Preparation method and application of DP980 chilled steel strip

A steel strip, chilled technology, applied in the field of preparation of DP980 chilled steel strip, can solve problems such as lack of technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

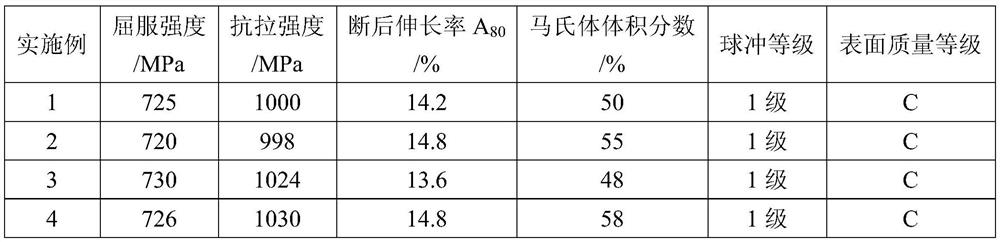

Examples

Embodiment 1

[0036] A kind of DP980 chilled steel strip is obtained according to the following preparation method:

[0037] (1) According to the mass percentage, C: 0.082%, Si: 0.212%, Mn: 1.410%, P: 0.008%, S: 0.0050%, Als: 0.042%, Cr: 0.452%, Mo: 0.205%, Nb: 0.042%, N: 0.002%, the rest is Fe and unavoidable impurities. The chemical composition of the product is configured with molten steel, and the molten steel is smelted. The continuous casting process of the molten steel is protected by blowing argon throughout the process to avoid oxidation of the molten steel; a medium-carbon covering agent is used to avoid exposure of the molten steel , the secondary cooling water is distributed according to the model to avoid problems such as nozzle blockage and excessive inclusions in the continuous casting process, and ensure the surface quality of the slab; the continuous casting process uses mold slag;

[0038] (2) Hot rolling the continuous casting slab to obtain a hot-rolled plate, the heatin...

Embodiment 2

[0045] A kind of DP980 chilled steel strip is obtained according to the following preparation method:

[0046] (1) According to mass percentage, C: 0.095%, Si: 0.252%, Mn: 1.456%, P: 0.008%, S: 0.0048%, Als: 0.045%, Cr: 0.455%, Mo: 0.212%, Nb: 0.035%, N: 0.002%, the rest is Fe and unavoidable impurities. The chemical composition of the product is configured with molten steel to smelt the molten steel. The continuous casting process of the molten steel is protected by blowing argon throughout the process to avoid the oxidation of the molten steel; a medium-carbon covering agent is used to avoid the exposure of the molten steel , the secondary cooling water is distributed according to the model to avoid problems such as nozzle blockage and excessive inclusions in the continuous casting process, and ensure the surface quality of the slab; the continuous casting process uses mold slag;

[0047] (2) Hot rolling the continuous casting slab to obtain a hot-rolled plate, the heating t...

Embodiment 3

[0054] A kind of DP980 chilled steel strip is obtained according to the following preparation method:

[0055] (1) According to mass percentage, C: 0.109%, Si: 0.305%, Mn: 1.505%, P: 0.006%, S: 0.0046%, Als: 0.048%, Cr: 0.523%, Mo: 0.252%, Nb: 0.045%, N: 0.003%, and the rest is Fe and unavoidable impurities. The chemical composition of the product is configured with molten steel to smelt the molten steel. The continuous casting process of the molten steel is protected by blowing argon throughout the process to avoid the oxidation of the molten steel; a medium-carbon covering agent is used to avoid the exposure of the molten steel , the secondary cooling water is distributed according to the model to avoid problems such as nozzle blockage and excessive inclusions in the continuous casting process, and ensure the surface quality of the slab; the continuous casting process uses mold slag;

[0056] (2) Hot rolling the continuous casting slab to obtain a hot-rolled plate, the heati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com