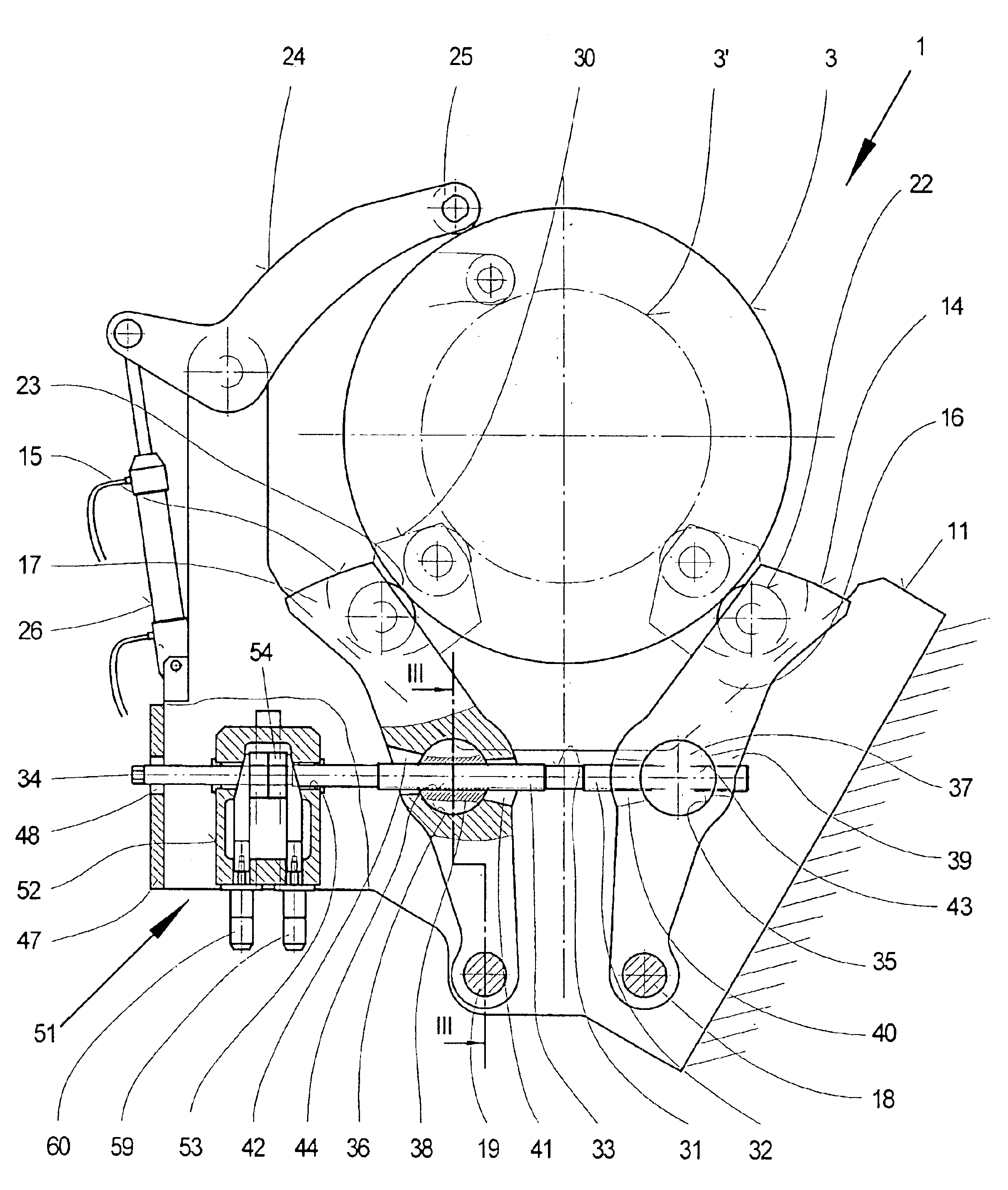

Automatic groove copy welder and welding method

InactiveUS20050103766A1Accurate control operationAccurately carry-outArc welding apparatusEngineeringCcd camera

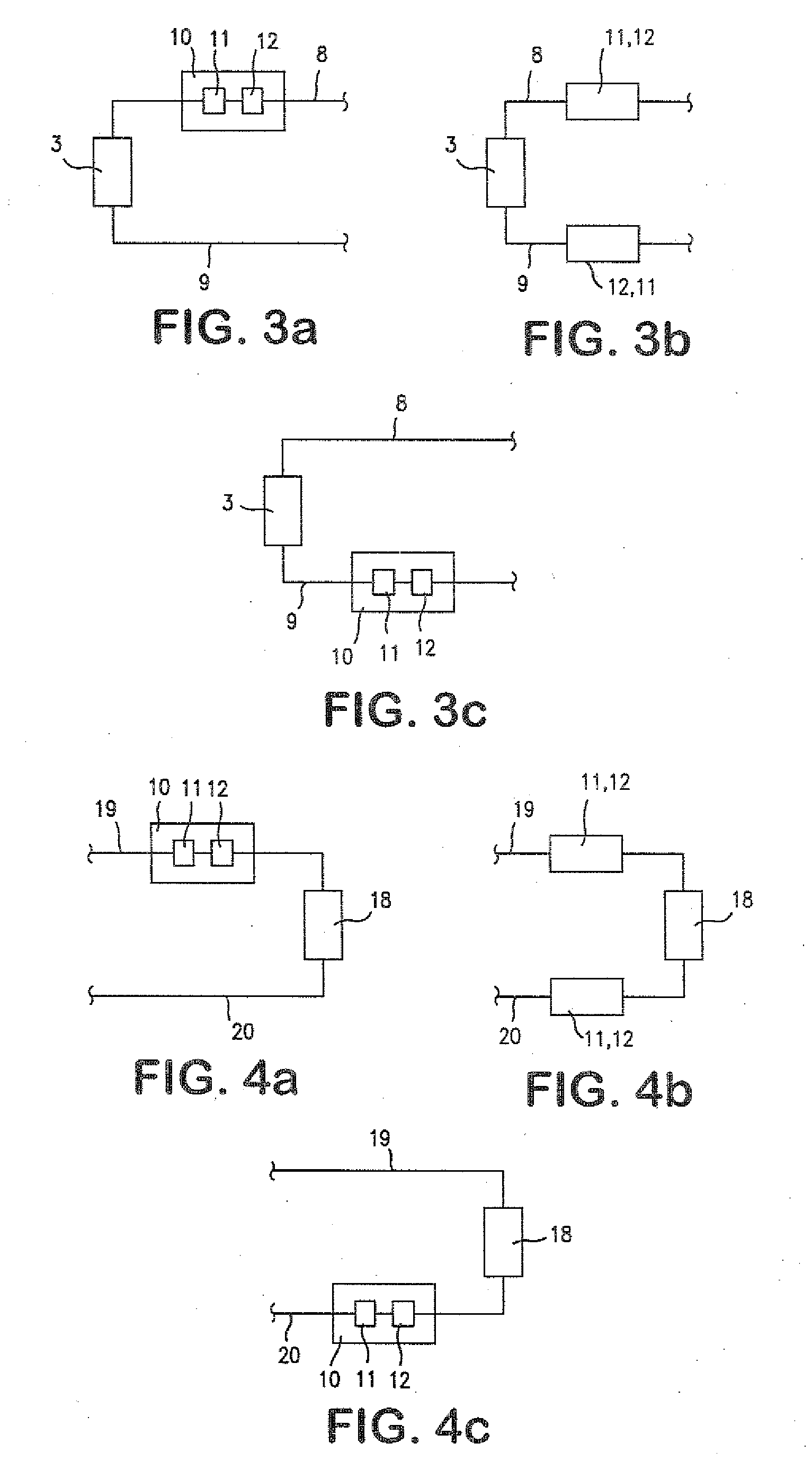

An automatic groove-tracing welding system is capable of carrying out a welding operation, particularly, a welding operation involving weaving, without requiring monitoring even if conditions of a groove is different from design conditions of the groove. An image processor 3 receives an image signal representing an image of a weld zone 52 including the tip of a welding wire from a camera head 2 provided with a CCD camera, processes the image of the weld zone 52 to determine the position of a groove, calculates the positional relation of the groove with a welding torch 1, and sends a position correction for correcting the position of the welding torch 1 so that the welding path of the tip of the welding torch 1 may coincide with a predetermined middle part in the groove to a robot controller 43 for controlling a welding robot. When the automatic groove-tracing welding system performs a welding operation involving weaving, the image processor 3 receives a weaving phase signal representing phases of weaving from the robot controller 43, calculates the positional relation between the groove and the welding torch on the basis of the phase of weaving, and sends a weaving width correction signal to the robot controller 43.

Owner:KAWASAKI HEAVY IND LTD

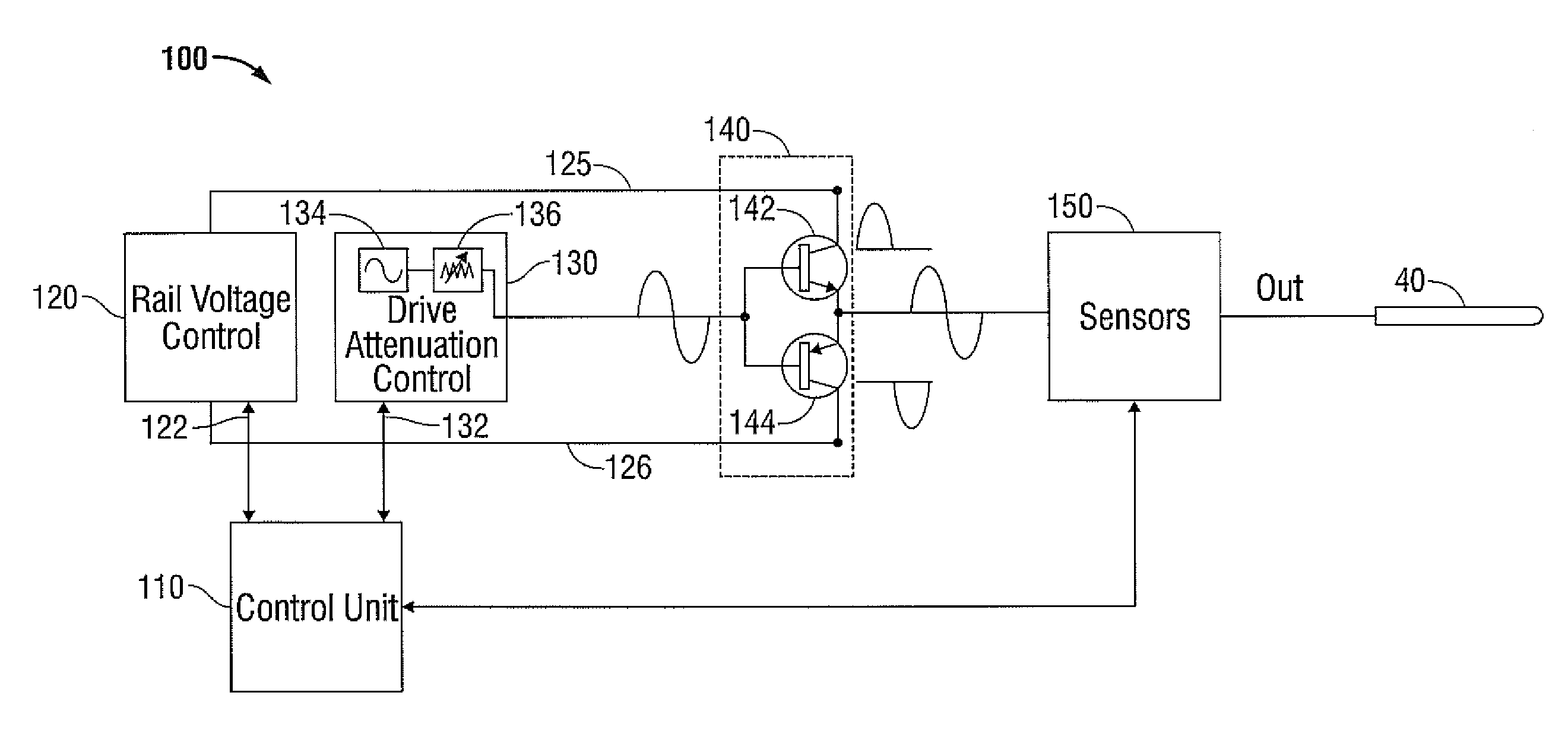

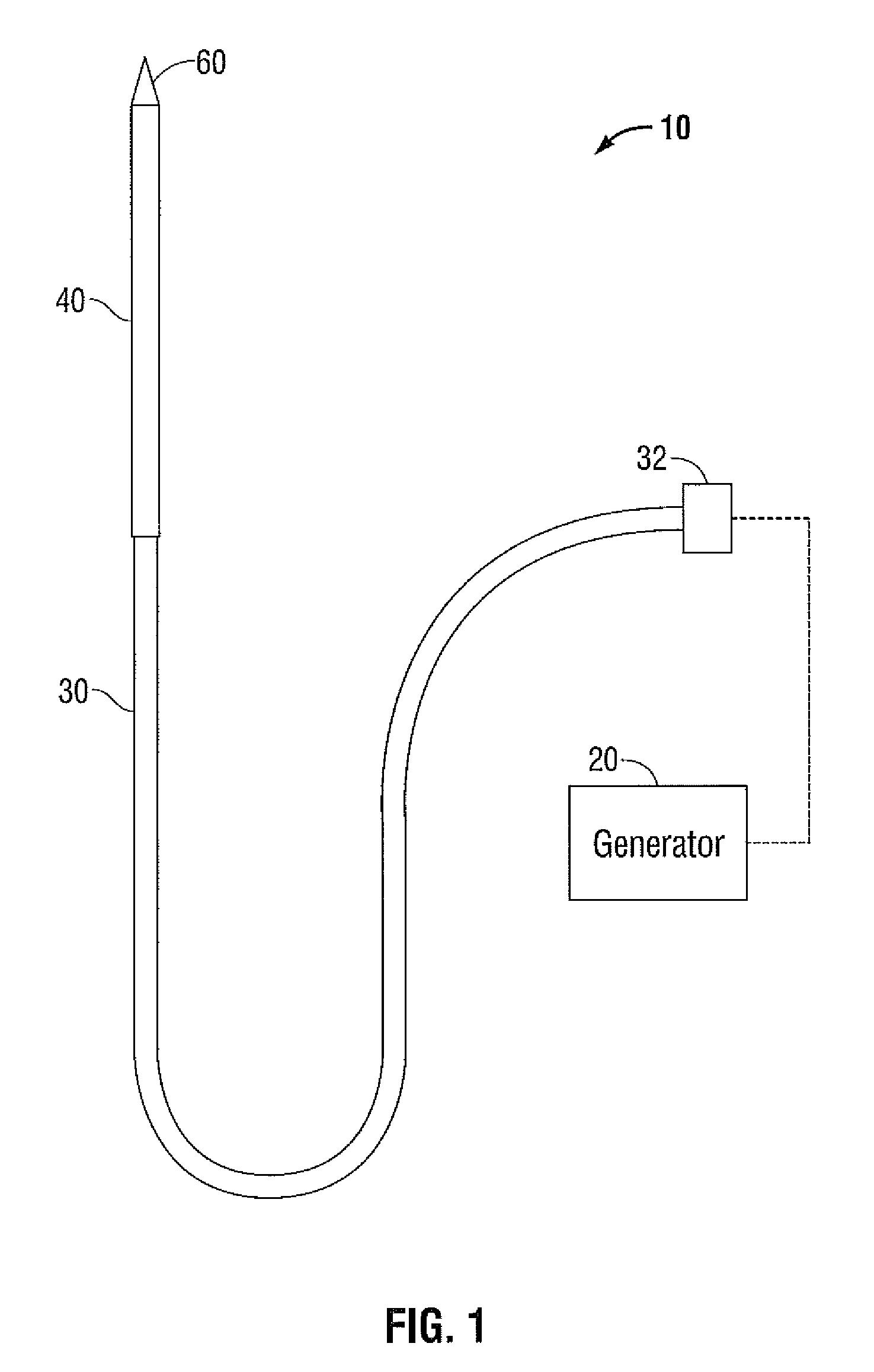

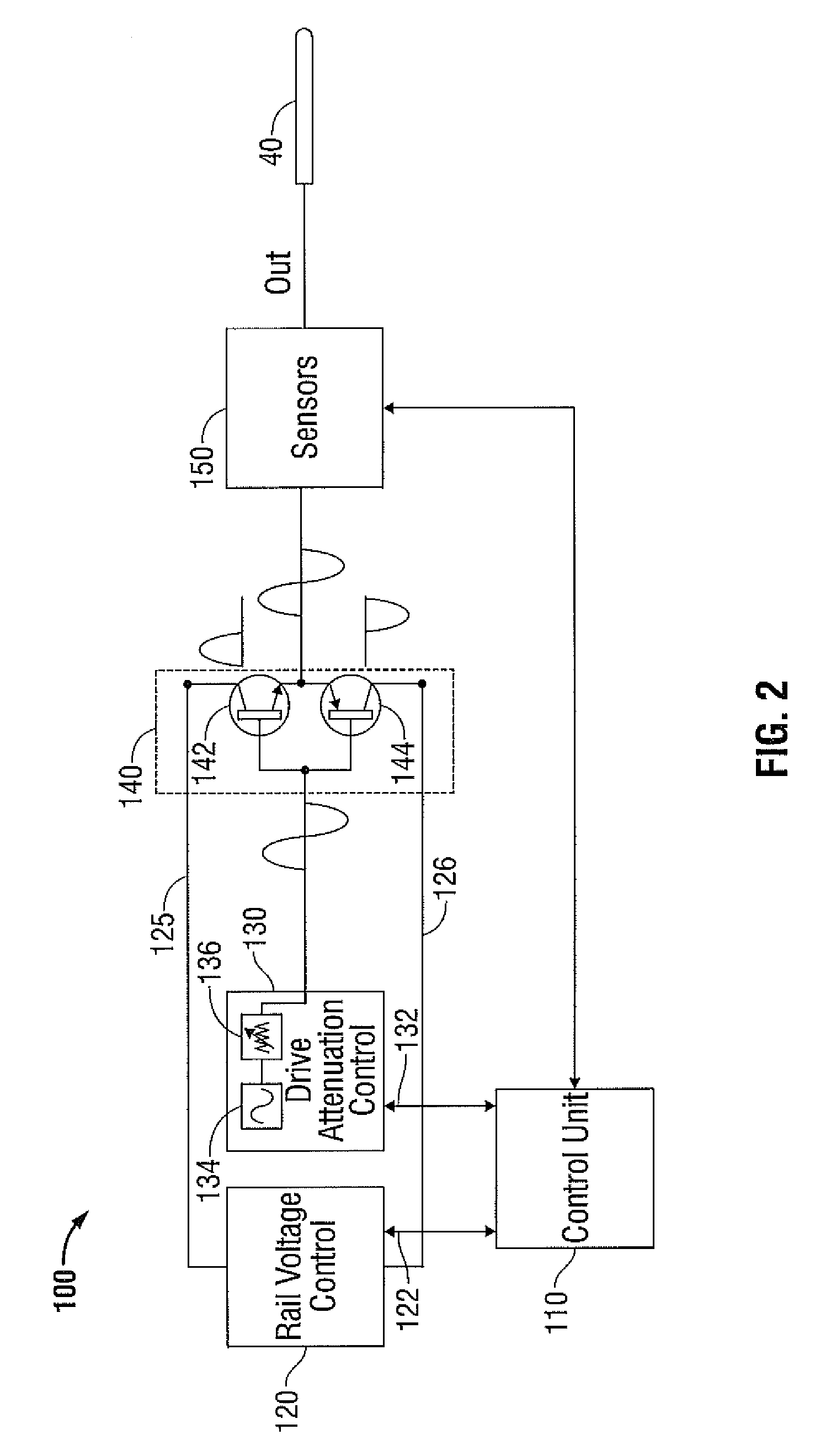

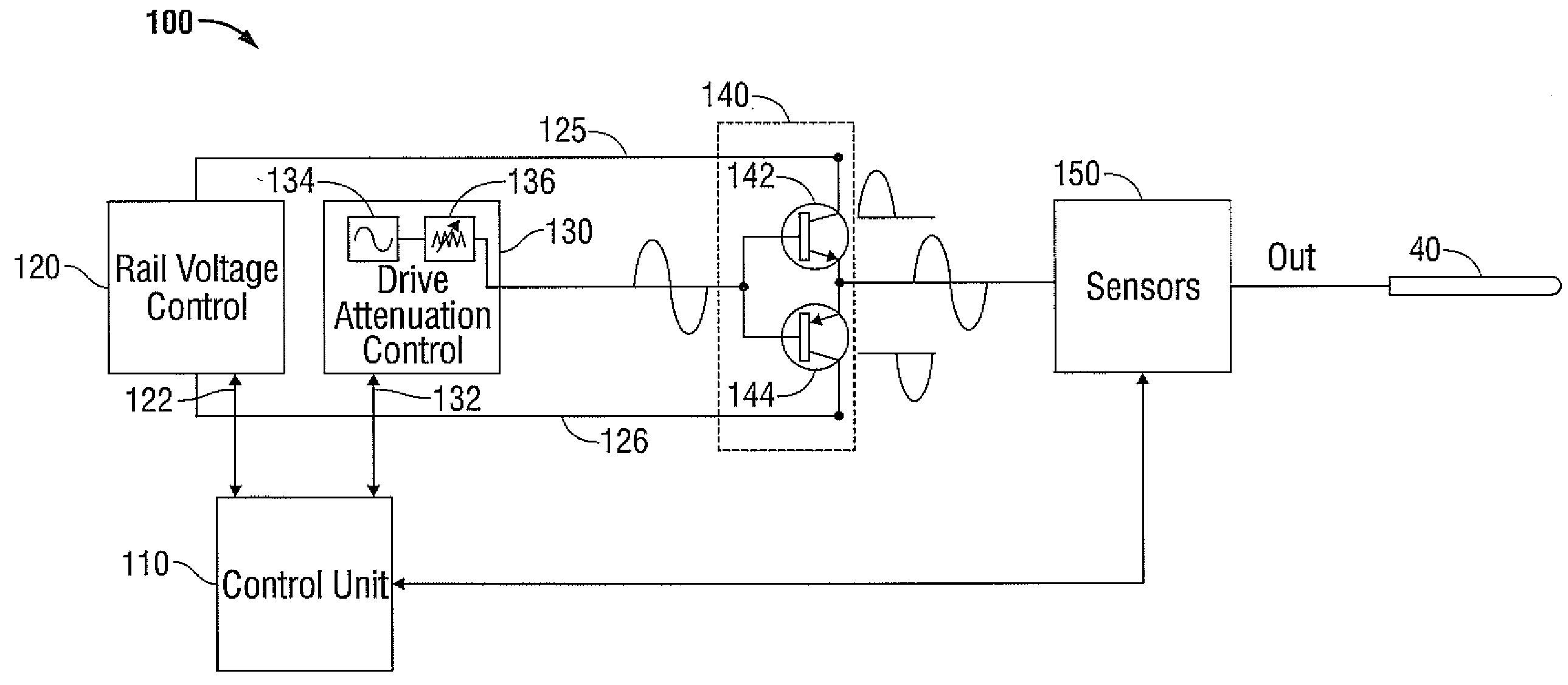

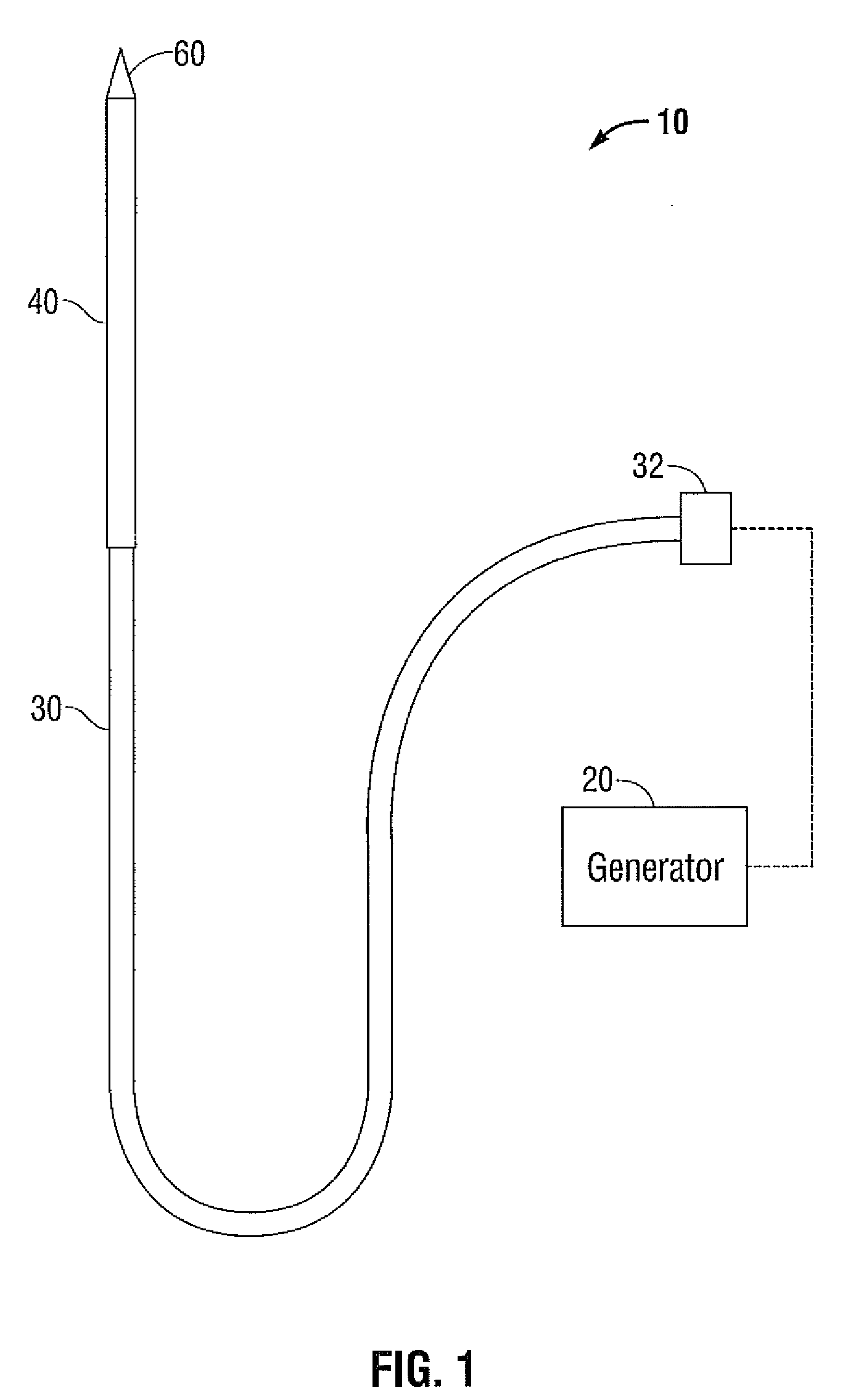

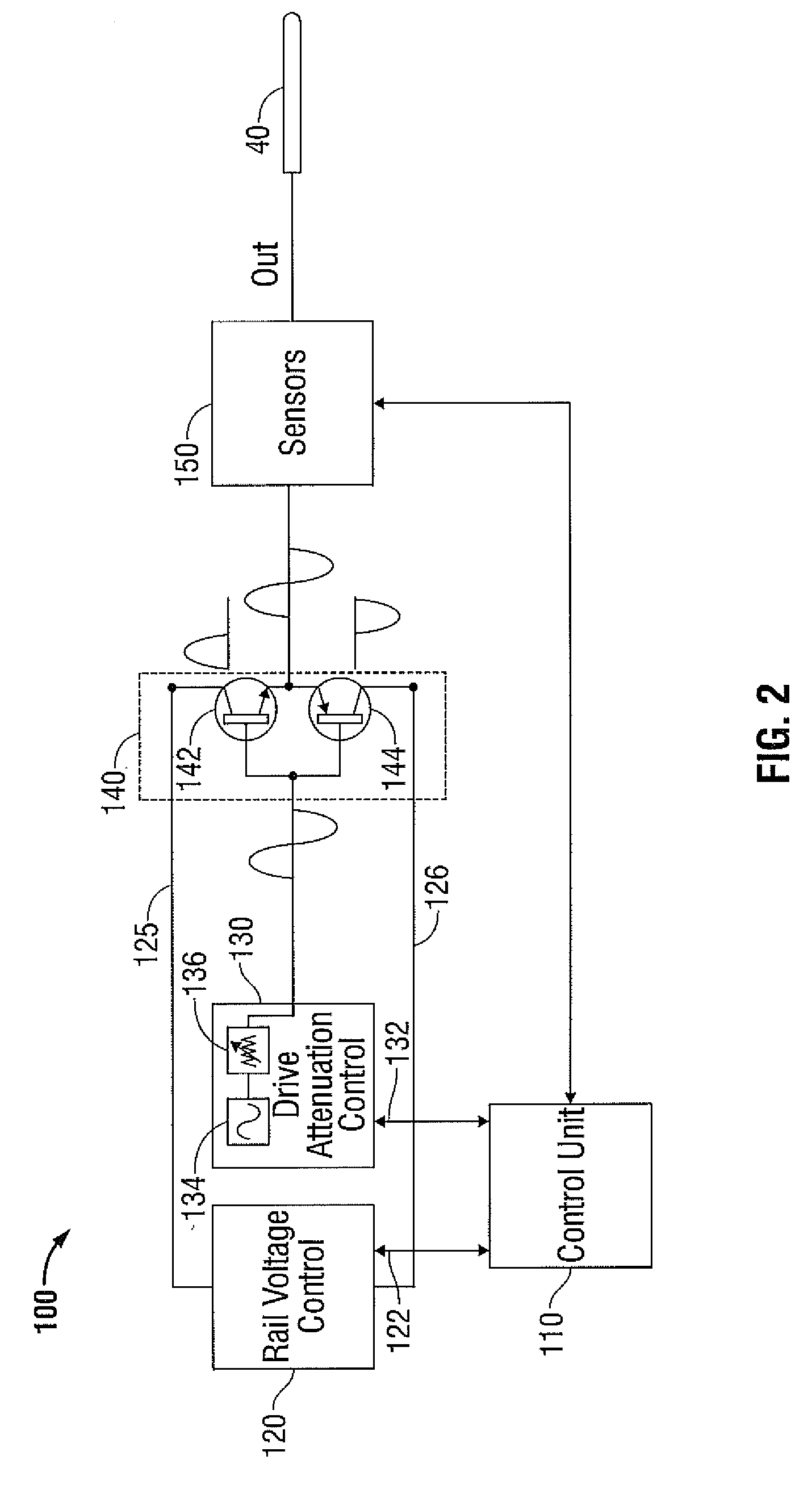

High efficiency microwave amplifier

ActiveUS7863984B1Reduce harmonicReduces undesirable radiofrequency interferencePush-pull amplifiersPhase-splittersLinear regionEngineering

Disclosed is an apparatus and method for operating a microwave amplifier with improved efficiency and reduced harmonic emissions. The disclosed amplifier includes a variable rail voltage supply and a variable input drive stage. A controller continually monitors the amplifier output and adjusts the rail voltage and input drive signal to achieve high efficiency and low harmonic emissions. The amplifier may include a dynamic bias controller configured to operate the gain elements outside the linear region. Efficiencies of over 70% may be achieved by the disclosed amplifier.

Owner:TYCO HEALTHCARE GRP LP

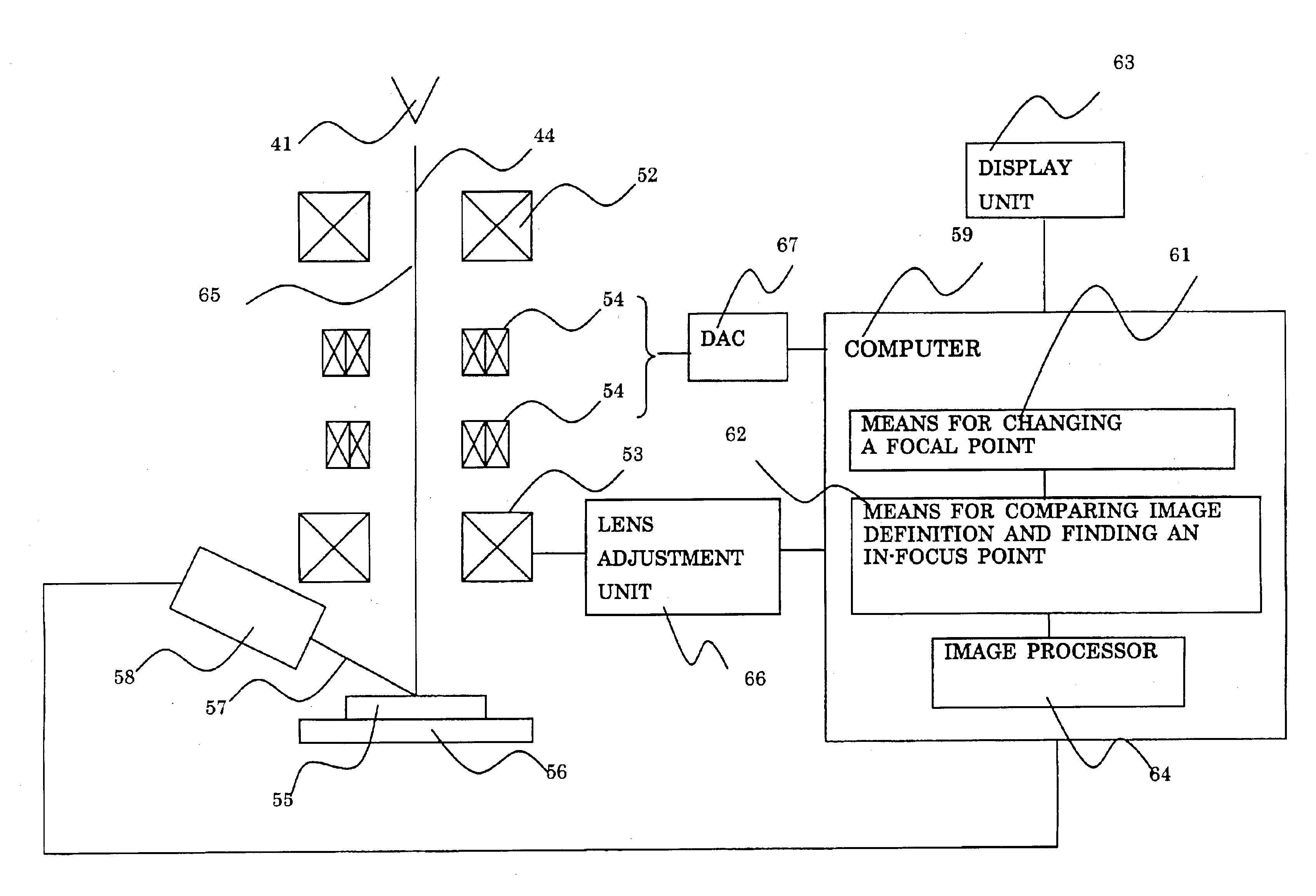

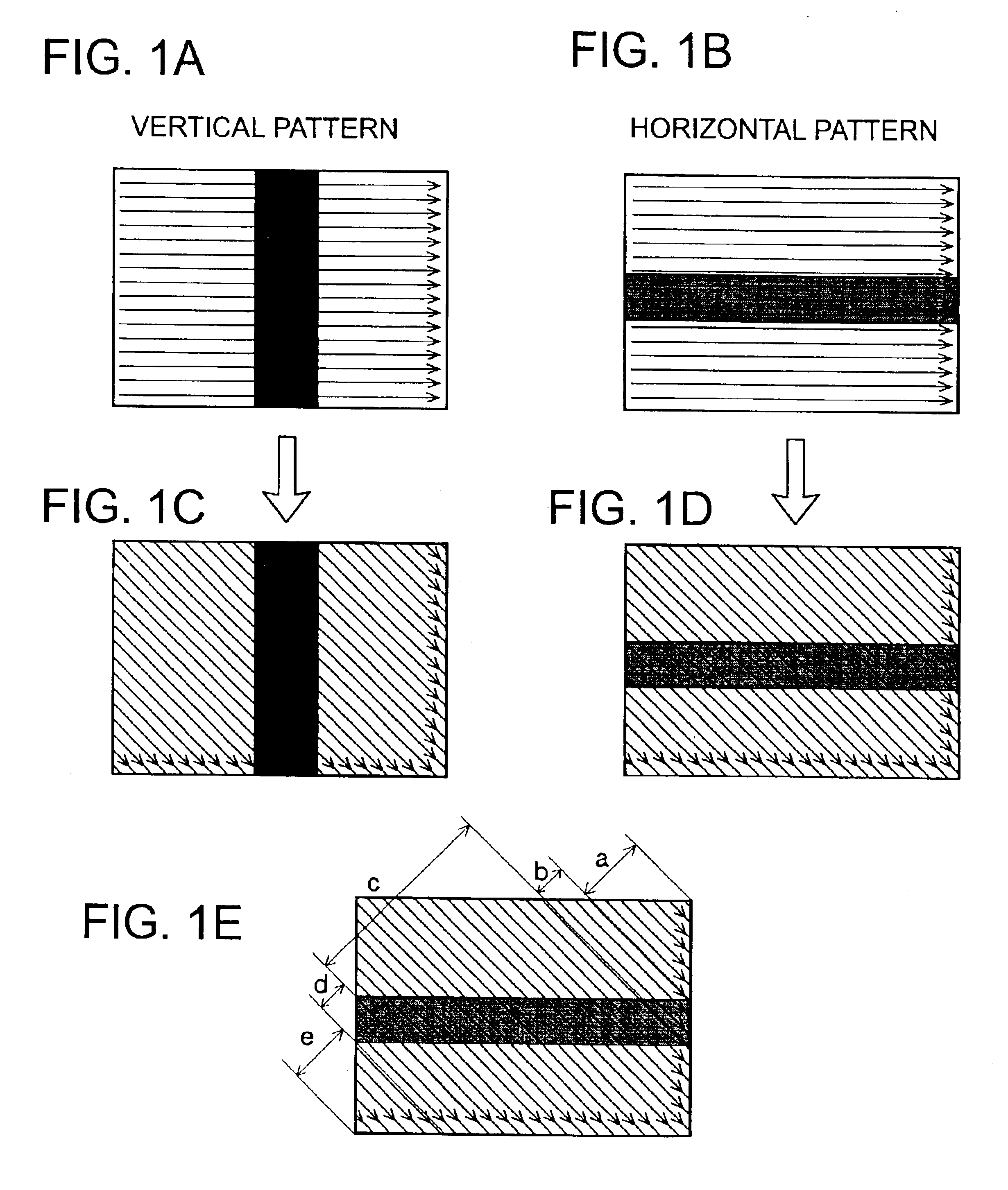

Scanning charged particle microscope

InactiveUS6852973B2Out of operationMaterial analysis using wave/particle radiationElectric discharge tubesEngineeringScan line

The present invention sets out to provide a scanning charged particle microscope equipped with a rapid control function capable of extrapolating an in-focus point from image information for a single frame and an automatic focusing system capable of reliably and precisely carrying out a focusing operation for a horizontal pattern image. The automatic focusing system provided in the scanning charged particle microscope of the present invention is provided with means for changing a focal point each raster scan line, and control means for comparing image information each scanning line and extrapolating focusing positions. The scanning line can then be made to be an inclined scanning line that is a combination of a horizontal component and a vertical component with respect to a chip array on a semiconductor wafer. Further, a method is adopted comprising a first step of reliably taking in a coarse in-focus point and a second step of detecting the in-focus point with a high degree of precision.

