Deep hypothermia forming method of electrolysis pure copper

A deep low temperature, pure copper technology, applied in the field of deep low temperature deformation of electrolytic pure copper, can solve the problems of high equipment requirements, high pressure, uneven grain refinement, etc., to improve deformation energy storage, reduce thermal activation, The effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

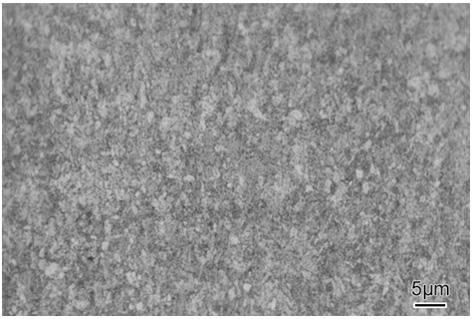

[0020] First, the electrolytic pure copper was subjected to 4 passes of equal-diameter angular extrusion on a universal testing machine equipped with an environmental chamber. The extrusion speed was 10mm / min, the extrusion angle was 110°, and the temperature of the environmental chamber was -70°C; The pressed sample was soaked in a liquid nitrogen storage device and kept warm for 20 minutes; then it was taken out and subjected to 6 passes of cold rolling deformation on the rolling mill, and a liquid nitrogen injection device was installed on both sides of the rolling mill roll, and the sample was sprayed with liquid nitrogen during rolling. The rolling temperature of the sample is controlled at -40°C, the rolling speed is 200m / s, and the total deformation is 95%; the rolled sample is annealed at 400°C for 10 minutes to obtain a grain size of 500nm The uniform recrystallized structure of the microstructure is as follows figure 1 As shown, its hardness value is increased from 4...

Embodiment 2

[0022] Firstly, the electrolytic pure copper is subjected to equal-diameter angular extrusion for 3 passes on a universal testing machine equipped with an environmental chamber. The extrusion speed is 50mm / min, the extrusion angle is 100°, and the temperature of the environmental chamber is -50°C; The pressed sample was soaked in a liquid nitrogen storage device and kept warm for 20 minutes; then it was taken out on the rolling mill for 5 passes of cold rolling deformation, and a liquid nitrogen injection device was installed on both sides of the rolling mill roll, and the sample was sprayed with liquid nitrogen during rolling. The rolling temperature of the sample is controlled at -20°C, the rolling speed is 160m / s, and the total deformation is 85%; the rolled sample is annealed at 400°C for 30 minutes to obtain a grain size of 1μm The homogeneous recrystallized structure, its hardness value is increased from 40HV in the electrolytic state to 145HV.

Embodiment 3

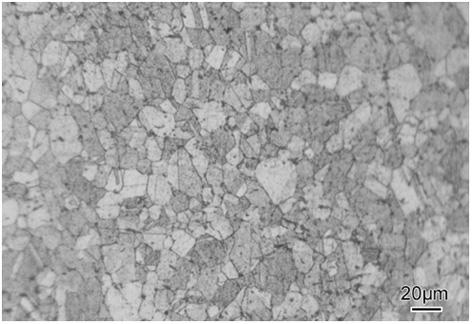

[0024] Firstly, the electrolytic pure copper is subjected to 2 passes of equal-diameter angular extrusion on a universal testing machine equipped with an environmental chamber. The extrusion speed is 50mm / min, the extrusion angle is 120°, and the temperature of the environmental chamber is -30°C; The pressed sample was soaked in a liquid nitrogen storage device and kept warm for 20 minutes; then it was taken out on the rolling mill for 3 passes of cold rolling deformation, and a liquid nitrogen injection device was installed on both sides of the rolling mill roll, and the sample was sprayed with liquid nitrogen during rolling. The rolling temperature of the control sample is -10°C, the rolling speed is 100m / s, and the total deformation is 85%; the rolled sample is annealed at 400°C for 60 minutes to obtain a grain size of 20μm The uniform recrystallized structure of the microstructure is as follows figure 2 As shown, its hardness value is increased from 40HV in the electrolyt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com