Preparation method and application of a 550mpa grade ultra-fine grain high-strength weathering steel

An ultra-fine grain, weathering steel technology, applied in the metallurgical field, can solve the problems of high energy consumption, increased production line length, high operation and maintenance costs, and achieve the effects of low energy consumption and high dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

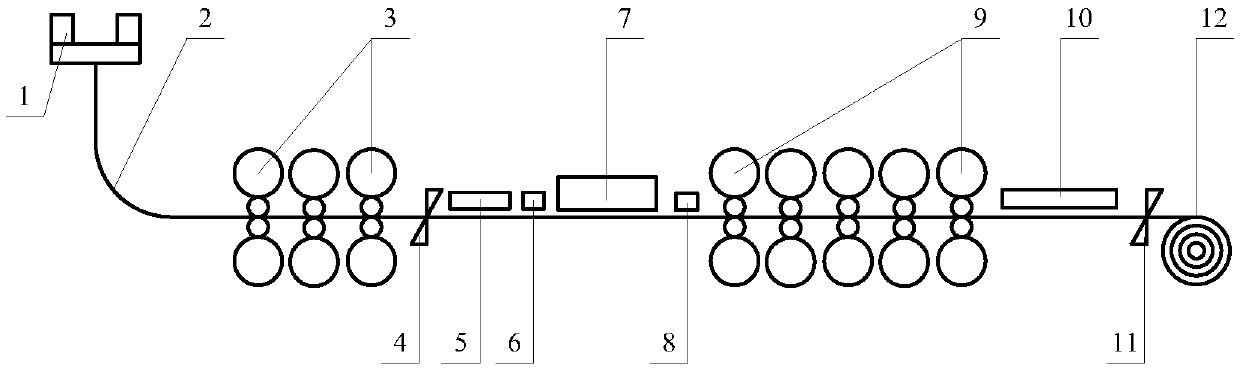

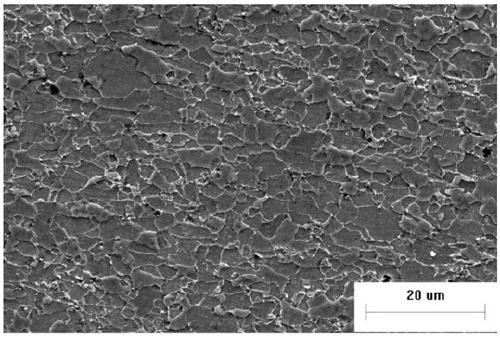

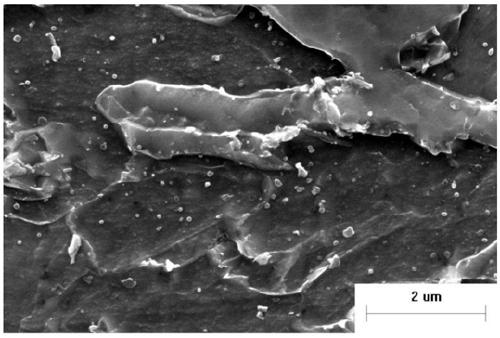

[0088] The present embodiment provides a kind of preparation method of 550MPa grade ultra-fine grain high-strength weathering steel, such as Figure 1-Figure 4 shown. Its technological process is as follows:

[0089] Firstly, tundish molten steel is prepared: the initial raw materials are melted to obtain molten iron, and then refined in BOF converter, LF furnace, and RH refining furnace in sequence to obtain the tundish molten steel.

[0090] Then said tundish molten steel is dropped into such as figure 1 ESP line shown.

[0091] In the ESP production line, the finished thin slab is obtained through continuous casting step→rough rolling step→intermediate slab processing step→finish rolling step→laminar flow cooling step→coiling step.

[0092] The tundish molten steel passes through the straight arc continuous casting machine 2 to form a continuous casting slab with a thickness of 80mm.

[0093] The continuous casting slab directly enters the 3-stand rough rolling unit 3 at ...

Embodiment 2

[0121] The method used in this example is basically the same as that in Example 1, except that the chemical composition of the initial raw materials and the relevant process parameters in the preparation method and the product specifications and average grains of the prepared 550MPa ultra-fine-grained high-strength weathering steel degree and mechanical properties.

[0122] The chemical composition of the starting raw materials and related process parameters in the preparation method are shown in Table 2-1 below. The product specifications, average grain size and mechanical properties of the 550MPa grade ultra-fine-grained high-strength weathering steel are shown in Table 2-2 below.

[0123] Table 2-1 The chemical composition of the initial raw materials and the relevant process parameters in the preparation method

[0124]

[0125] According to the preparation method described in the present invention and the chemical composition of the initial raw materials in this examp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com