Owner:SII NANOTECHNOLOGY INC

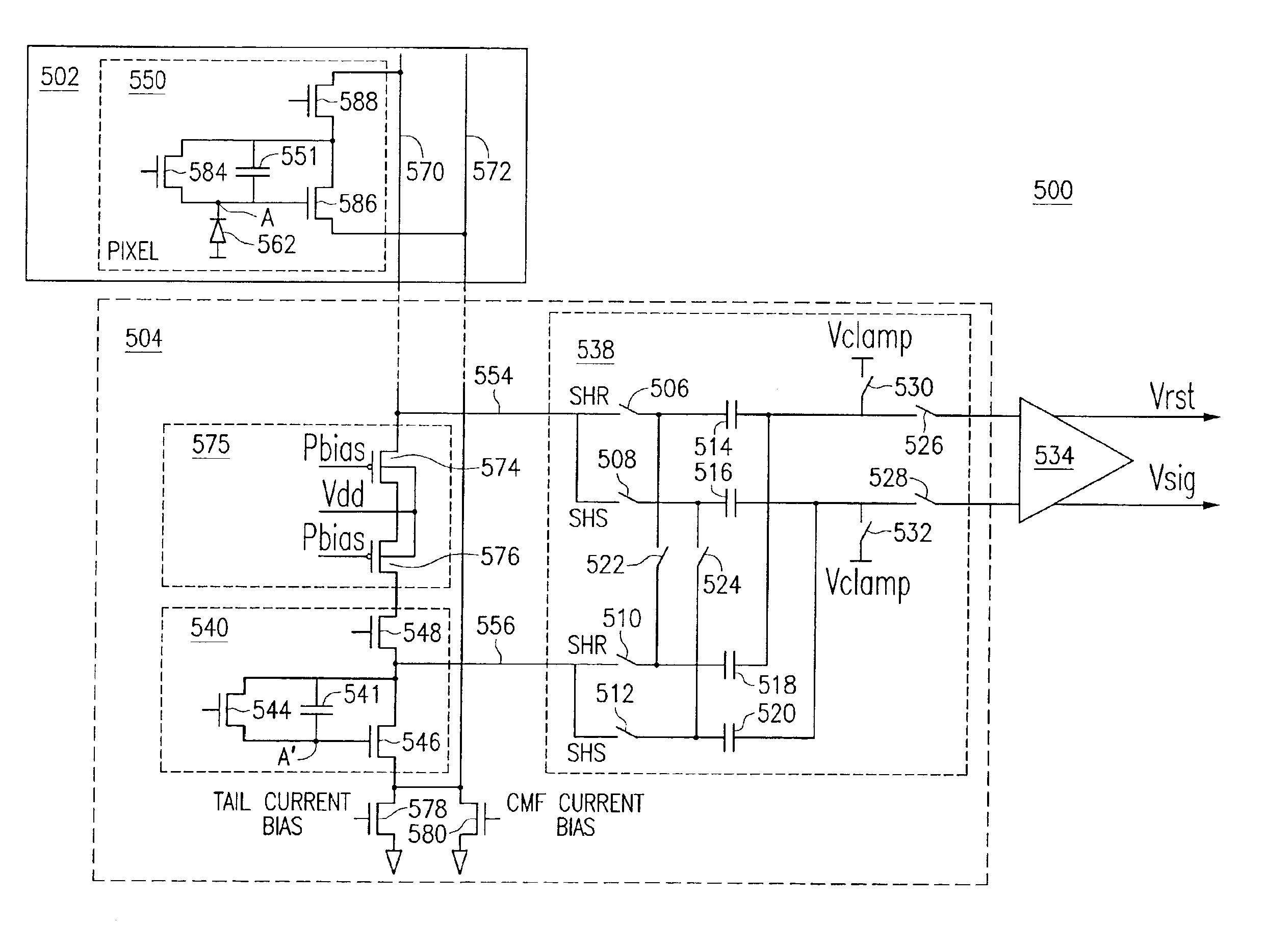

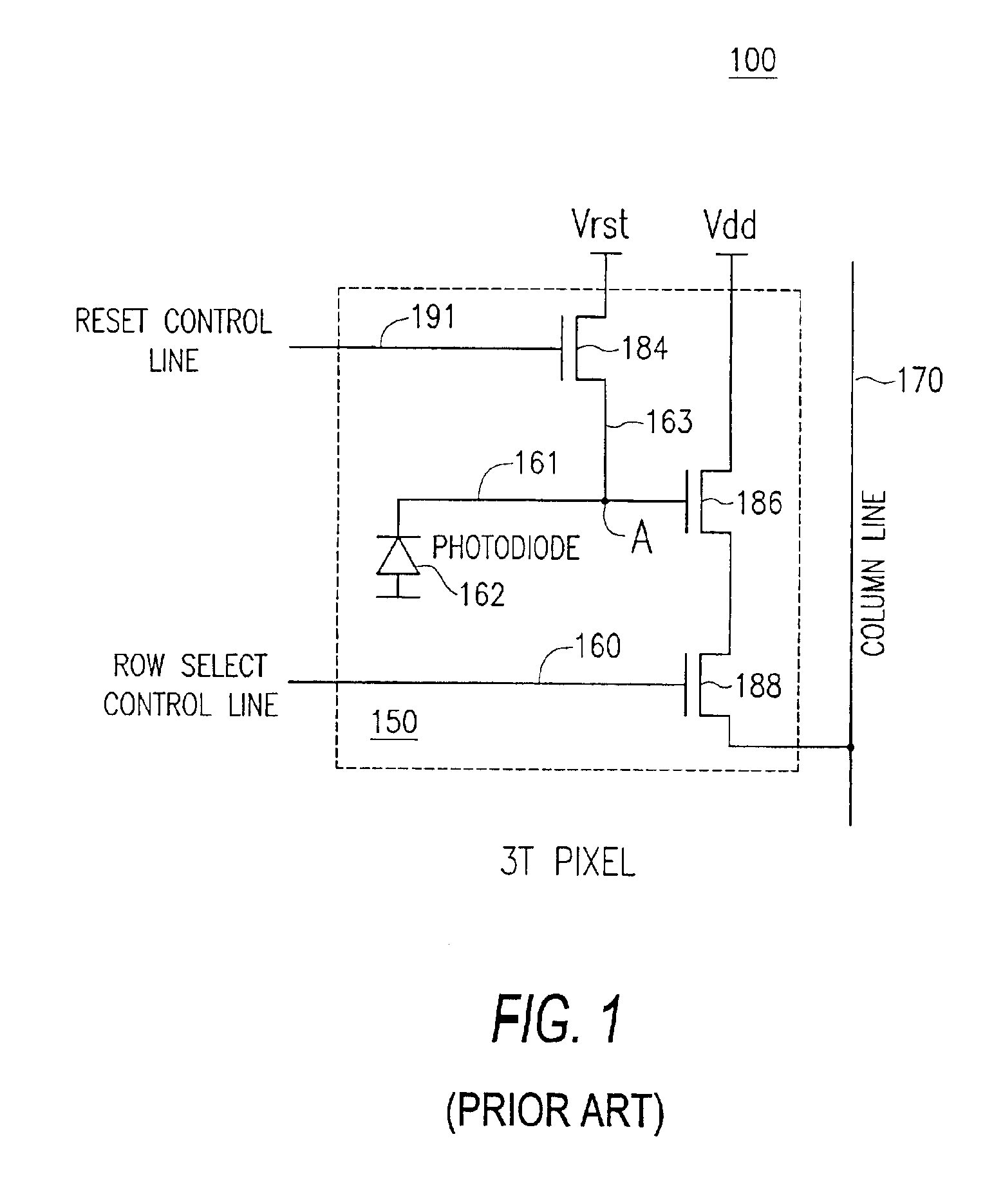

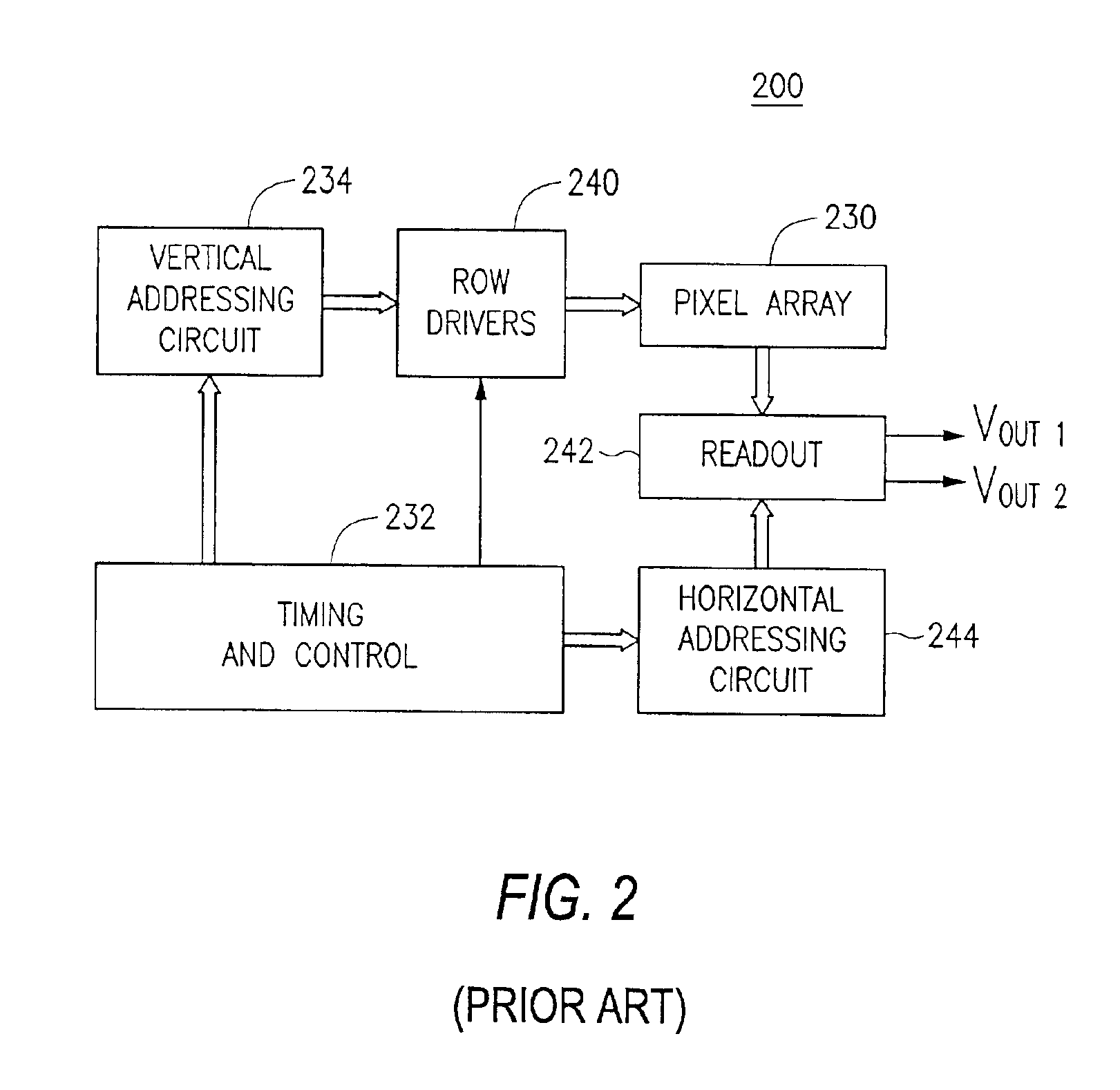

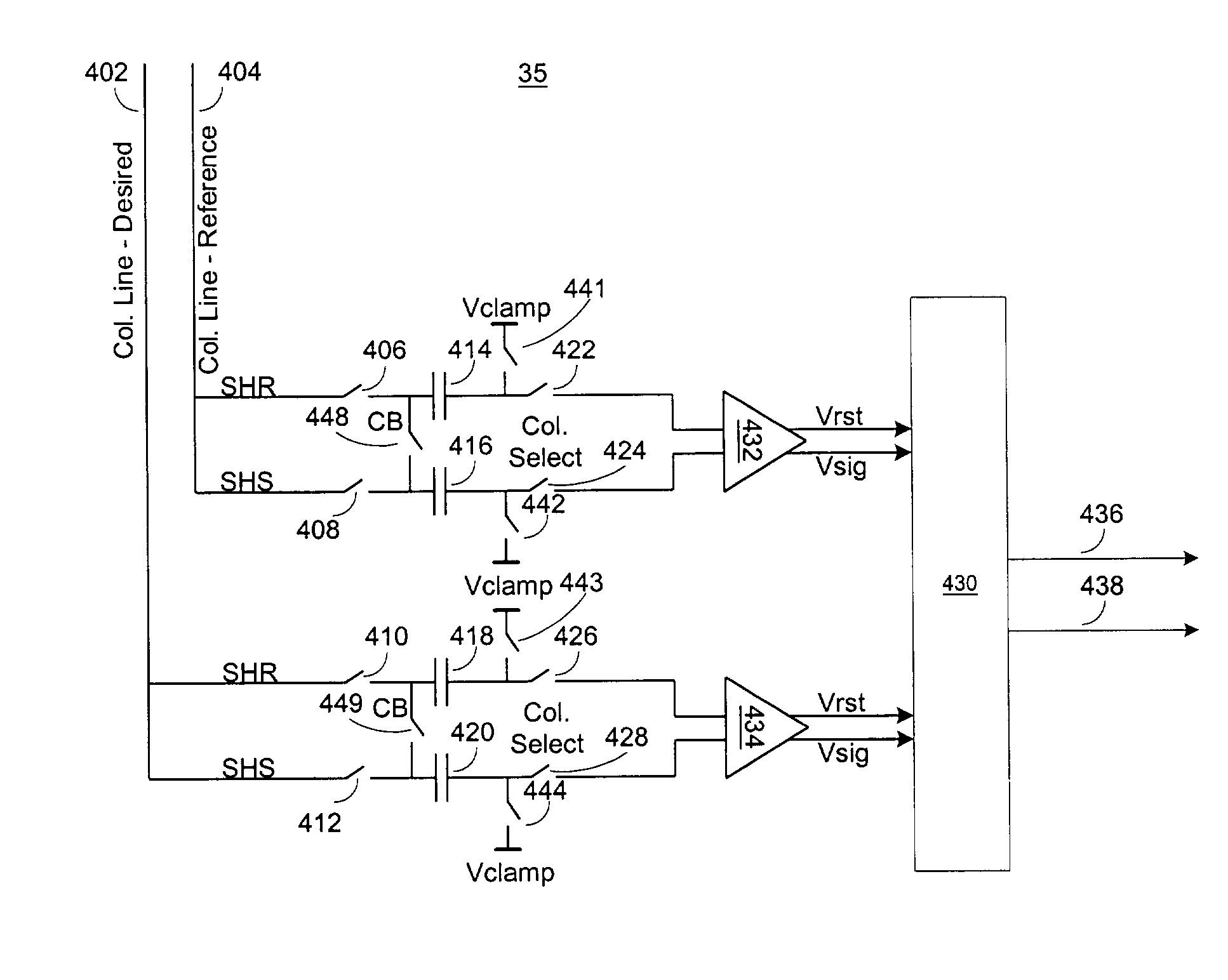

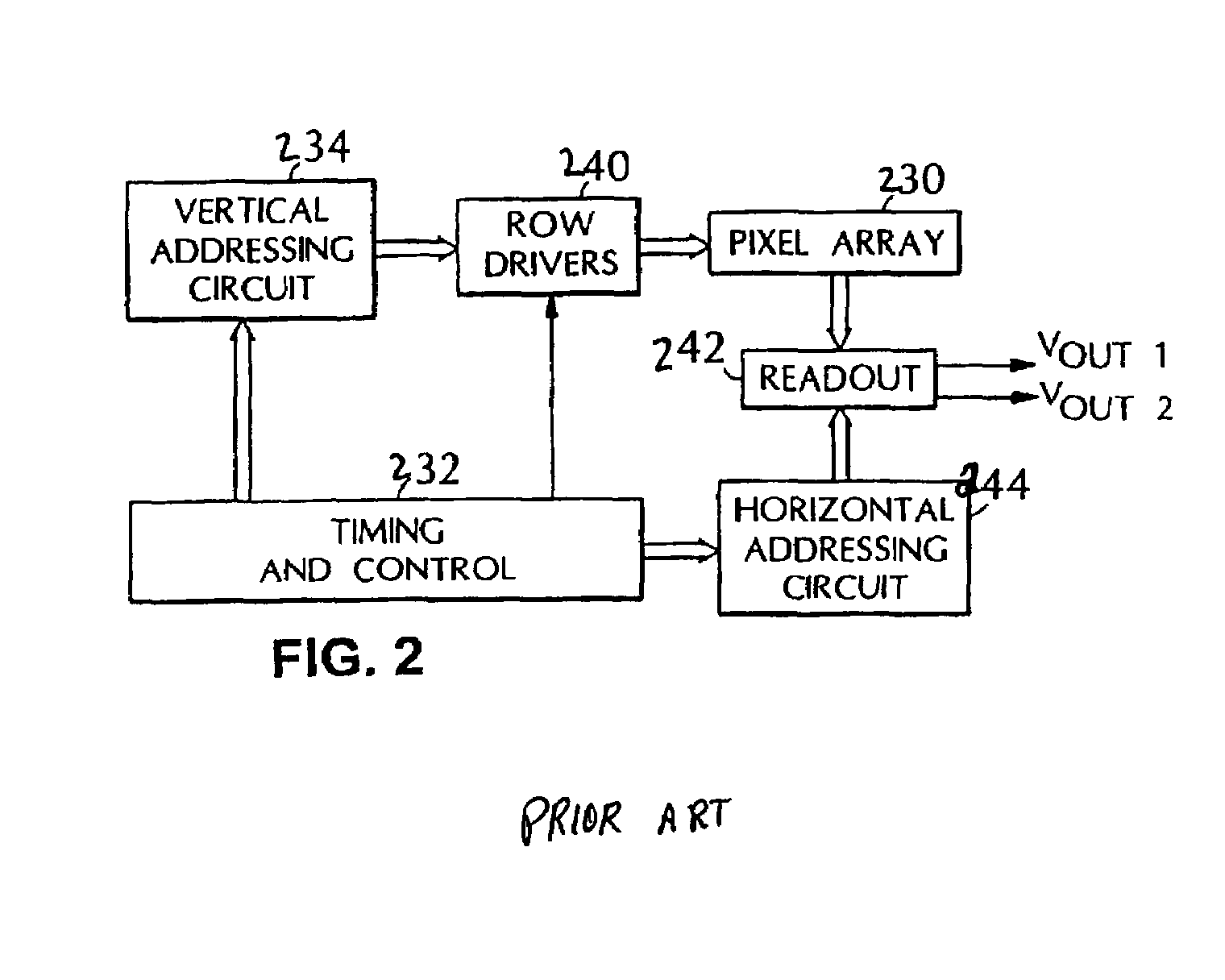

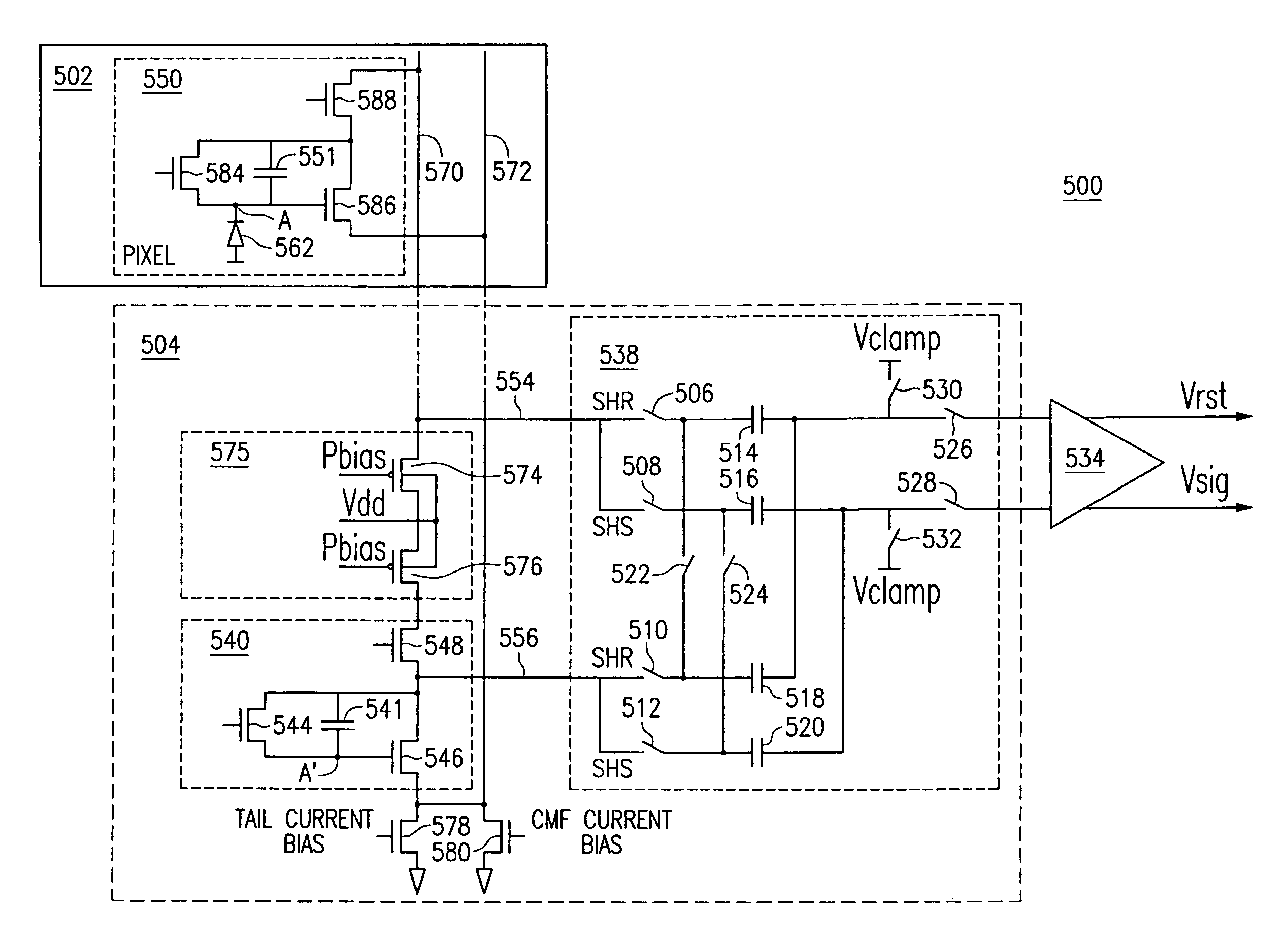

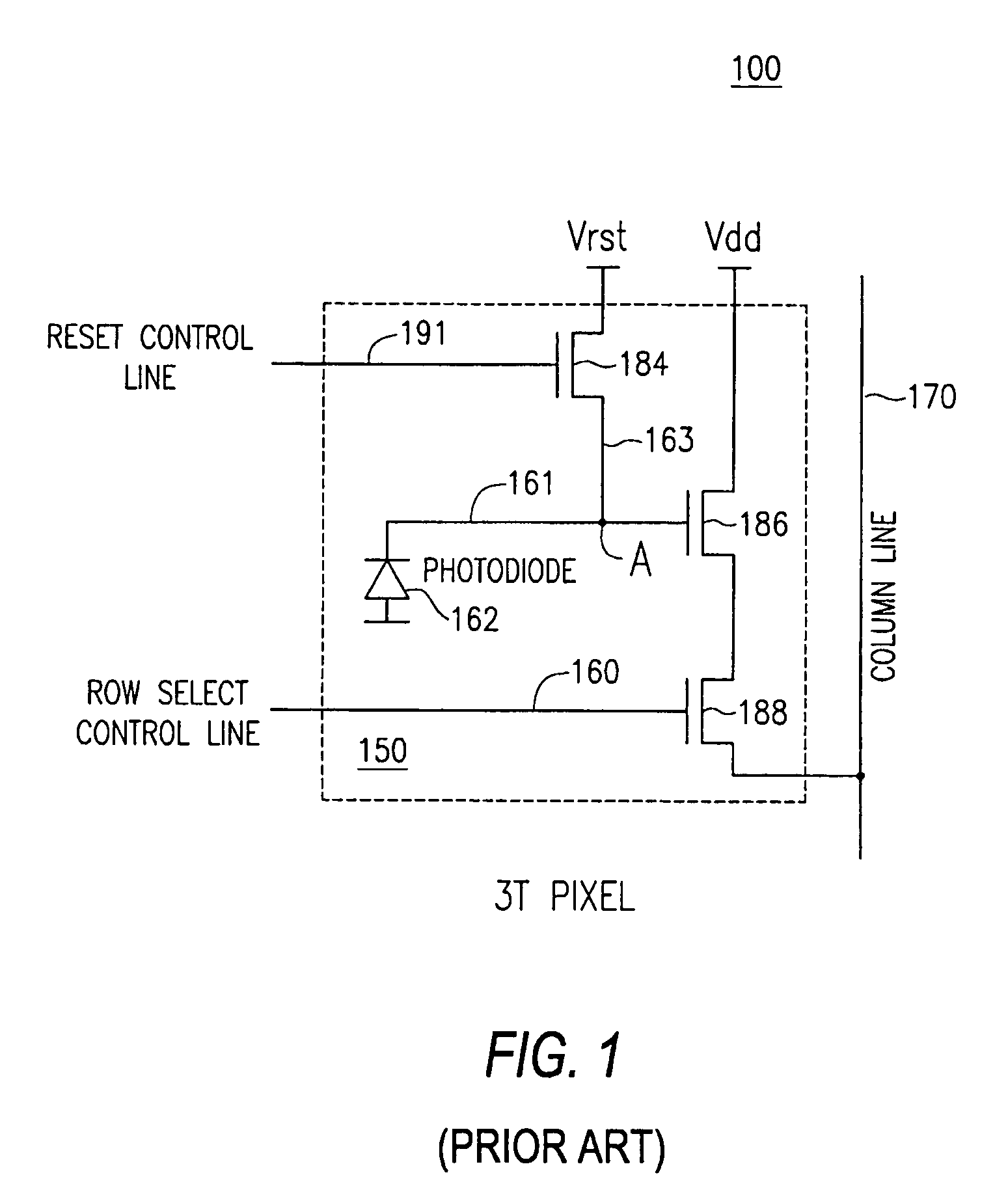

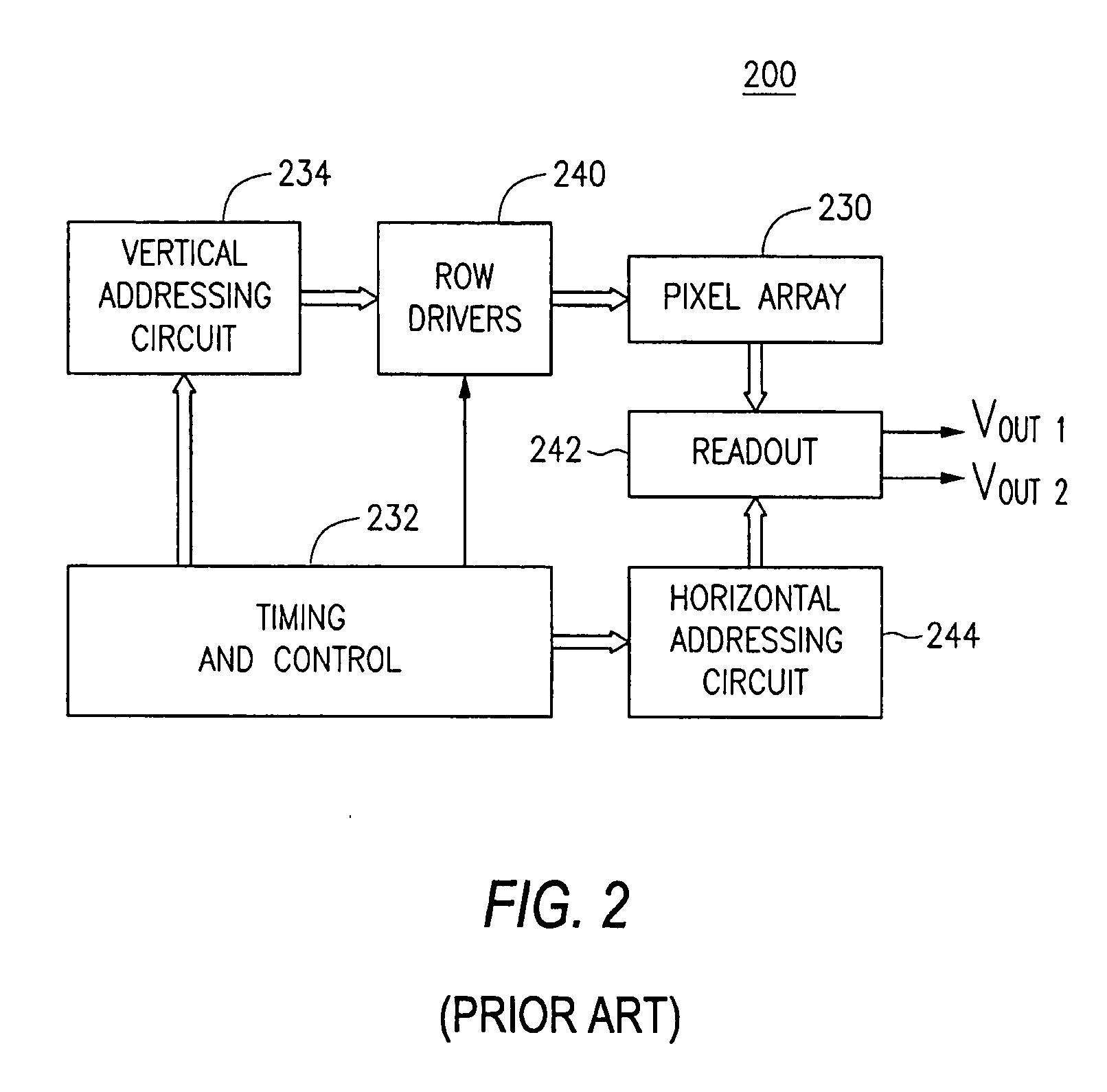

Differential column readout scheme for CMOS APS pixels

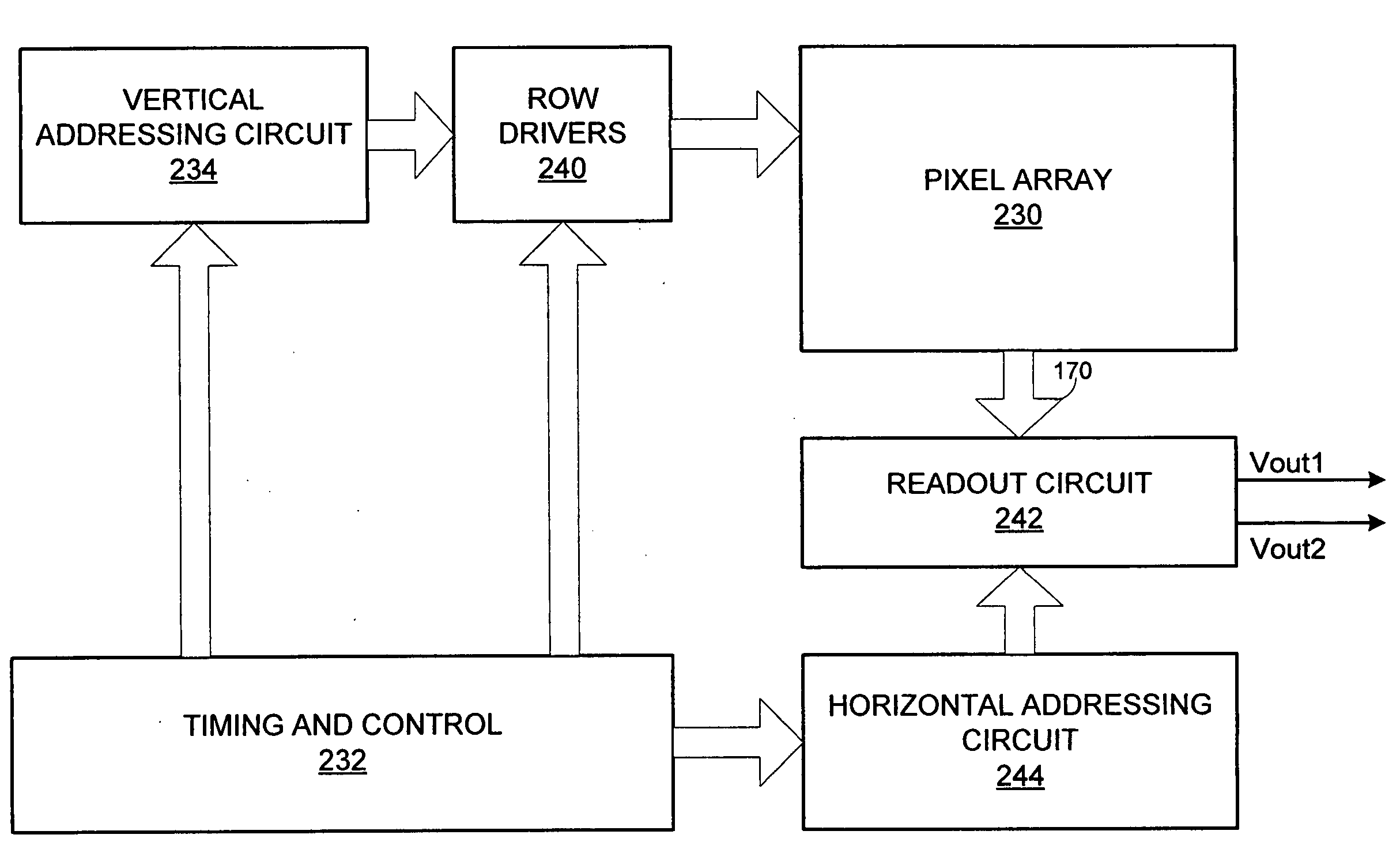

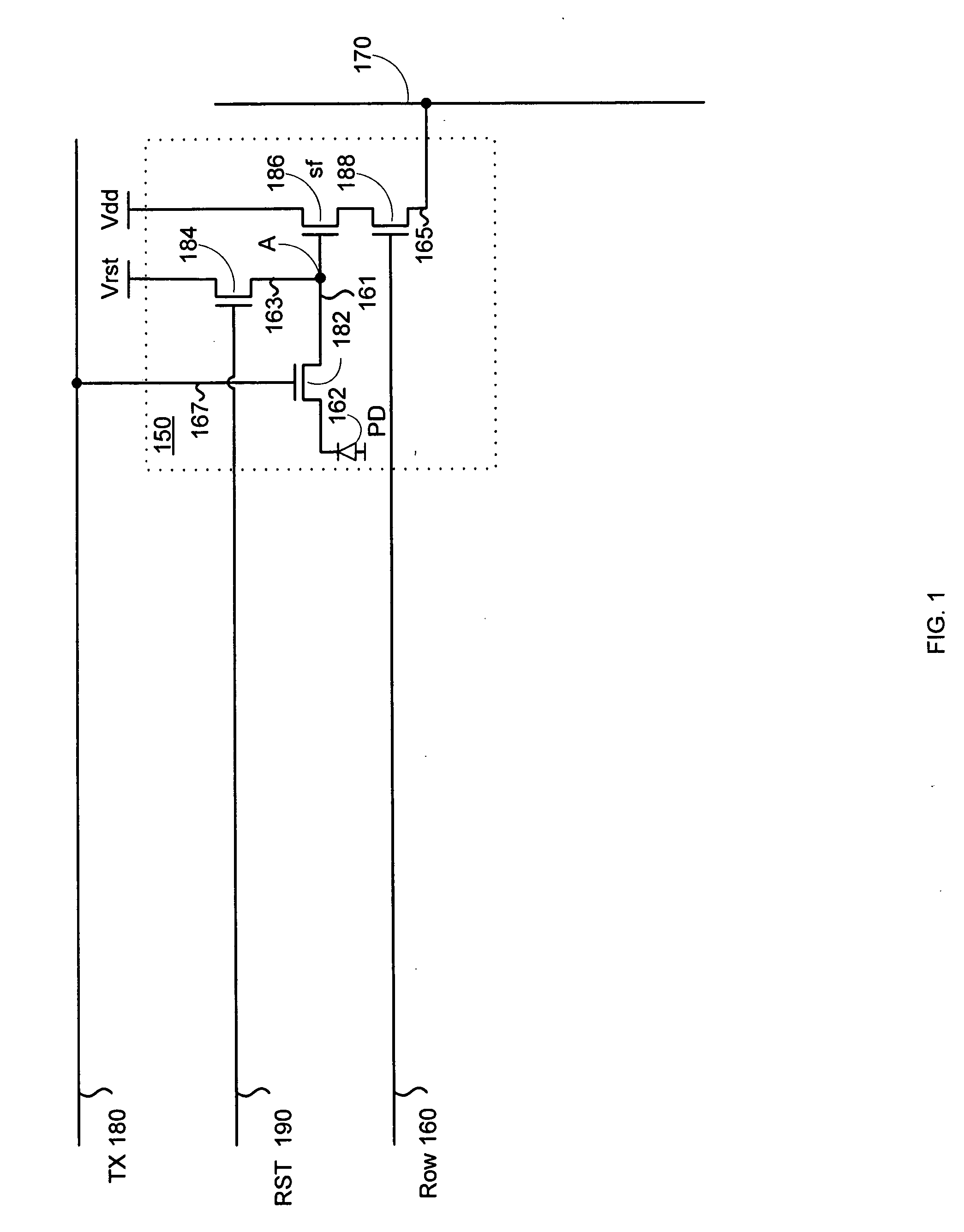

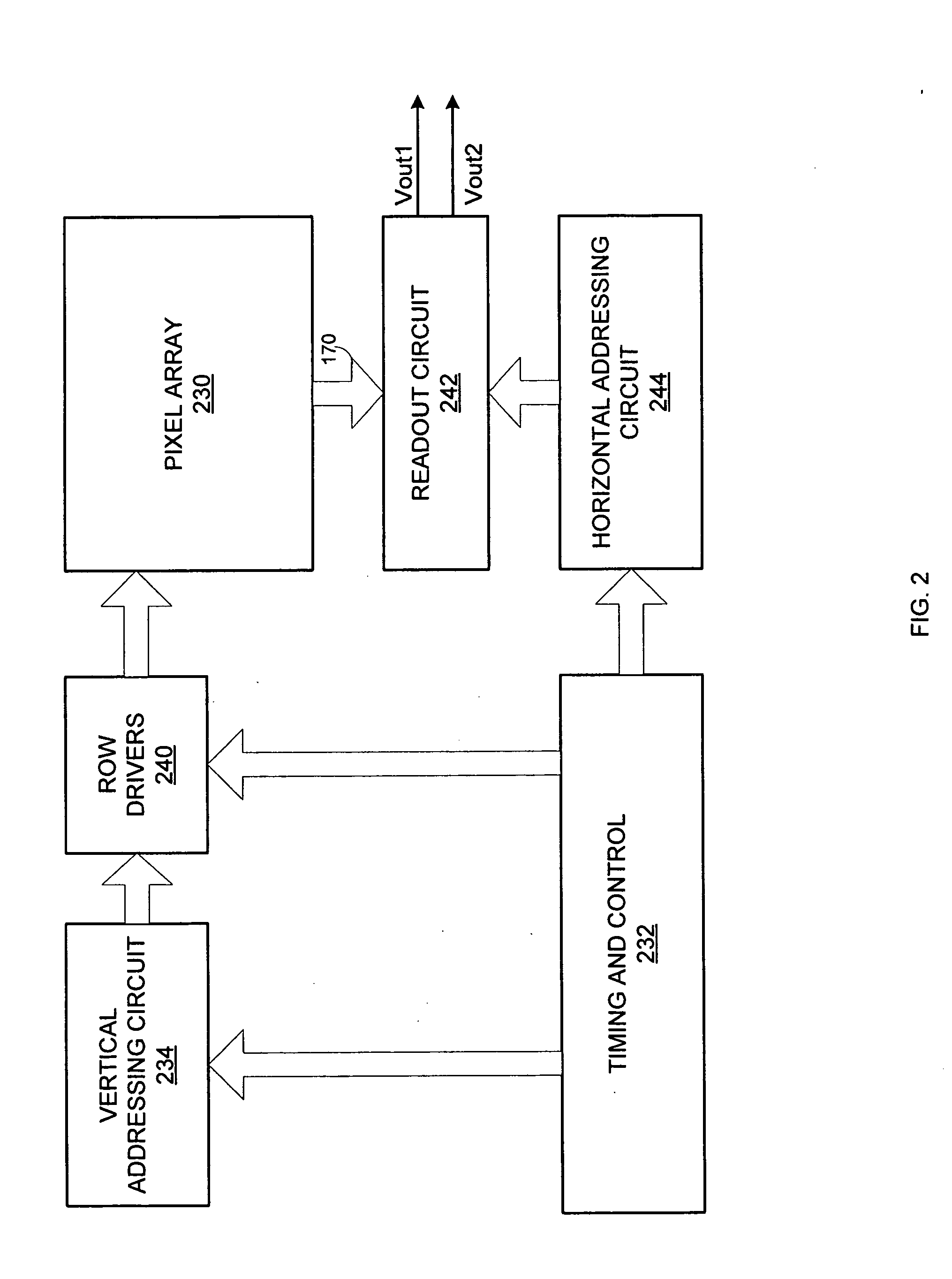

InactiveUS6919551B2Minimizes substrateMinimizes other common mode noiseTelevision system detailsColor signal processing circuitsEngineeringCmos aps

The present invention provides an improved column readout circuitry and method of operation which minimizes substrate and other common mode noise during a read out operation. The circuit improves the consistency of the pixel to pixel output of the pixel array and increases the dynamic range of the pixel output. This is accomplished by obtaining a differential readout of the reset signal and integrated charge signal from a desired pixel along with the reset signal and charge signal from a reference circuit. In this manner common mode noise can be minimized by a combination of signals from the desired and reference pixels in the sample and hold aspect of the column circuitry. In one exemplary embodiment of the invention, a 3T pixel arrangement is used. In another exemplary embodiment, a 4T arrangement is used. Additional exemplary embodiments provide differential column readout circuitry that can be used with any two signal sources.

