Patents

Literature

42results about How to "More precipitation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

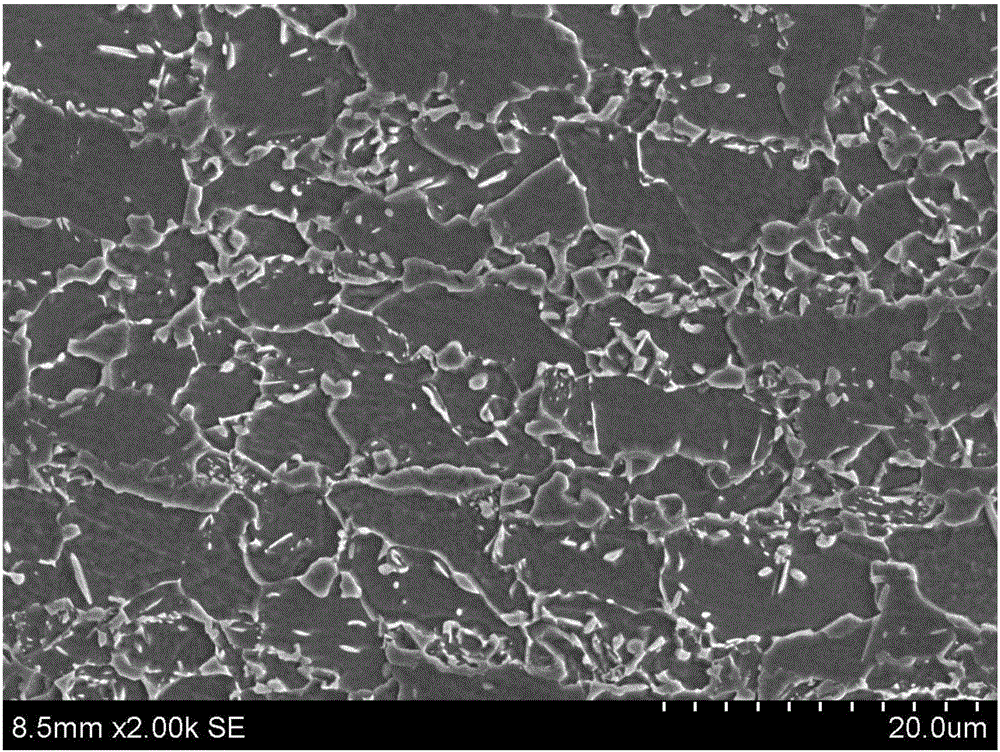

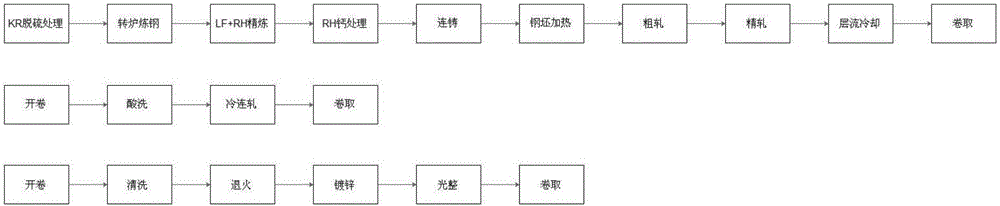

Zinc-plated double-phase steel and production method thereof

The invention belongs to the technical field of cold rolled steel and discloses zinc-plated double-phase steel and a production method of the zinc-plated double-phase steel. The zinc-plated double-phase steel comprises, by weight percentage, 0.085%-0.115% of C, 0.15%-0.24% of Si, 1.45%-1.55% of Mn, not larger than 0.015% of P, not larger than 0.005% of S, 0.025%-0.065% of Alt, 0.14%-0.24% of Cr, 0.24%-0.29% of Mo, not larger than 0.006% of N and the balance Fe and other inevitable impurities. The production method includes the steps of KR desulfuration, converter steelmaking, LF+RH refining treatment, RH calcium treatment, continuous steel casing, billet heating, rough rolling, finish rolling, laminar cooling and winding; unwinding, acid pickling, cold continuous rolling and winding; and unwinding, cleaning, annealing, zinc plating, finishing and winding. Through composition design and process control, the zinc-plated double-phase steel is suitable for annealing production lines having the rapid cooling segment or not.

