A method for improving the performance stability of the whole coil of niobium-titanium composite strengthened 700mpa girder steel

A beam steel, stability technology, applied in the field of iron and steel materials, can solve the problems of large fluctuations in the performance of the whole roll and different rolls, inconsistent thermal cutting deformation, frequent adjustment of punching die gaps, etc., to reduce degradation and change judgments , the strength remains consistent, and the effect of reducing cooling stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

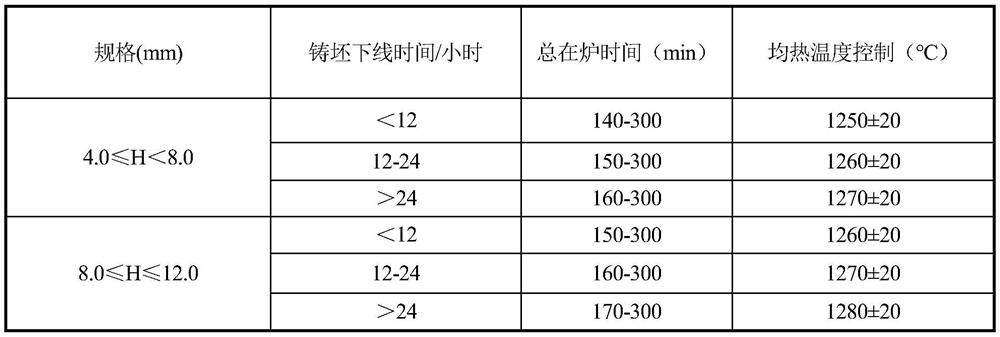

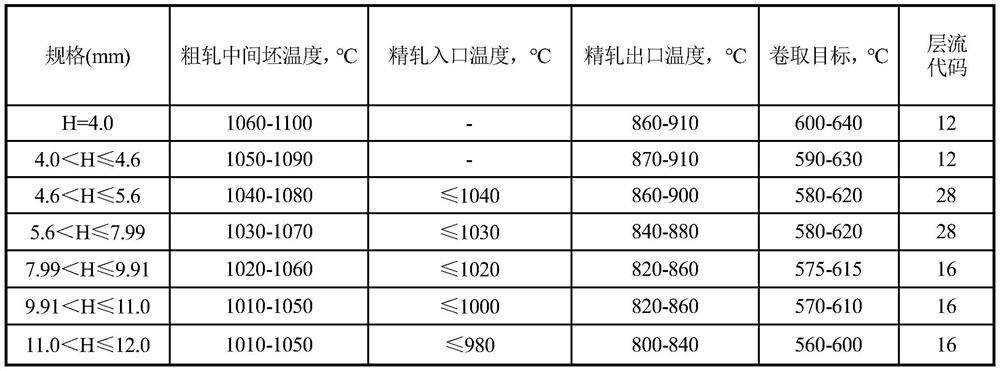

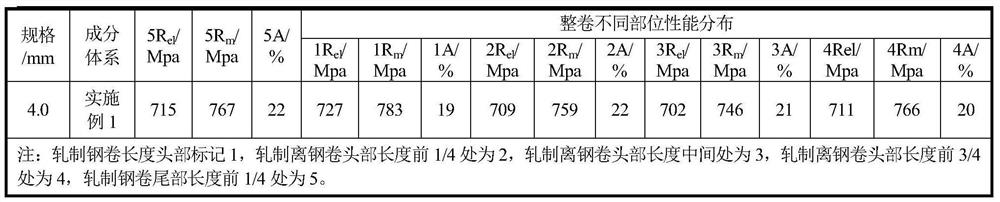

[0046] This example adopts our company's conventional hot continuous rolling 1780 production line to produce 700MPa-grade automobile frame steel with a product specification of 4.0mm thick, and further explains the method for improving the performance stability of the whole coil of 700MPa frame steel strengthened by niobium-titanium composite.

[0047] The automobile frame steel of this embodiment is proportioned according to the following weight percentages: C: 0.07%, Si: 0.12%, Mn: 1.52%, P: 0.011%, S: 0.003%, Mo: 0.02%, Nb: 0.027%, Ti : 0.088%, N: 0.0053%, Als: 0.036%, the balance is Fe and unavoidable impurities.

[0048] The production process route of the automobile frame steel in this embodiment includes top-bottom combined blowing converter, new environment-friendly smokeless modifier participating in LF refining, 1780mm rolling mill rolling, laminar flow code 12 cooling process, and box-type slow cooling of steel coil after rolling 36 hours.

[0049] Among them, the ...

Embodiment 2

[0055] This example adopts our company's conventional hot continuous rolling 1780 production line to produce 700MPa grade automobile frame steel with a product specification of 7.9mm thick, and further explains the method for improving the performance stability of the whole coil of 700MPa frame steel strengthened by niobium-titanium composite.

[0056] The automobile frame steel of this embodiment is proportioned according to the following weight percentages: C: 0.07%, Si: 0.14%, Mn: 1.61%, P: 0.012%, S: 0.002%, Mo: 0.03%, Nb: 0.032%, Ti : 0.098%, N: 0.0056%, Als: 0.034%, the balance is Fe and unavoidable impurities.

[0057] The production process route of the automobile frame steel in this embodiment includes top-bottom combined blowing converter, new environment-friendly smokeless modifier participating in LF refining, 1780mm rolling mill rolling, laminar flow code 28 cooling process, and box-type slow cooling of steel coil after rolling 48 hours.

[0058] Among them, the ...

Embodiment 3

[0064] This example adopts our company's conventional hot continuous rolling 1780 production line to produce 700MPa-grade automobile frame steel with a product specification of 12.0mm in thickness, and further illustrates the method for improving the performance stability of the whole coil of 700MPa frame steel reinforced by niobium-titanium composite.

[0065] The automobile frame steel of this embodiment is proportioned according to the following weight percentages: C: 0.08%, Si: 0.14%, Mn: 1.73%, P: 0.014%, S: 0.002%, Mo: 0.03%, Nb: 0.042%, Ti : 0.108%, N: 0.0049%, Als: 0.035%, the balance is Fe and unavoidable impurities.

[0066] The production process route of the automobile frame steel in this embodiment includes top-bottom combined blowing converter, new environment-friendly smokeless modifier participating in LF refining, 1780mm rolling mill rolling, laminar flow code 16 cooling process, and box-type slow cooling of steel coil after rolling 72 hours.

[0067] Among t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com