Preparation method of high-performance fine-grain FeCoCrNi alloy

A high-performance, high-entropy alloy technology, applied in the field of alloy materials, can solve the problem of difficult accumulation of deformation energy storage and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

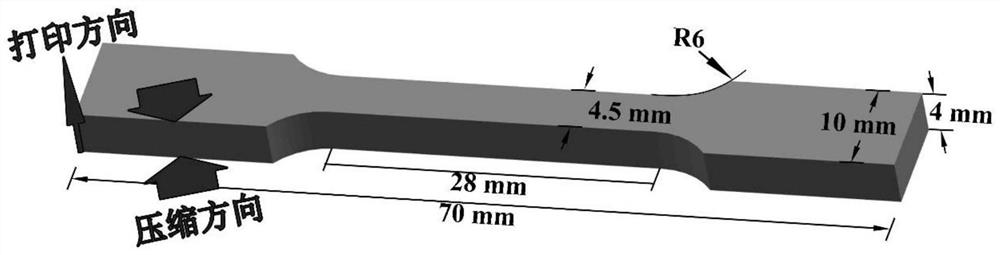

[0044] Laser selective melting method to print high-entropy alloys to prepare printed FeCoCrNi alloys

[0045] The printing powder is a gas-atomized spherical powder with an equimolar ratio of FeCoCrNi. The substrate is 316L stainless steel, and the size is 250mm×250mm×15mm. Use acetone and alcohol to clean the oil and dirt on the surface respectively. Sand blast the surface using a sandblasting machine.

[0046] Use the AM-400 laser 3D printing equipment produced by Renishaw to print, and build a block with a size of 10mm×10mm×80mm in the software Renishaw-QuantAM that comes with the Renishaw equipment, with a power of 200W and a layer thickness of 40μm. The rotation angle is 67°, the line spacing is 40μm, and the scanning speed is 740mm / s. Before printing, the printing chamber is evacuated, the oxygen content is lower than 100ppm, and the argon gas is used for protection. After printing, the specimen is cooled with the chamber for 2 hours, and the printed sample is obtaine...

Embodiment 2

[0059] Laser selective melting method to print high-entropy alloys to prepare printed FeCoCrNi alloys

[0060] The printing powder is a gas-atomized spherical powder with an equimolar ratio of FeCoCrNi. The substrate is 316L stainless steel, and the size is 250mm×250mm×15mm. Use acetone and alcohol to clean the oil and dirt on the surface respectively. Sand blast the surface using a sandblasting machine.

[0061] Use the AM-400 laser 3D printing equipment produced by Renishaw to print, and build a block with a size of 10mm×10mm×80mm in the software Renishaw-QuantAM that comes with the Renishaw equipment, with a power of 200W and a layer thickness of 40μm. The rotation angle is 67°, the line spacing is 40μm, and the scanning speed is 740mm / s. Before printing, the printing chamber is evacuated, the oxygen content is lower than 100ppm, and the argon gas is used for protection. After printing, the specimen is cooled with the chamber for 2 hours, and the printed sample is obtaine...

Embodiment 3

[0067] Laser selective melting method to print high-entropy alloys to prepare printed FeCoCrNi alloys

[0068] The printing powder is a gas-atomized spherical powder with an equimolar ratio of FeCoCrNi. The substrate is 316L stainless steel, and the size is 250mm×250mm×15mm. Use acetone and alcohol to clean the oil and dirt on the surface respectively. Sand blast the surface using a sandblasting machine.

[0069] Use the AM-400 laser 3D printing equipment produced by Renishaw to print, and build a block with a size of 10mm×10mm×80mm in the software Renishaw-QuantAM that comes with the Renishaw equipment, with a power of 200W and a layer thickness of 40μm. The rotation angle is 67°, the line spacing is 40μm, and the scanning speed is 740mm / s. Before printing, the printing chamber is evacuated, the oxygen content is lower than 100ppm, and the argon gas is used for protection. After printing, the specimen is cooled with the chamber for 2 hours, and the printed sample is obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com