Owner:APTINA IMAGING CORP

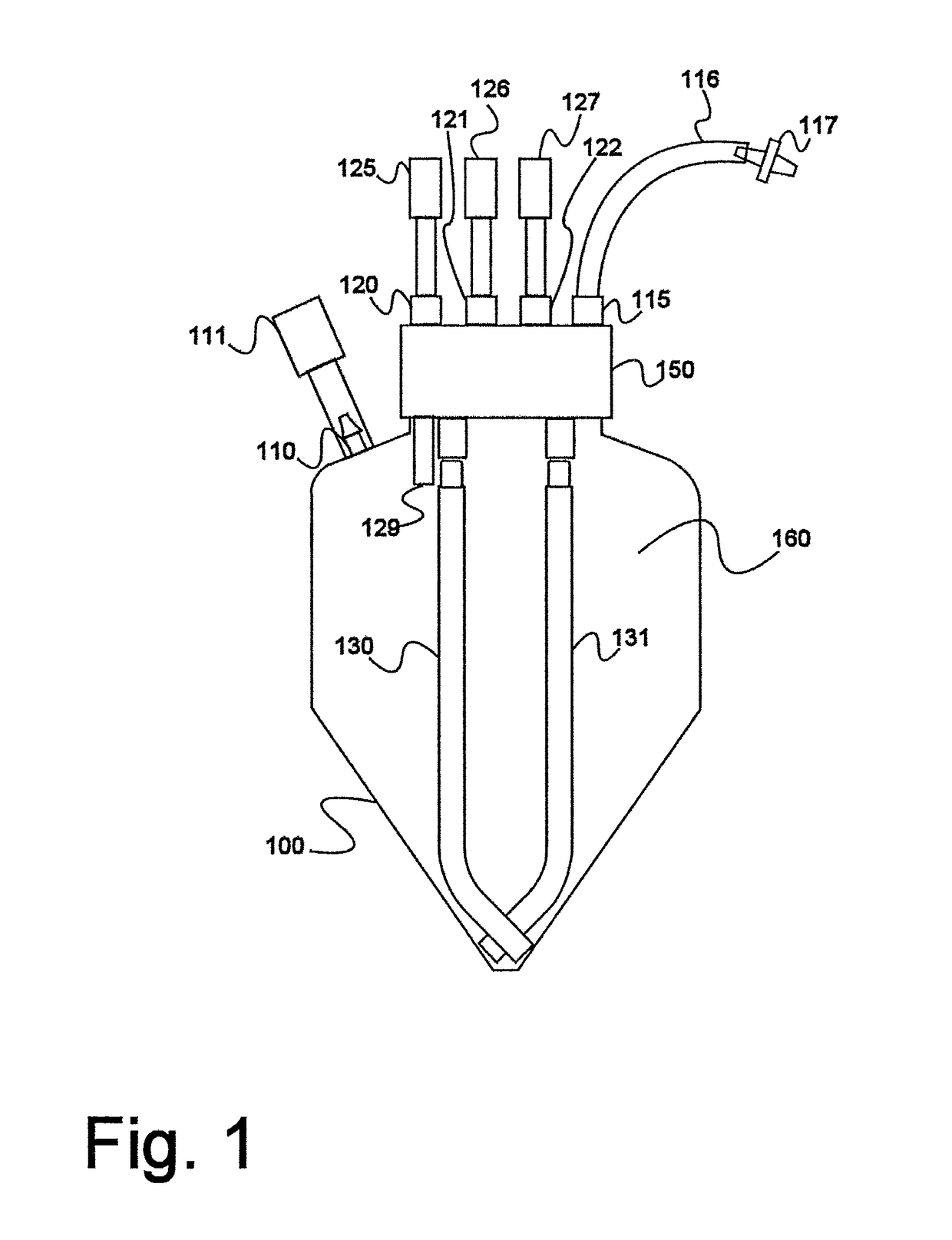

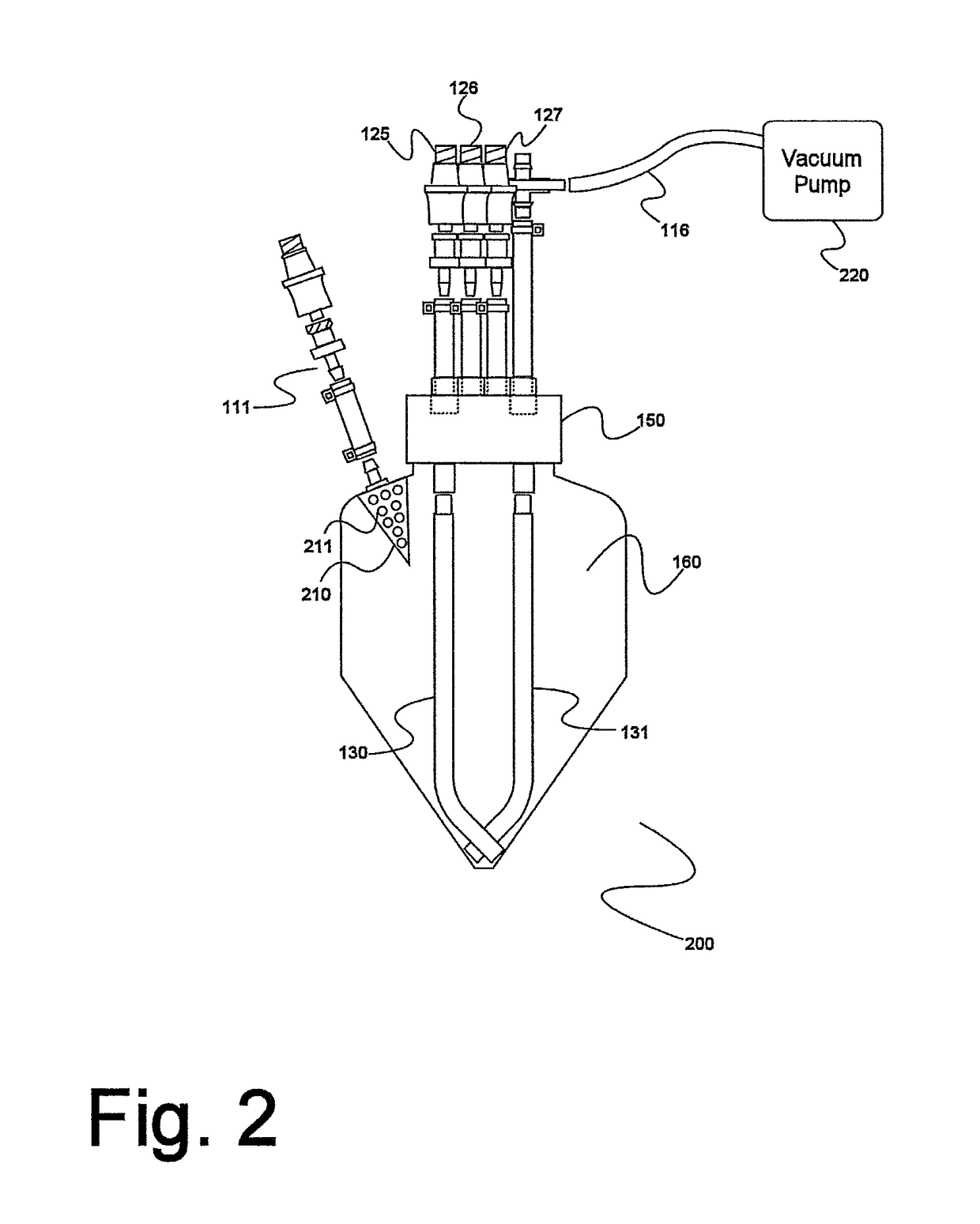

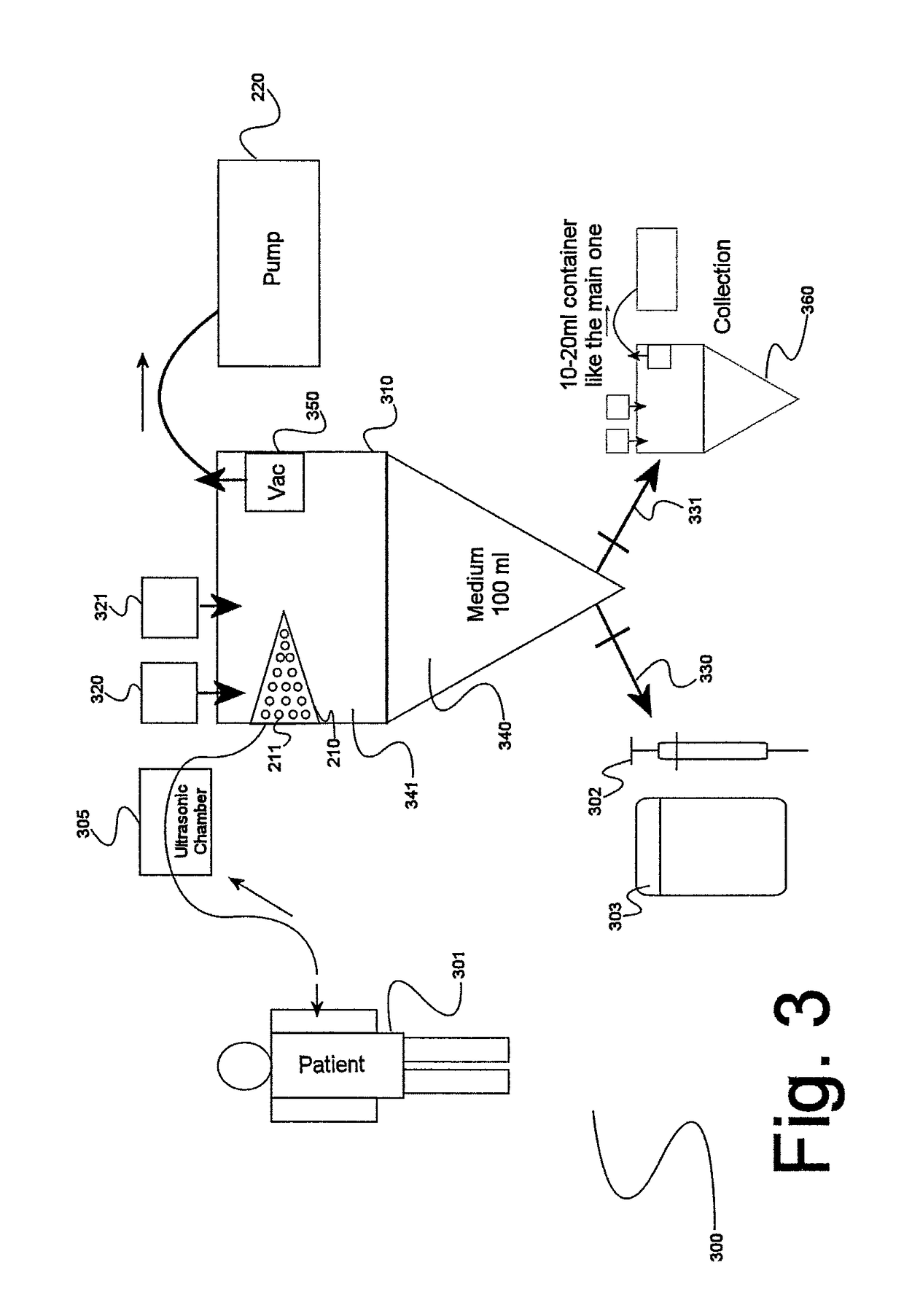

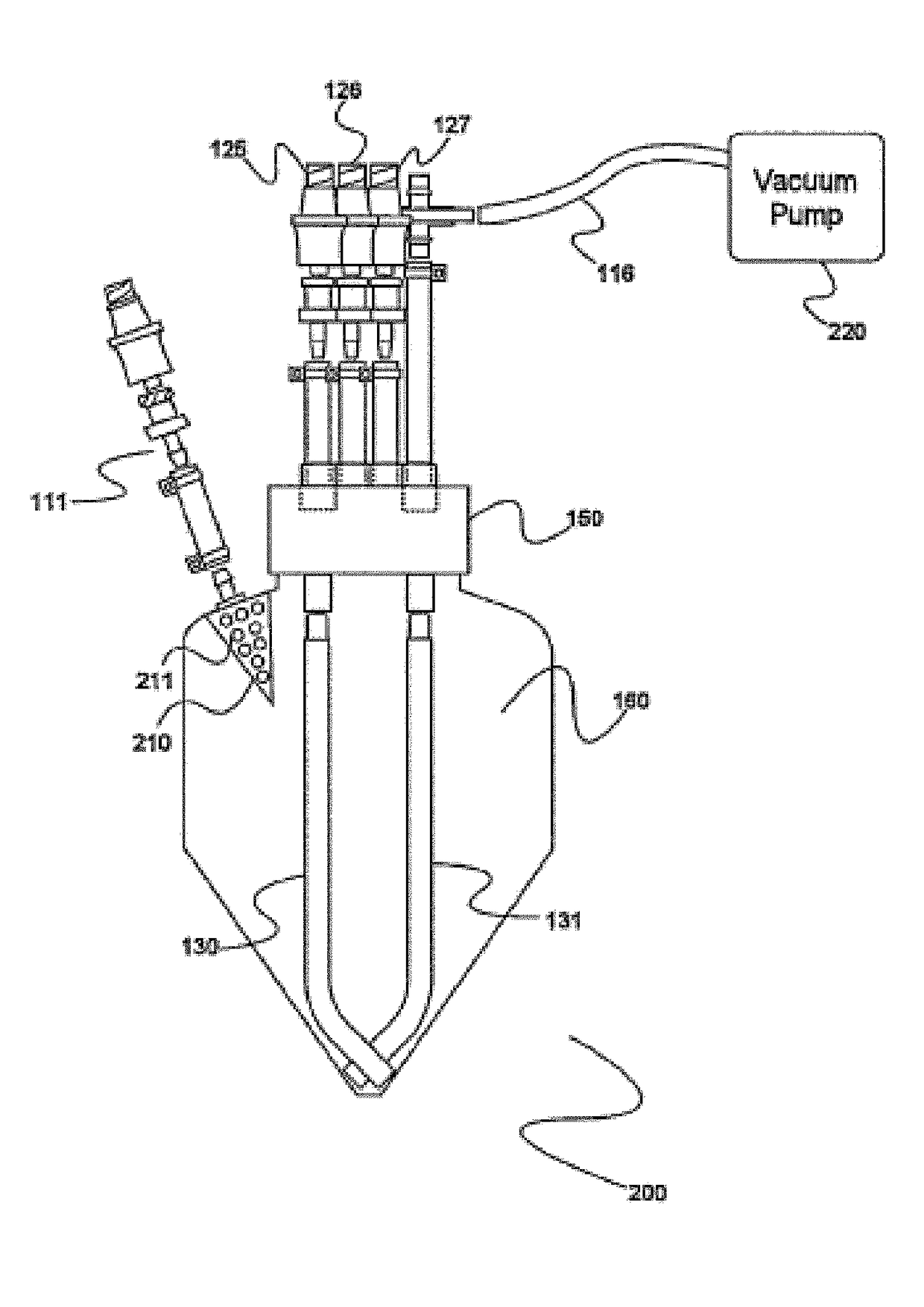

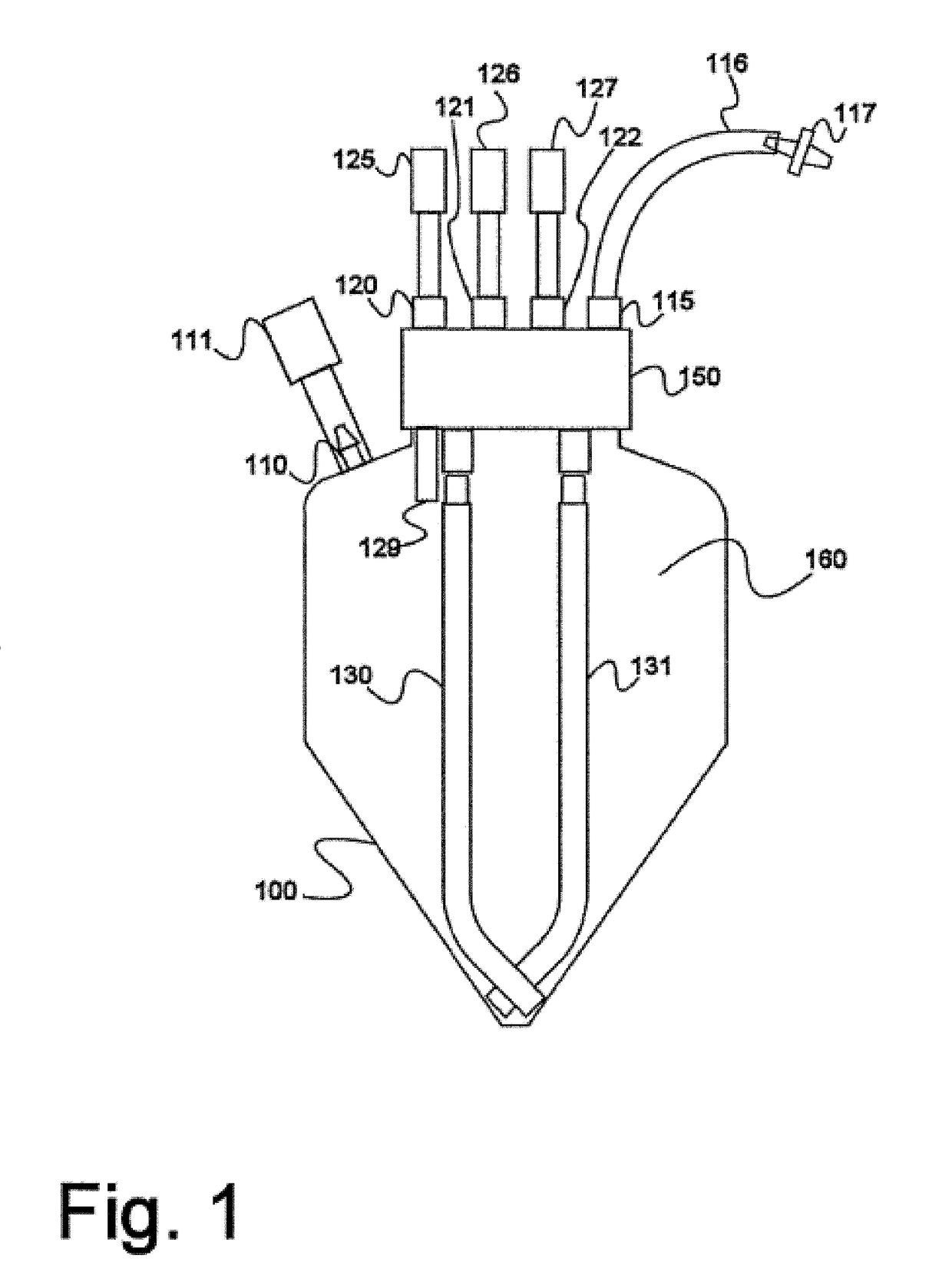

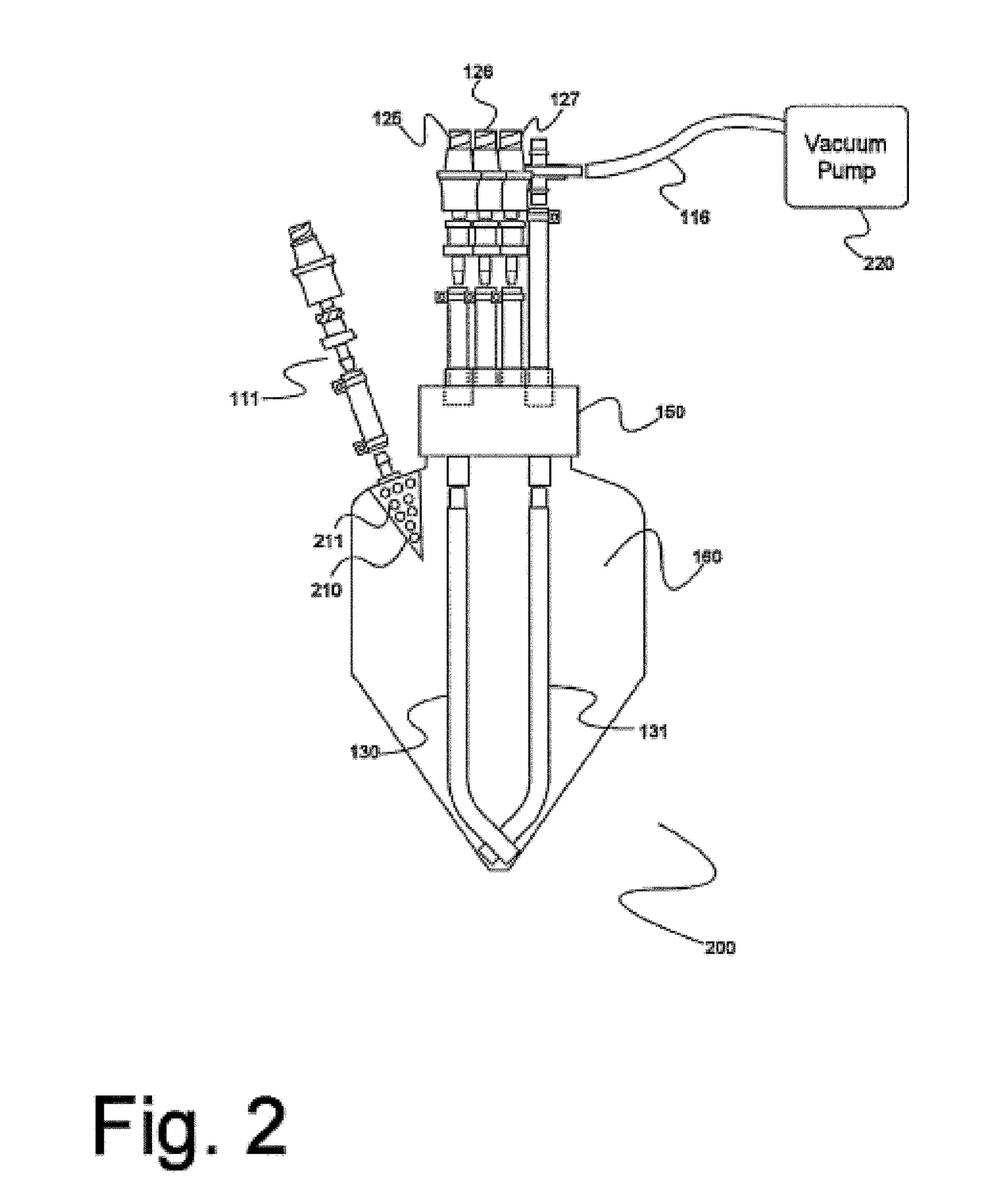

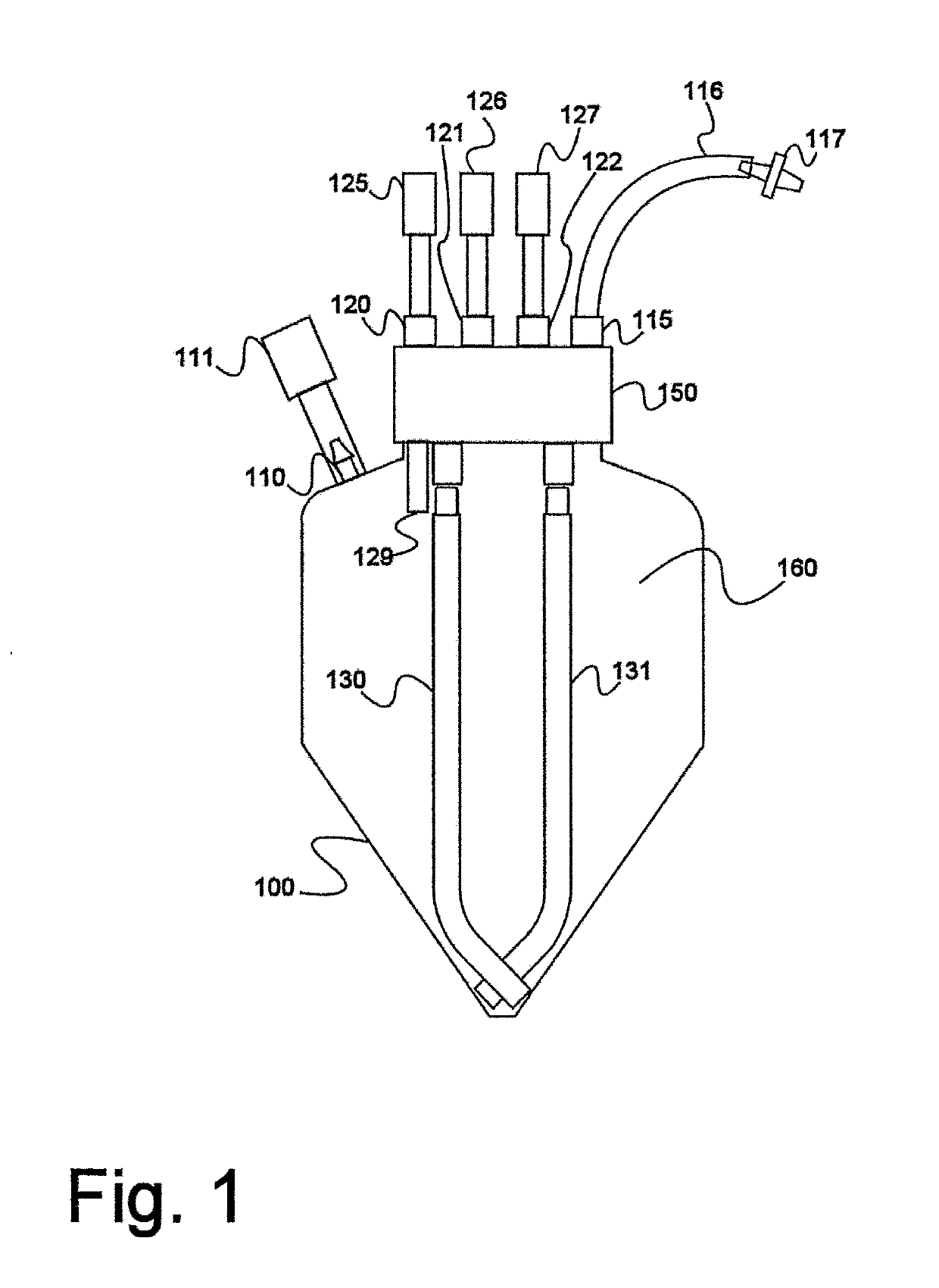

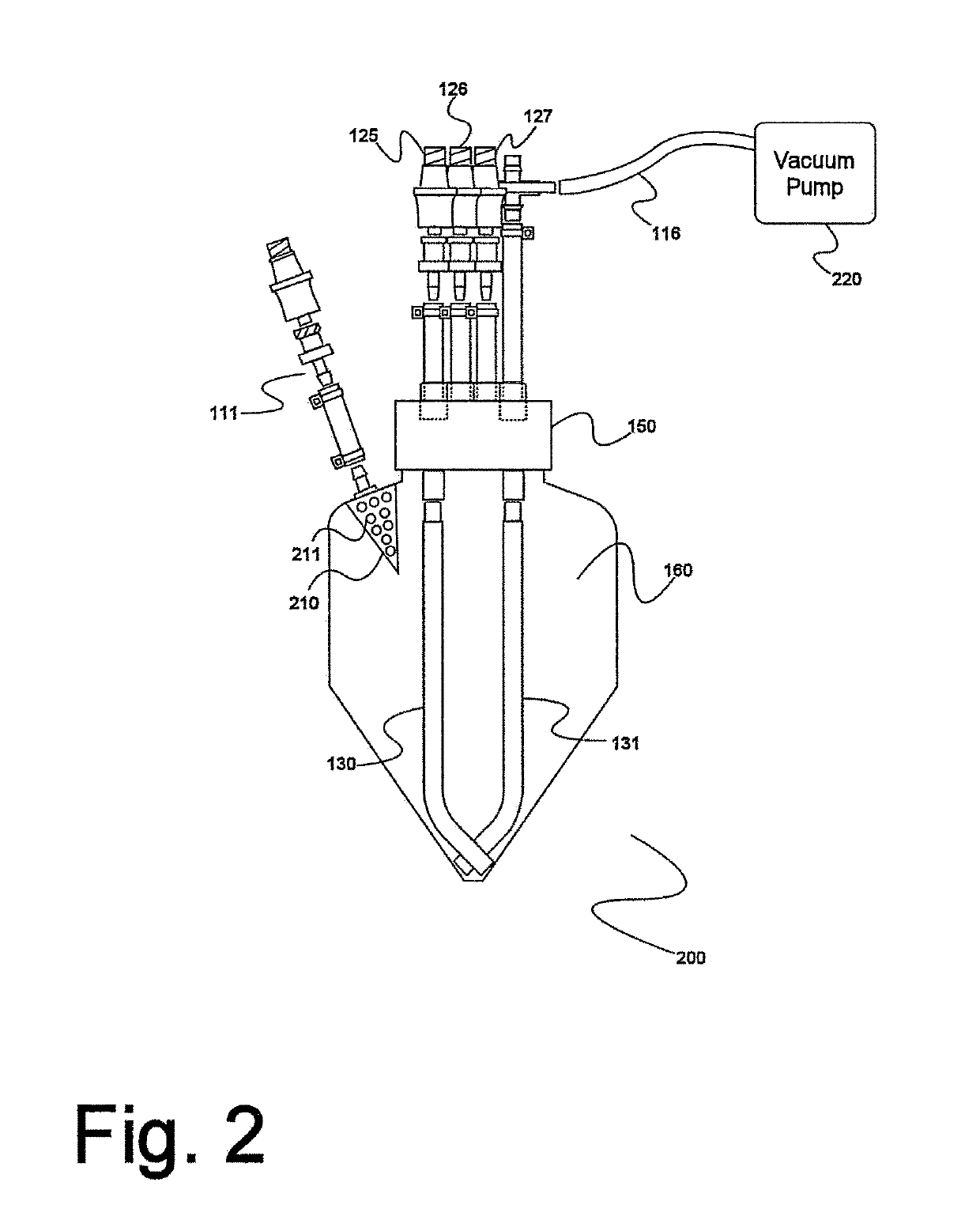

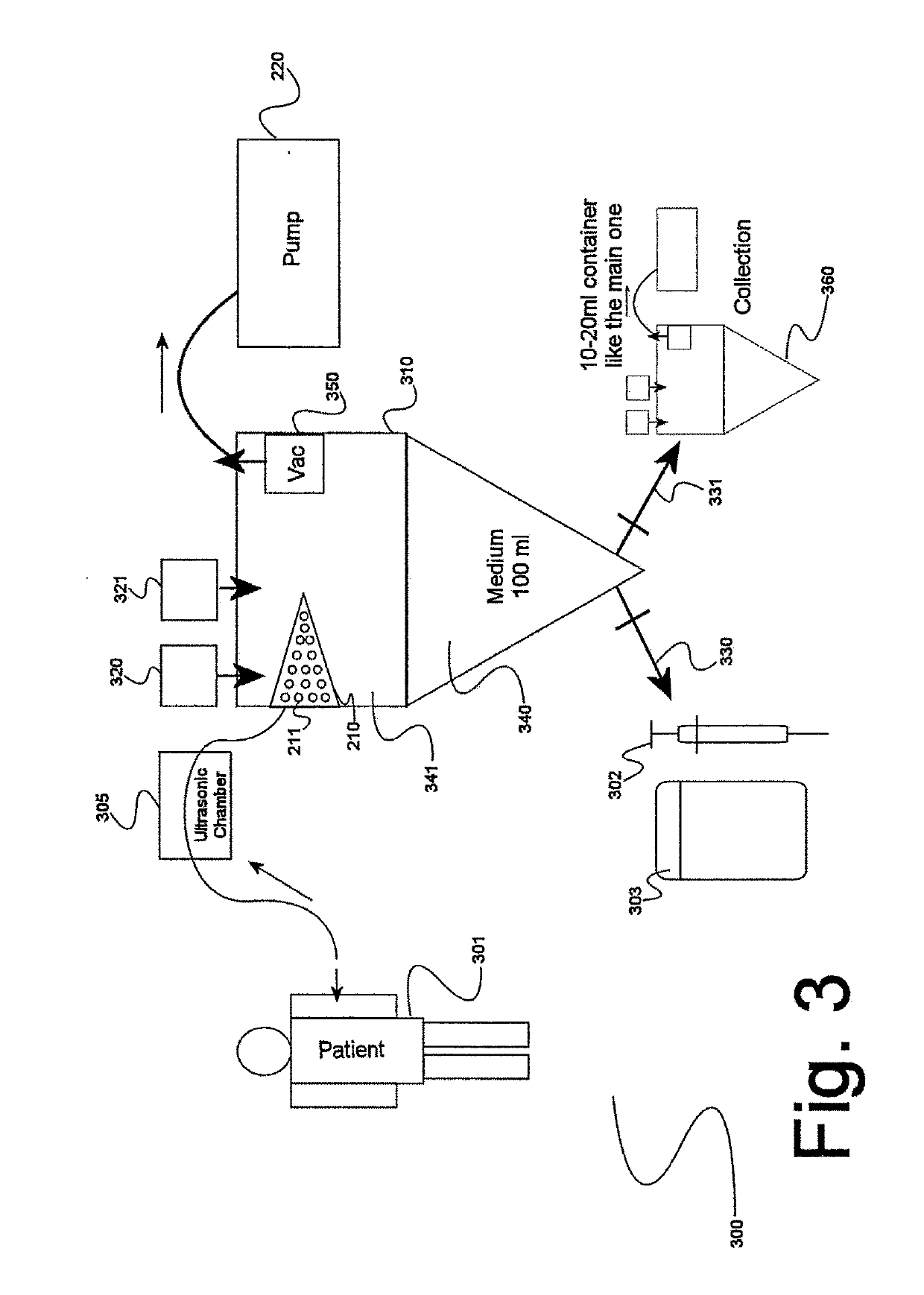

System and methods for preparation of adipose-derived stem cells

ActiveUS9931445B2Requires environmentOut of operationOther blood circulation devicesMedical devicesMedicineHuman patient

A system for extracting and processing adipose tissue to generate a therapeutically effective amount of adipose-derived stem cells, comprising an adipose tissue extraction device and a modified centrifuge tube comprising a plurality of lipoaspirate inlet fittings, a plurality of processing fluid inlet fittings, and a plurality of pellet extraction tubes. The adipose tissue extraction device is used to extract a quantity of adipose tissue from a human being, the lipoaspirate is moved into the first modified centrifuge tube via a sterile transfer, a plurality of processing steps are performed to clean and dissociate the lipoaspirate, and a pellet containing an enhanced fraction of stem cells is obtained by centrifuging the modified centrifugal tube. The pellet is resuspended in a fluid and administered to a human patient for a therapeutic or cosmetic purpose.

Owner:JOINTECHLABS

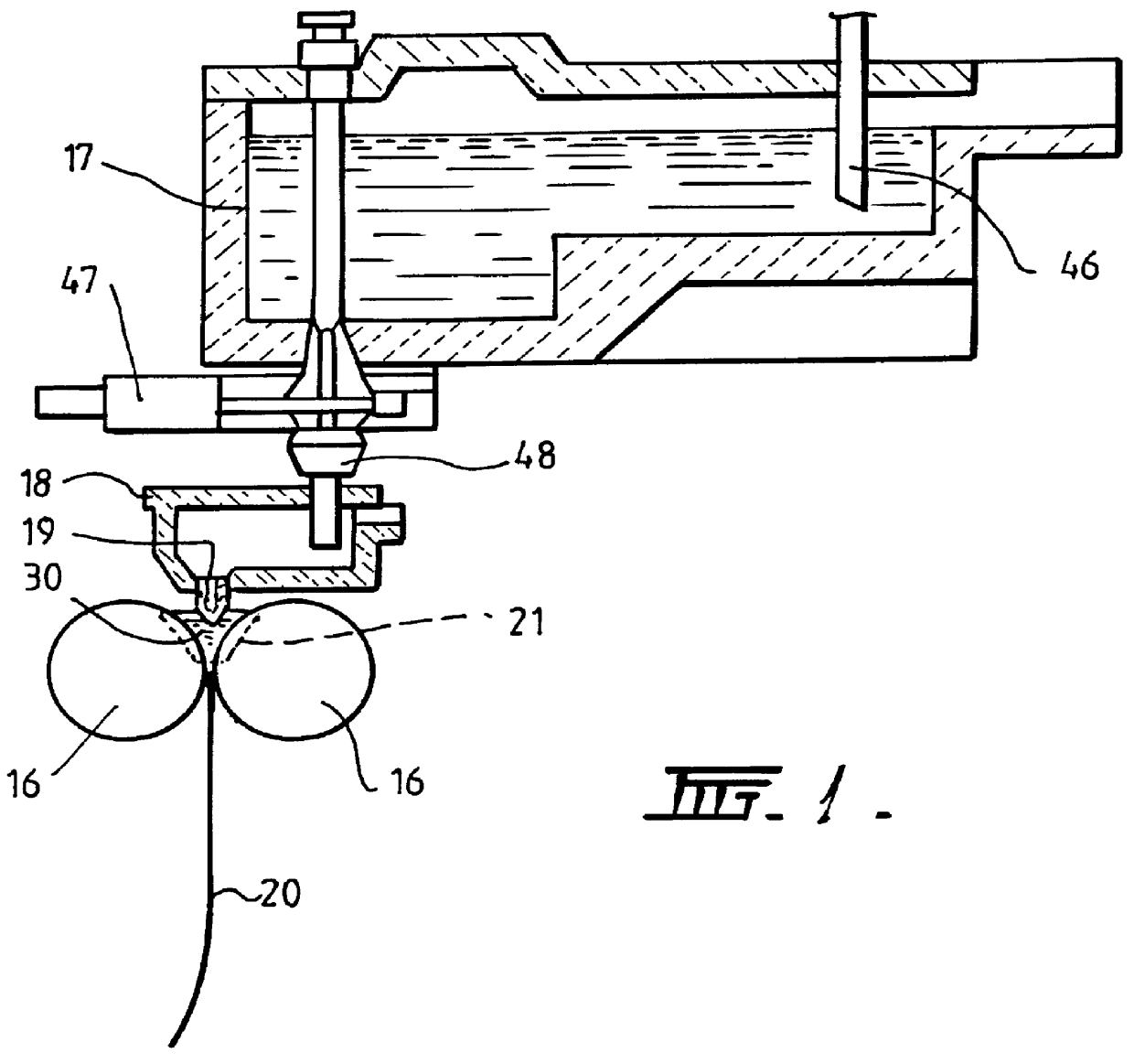

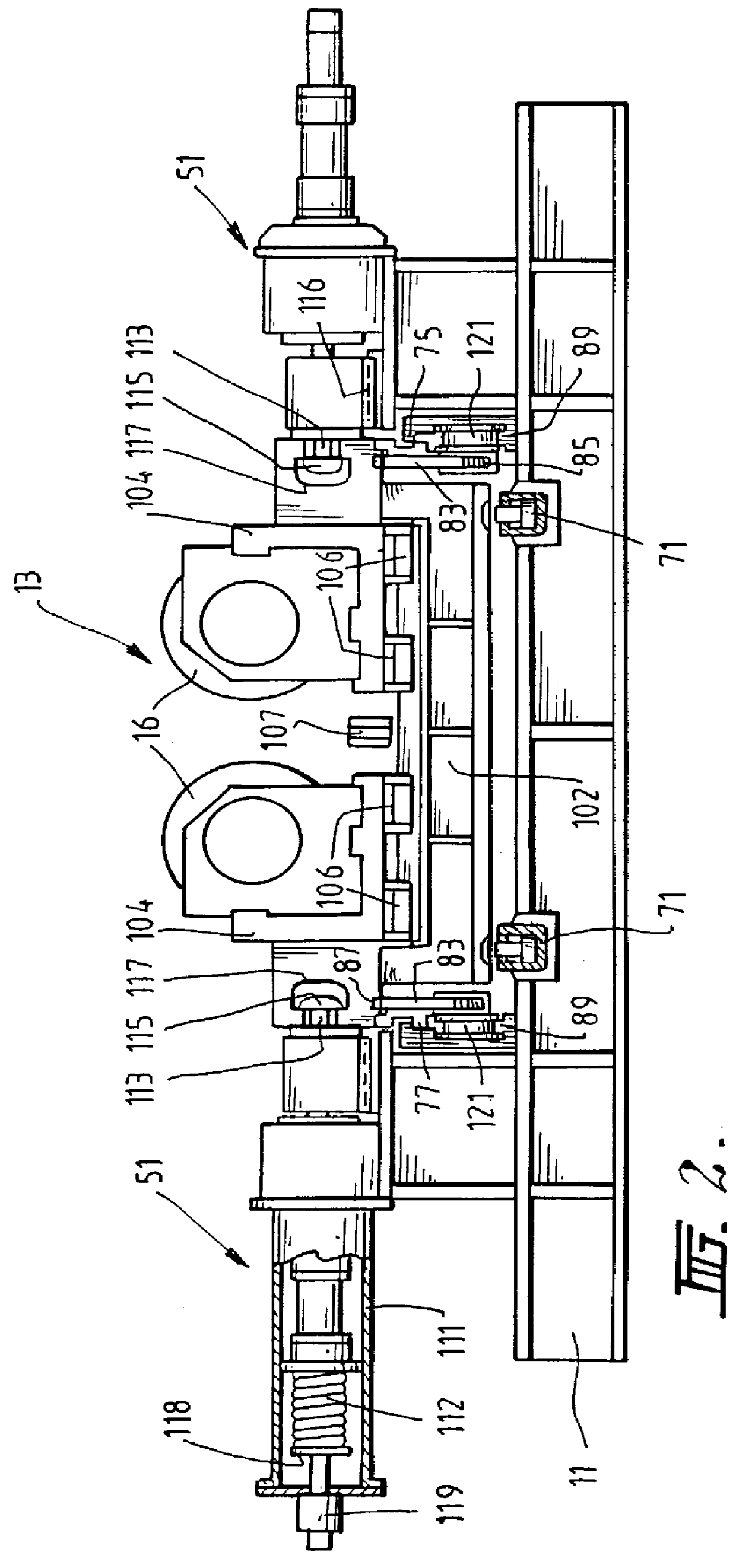

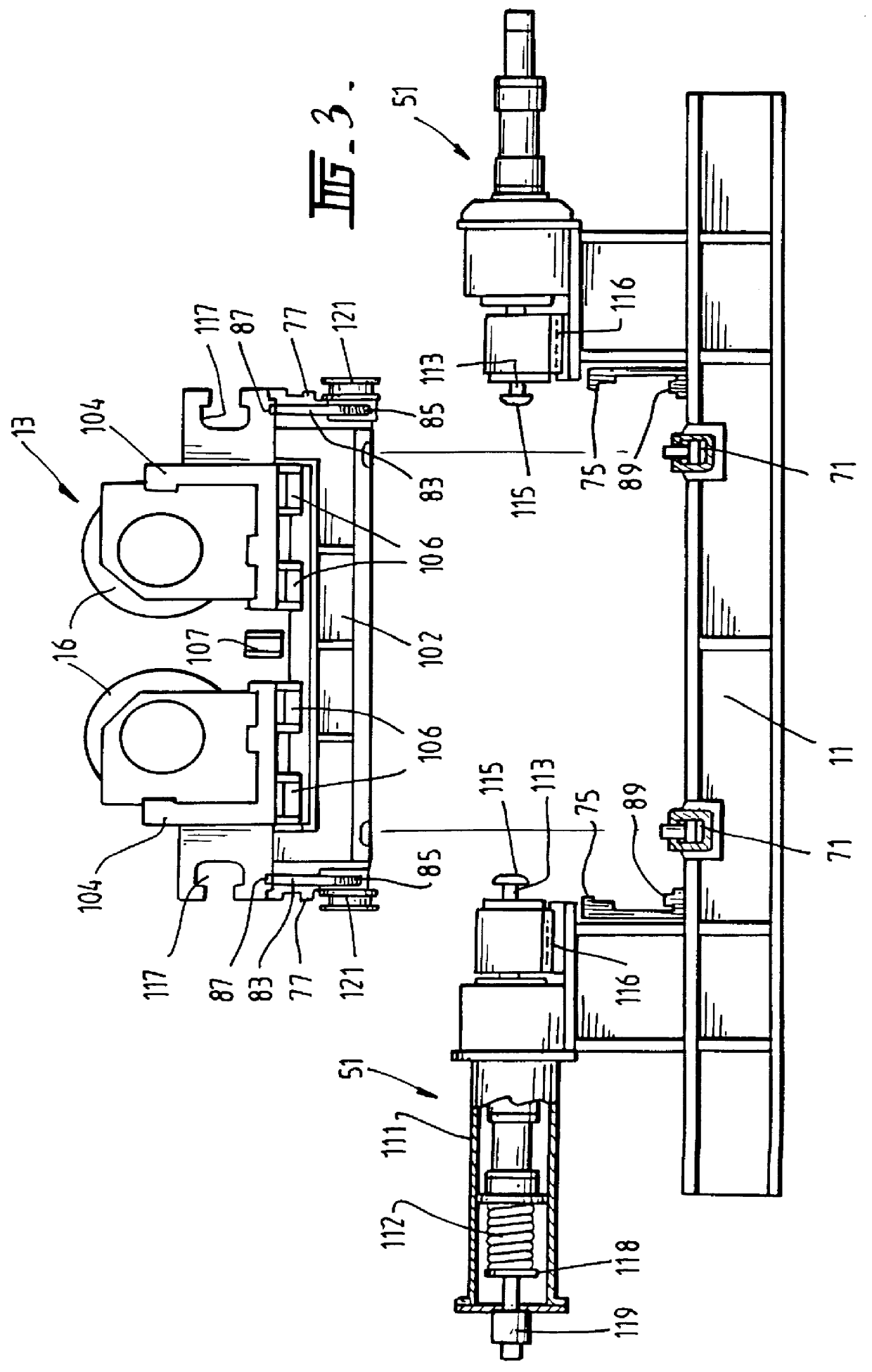

Strip casting apparatus

InactiveUS6164366APrecise positioningOut of operationMetal rolling stand detailsMetal rolling arrangementsStrip castingMolten metal

Apparatus for continuously casting metal strip comprises a pair of parallel casting rolls (16). In use of the apparatus molten metal is delivered between the casting rolls which are rotated to deliver cast strip product downwardly from the rolls. Casting rolls (16) are mounted on a roll module (13) installed in and removable from the caster as a unit. Module (13) is movable horizontally from a stand-by position to an intermediate position beneath a casting position of the rolls and can be hoisted from the intermediate position by operation of hoists (71) to lift the rolls (16) into their casting position.

