High-strength wire rod for steel stranded wire and production method thereof

A production method and high-strength steel technology, applied in the direction of temperature control, etc., can solve the problem of high cost of SWRS82B wire rod

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-11

[0011] A wire rod for high-strength steel strands and a production method thereof, comprising the following steps:

[0012] (1) Ore blending: mix 6-9% iron ore rich in Cr, Ni and other elements, the elemental composition of the iron ore composition weight percentage is TFe: 54%-55%, Cr: 2.0%- 2.5%, Ni: 0.50%-0.60%;

[0013] (2) Blast furnace smelting: through the reduction reaction in the blast furnace, the element composition of the molten iron composition weight percentage reaches: Si: 0.30%-0.80%, Mn: 0.30%-0.80%, Cr: 0.20%-0.30%, Ni: 0.05 %-0.06%, P≤0.120%, S≤0.040%, and the rest is iron content.

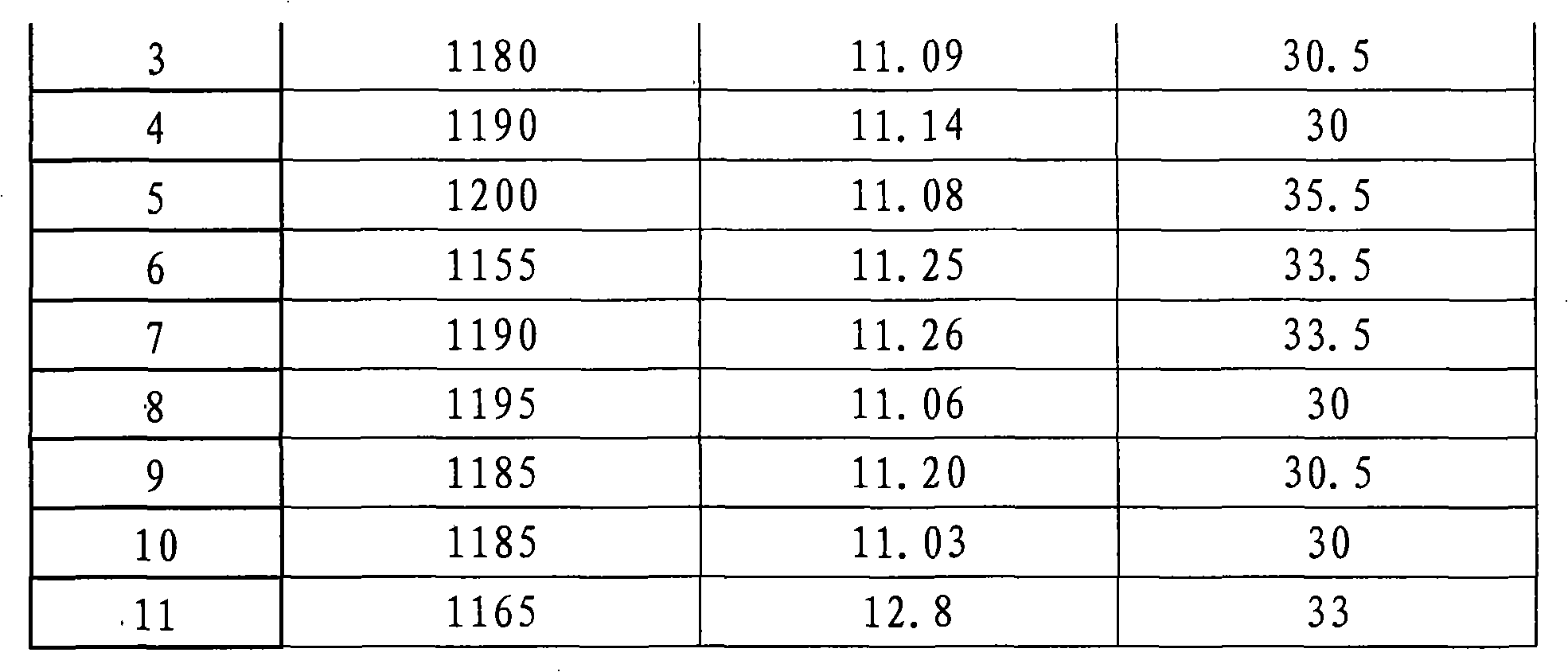

[0014] The specific composition of molten iron for blast furnace smelting is shown in the table below:

[0015] Example

[0016] 8

[0017] (3) Converter smelting

[0018] The total charging capacity of the converter: 92 ± 0.5 tons, the ratio of molten iron is adjusted according to the heat situation. The working oxygen pressure of the oxygen lance is 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com