Heat treatment technology of high-strength and high-plasticity ferrite-austenite duplex stainless steel

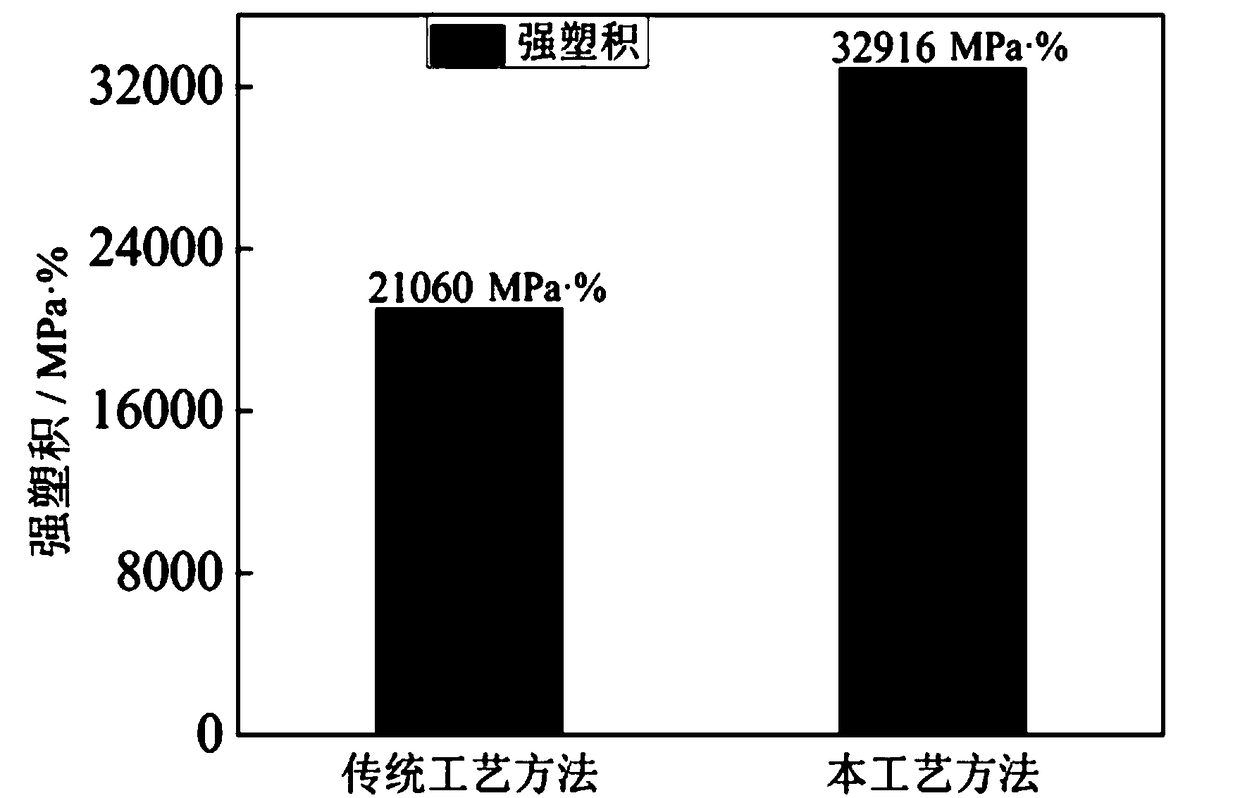

A technology of duplex stainless steel and ferrite, which is applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve problems such as the layered structure heat treatment process of duplex stainless steel that no one has proposed, so as to eliminate layered structures and avoid harmful Phase formation, effect of inhibiting grain boundary austenite formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