Owner:CASTRIP

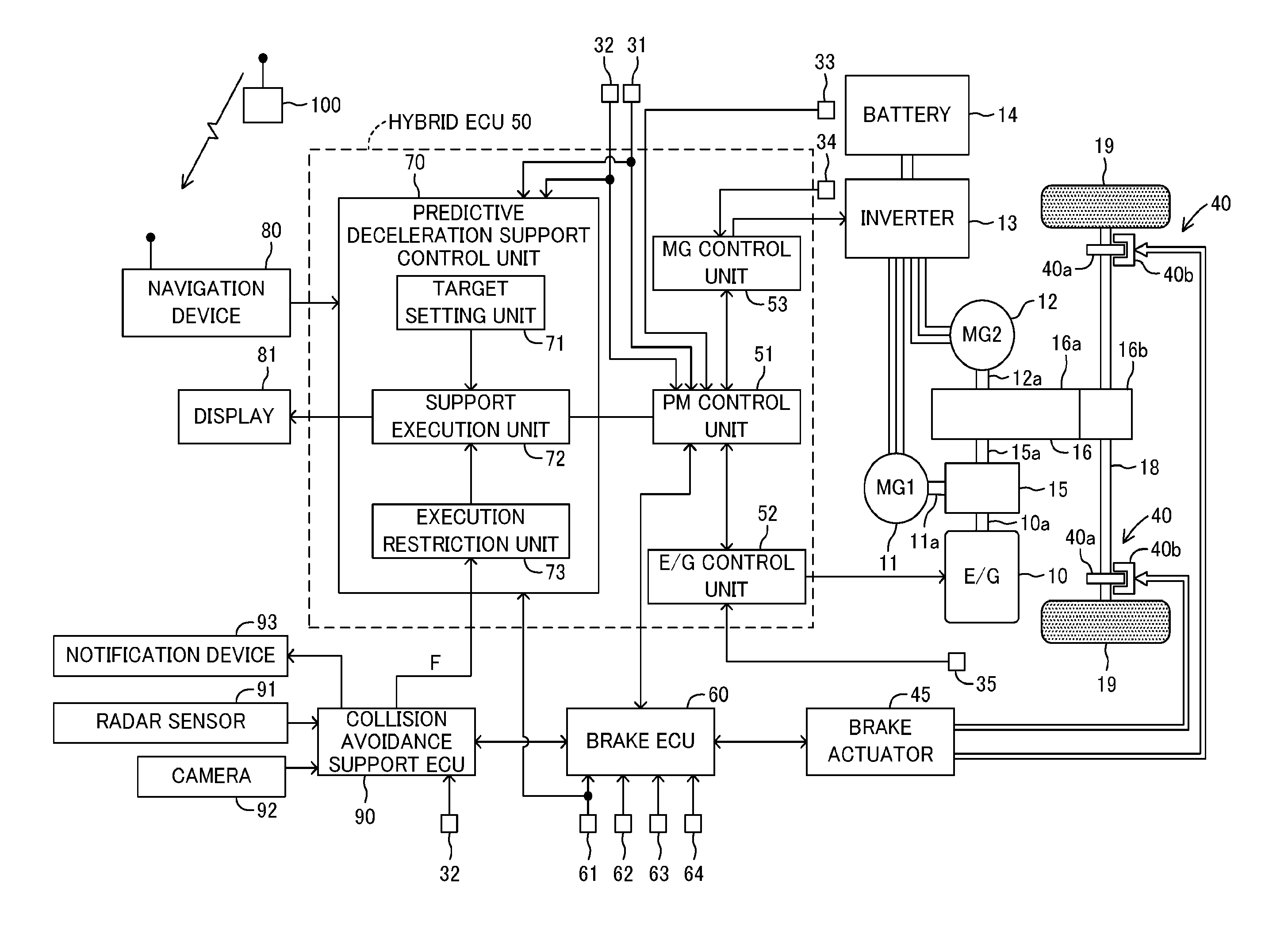

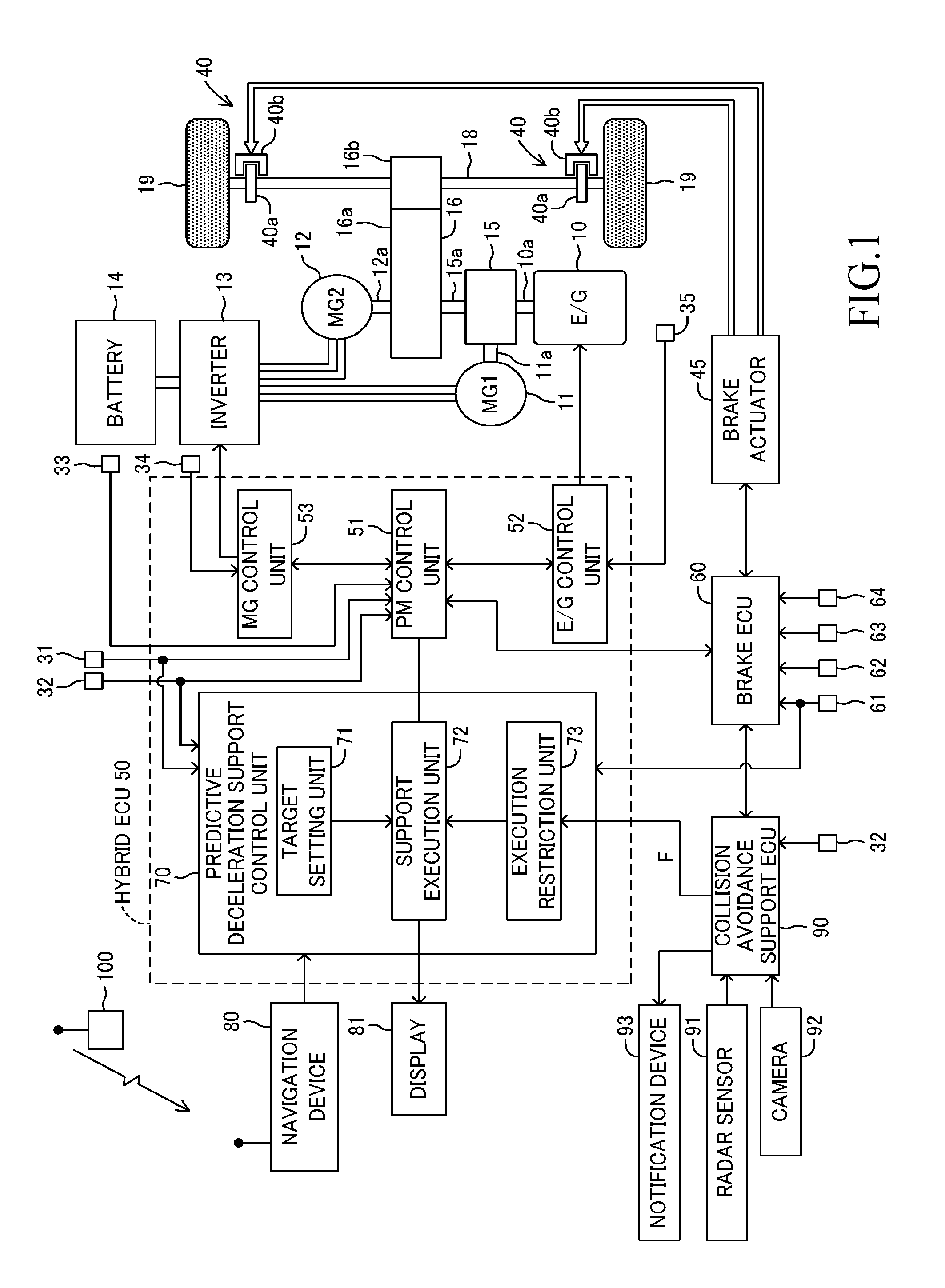

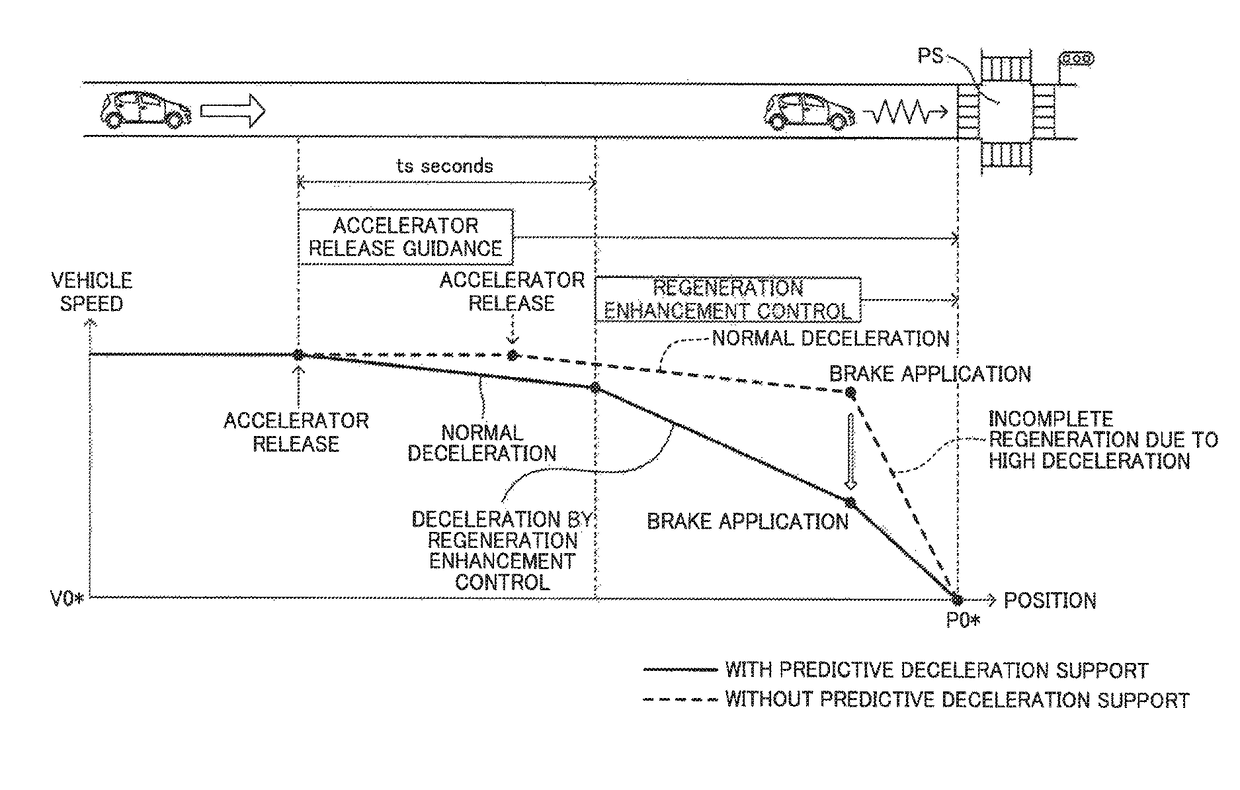

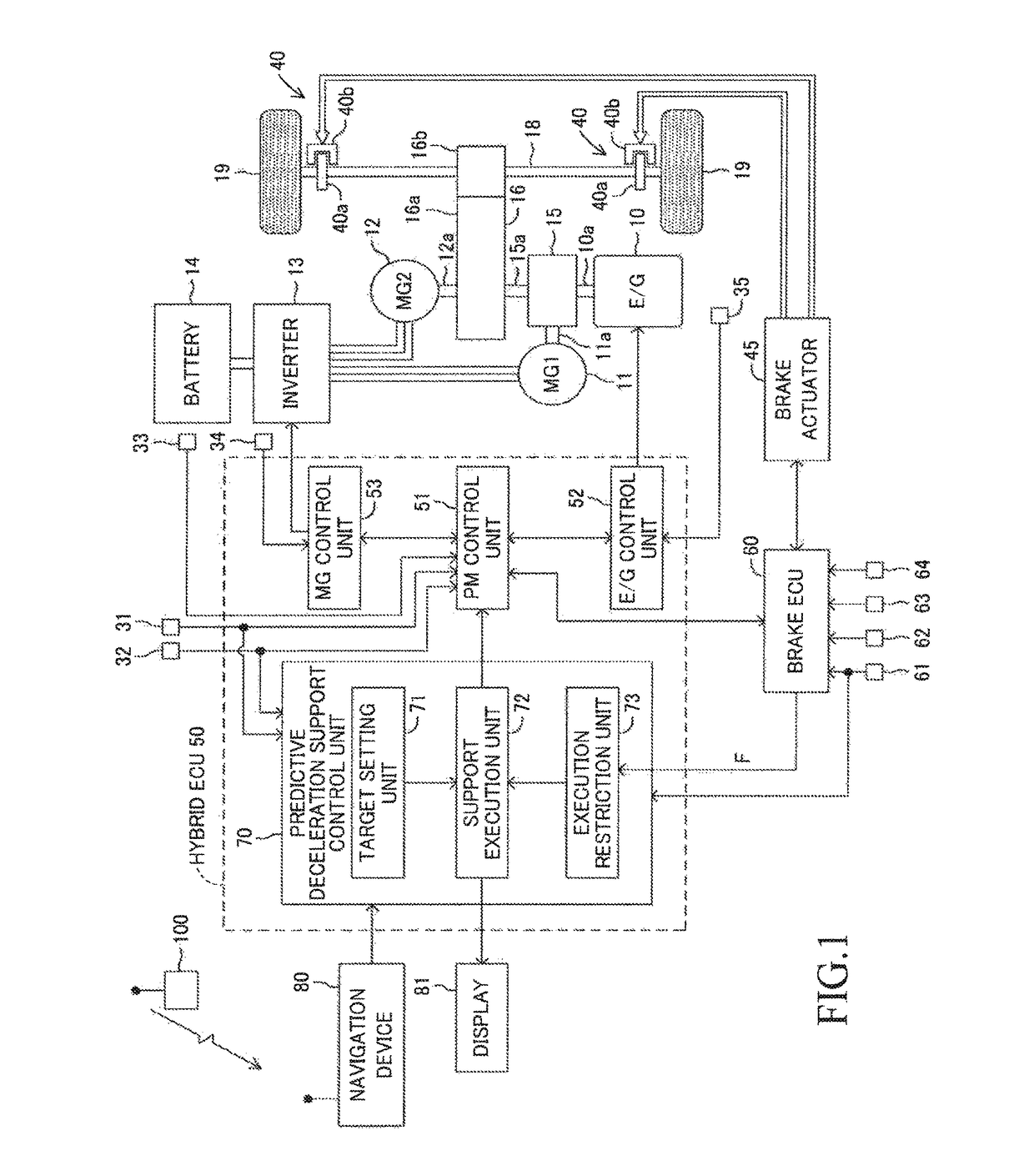

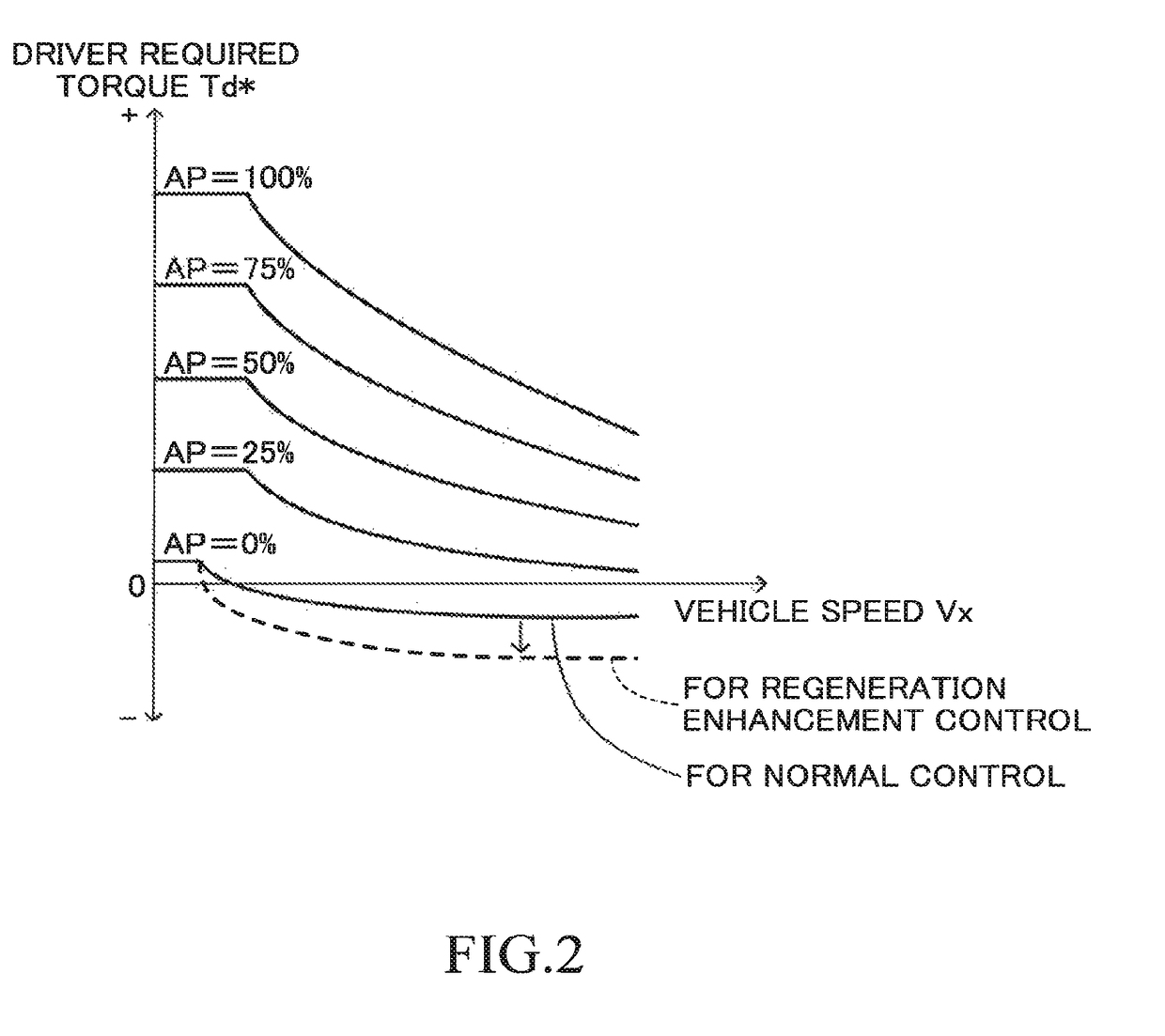

Vehicle control device

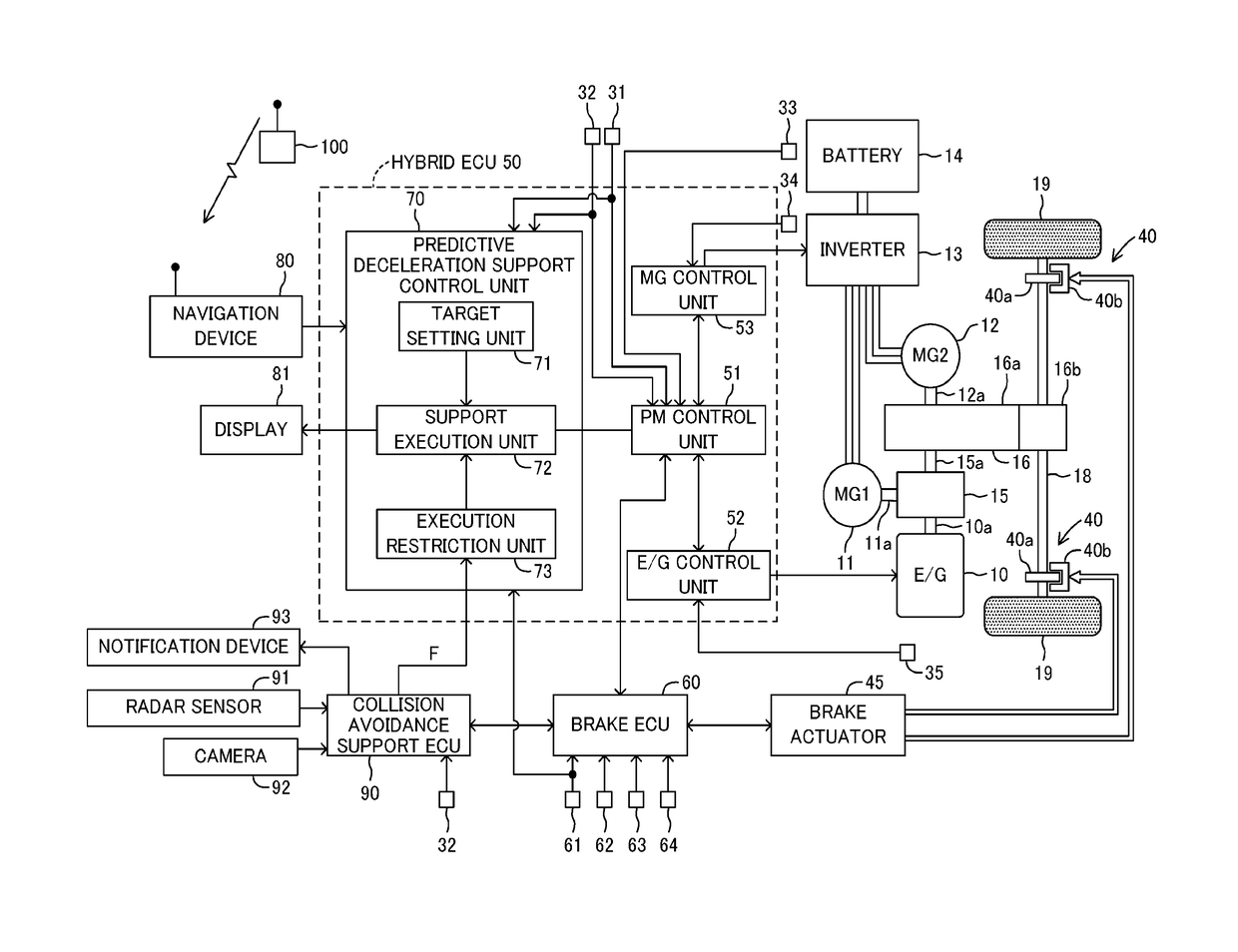

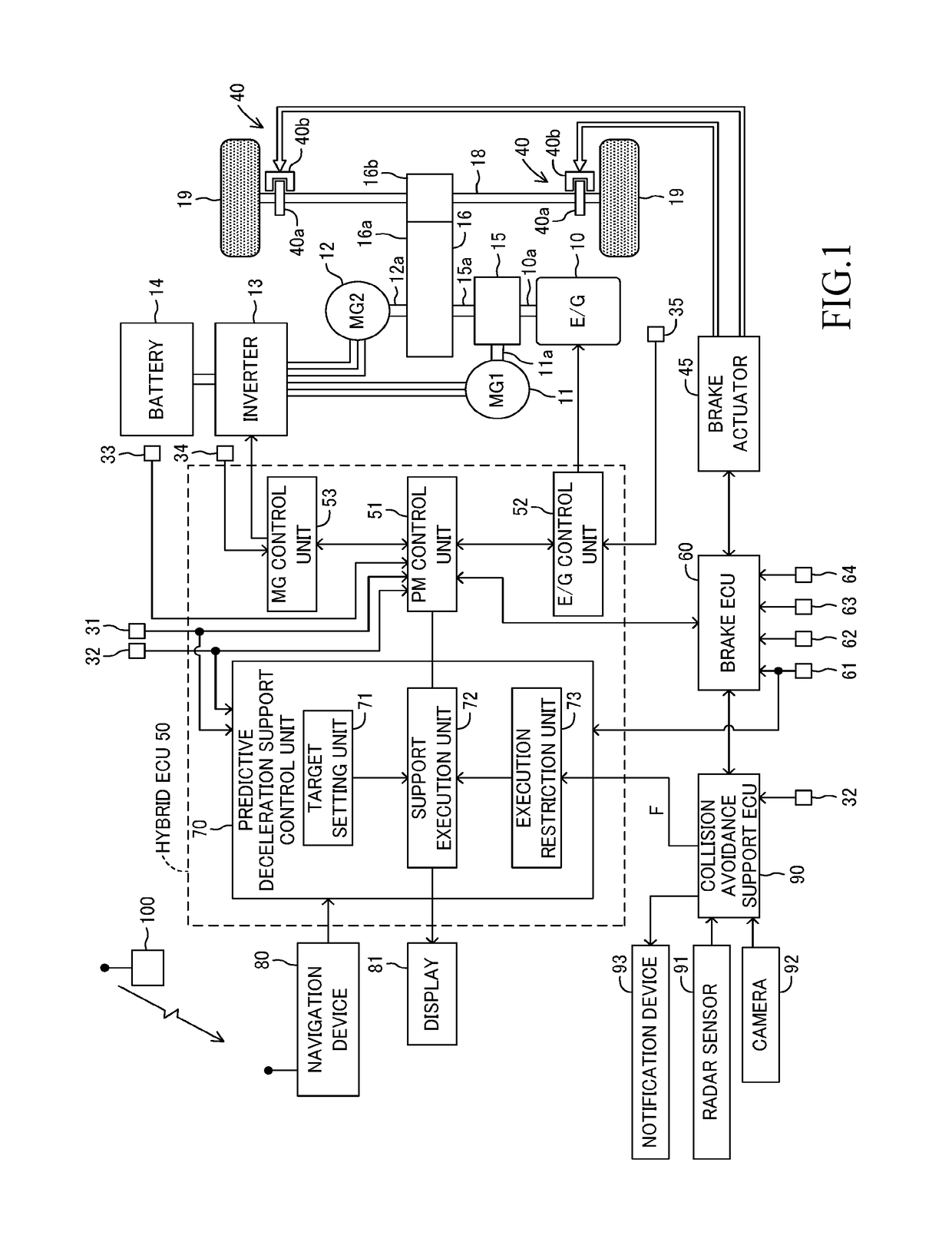

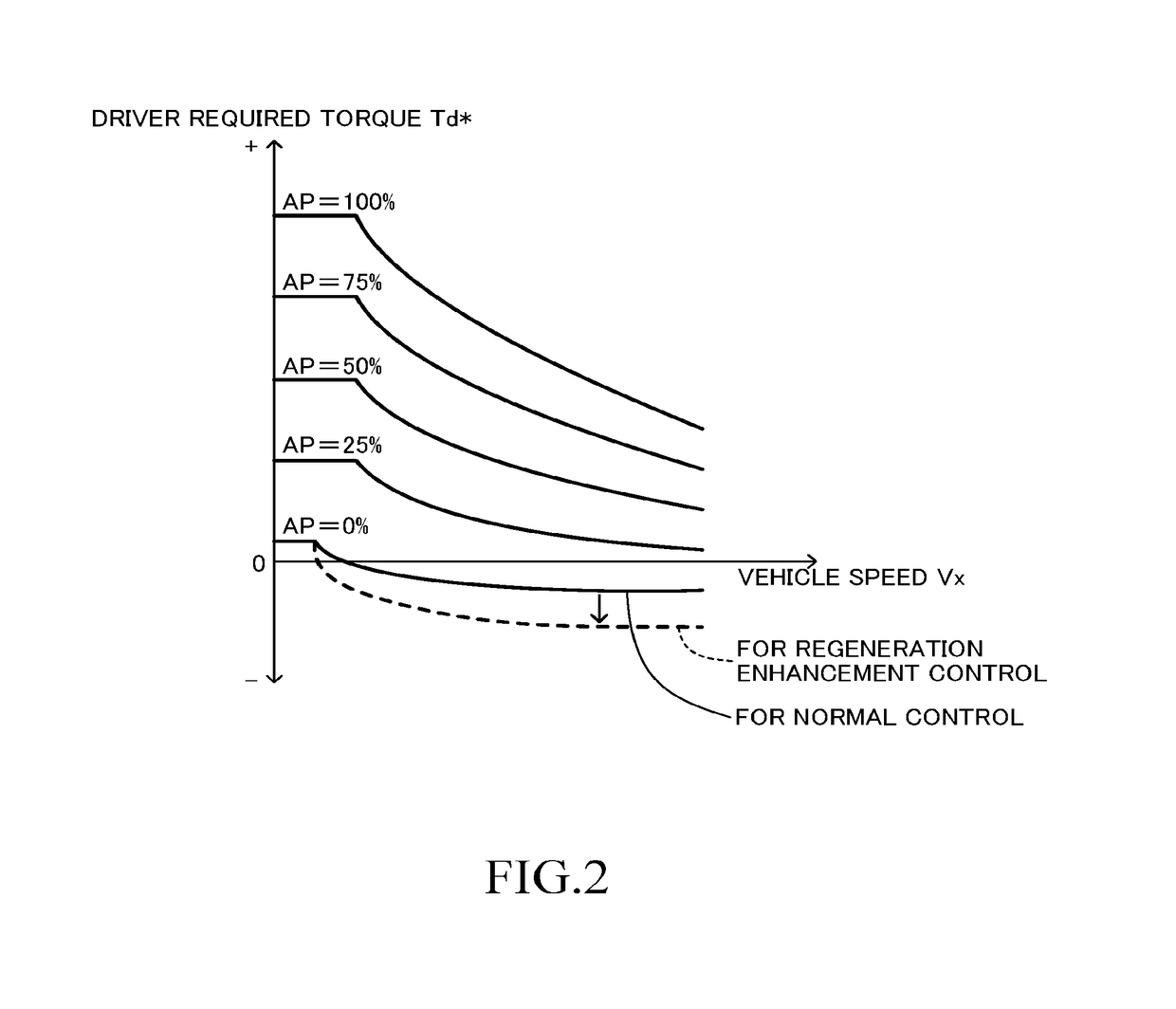

ActiveUS20170015203A1Easy to controlAppropriately carry-outHybrid vehiclesBraking element arrangementsDriver/operatorEngineering