Owner:SHOUGANG CORPORATION

Manufacturing process of high-strength aluminum alloy ring forge

ActiveCN106363352AImprove the problem of low mechanical propertiesAchieve productionNumerical controlHigh intensity

The invention relates to a manufacturing process of a high-strength aluminum alloy ring forge. The manufacturing process comprises the following operation steps of blank purchasing, blank cut-off, heating of the forge, blank forming, machining of an inner hole, heating, broaching of a mandrel supporter, return heating, ring milling, cooling, curing, cold deformation, aging and machining to the required dimension. Through combination of the multiway improving forging technology, the mandrel supporter broaching technology, the lubricating technology, the numerical control ring-milling technology, the high-intensity thermal treatment technology and the cold deformation technology, the problems that an existing aluminum alloy ring forge is low in overall performance, nonuniform in mechanical property, obvious in anisotropism and the like.

Owner:WUXI PAIKE HEAVY CASTING & FORGING

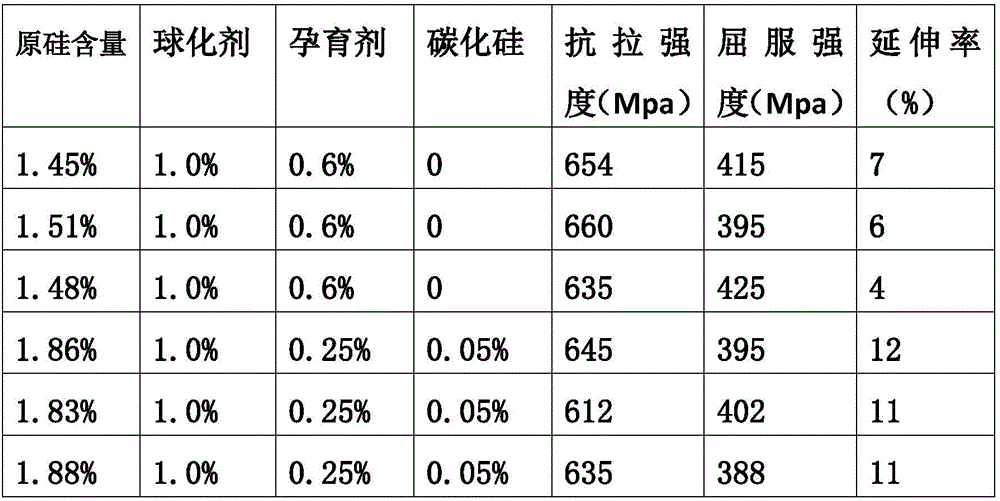

Production technology for ductile iron casting with high strength and high ductility

ActiveCN104878275AAvoid burnsQuality improvementProcess efficiency improvementDuctile ironUltimate tensile strength

The invention discloses a production technology for a ductile iron casting with high strength and high ductility. The production technology comprises the following steps: 1, adding 18-22 parts of steel scrap into an electric furnace for smelting, adding 58-62 parts of foundry returns, and finally, adding 0.5 part of a structure modifier and 18-22 parts of pig iron at the same time for smelting, so as to obtain raw molten iron; 2, adding a nodulizing agent into a nodulizing chamber of a nodulizing ladle, and coating the nodulizing agent with a nucleating agent, covering the nucleating agent with a silicon steel sheet, and finally, adding the structure modifier into the nodulizing ladle; 3, enabling the raw molten iron of which the temperature is controlled to be 1460-1480 DEG C in the electric furnace to react in the nodulizing ladle, so as to obtain final molten iron; 4, pouring the final molten iron for casting, and cooling, so as to obtain the ductile iron casting. According to the invention, the burning loss of crystal cores in molten iron can be prevented, the quality of molten iron is improved, and the ductility and strength can be greatly improved.