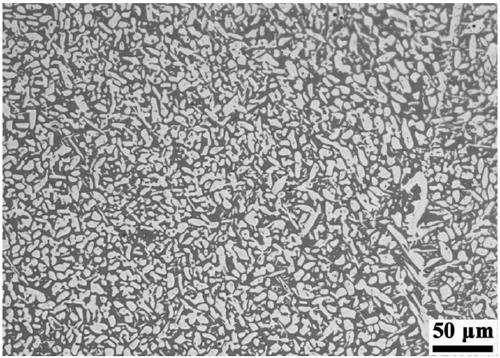

[0026] A heat treatment process for high-strength plastic ferrite-austenite duplex stainless steel is carried out according to the following steps:

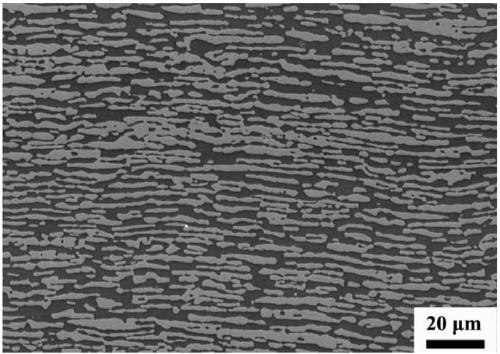

[0027] Step 1: Select the hot-rolled s3 2205 duplex stainless steel plate, the content (wt.%) of the main alloying elements Cr, Ni, Mo, Mn, Si, N is: 22.5, 5.5, 3.1, 1.18, 0.496, 0.162. The hot-rolled s3 2205 ferritic-austenitic duplex stainless steel plate is placed in a resistance furnace, heated to 1350°C under atmospheric conditions, kept for 20 minutes, and then water-quenched to room temperature. Melting treatment; the resistance furnace used is a box-type resistance furnace with a rated power of 4kW, and the maximum operating temperature is 1400°C.

[0028] Step 2: at room temperature, cold rolling pre-deformation treatment with a reduction of 20% is performed on the s3 2205 duplex stainless steel plate after the primary solution treatment;

[0029] Step 3: Place the pre-deformed s3 2205 stainless steel plate in the resis...

Embodiment 2

[0032] A heat treatment process method for high-strength plastic ferrite-austenite duplex stainless steel is carried out according to the following steps:

[0033] Step 1: Select the hot-rolled s3 2205 duplex stainless steel plate, the content (wt.%) of the main alloying elements Cr, Ni, Mo, Mn, Si, N is: 22.5, 5.5, 3.1, 1.18, 0.496, 0.162. Put the hot-rolled s3 2205 ferritic-austenitic duplex stainless steel plate in a resistance furnace, heat it up to 1350°C under atmospheric conditions, keep it for 40 minutes, and then perform water quenching treatment to room temperature. This process is a first-class solidification process. Melting treatment; the resistance furnace used is a box-type resistance furnace with a rated power of 4kW, and the maximum operating temperature is 1400°C.

[0034] Step 2: at room temperature, cold rolling pre-deformation treatment with a reduction of 40% is performed on the duplex stainless steel plate after the primary solution treatment;

[0035] ...

Embodiment 3

[0038] A heat treatment process method for high-strength plastic ferrite-austenite duplex stainless steel is carried out according to the following steps:

[0039] Step 1: Select the hot-rolled s3 2205 duplex stainless steel plate, the content (wt.%) of the main alloying elements Cr, Ni, Mo, Mn, Si, N is: 22.5, 5.5, 3.1, 1.18, 0.496, 0.162. Put the hot-rolled s3 2205 ferritic-austenitic duplex stainless steel plate in a resistance furnace, heat it up to 1350°C under atmospheric conditions, keep it for 60 minutes, and then perform water quenching treatment to room temperature. This process is a first-class solidification process. Melting treatment; the resistance furnace used is a box-type resistance furnace with a rated power of 4kW, and the maximum operating temperature is 1400°C;

[0040] Step 2: at room temperature, the s3 2205 duplex stainless steel plate after the primary solution treatment is subjected to a cold rolling pre-deformation treatment with a reduction of 60%;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com