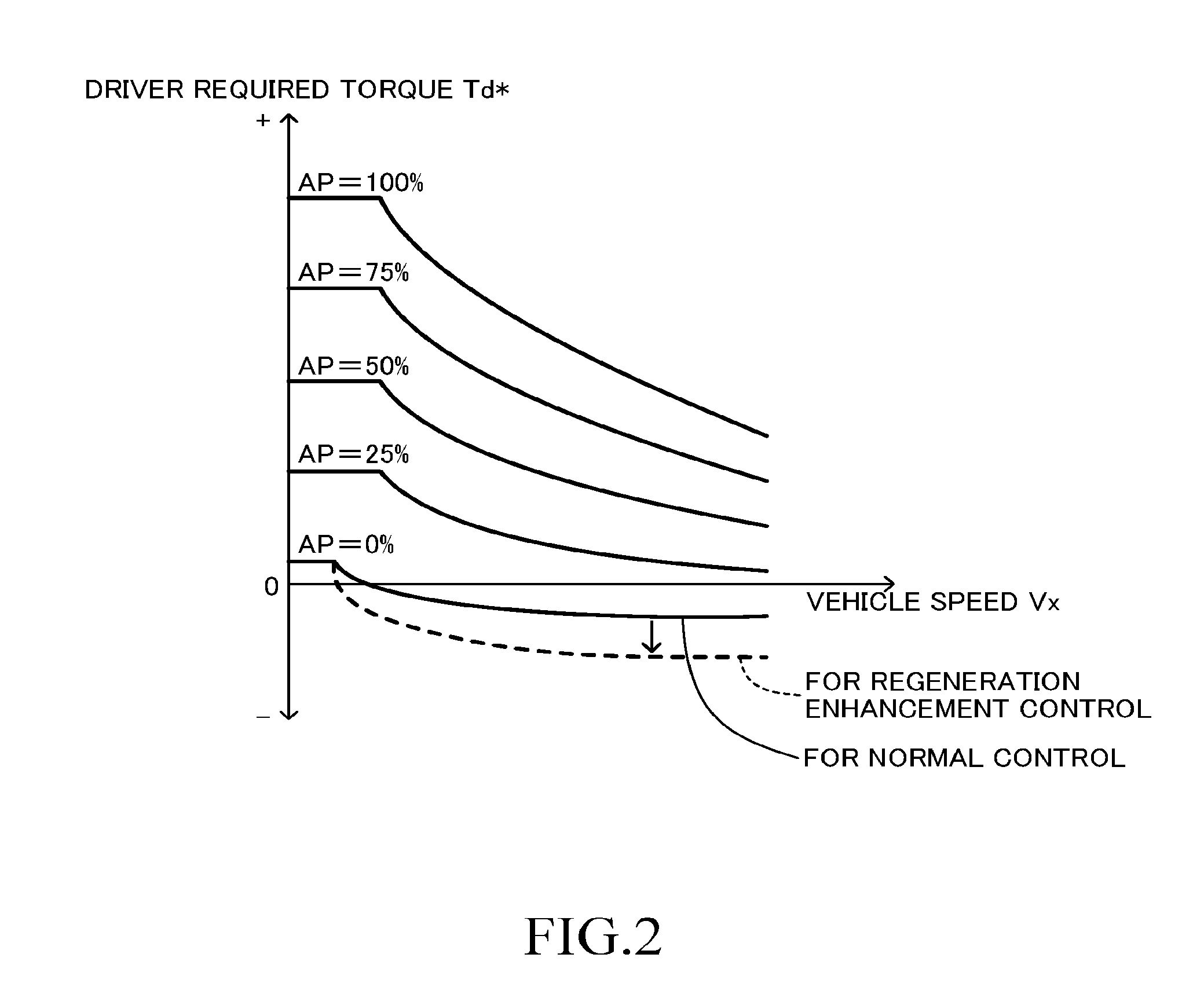

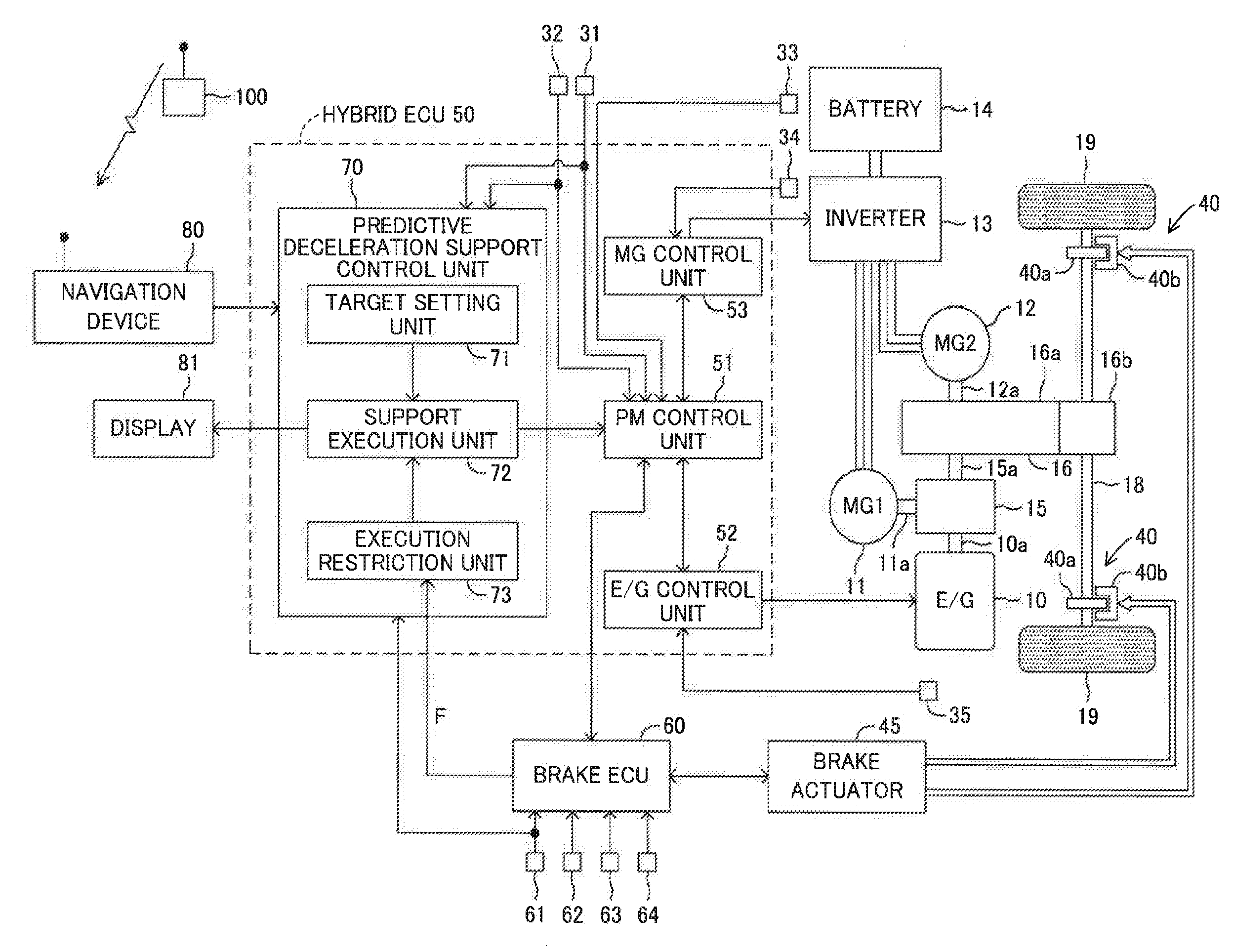

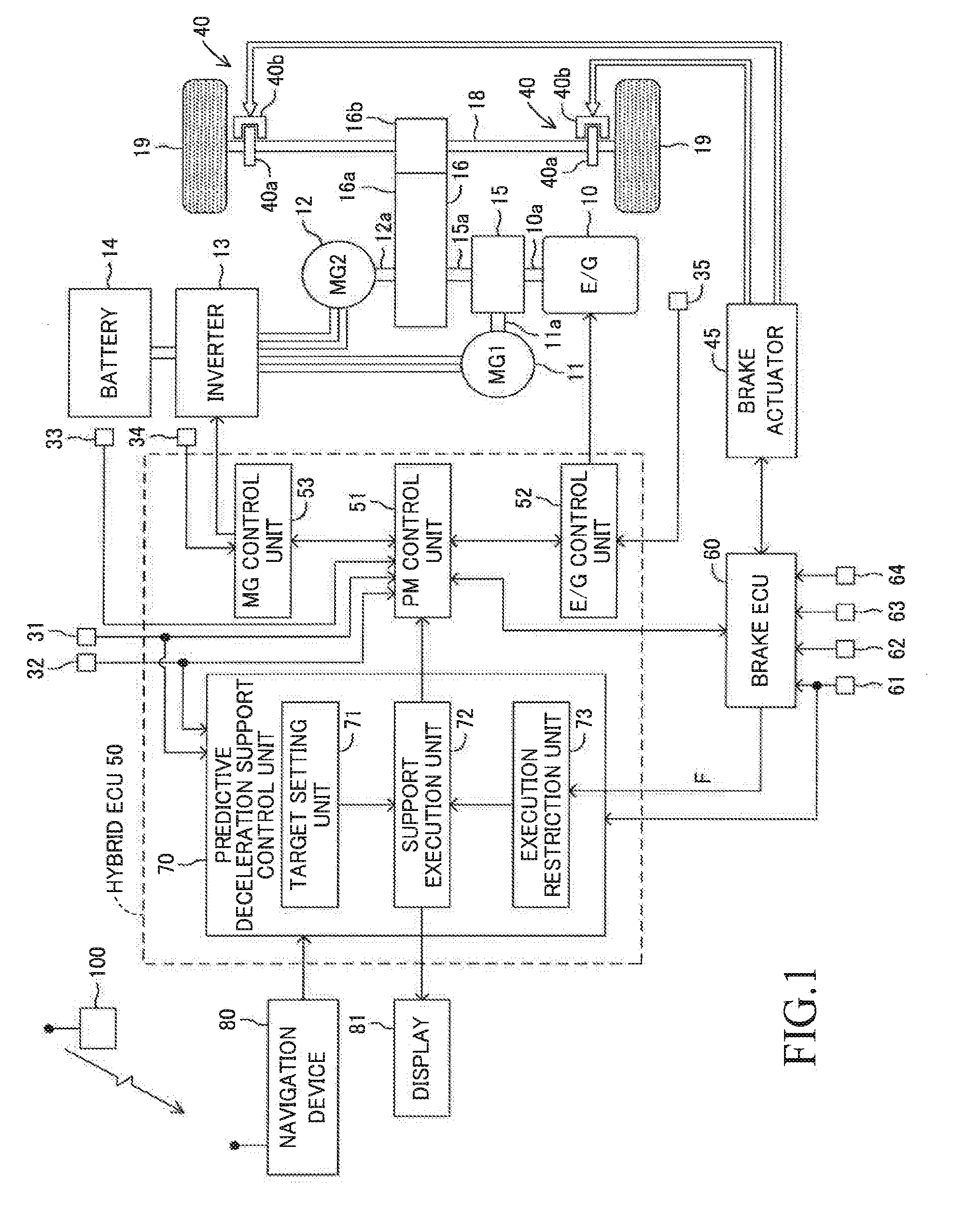

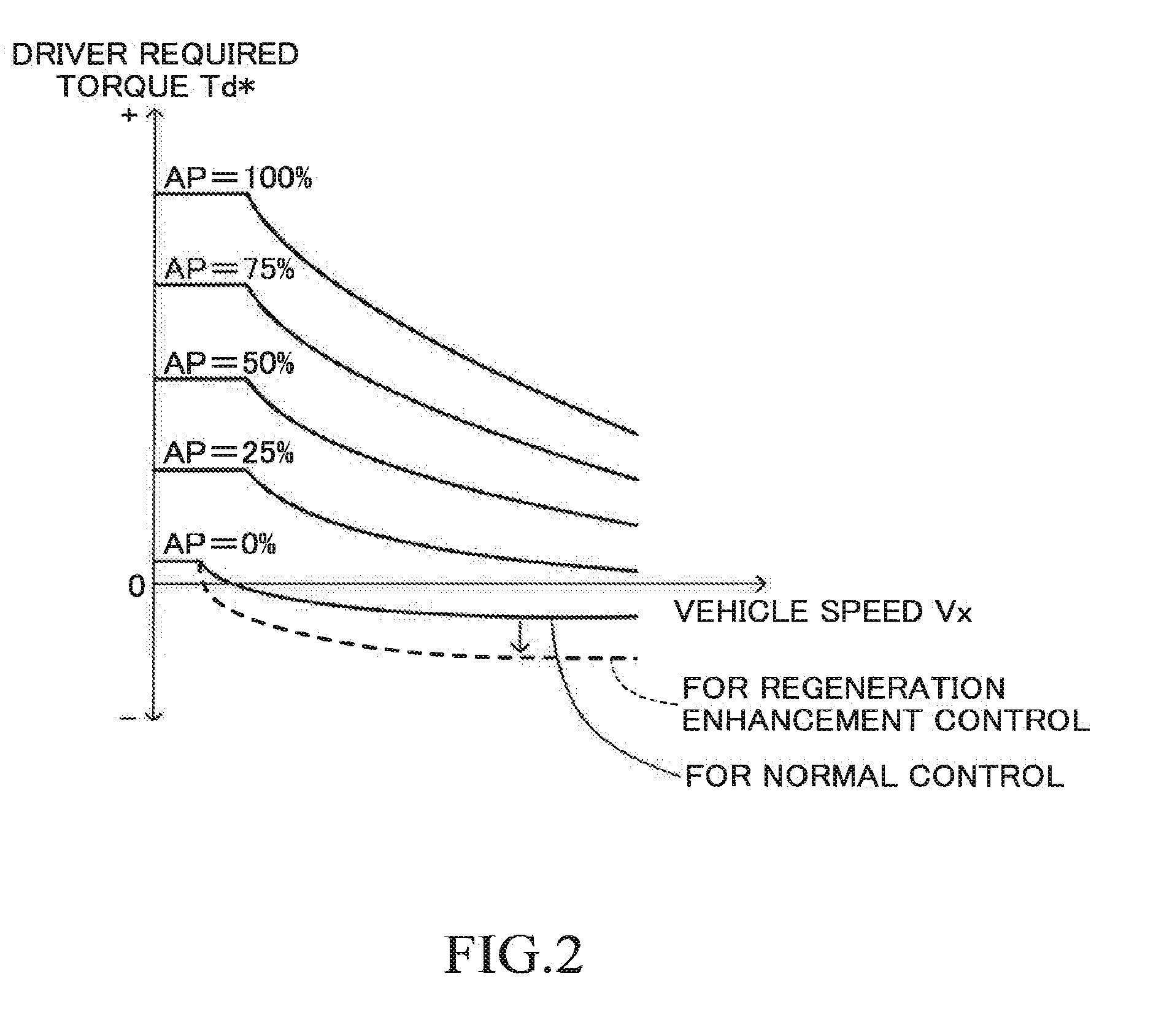

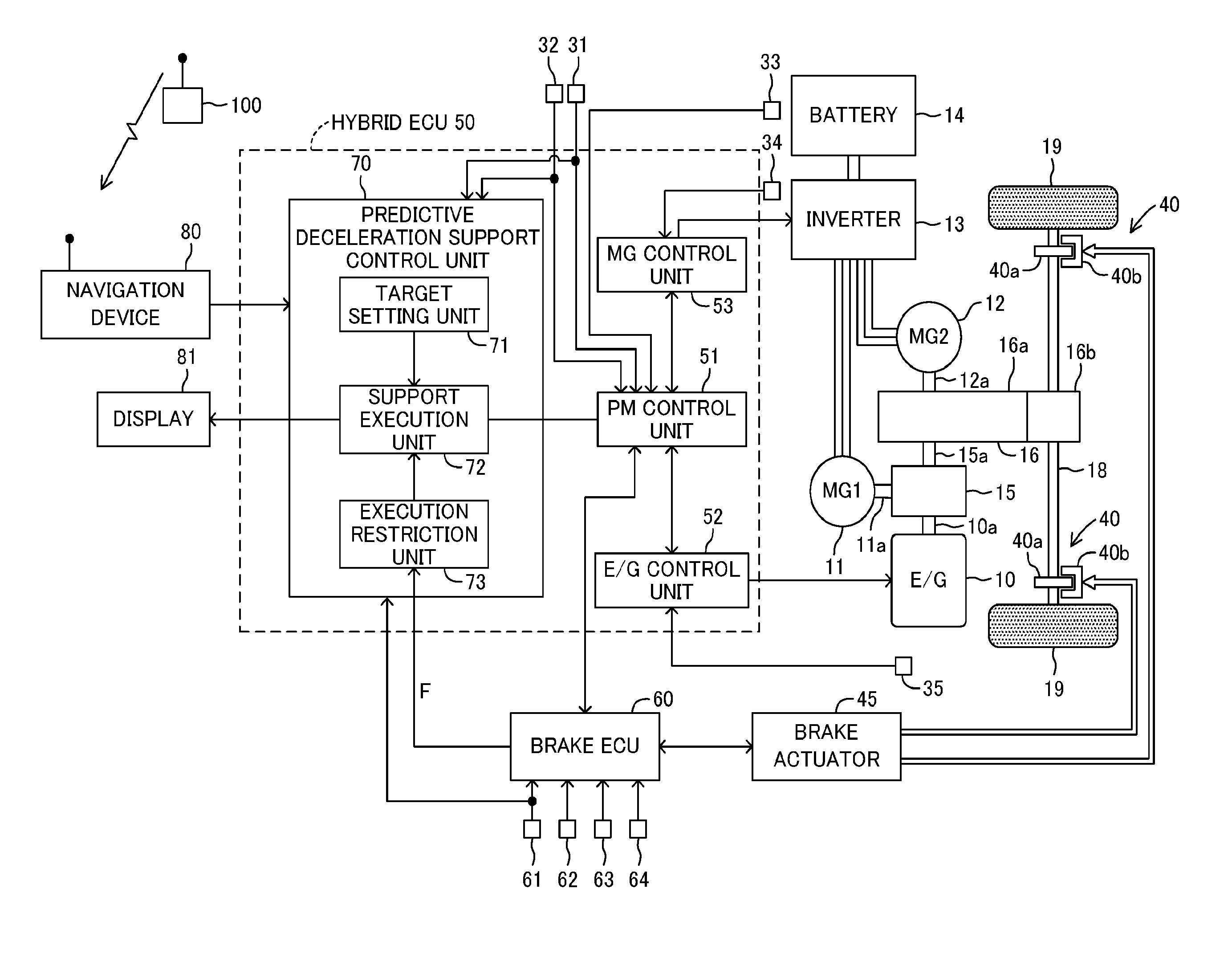

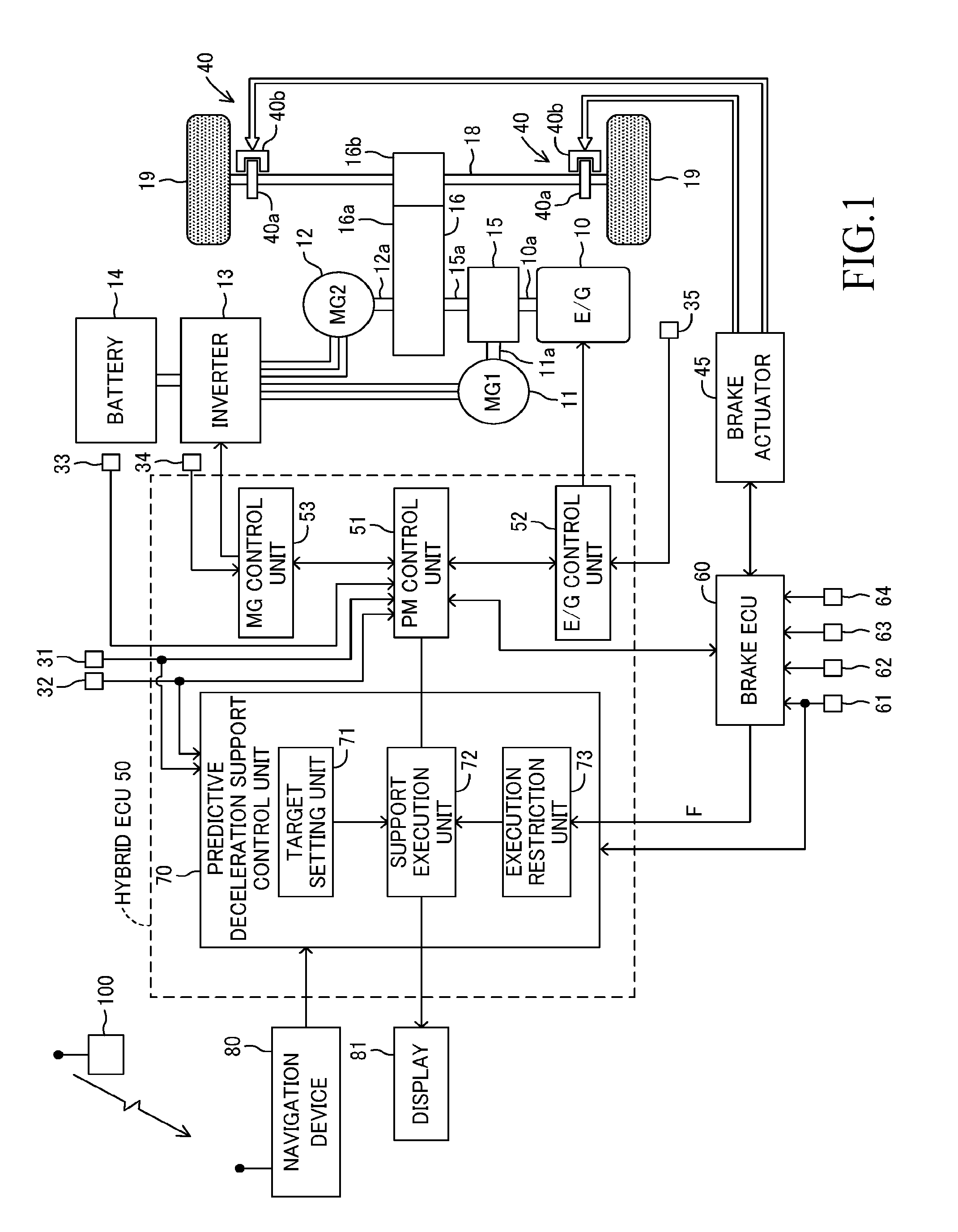

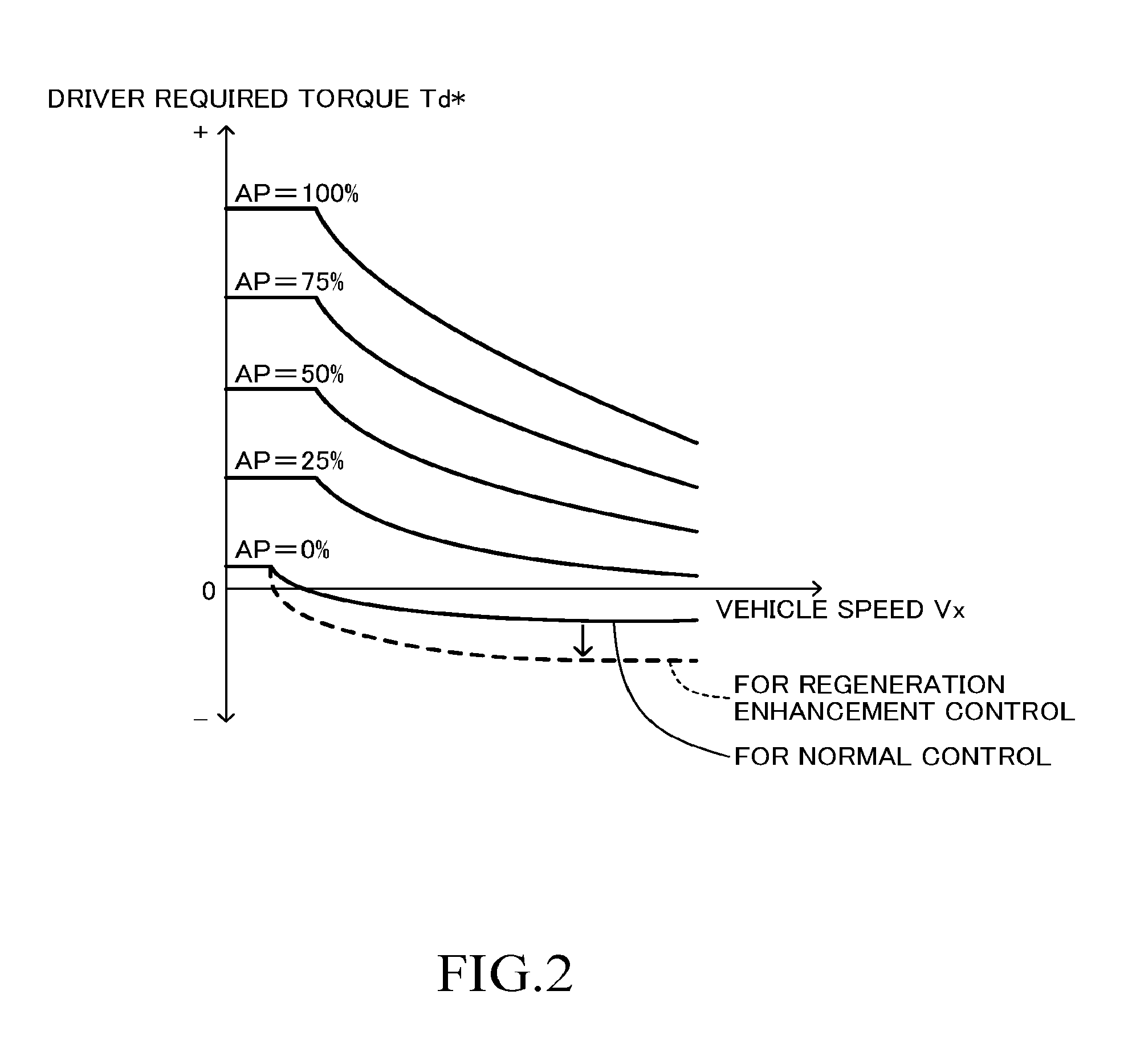

Appropriate collision avoidance support control is enabled in a vehicle configured to carry out regeneration enhancement control. A predictive deceleration support control unit is configured to set a position at which the vehicle is predicted to finish deceleration as a target deceleration end position, and guide a driver to release an accelerator pedal so that the deceleration of the vehicle is finished at the target deceleration end position, to thereby carry out regeneration enhancement control under a state in which the accelerator pedal is released so as to generate a larger deceleration than in a normal state. The predictive deceleration support control unit is configured to read a collision avoidance support control flag from a collision avoidance support ECU, and stop the regeneration enhancement control when the collision avoidance support control is being carried out.

Owner:TOYOTA JIDOSHA KK

Vehicle control device

ActiveUS20170015323A1Reduce braking forceIncrease braking powerHybrid vehiclesGas pressure propulsion mountingNormal stateVehicle control

Appropriate vehicle stability control is enabled in a vehicle configured to carry out regeneration enhancement control. A predictive deceleration support control unit is configured to set a position at which the vehicle is predicted to finish deceleration as a target deceleration end position, and guide a driver to release an accelerator pedal so that the deceleration of the vehicle is finished at the target deceleration end position, to thereby carry out regeneration enhancement control under a state in which the accelerator pedal is released so as to generate a larger deceleration than in a normal state. The predictive deceleration support control unit is configured to read a vehicle stability control flag from a brake ECU and stop the regeneration enhancement control when the vehicle stability control is being carried out.

Owner:TOYOTA JIDOSHA KK

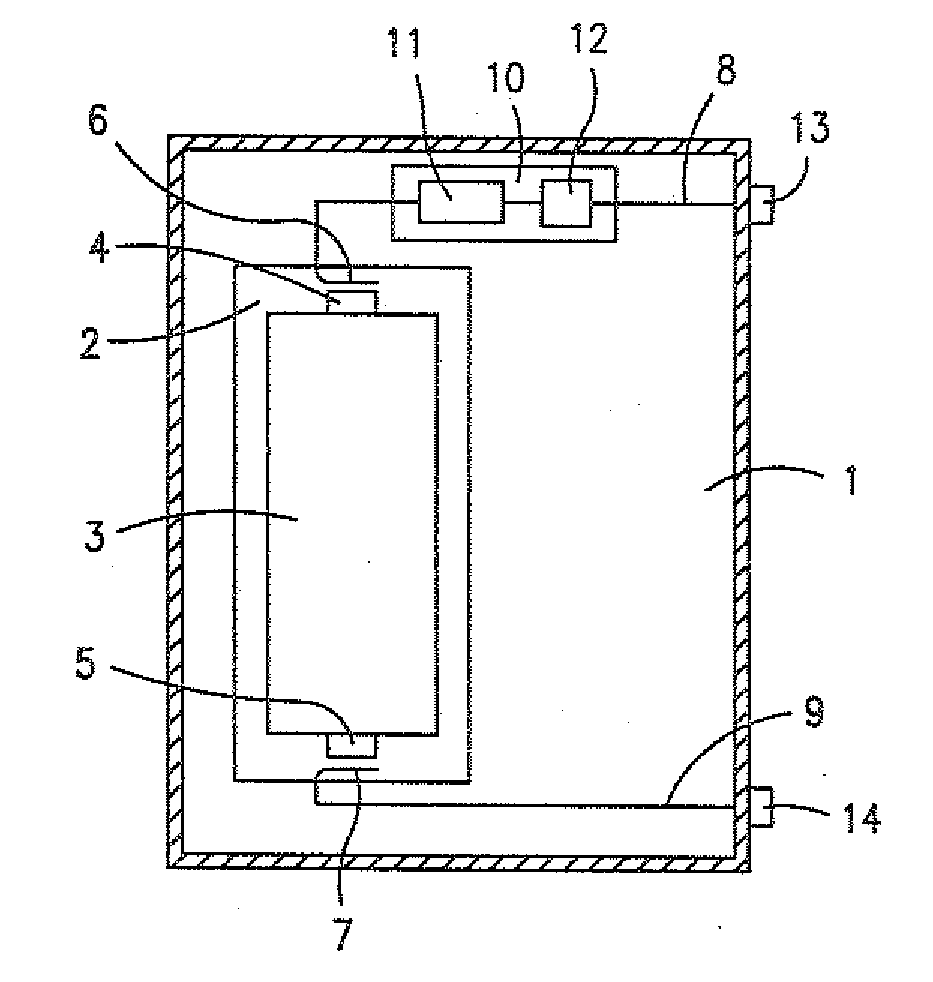

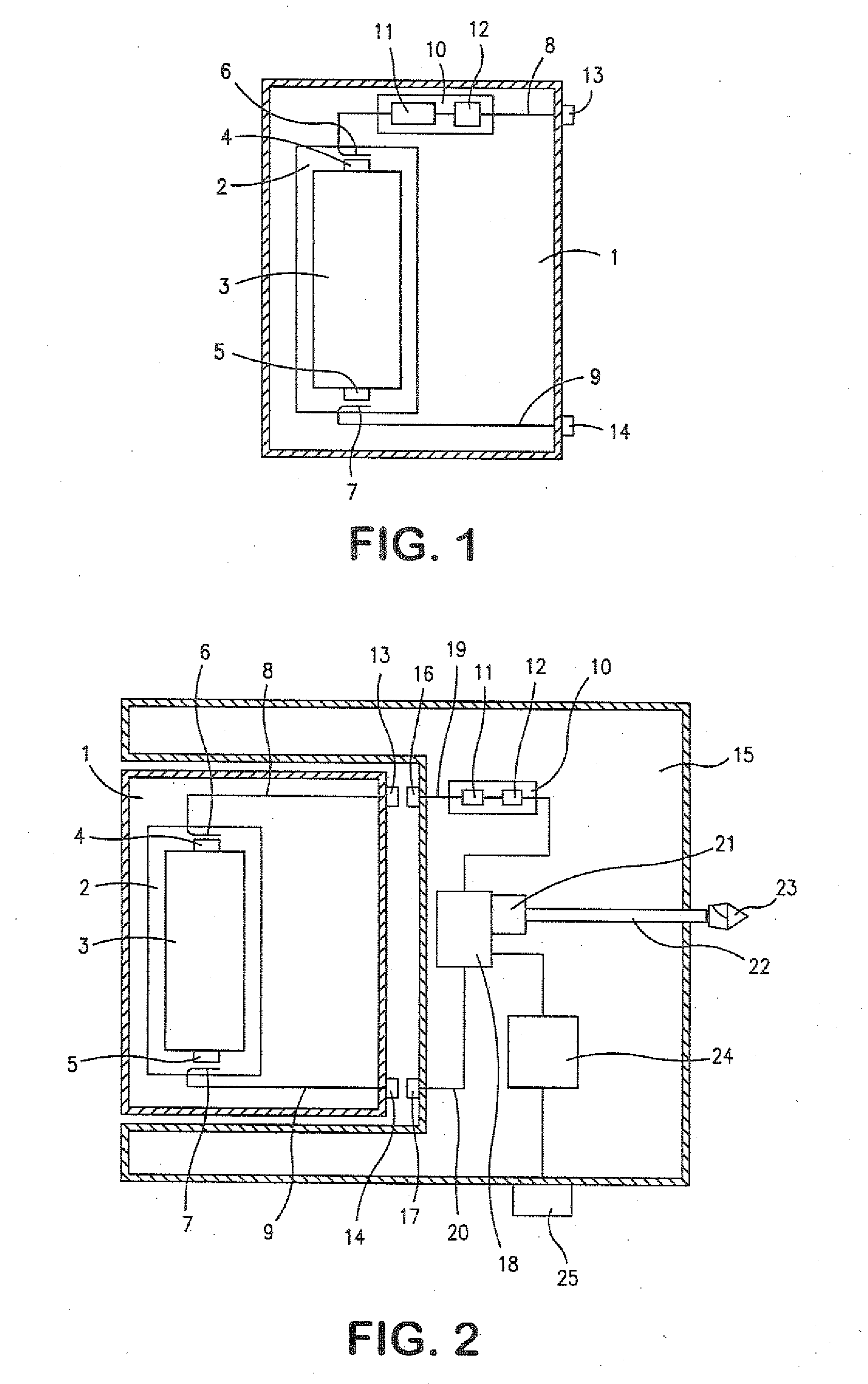

System and methods for preparation of adipose-derived stem cells

ActiveUS20180221550A1Requires environmentOut of operationBiological substance pretreatmentsRotary centrifugesInterior spaceCell Fraction

A device that allows for either fat graft preparation or cell fraction harvest is disclosed. The device includes a first centrifuge tube configured to receive and process a biological substance, the first centrifuge tube comprising an upper cylindrical portion and a lower conical portion, a sterile tissue inlet fitting, at least one sterile processing fluid inlet fitting, a sterile suction fitting, and at least one sterile extraction port connected to a first extraction tube. The first centrifuge tube further includes an internal space including a screen being positioned therein, the screen being configured to divide the internal space in half, and a filter positioned therein, the filter being positioned below the screen in the lower conical portion of the first centrifuge tube. The device may further include a second centrifuge tube configured to receive and further process the biological substance from the first centrifuge tube. The second centrifuge tube has at least one sterile fitting, wherein the second centrifuge tube is releasably connected via the at least one sterile fitting to one of the at least one sterile extraction ports of the first centrifuge tube.

Owner:JOINTECHLABS

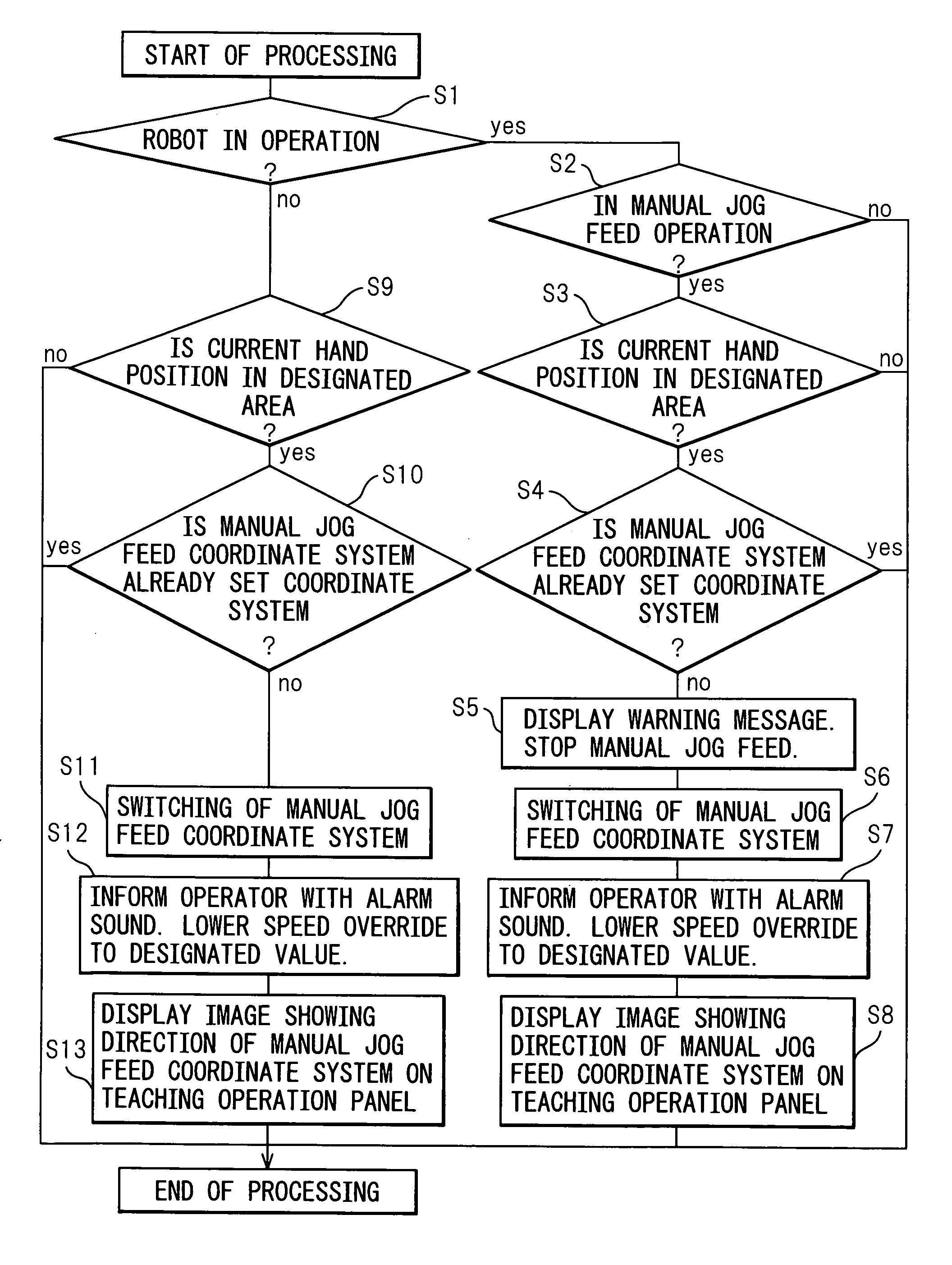

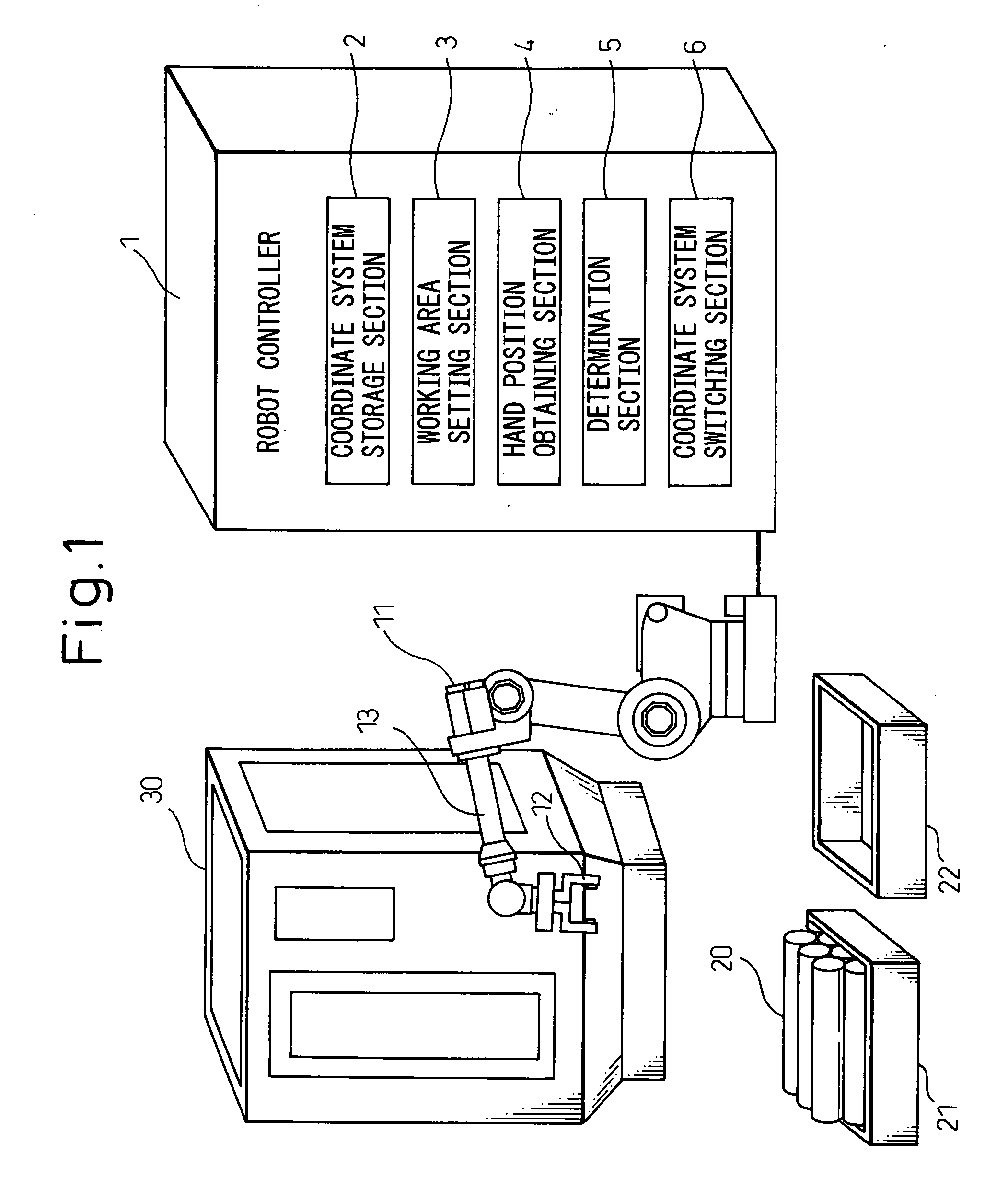

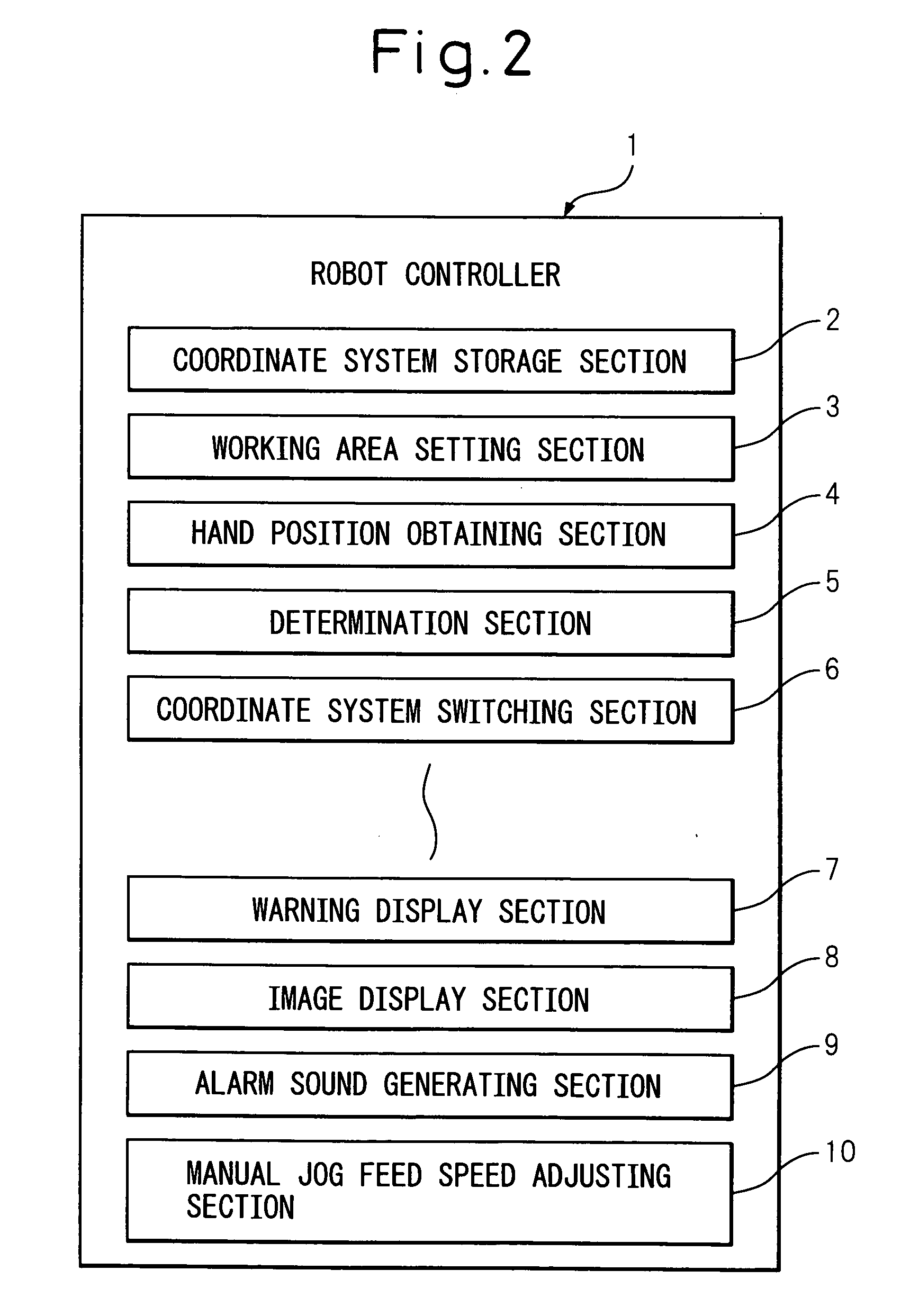

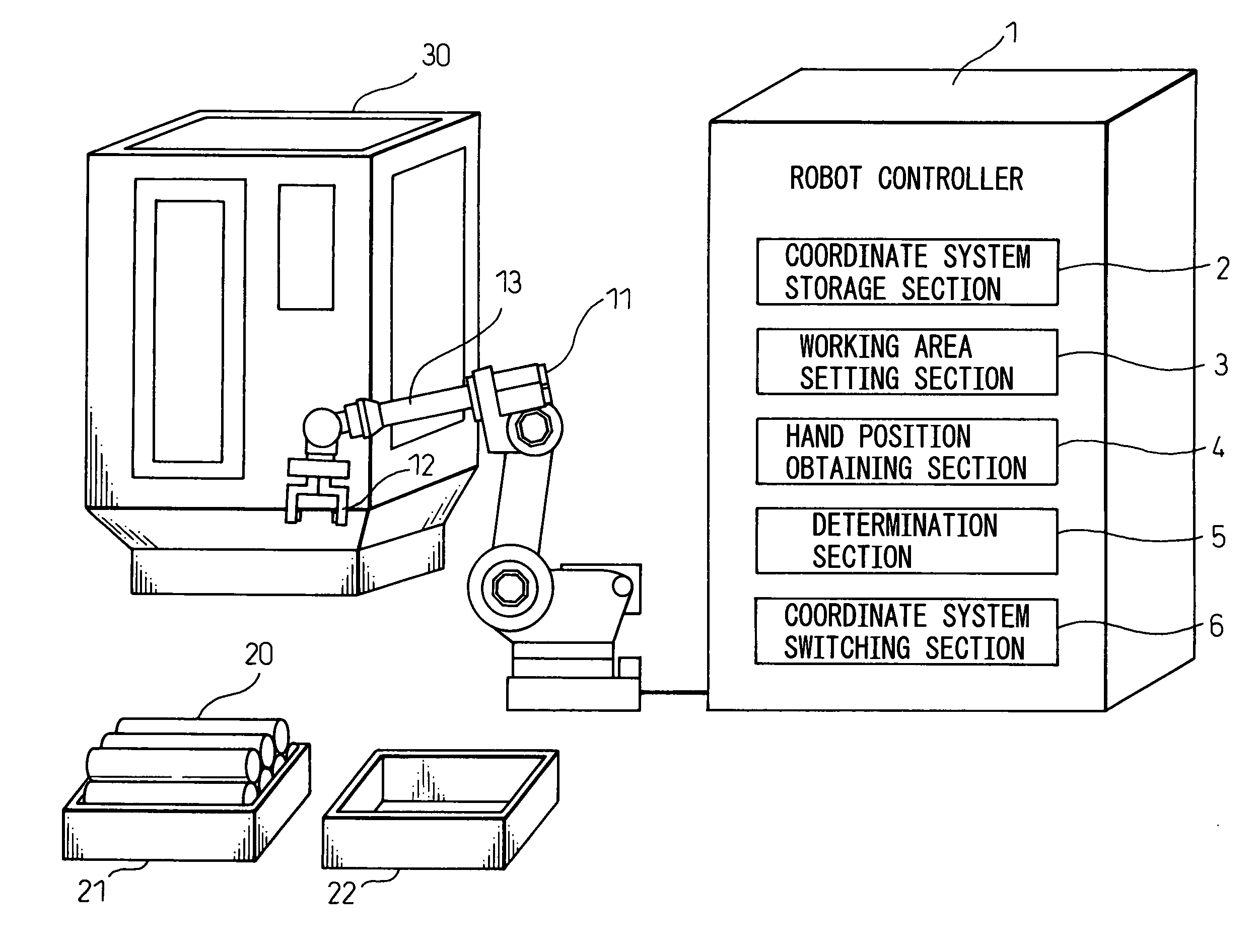

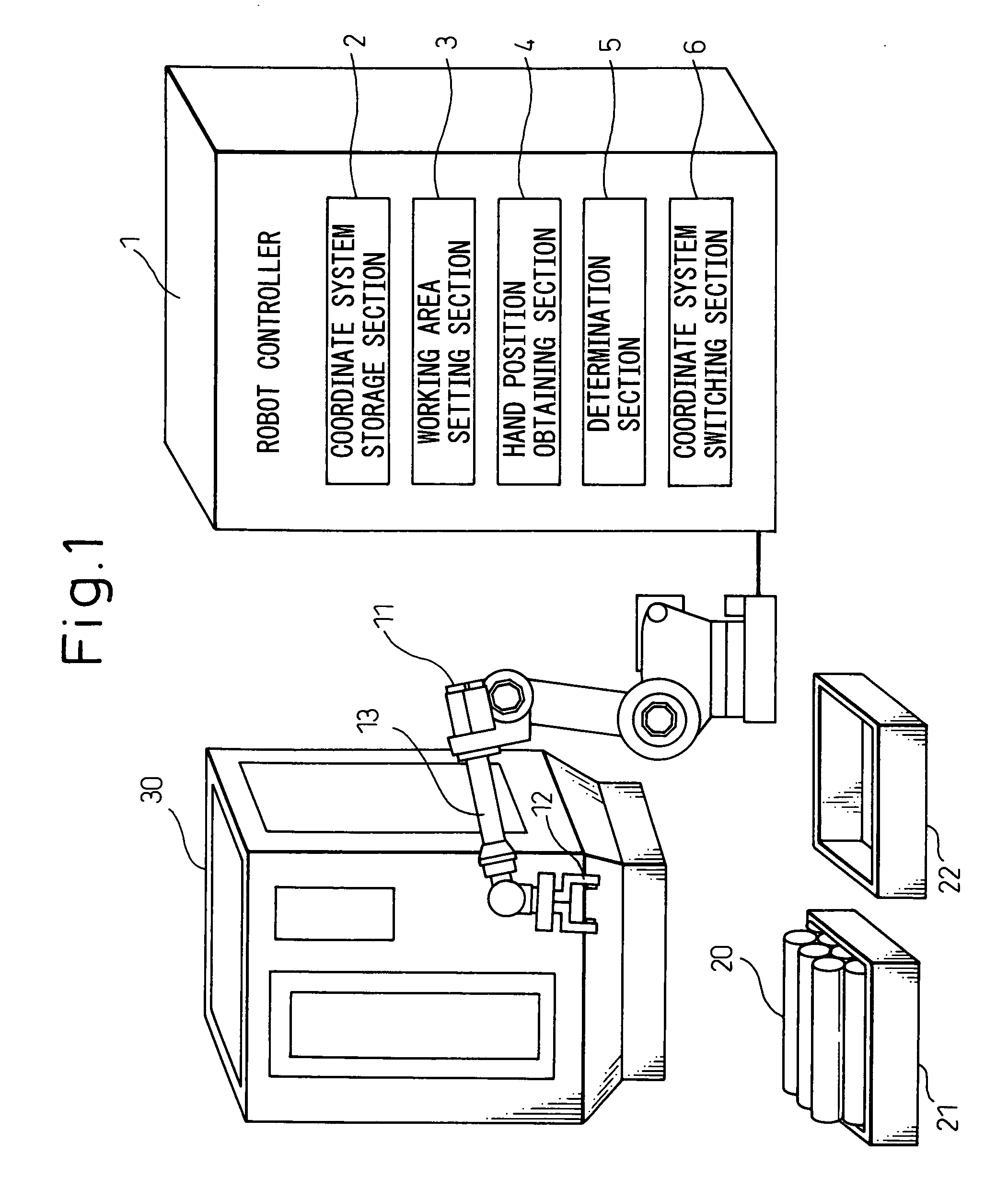

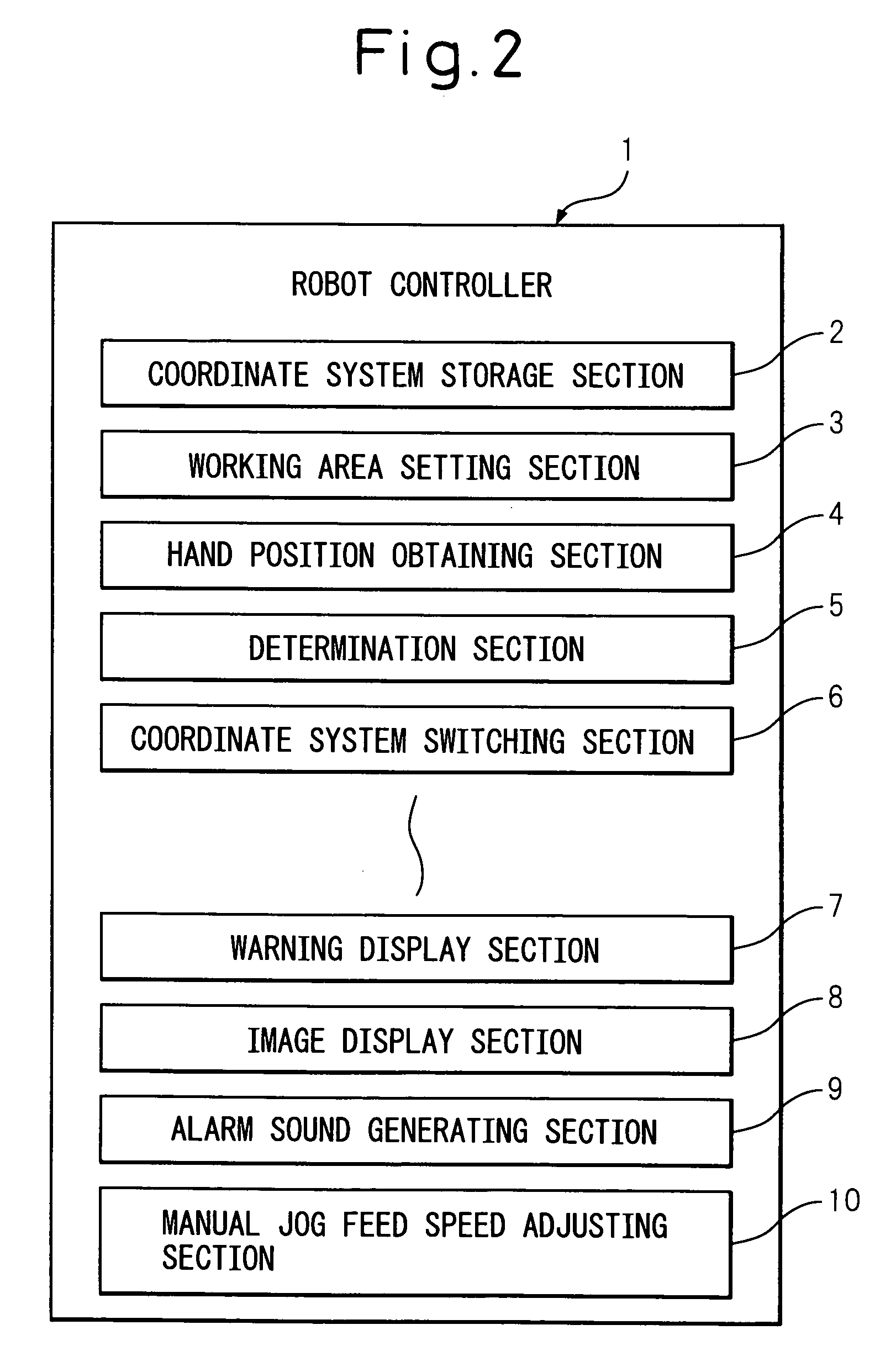

Controller of work piece-conveying robot

ActiveUS20090112362A1Easy to set upEliminate needProgramme-controlled manipulatorComputer controlRobot handSimulation

A controller for work piece-conveying robot having: a coordinate system storage section for storing one or more manual jog feed coordinate systems; a working area setting section for setting to a machine tool a working area to which the manual jog feed coordinate system is assigned; a hand position obtaining section for obtaining a current position of the robot hand at each specified sampling period; a determination section for determining whether or not the current position of the robot hand obtained by the hand position obtaining section is within the working area set by the working area setting section; and a coordinate system switching section for switching a present manual jog feed coordinate system to the manual jog feed coordinate system assigned to the working area if it is determined by the determination section that the current position of the robot hand is within the working area.

Owner:FANUC LTD

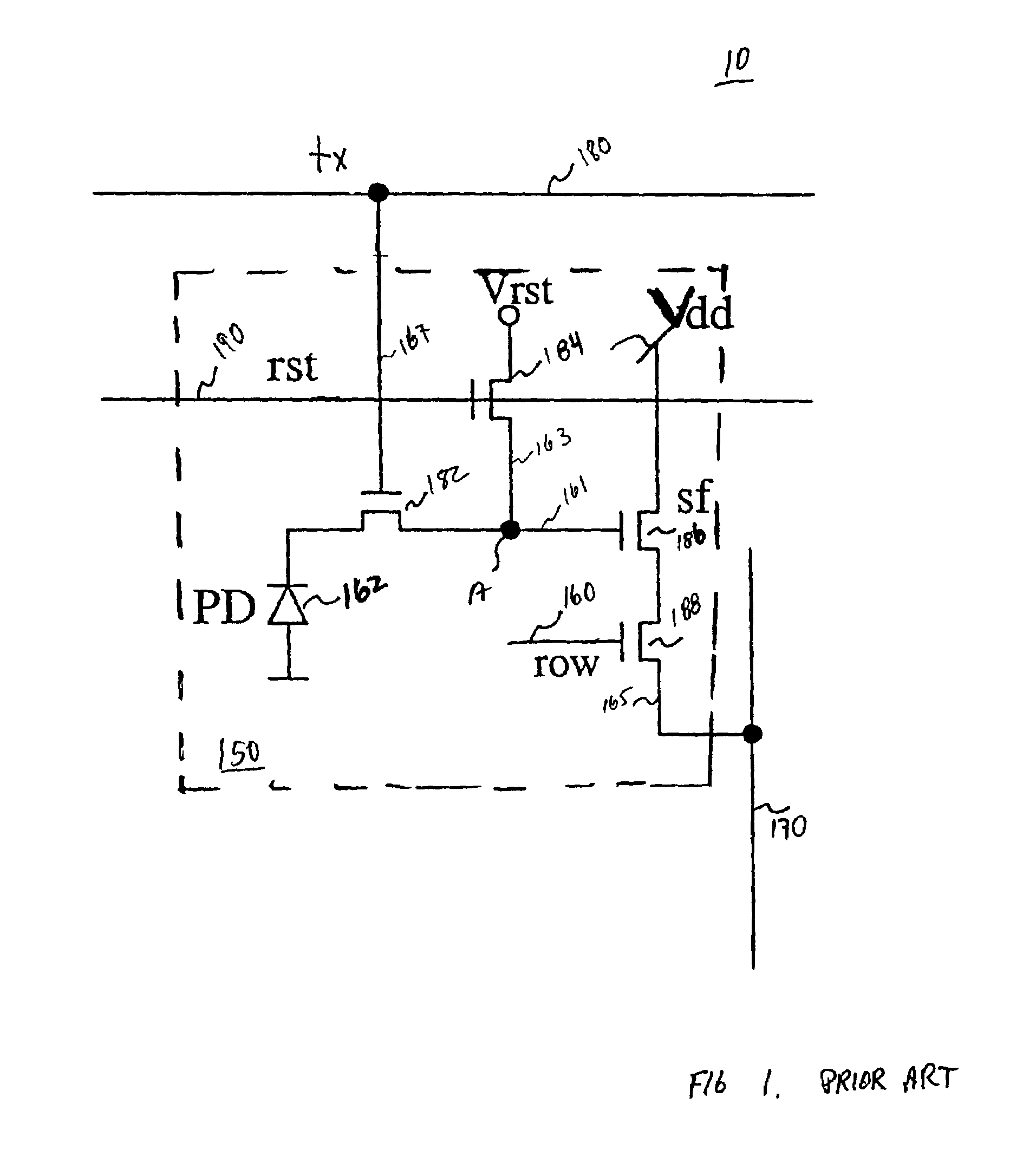

Differential readout from pixels in CMOS sensor

ActiveUS7375748B2Minimizes substrateMinimizes other common mode noiseTelevision system detailsTelevision system scanning detailsCMOS sensorNear neighbor

The present invention provides an improved pixel readout circuit that compensates for common mode noise during a read out operation. This is accomplished by using a differential readout of the signal and reset value from the desired pixel compared with the reset value from a reference pixel. In this manner common mode noise can be offset and therefore minimized. In one embodiment of the invention, the reference pixel is the nearest neighbor pixel in the same row. In another embodiment, the reference pixel is the nearest neighboring pixel in a different row.

Owner:APTINA IMAGING CORP

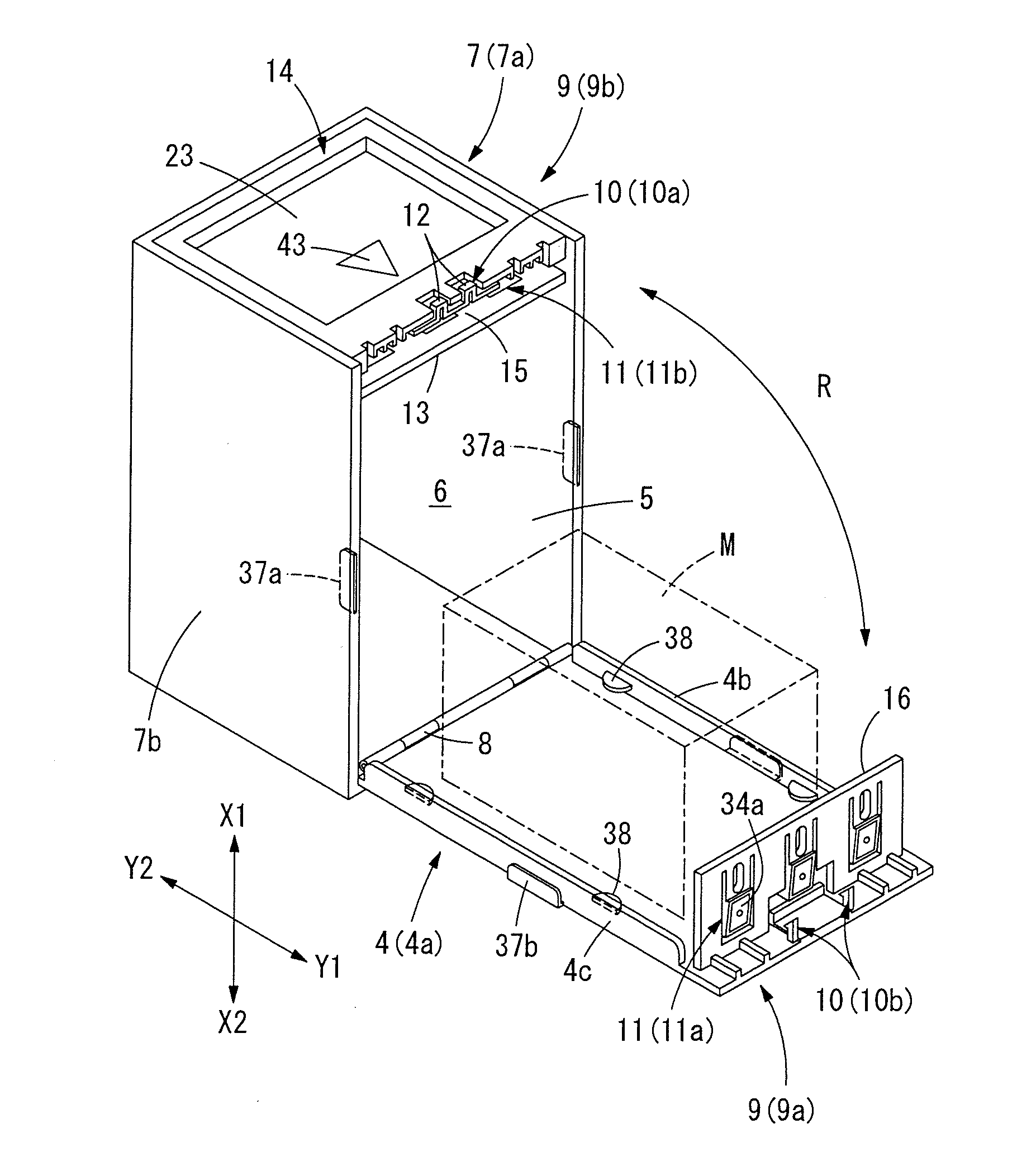

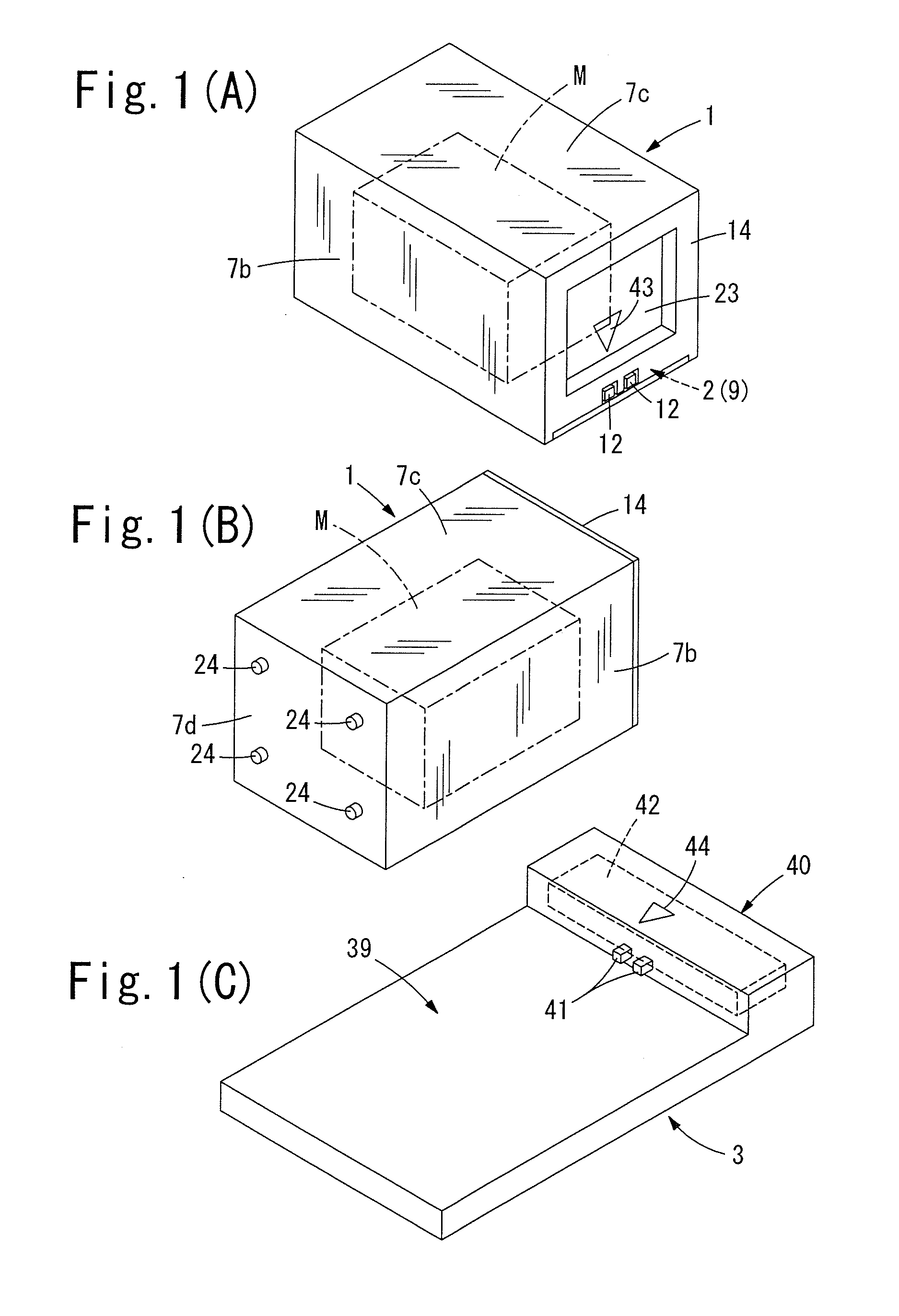

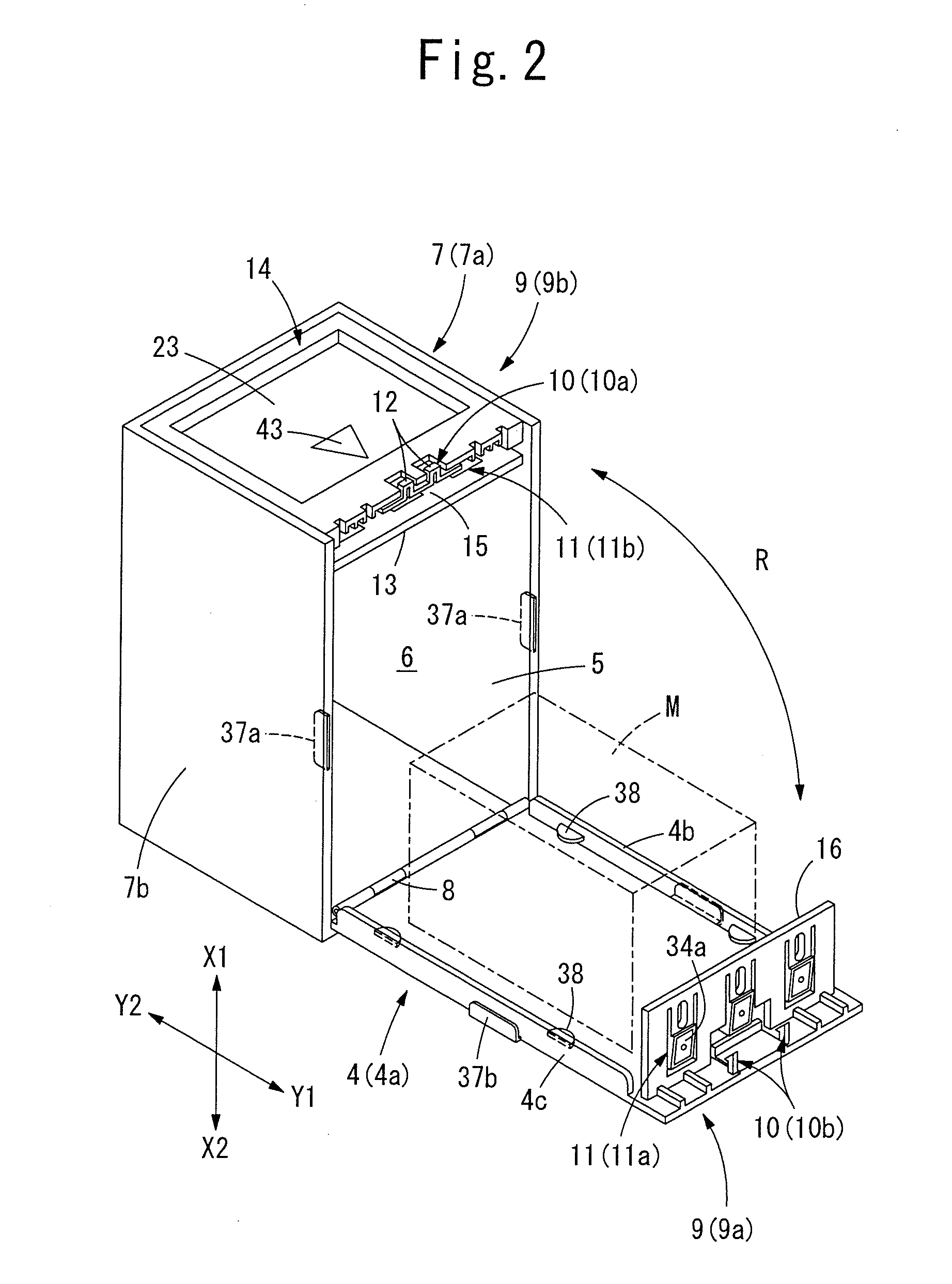

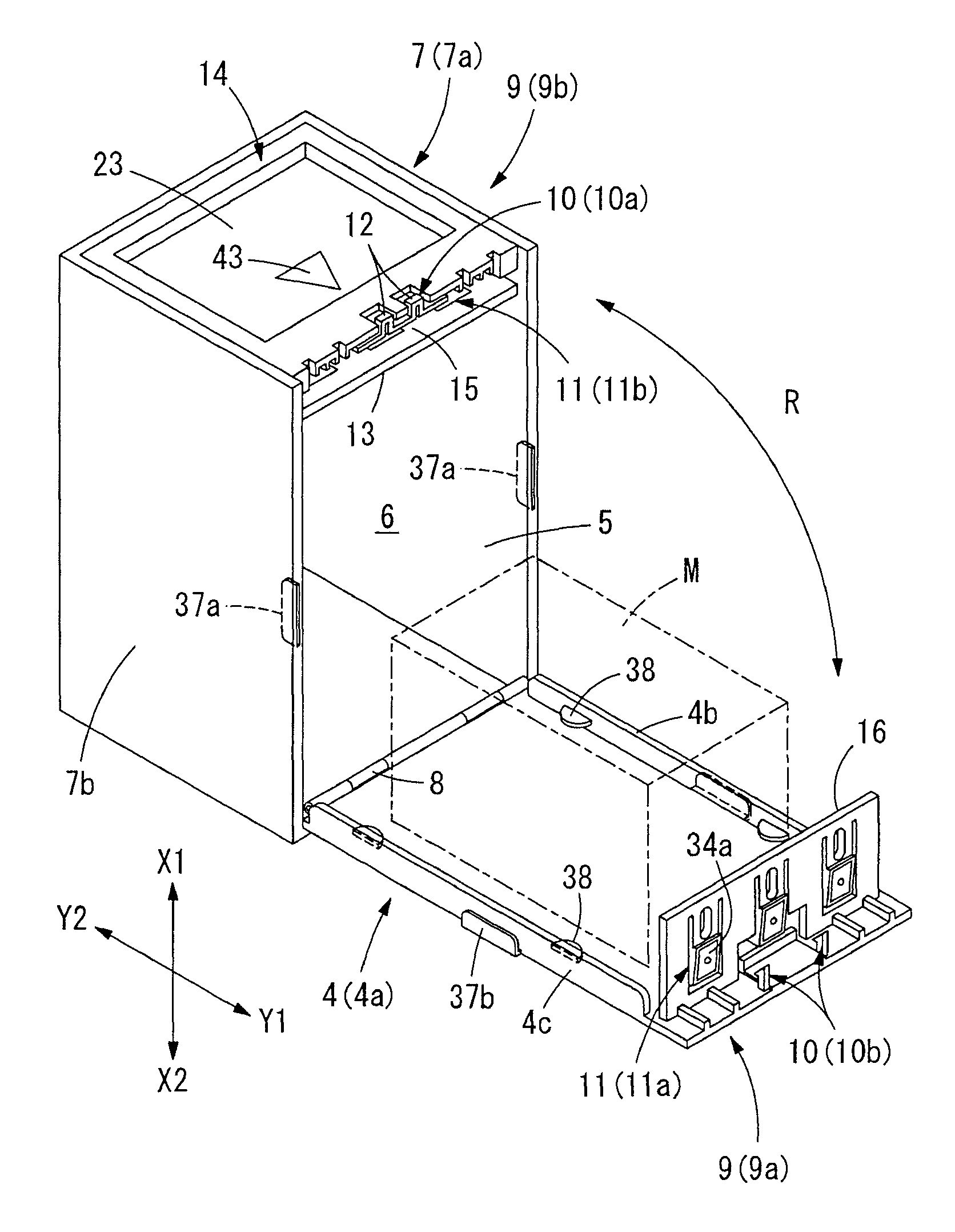

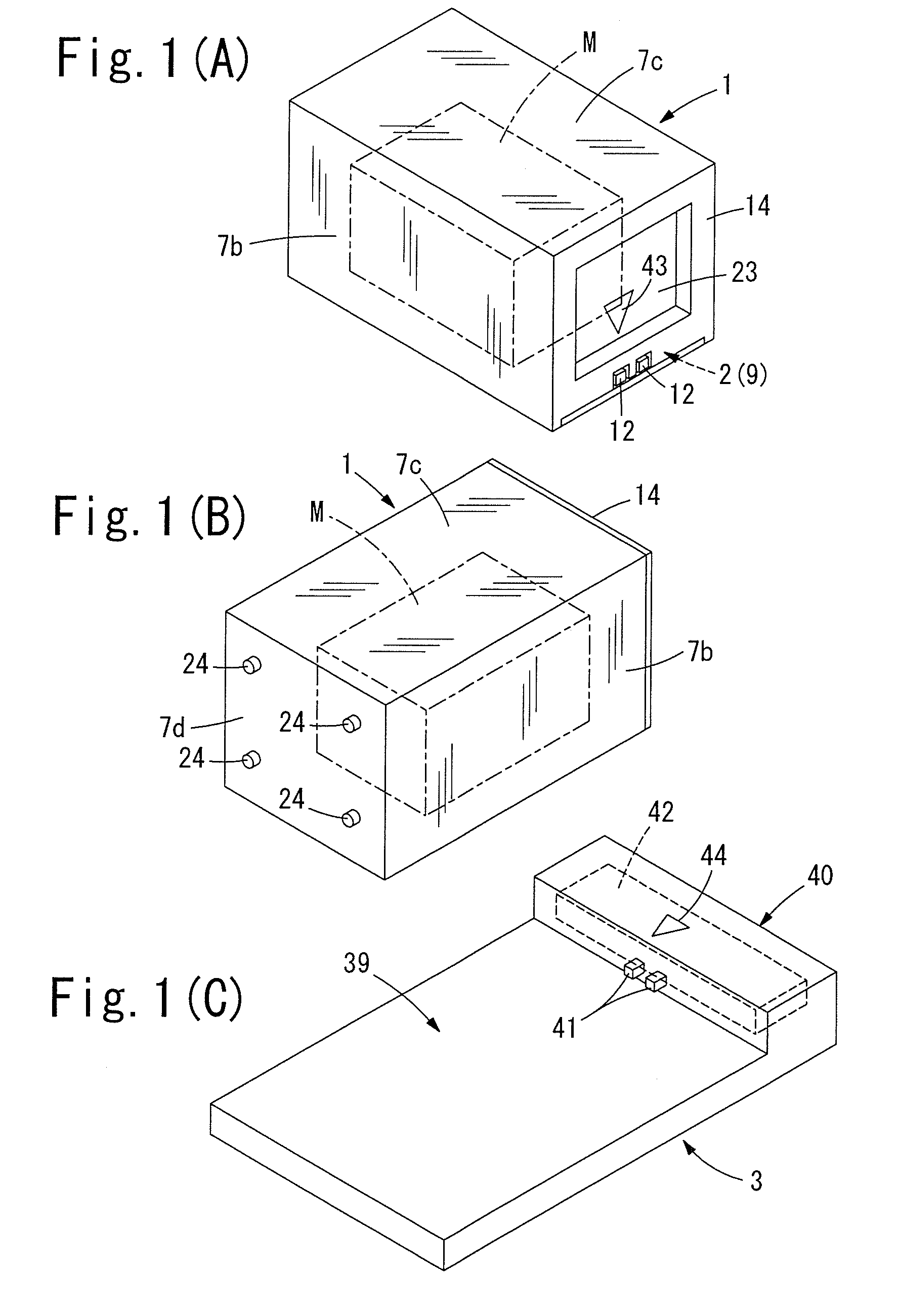

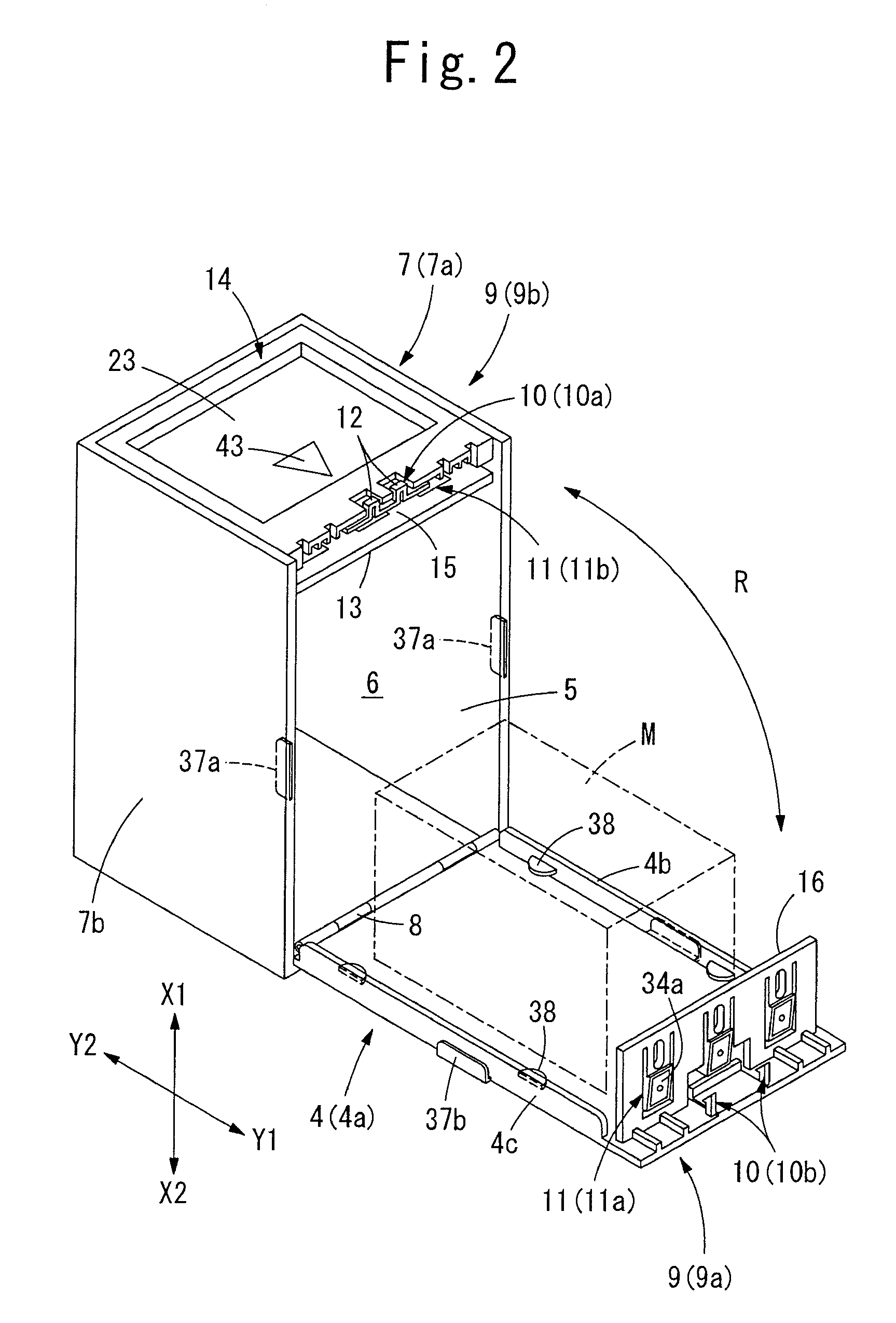

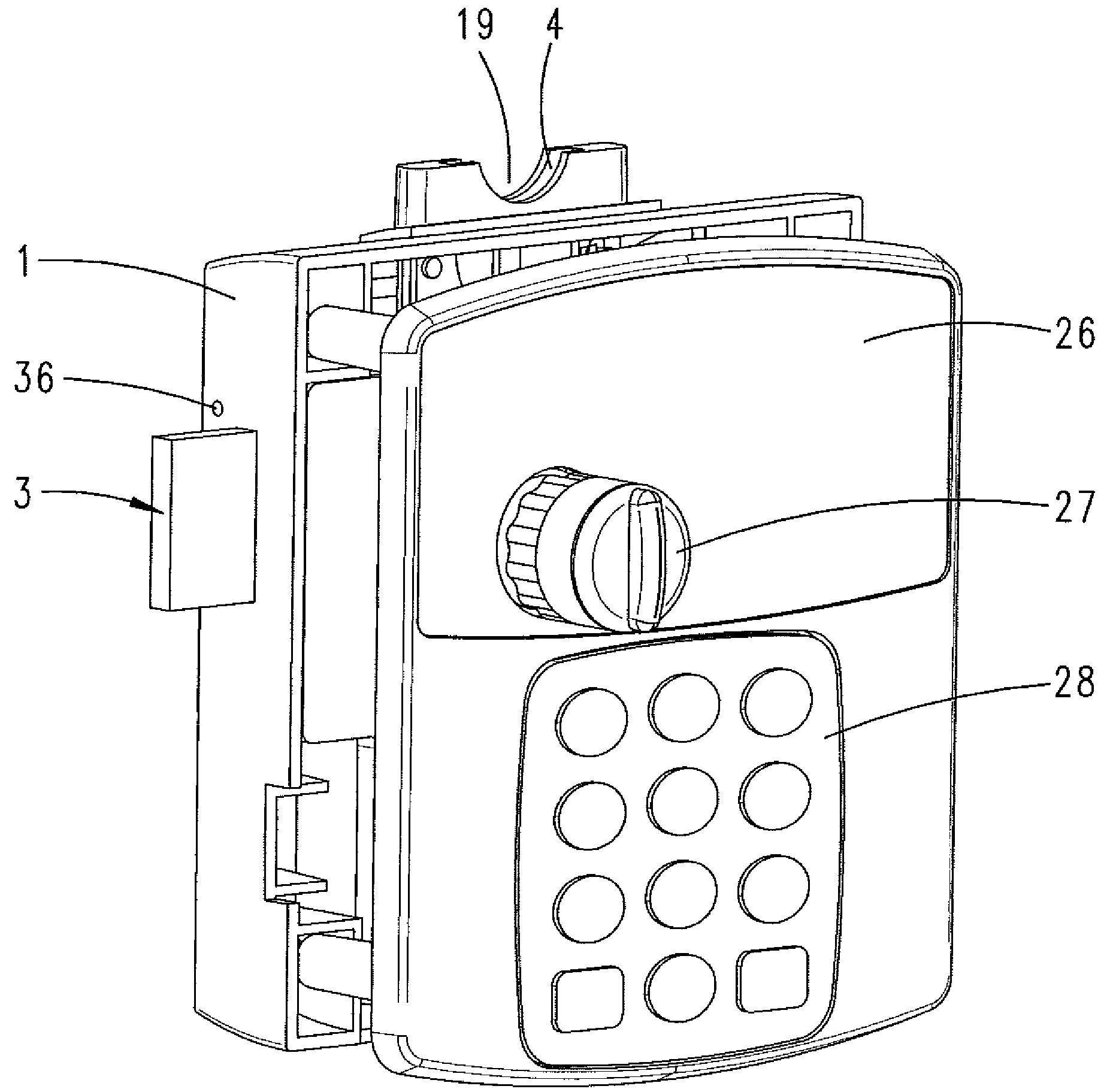

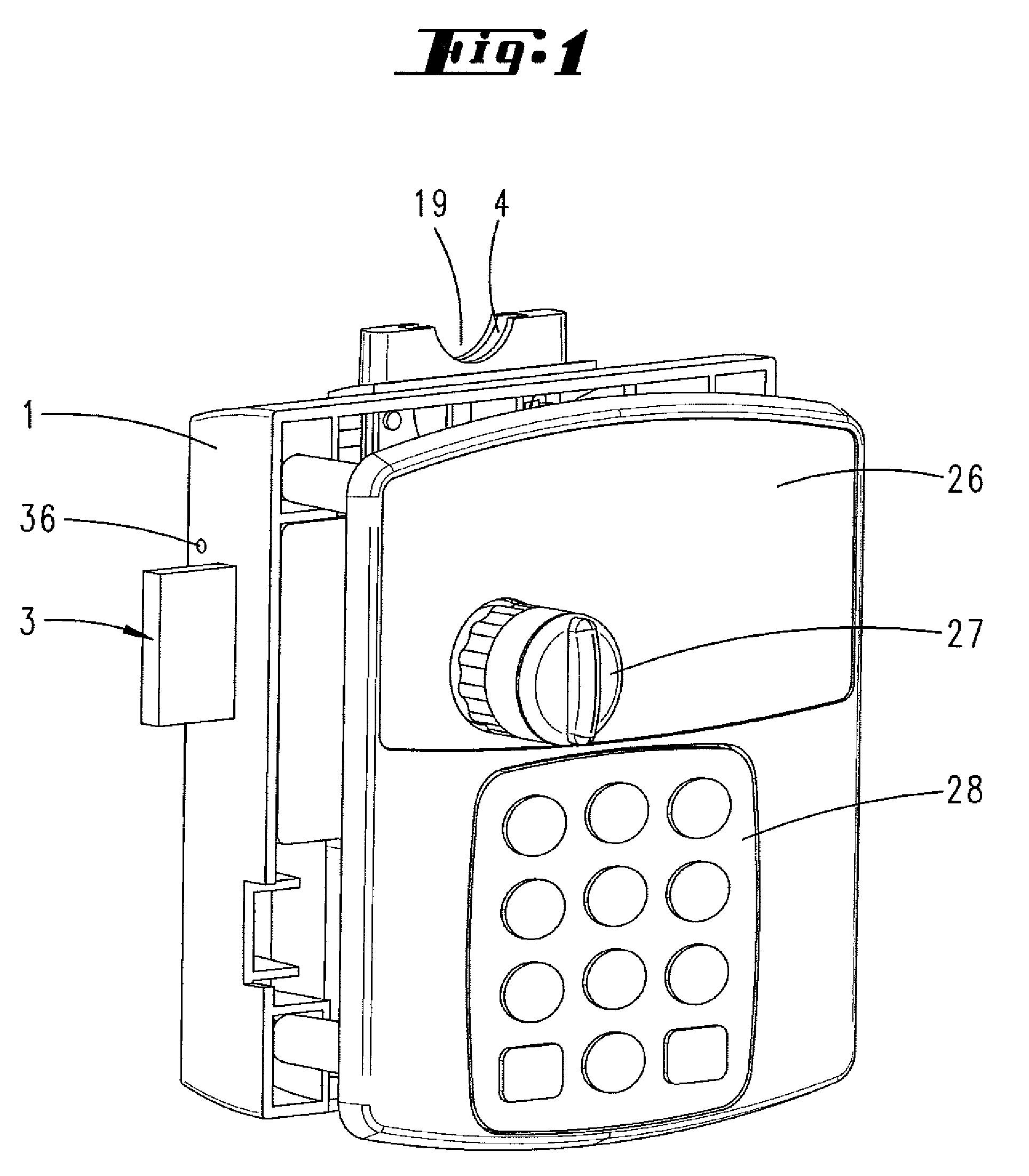

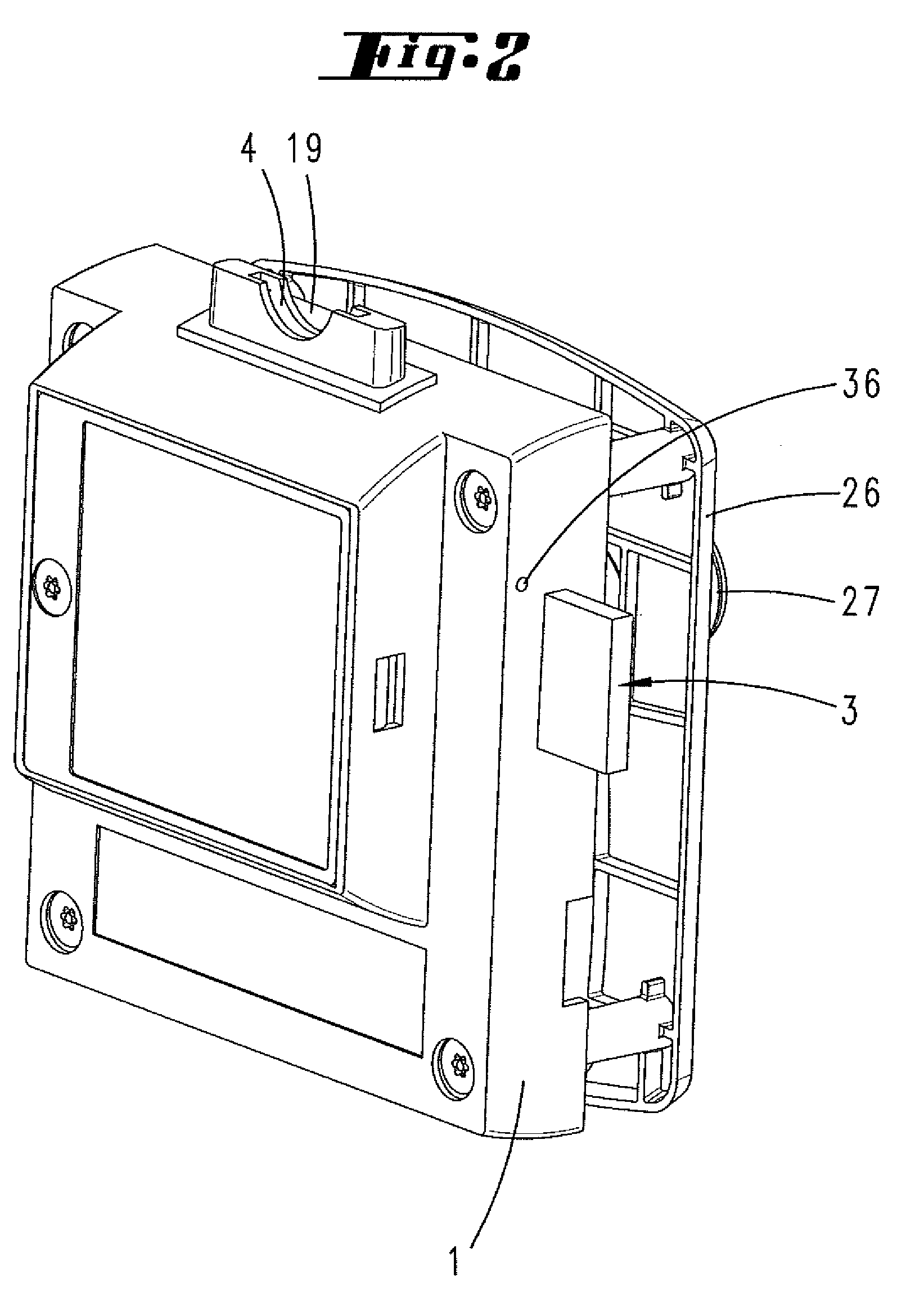

Antitheft device for a product display case

InactiveUS20110215683A1Effect of product highEfficient processLocks for portable objectsNon-mechanical controlsComputer hardwareLocking mechanism

An antitheft device having a product display case with a double locking mechanism and an unlocking device for unlocking the locking mechanism. A product display case having a locking mechanism, and an unlocking device are provided. An attachment portion for a security tag is provided on the inside of the product display case, and a first case component and a second case component are openably fitted together in an X direction. The locking mechanism has a first lock device and a second lock device that latch together in a Y direction which intersects the X direction. The first lock device locks by latching in a Y1 direction, and unlocks upon being pressed in a Y2 direction by a projection of the unlocking device. The second lock device locks by latching in the Y2 direction, and unlocks upon being pulled in the Y 1 direction by a magnet in the unlocking device.

Owner:SANEI KK

Vehicle control device

ActiveUS20170015204A1High energyReduce computationHybrid vehiclesPlural diverse prime-mover propulsion mountingVehicle controlNormal state

Appropriate tuck-in suppression control is enabled in a vehicle configured to carry out regeneration enhancement control. A predictive deceleration support control unit is configured to set a position at which the vehicle is predicted to finish deceleration as a target deceleration end position, and guide a driver to release an accelerator pedal so that the deceleration of the vehicle is finished at the target deceleration end position, to thereby carry out regeneration enhancement control under a state in which the accelerator pedal is released so as to generate a larger deceleration than in a normal state. The predictive deceleration support control unit is configured to read a tuck-in control flag from a brake ECU, and stop the regeneration enhancement control when the tuck-in suppression control is being carried out.

Owner:TOYOTA JIDOSHA KK

Controller of work piece-conveying robot

ActiveUS7848851B2Out of operationSafe and efficientProgramme-controlled manipulatorComputer controlRobot handSimulation

A controller for work piece-conveying robot having: a coordinate system storage section for storing one or more manual jog feed coordinate systems; a working area setting section for setting to a machine tool a working area to which the manual jog feed coordinate system is assigned; a hand position obtaining section for obtaining a current position of the robot hand at each specified sampling period; a determination section for determining whether or not the current position of the robot hand obtained by the hand position obtaining section is within the working area set by the working area setting section; and a coordinate system switching section for switching a present manual jog feed coordinate system to the manual jog feed coordinate system assigned to the working area if it is determined by the determination section that the current position of the robot hand is within the working area.

Owner:FANUC LTD

Assembly with a housing

InactiveUS20090021897A1More currentOut of operationDigital data processing detailsCell electrodesEngineeringStorage cell

An assembly with a housing, having a storage cell with two electrical poles, in which the storage cell is retained in the housing, with two electric lines, and each line is connected to one of the electrical poles, and the two lines are extended to two electrical contacts, having a protection device, which is disposed in the current flow of at least one of the two lines, and the protection device is disposed outside the storage cell in the housing, and the protection device protects the storage cell against overheating and / or excess current.

Owner:ROBERT BOSCH GMBH

Differential readout from pixels in CMOS sensor

InactiveUS20080246869A1Improve consistencyImprove dynamic rangeTelevision system detailsTelevision system scanning detailsCMOS sensorNear neighbor

The present invention provides an improved pixel readout circuit that compensates for common mode noise during a read out operation. This is accomplished by using a differential readout of the signal and reset value from the desired pixel compared with the reset value from a reference pixel. In this manner common mode noise can be offset and therefore minimized. In one embodiment of the invention, the reference pixel is the nearest neighbor pixel in the same row. In another embodiment, the reference pixel is the nearest neighboring pixel in a different row.

Owner:KRYMSKI ALEXANDER

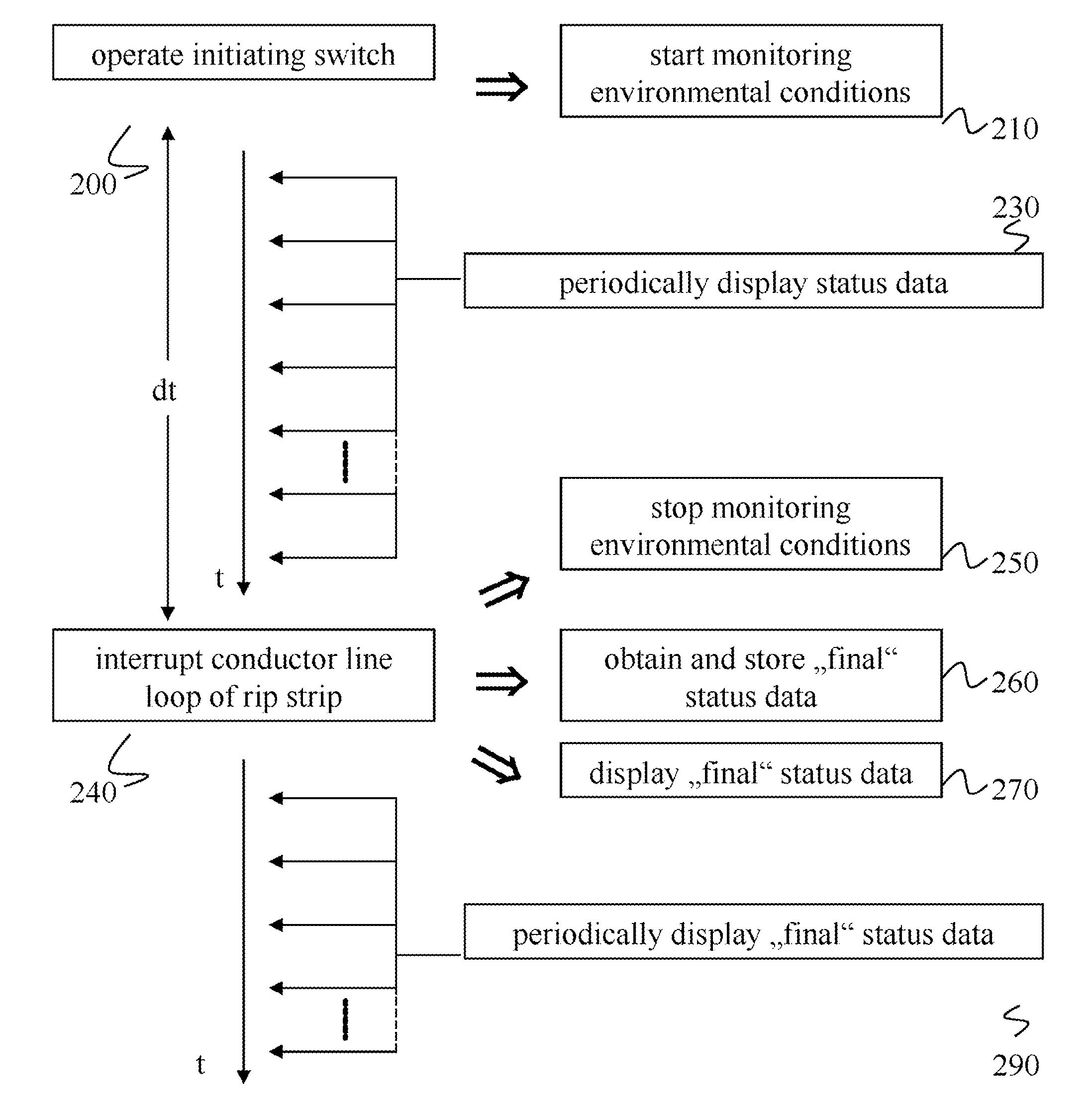

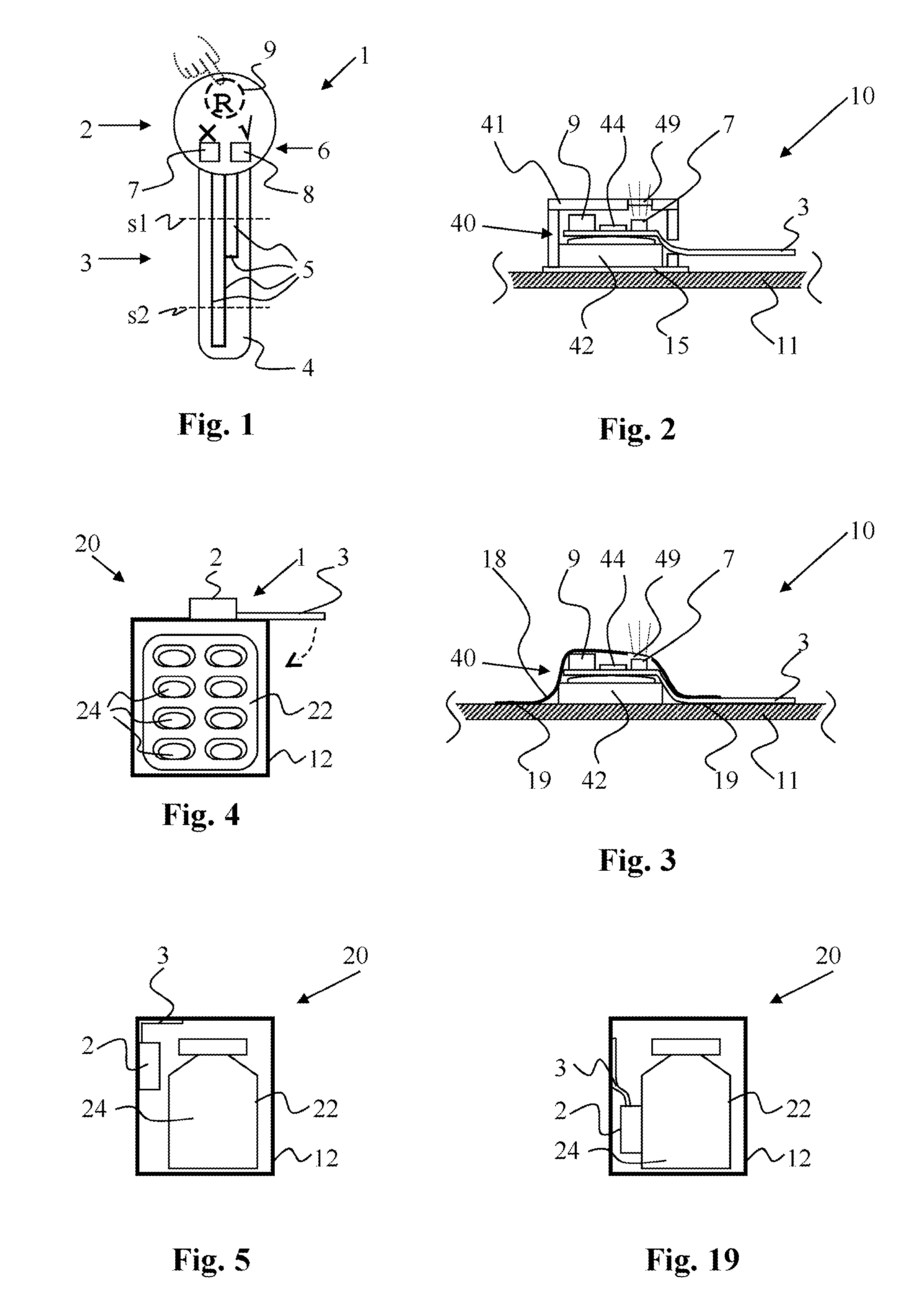

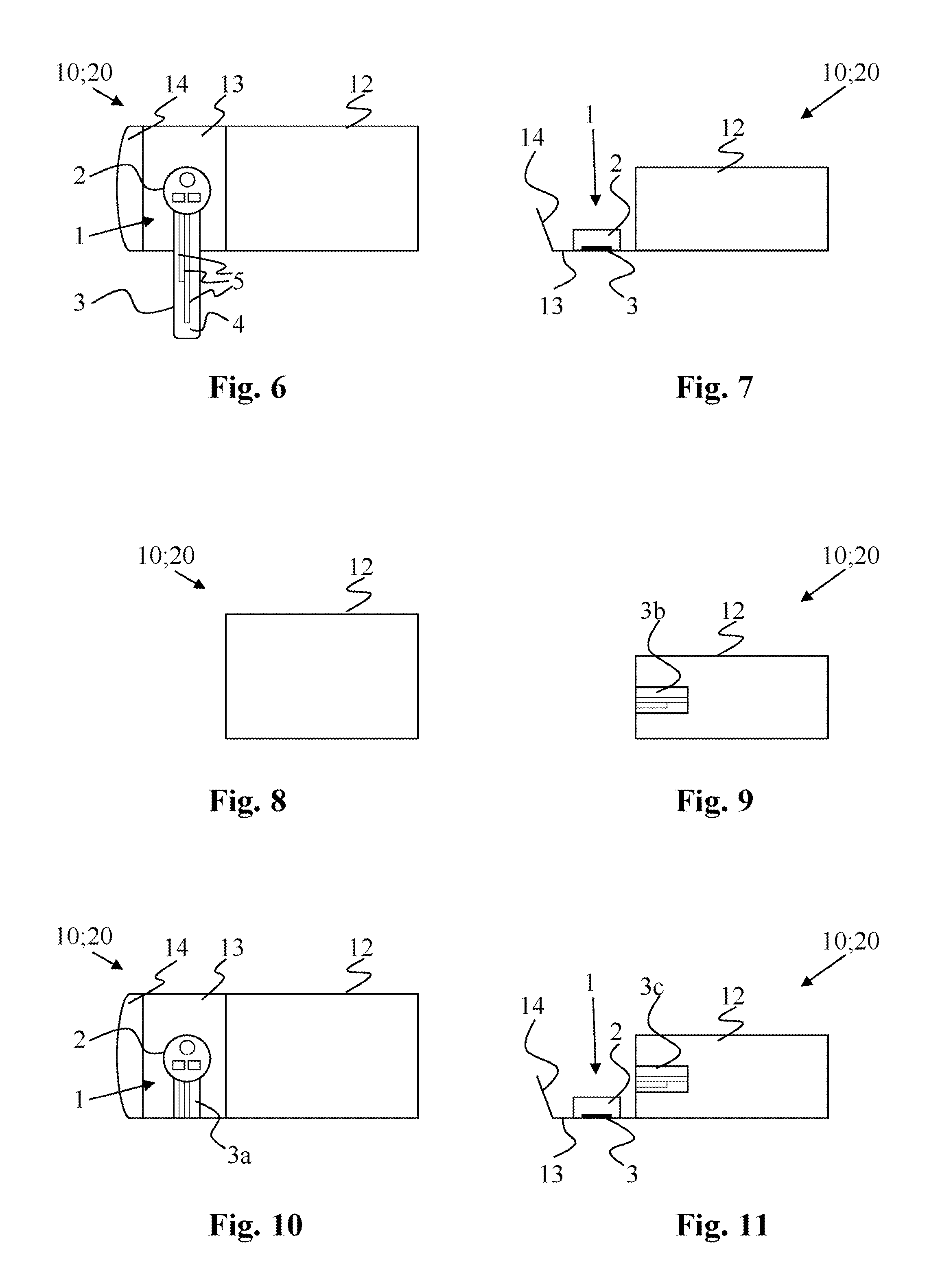

Package for pharmaceutical product, comprising miniaturized electronic tag for monitoring product integrity

ActiveUS20160166470A1Out of operationLess costlyPharmaceutical containersMeasurement/indication equipmentsElectricityElectrical connection

A retail package for a perishable product includes a box as an outer package; and an electronic tag for obtaining information relating to the integrity of the product as assessed from an exposure of the product to physical or environmental conditions during a time span. The tag has a main part including an electronics unit and a rip strip having a breakable electrical connection operationally connected to the electronics unit. The electronics unit includes a control unit; at least one sensor for monitoring the physical or environmental conditions; a display for displaying data relating to the integrity; and a switch. The control unit is structured and configured to detect a breaking of the electrical connection; to terminate the monitoring in reaction to detection of breaking of the electrical connection; and to effect that the display unit displays the status data in reaction to an operation of the switch.

Owner:BERLINGER

System and Methods for Preparation of Adipose-Derived Stem Cells

PendingUS20190224245A1Safe extractionSimplify processAdditive manufacturing apparatusRotary centrifugesCell FractionBiological substances

A device that allows for either fat graft preparation or cell fraction harvest is disclosed. The device includes a first centrifuge tube configured to receive and process a biological substance, the first centrifuge tube comprising an upper cylindrical portion and a lower conical portion, a sterile tissue inlet fitting, at least one sterile processing fluid inlet fitting, a sterile suction fitting, and at least one sterile extraction port connected to a first extraction tube. The first centrifuge tube further includes an internal space including a screen being positioned therein, the screen being configured to divide the internal space in half, and a filter positioned therein, the filter being positioned below the screen in the lower conical portion of the first centrifuge tube. The device may further include a second centrifuge tube configured to receive and further process the biological substance from the first centrifuge tube. The second centrifuge tube has at least one sterile fitting, wherein the second centrifuge tube is releasably connected via the at least one sterile fitting to one of the at least one sterile extraction ports of the first centrifuge tube.

Owner:JOINTECHLABS

Differential column readout scheme for CMOS APS pixels

InactiveUS20060175534A1Improve consistencyImprove dynamic rangeTelevision system detailsTelevision system scanning detailsEngineeringReference circuit

Owner:APTINA IMAGING CORP

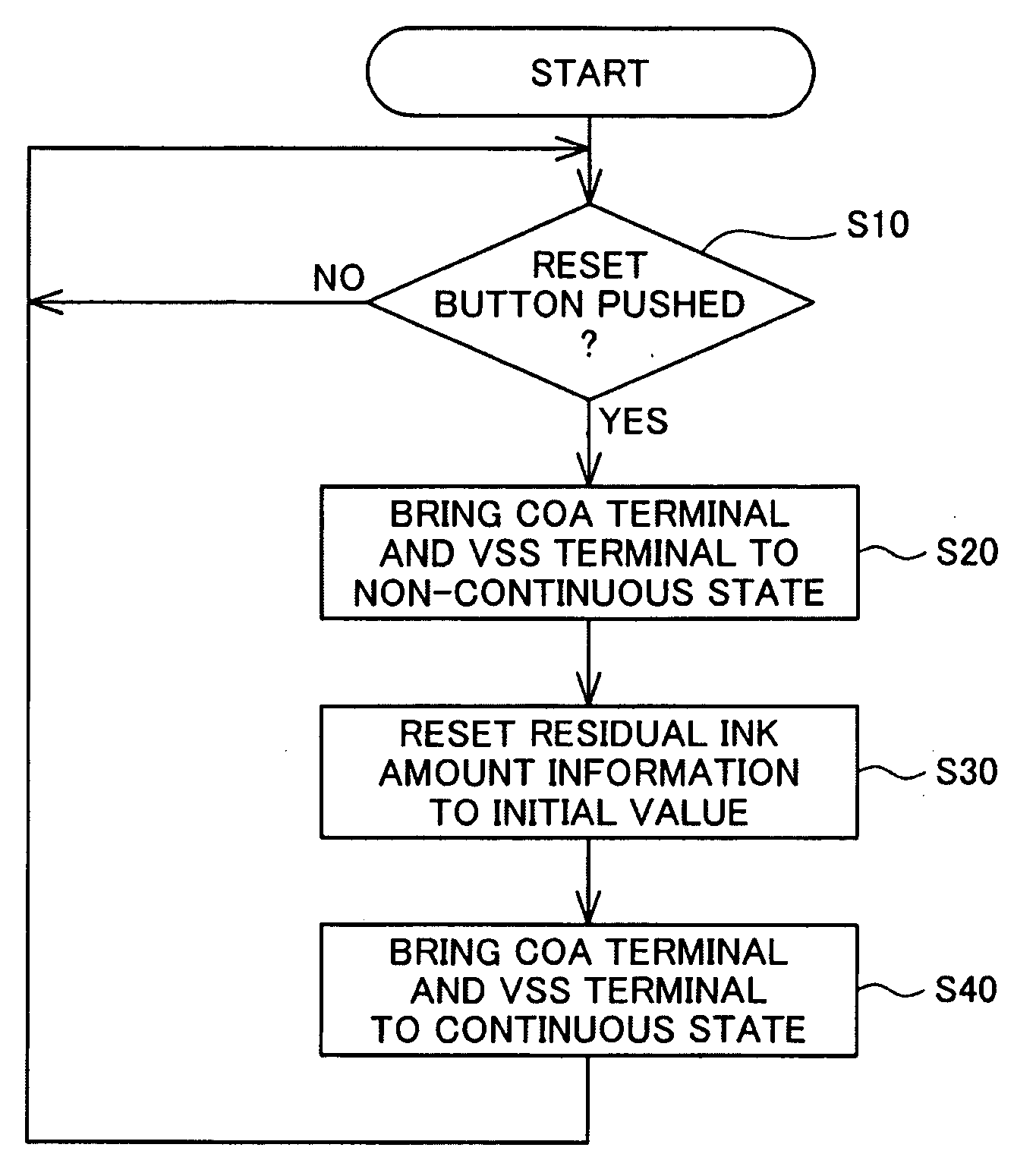

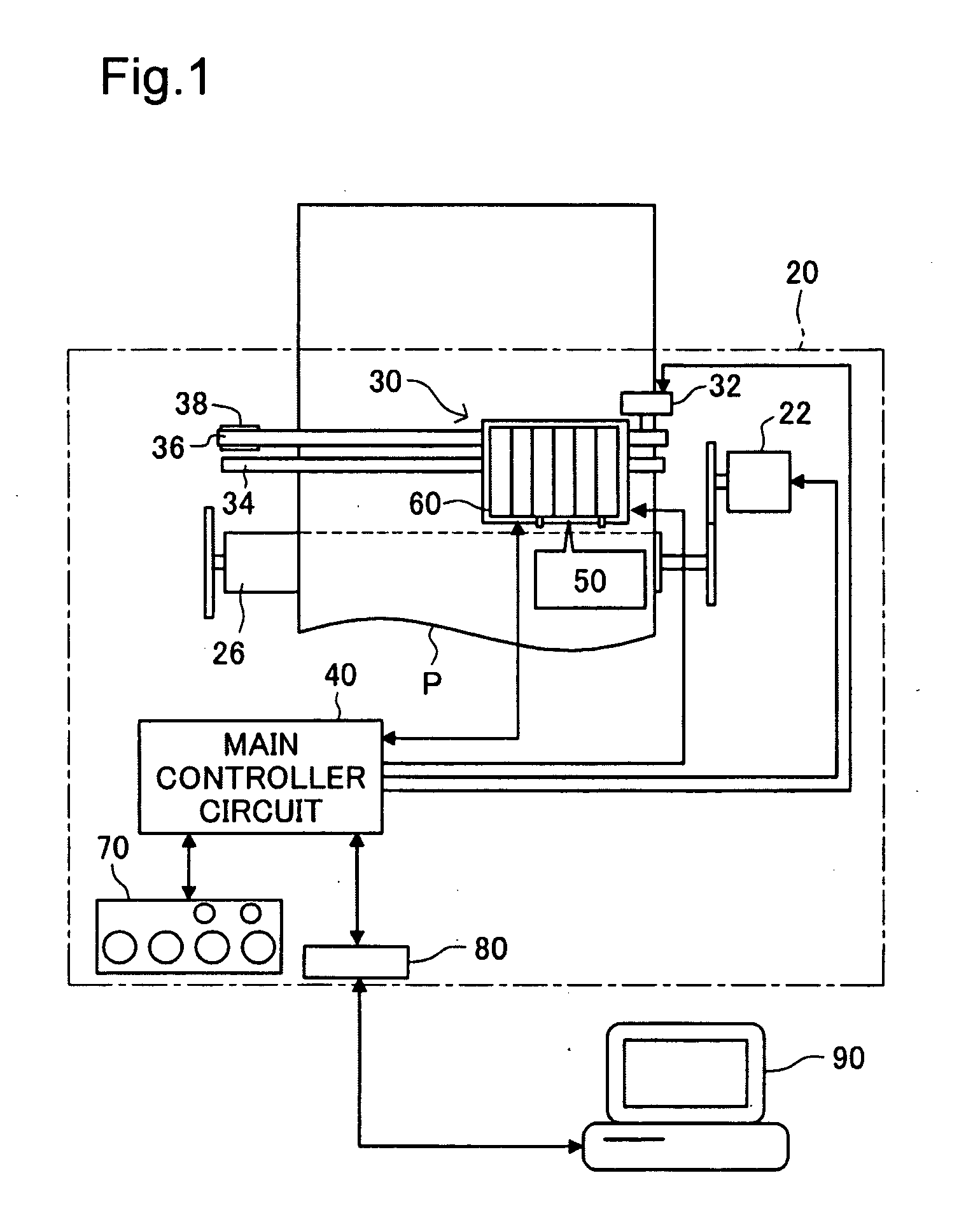

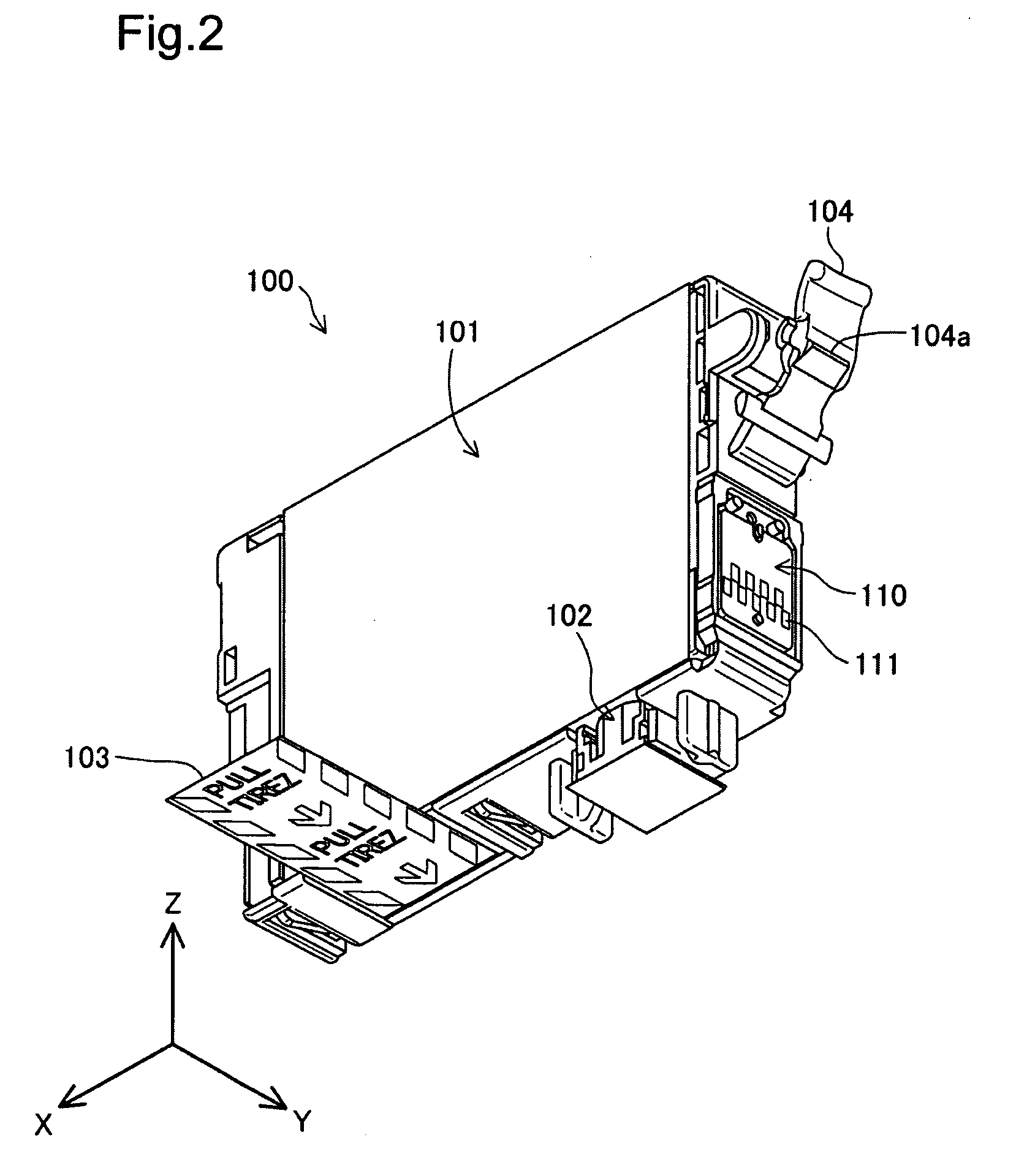

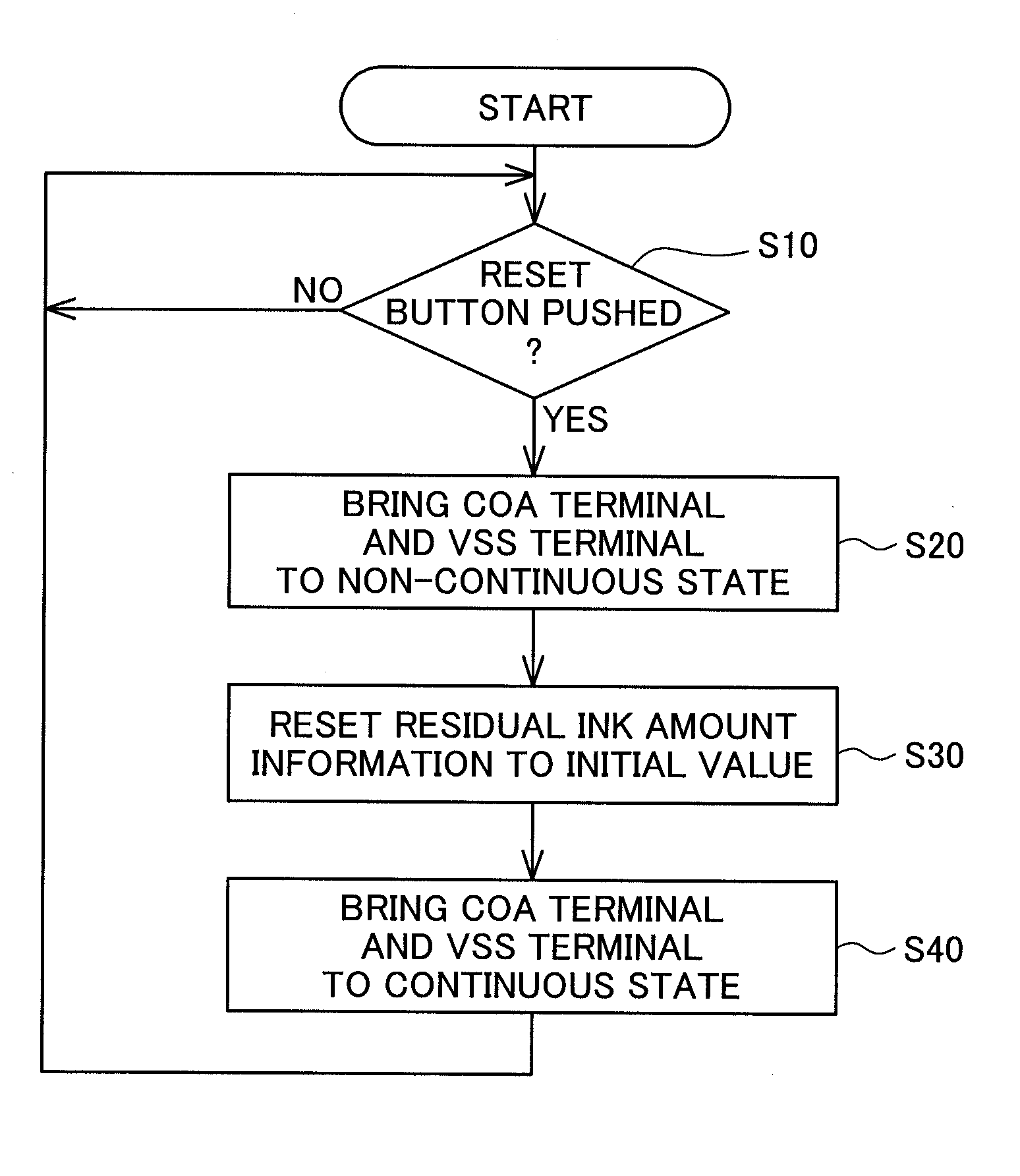

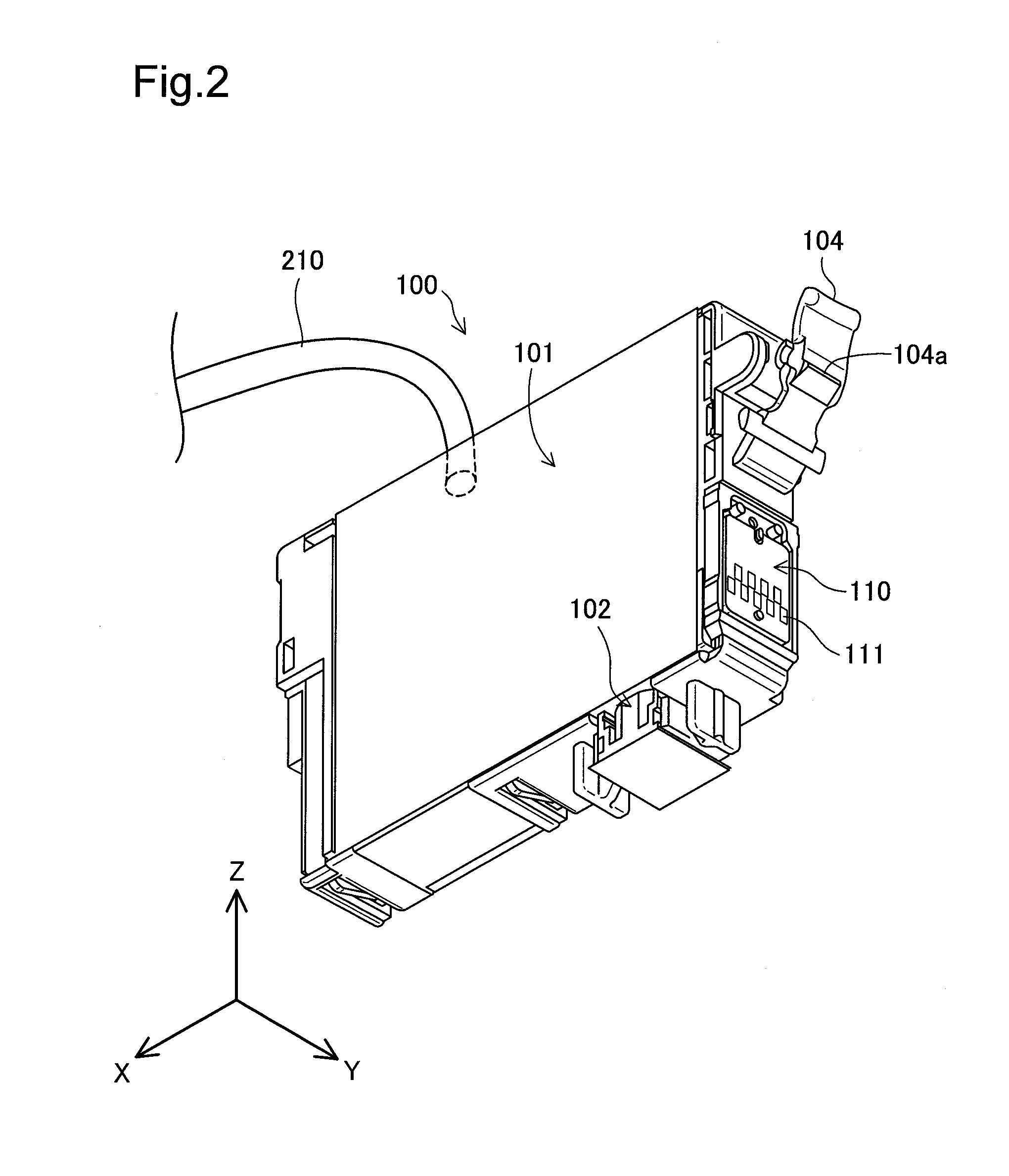

Liquid container, board, and method of rewriting liquid information

Owner:SEIKO EPSON CORP

Antitheft device for a product display case

InactiveUS8833115B2Effect of product highEfficient processRecord information storageKitchen cabinetsLocking mechanismEngineering

An antitheft device having a product display case with a double locking mechanism and an unlocking device for unlocking the locking mechanism. A product display case having a locking mechanism, and an unlocking device are provided. An attachment portion for a security tag is provided on the inside of the product display case, and a first case component and a second case component are openably fitted together in an X direction. The locking mechanism has a first lock device and a second lock device that latch together in a Y direction which intersects the X direction. The first lock device locks by latching in a Y1 direction, and unlocks upon being pressed in a Y2 direction by a projection of the unlocking device. The second lock device locks by latching in the Y2 direction, and unlocks upon being pulled in the Y 1 direction by a magnet in the unlocking device.

Owner:SANEI KK

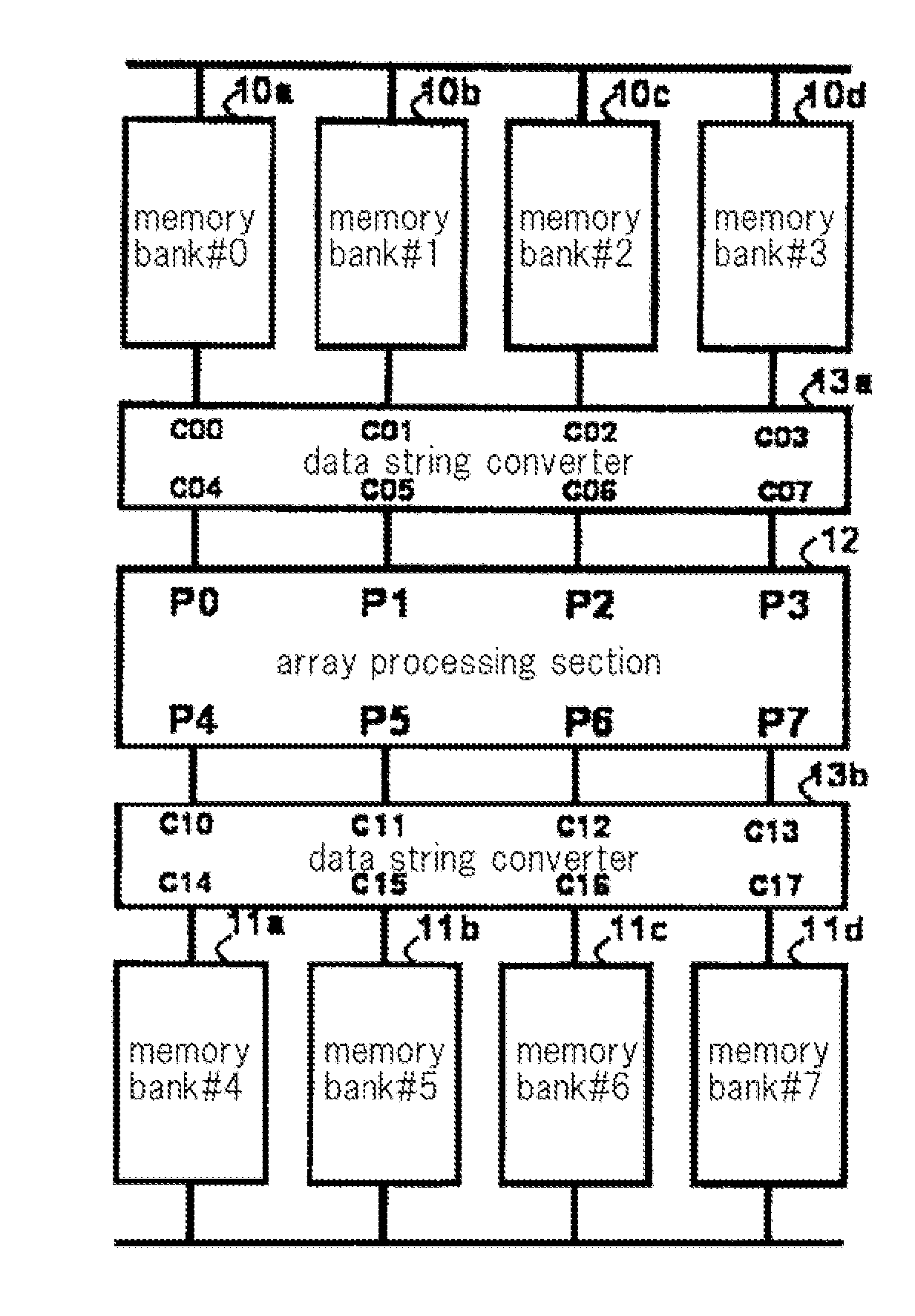

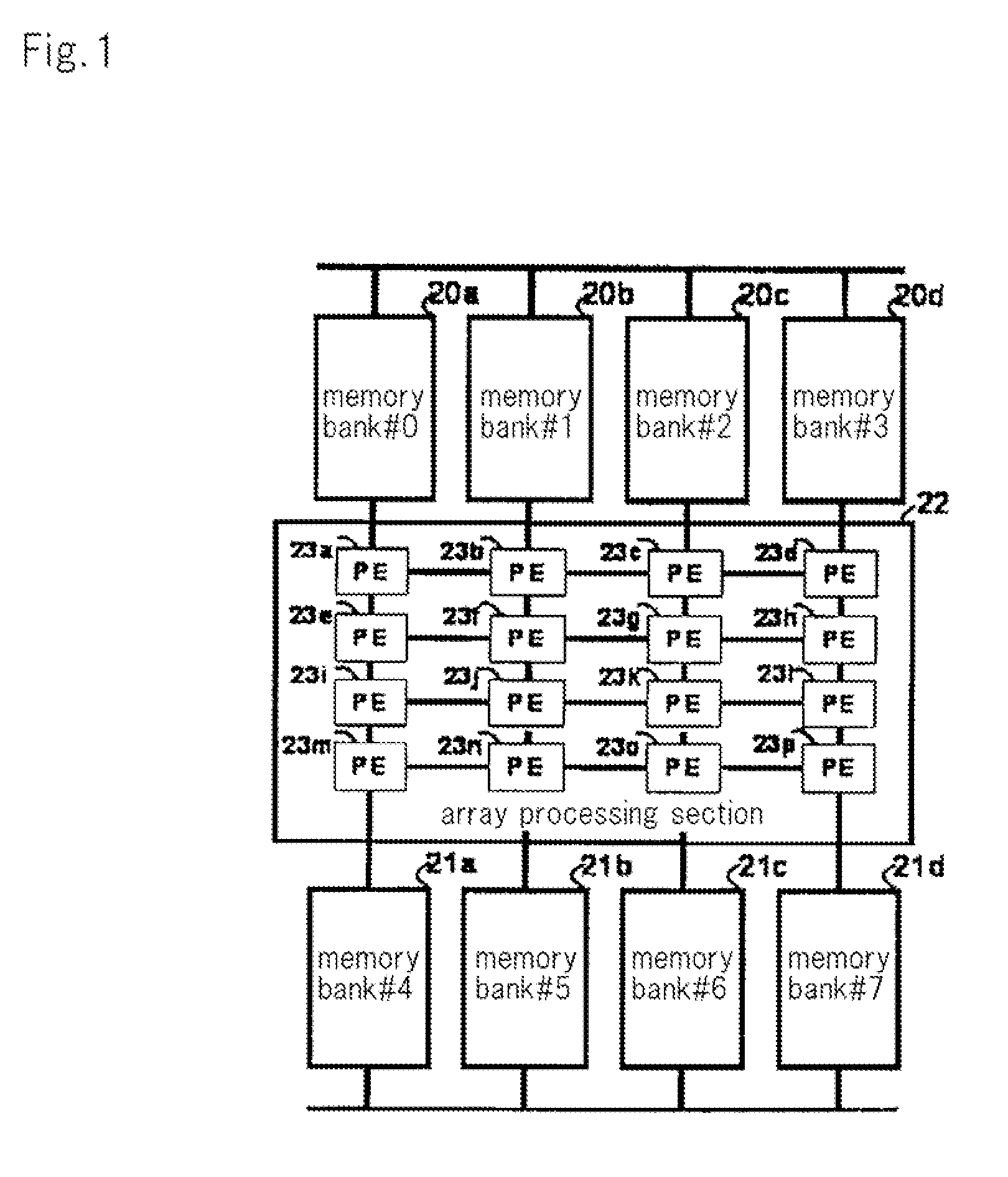

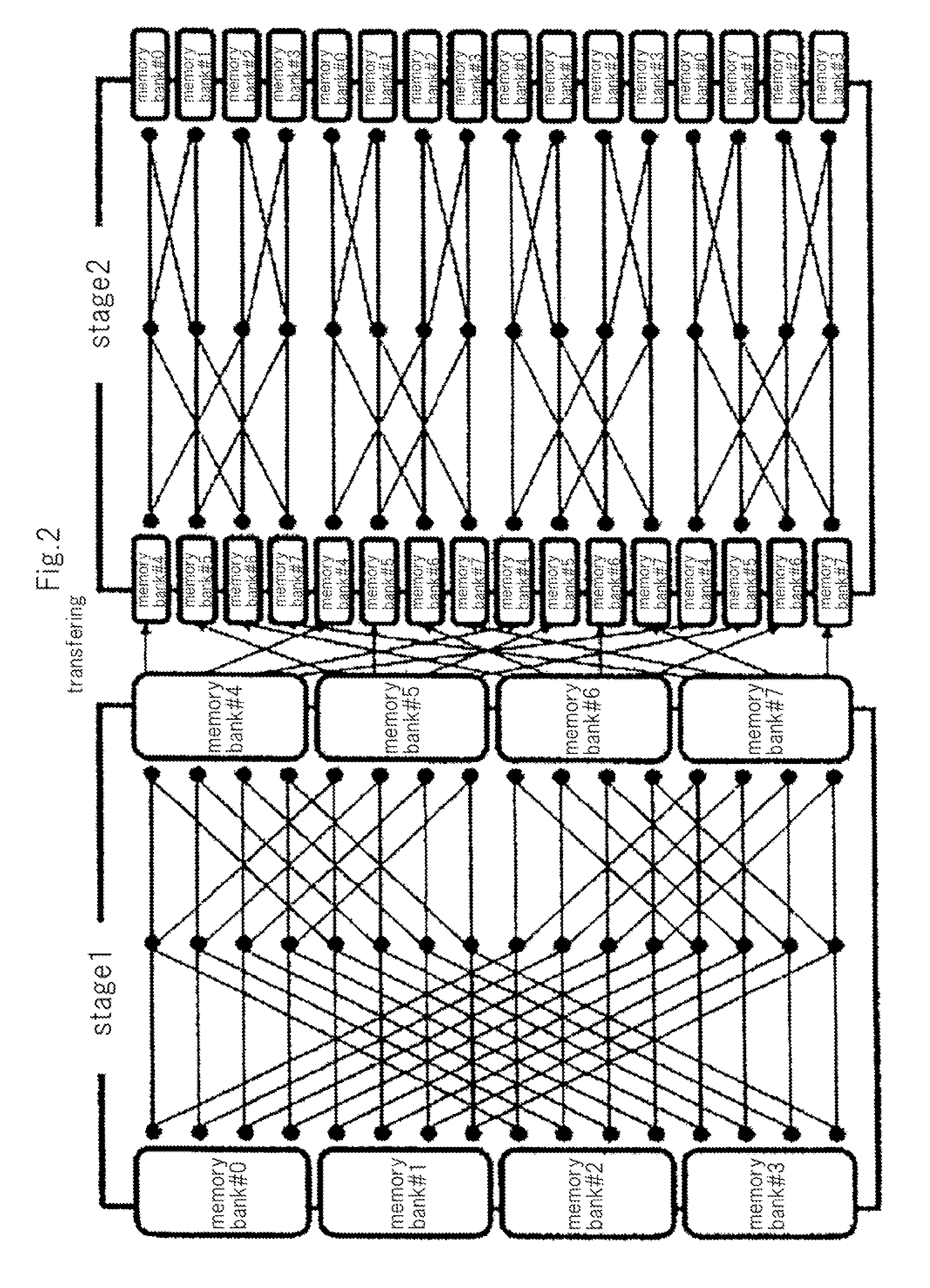

Array processor type data processing apparatus

ActiveUS20100131738A1Improve processing efficiencyOut of operationSystolic arraysProgram control using wired connectionsProcessor elementData memory

In an array processing section, using data strings entered from input ports, a plurality of data processor elements execute predetermined operations while transferring data to each other, and output data strings of results of the operations from a plurality of output ports. A first data string converter converts data strings stored in a plurality of data storages of a data storage group into a placement suitable for the operations in the array processing section, and enters the converted data strings into the input ports of the array processing section. A second data string converter converts the data strings output from output ports of the array processing section into a placement to be stored in the plurality of data storages of the data storage group.

Owner:NEC CORP

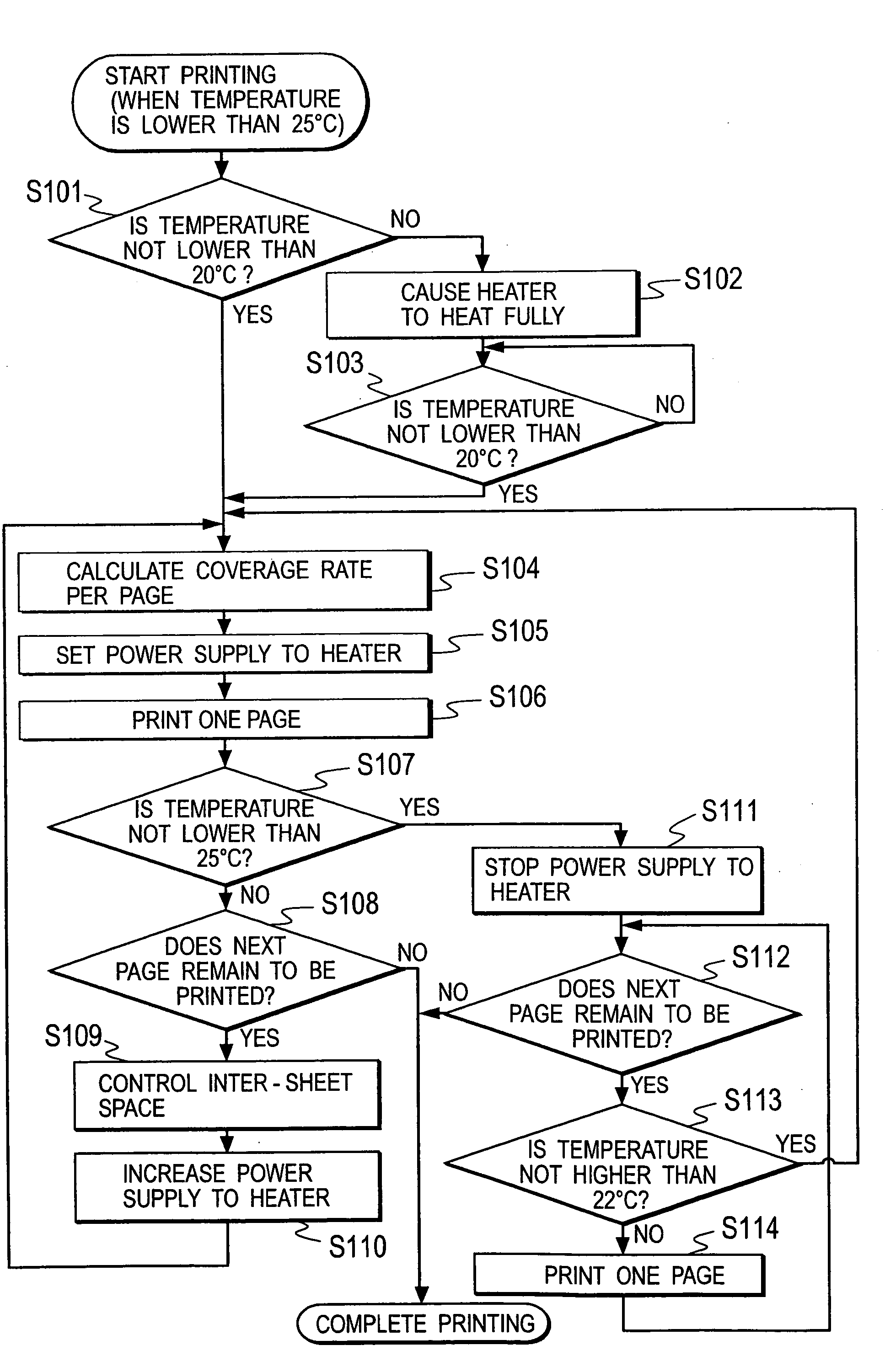

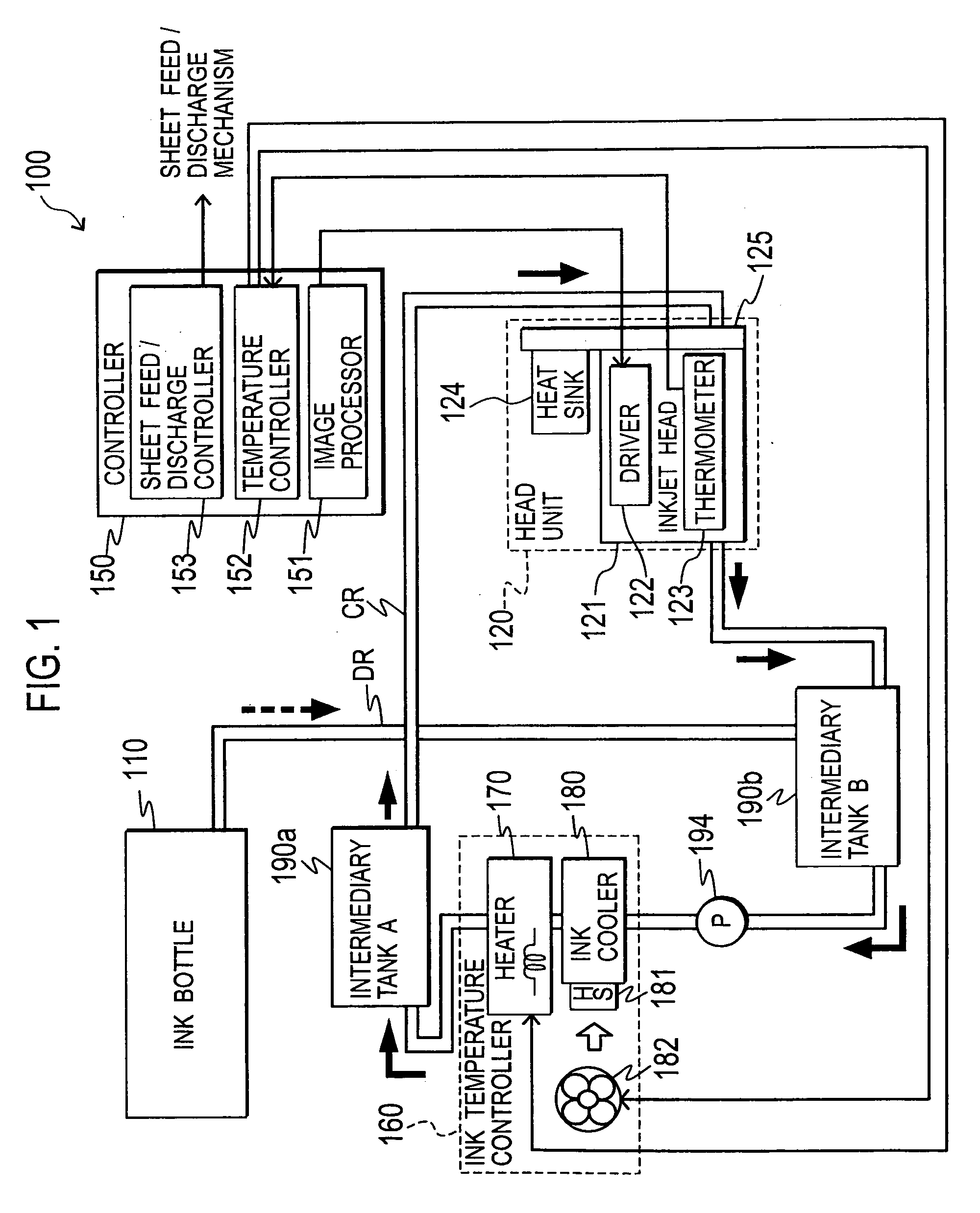

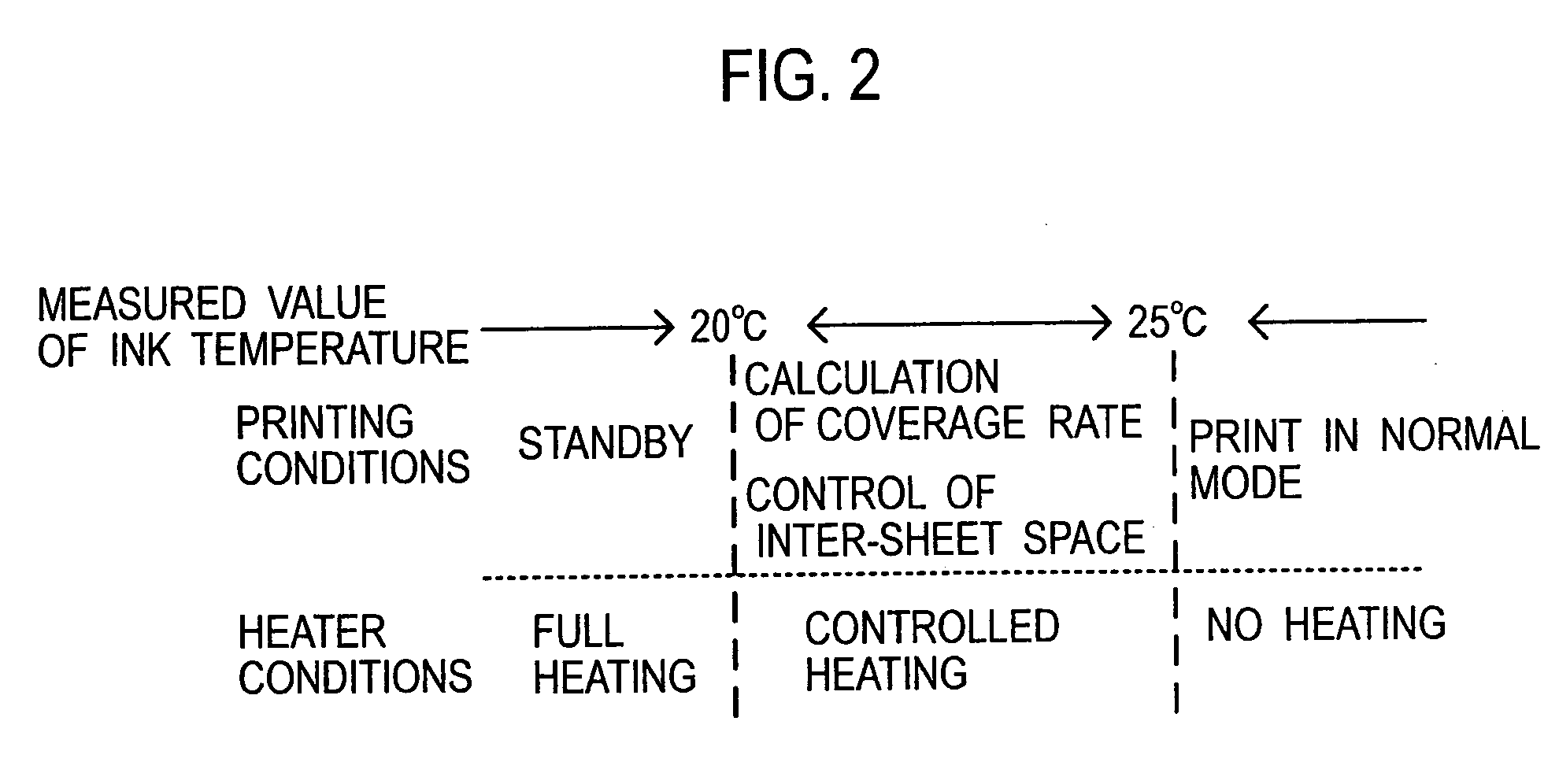

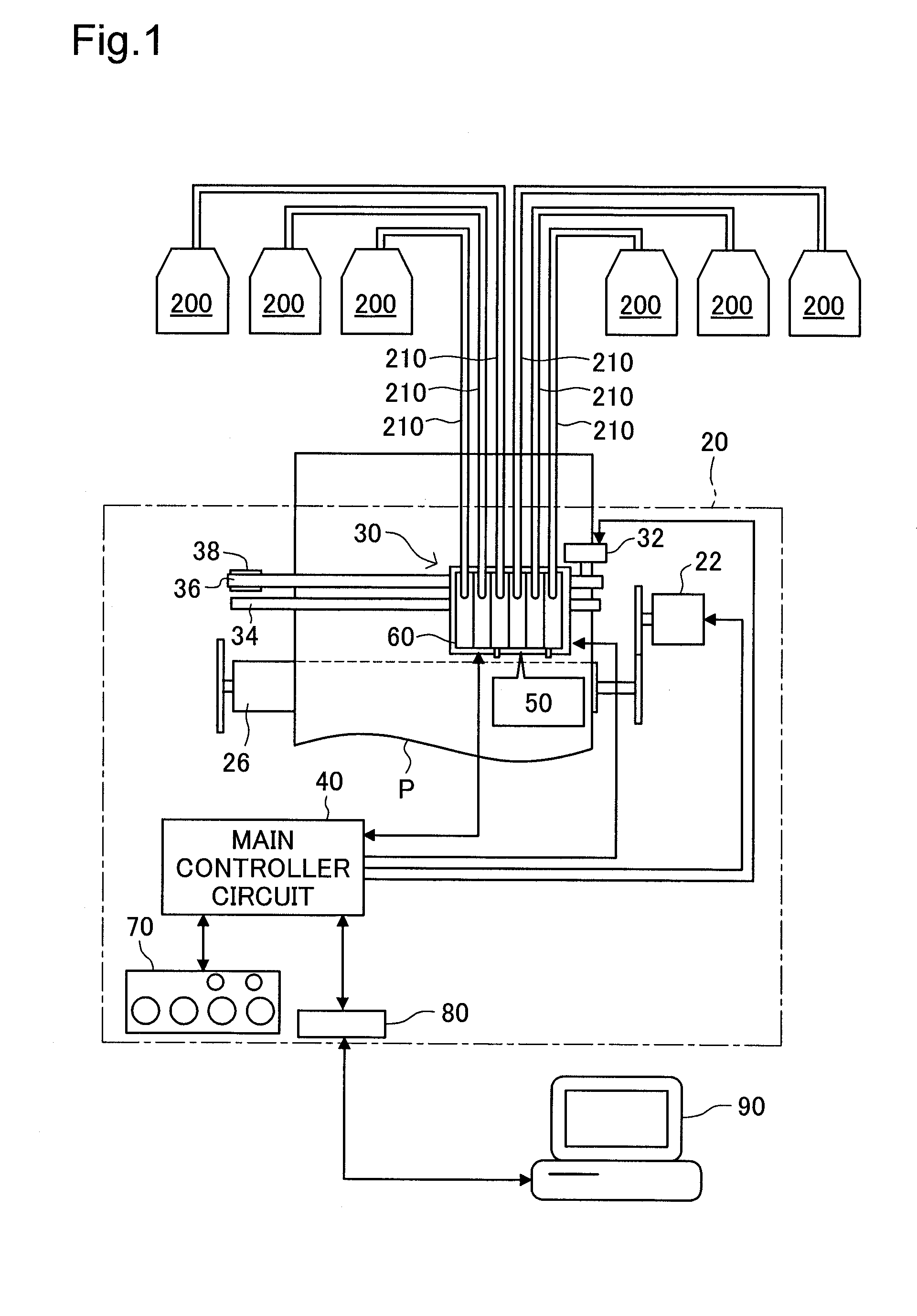

Printer and control method thereof

An inkjet printer includes an inkjet head configured to perform printing on a printing sheet by use of ink. The inkjet printer includes: a heater configured to heat the ink; a thermometer configured to measure the temperature of the ink; and a controller configured to control the amount of electric power to be supplied to the heater and to control the inkjet head. In a case where the measured value of the ink temperature measured by the thermometer is in a range of a first reference temperature inclusive to a second reference temperature exclusive, the controller calculates a coverage rate of a page to be printed, and accordingly changes the amount of electric power to be supplied to the heater depending on the coverage rate thus calculated.

Owner:RISO KAGAKU CORP

Mountable apparatus, board, and method of rewriting liquid information

ActiveUS20090237439A1InhibitionOut of operationOther printing apparatusMemory systemsLiquid jetEngineering

Owner:SEIKO EPSON CORP

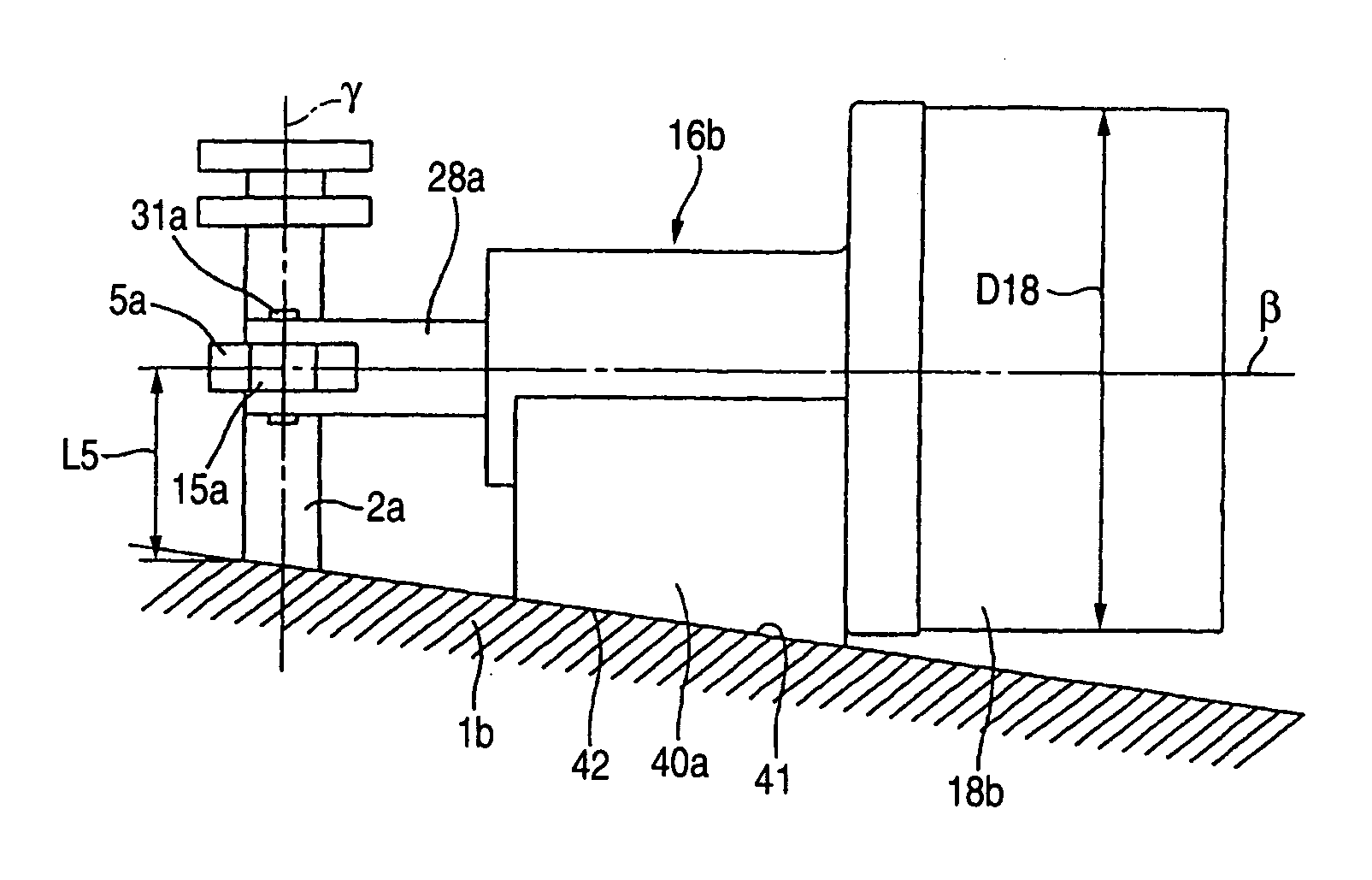

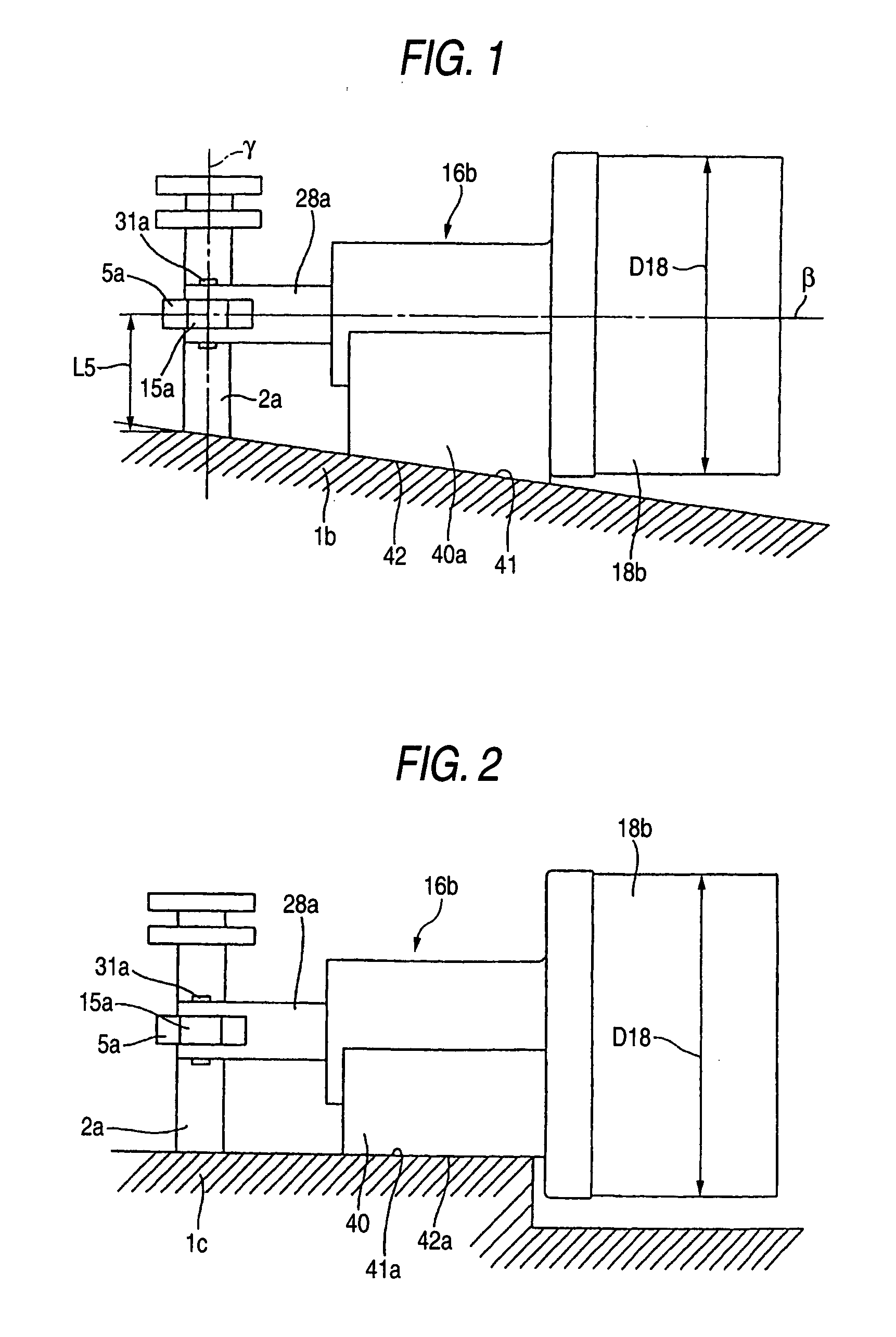

Electric actuator

InactiveUS20050128035A1Out of operationReduce rigidityGearing controlMechanical energy handlingEngineeringActuator

A portion of an outer face 41a installed with a second electric motor 18b is recessed more than a portion of projecting a switch shaft 2a. By the constitution, an outer diameter D18 of the shifting electric motor 18b is increased while ensuring a rigidity of a switch shaft 2a by restraining an amount of projecting the switch shaft 2a. Further, swift and firm gear change operation is made to be able to carry out by increasing an output of the shifting electric motor 18b.

Owner:NSK LTD

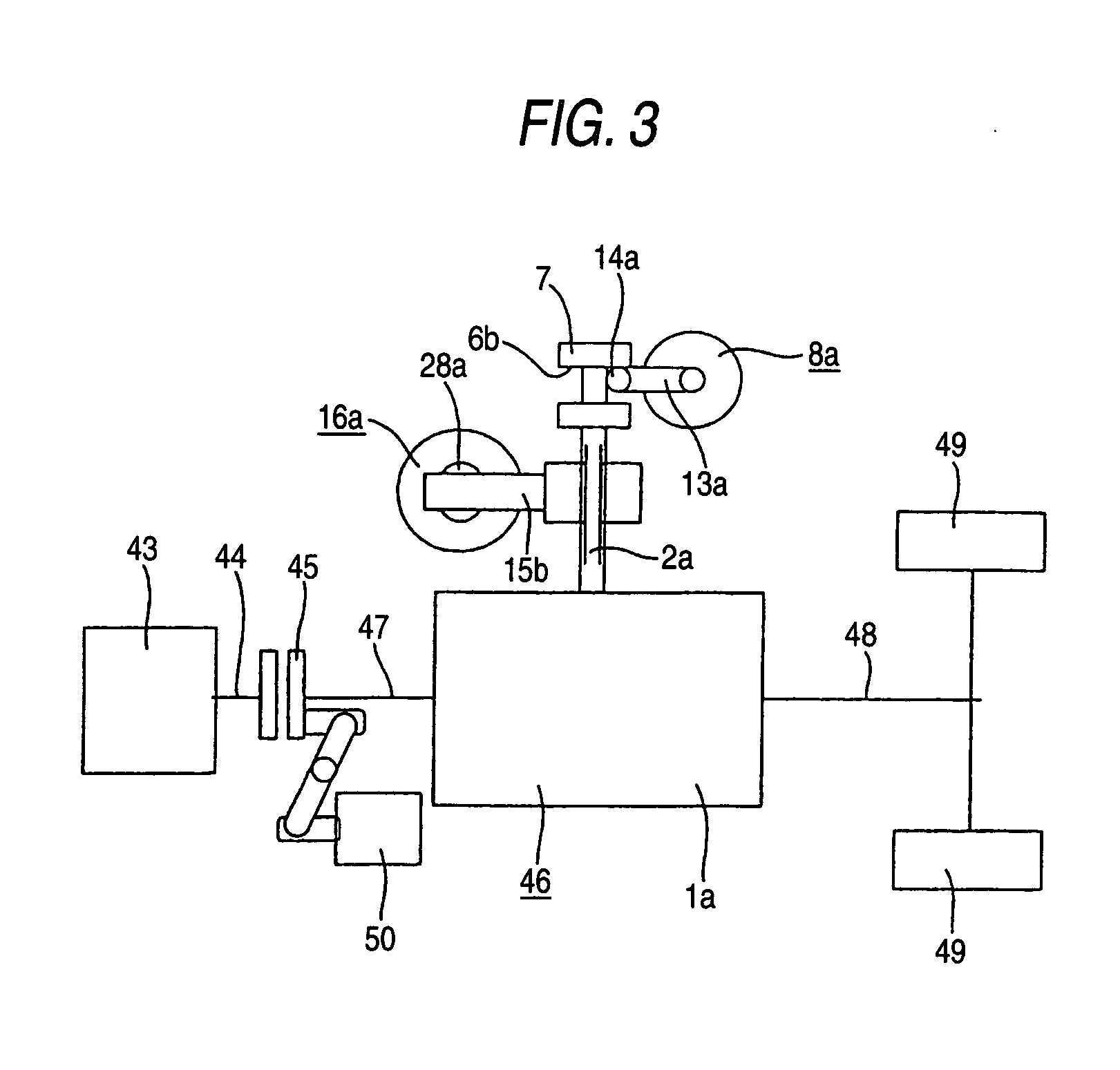

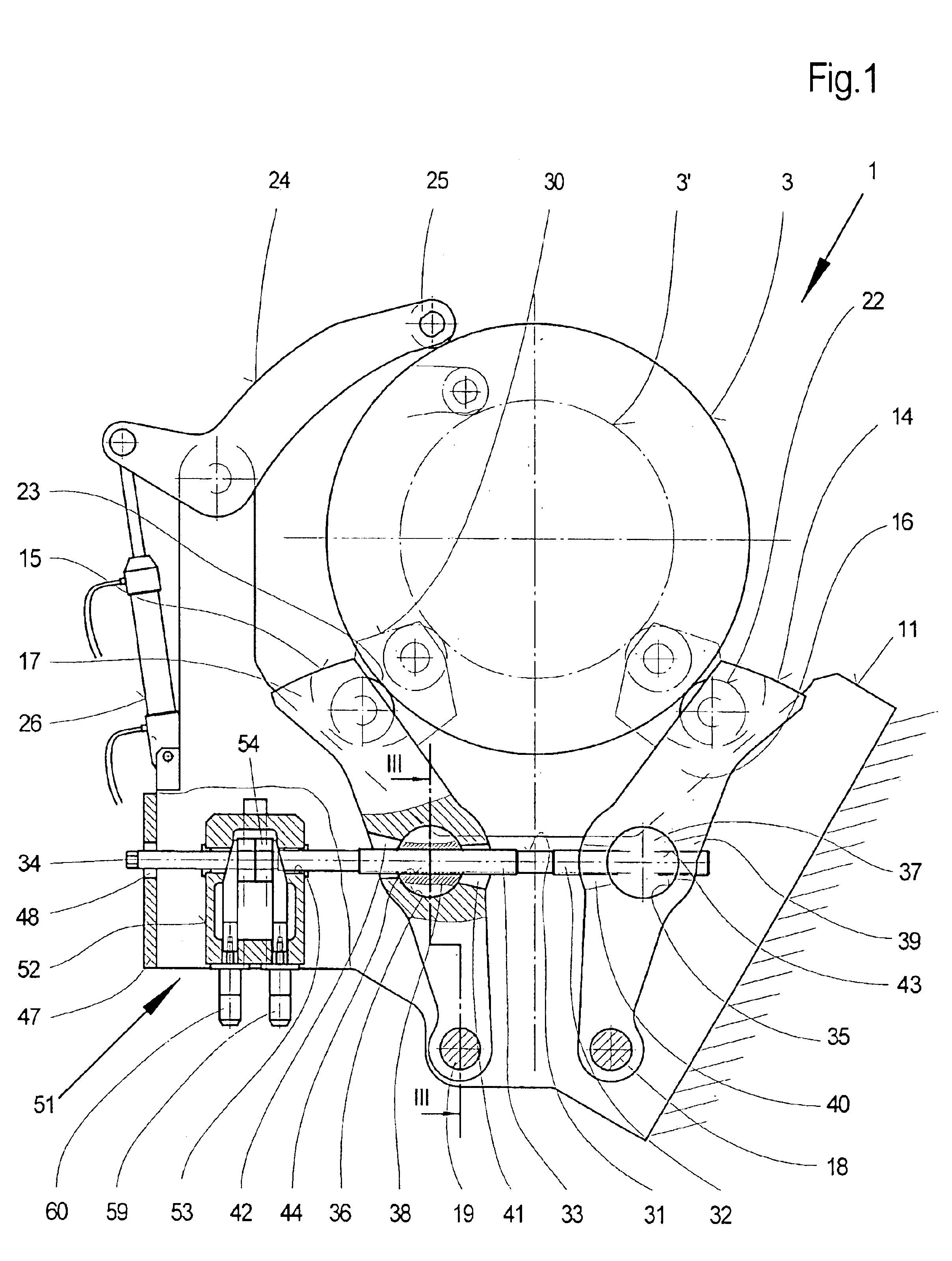

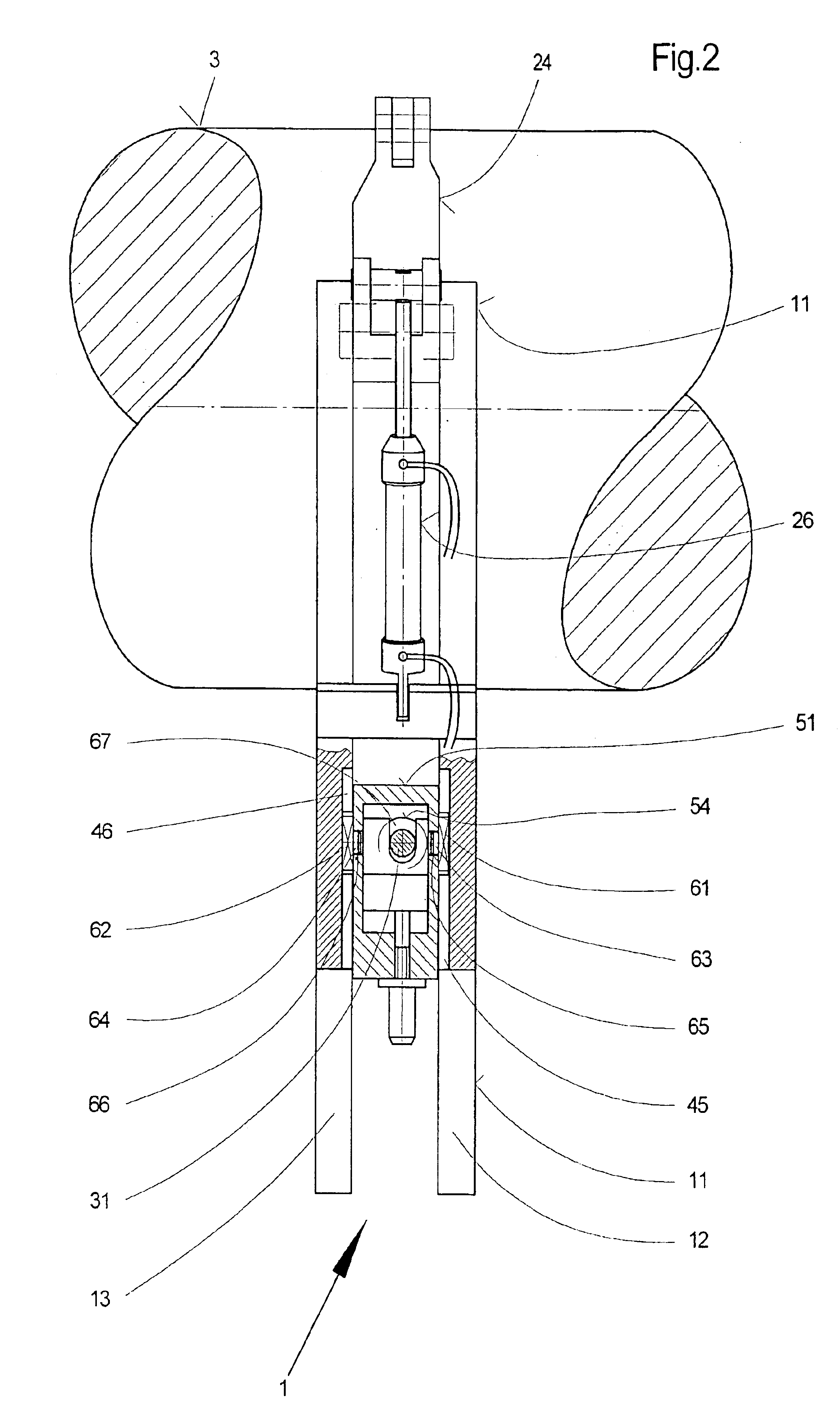

Support fixture

InactiveUS6901831B2Quick and easyEasy to useLathesAutomatic conveying/guiding stockEngineeringMachine tool

In a fixture for supporting a workpiece in a machine tool by means of two support elements held in a housing with the workpiece lying on them, the support elements are configured as levers held in a rotating mounting in the housing, the levers being driveably connected together by means of a threaded spindle. The threaded spindle has counter-rotating thread sections in areas corresponding to the support elements, and each of the counter-rotating thread sections of the spindle engage in a sliding block, the sliding blocks being rotatably mounted in holes in the support elements. The threaded spindle is provided with a device for locking the support elements in a set operating position. The two support elements are jointly adjustable and lockable, so that they can be set and readjusted within a short time and in a manner so that production inaccuracies are precluded.

Owner:WFL MILLTURN TECH

High efficiency microwave amplifier

ActiveUS20110012679A1Improve efficiencyHarmonic reductionPush-pull amplifiersPhase-splittersAudio power amplifierLinear region

Disclosed is an apparatus and method for operating a microwave amplifier with improved efficiency and reduced harmonic emissions. The disclosed amplifier includes a variable rail voltage supply and a variable input drive stage. A controller continually monitors the amplifier output and adjusts the rail voltage and input drive signal to achieve high efficiency and low harmonic emissions. The amplifier may include a dynamic bias controller configured to operate the gain elements outside the linear region. Efficiencies of over 70% may be achieved by the disclosed amplifier.

Owner:TYCO HEALTHCARE GRP LP

Vehicle control device

ActiveUS9981542B2High energyReduce computationHybrid vehiclesDigital data processing detailsEngineeringNormal state

Appropriate vehicle stability control is enabled in a vehicle configured to carry out regeneration enhancement control. A predictive deceleration support control unit is configured to set a position at which the vehicle is predicted to finish deceleration as a target deceleration end position, and guide a driver to release an accelerator pedal so that the deceleration of the vehicle is finished at the target deceleration end position, to thereby carry out regeneration enhancement control under a state in which the accelerator pedal is released so as to generate a larger deceleration than in a normal state. The predictive deceleration support control unit is configured to read a vehicle stability control flag from a brake ECU and stop the regeneration enhancement control when the vehicle stability control is being carried out.

Owner:TOYOTA JIDOSHA KK

Vehicle control device

ActiveUS9944185B2High energyReduce computationBraking element arrangementsPropulsion by batteries/cellsDriver/operatorEngineering

Appropriate collision avoidance support control is enabled in a vehicle configured to carry out regeneration enhancement control. A predictive deceleration support control unit is configured to set a position at which the vehicle is predicted to finish deceleration as a target deceleration end position, and guide a driver to release an accelerator pedal so that the deceleration of the vehicle is finished at the target deceleration end position, to thereby carry out regeneration enhancement control under a state in which the accelerator pedal is released so as to generate a larger deceleration than in a normal state. The predictive deceleration support control unit is configured to read a collision avoidance support control flag from a collision avoidance support ECU, and stop the regeneration enhancement control when the collision avoidance support control is being carried out.

Owner:TOYOTA JIDOSHA KK

Lock for coin deposit container

InactiveUS20090113951A1Adjustable distanceOut of operationCoin-freed apparatus detailsNon-mechanical controlsMechanical engineeringEngineering

A container lock with a housing and, positioned in it, a bolt that can be displaced by actuating a handle, with an insertion shaft for inserting a coin, with a scanning device for scanning the diameter of the coin inserted into the insertion shaft as far as a scanning position, where the scanning device interacts with a blocking device in such a way that the bolt can be displaced only with a coin having a correct diameter. It is proposed that the scanning device should configure a fixing jaw, which securely grips the coin that is inserted in the insertion shaft so that it is partly accessible from outside in the scanning position with the bolt pre-locked to prevent its withdrawal.

Owner:SCHULTE SCHLAGBAUM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com