Owner:江苏力源金河铸造有限公司

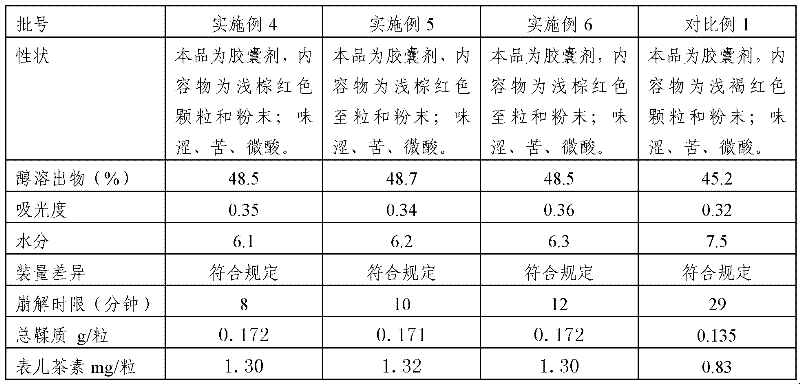

Golden buckwheat rhizome extract, pharmaceutical preparation containing golden buckwheat rhizome extract and preparation method thereof

ActiveCN102397342AConducive to low-carbon environmental protectionSave energyComponent separationCapsule deliveryElutionBULK ACTIVE INGREDIENT

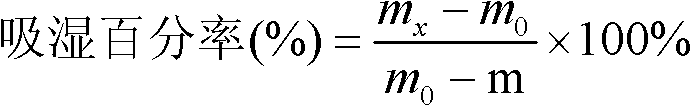

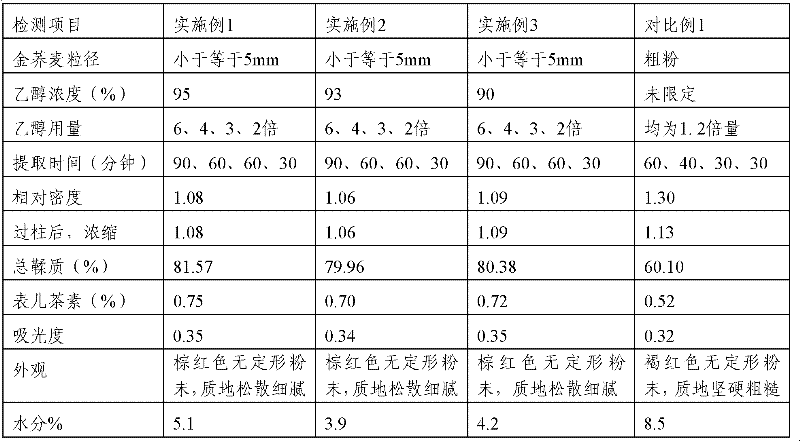

The invention relates to golden buckwheat rhizome extract and a pharmaceutical preparation containing same. The golden buckwheat rhizome extract is prepared through the following methods: golden buckwheat rhizome is taken, pulverized and then is extracted by circulated ethanol for four times, mass of each extraction solvent is respectively 6 times, 4 times, 3 times and twice of that of the golden buckwheat rhizome particles, extraction time is sequentially 90 minutes, 60 minutes, 60 minutes and 30 minutes, extracted liquid is combined and filtered, and the filtered liquid is decompressed and concentrated; water which is 20 times of the plaster is added to immerse the plaster to be mixed and suspended and then to be statically placed for one night; the upper clear liquid is chromatographically separated by macroporous adsorbent resin after being filtered; then the liquid is washed by water until the outflow liquid is colorless, then the liquid is eluted by 80% ethanol until the elution liquid is free from being reacted with ferric trichloride test solution, the elution liquid is collected, decompressed and concentrated and then is dried in an atomizing way, so the golden buckwheat rhizome extract is obtained. The golden buckwheat rhizome extract has higher content of active ingredients, the preparation has better characteristics, and the drug action is better.

Owner:HUAYI PHARMA

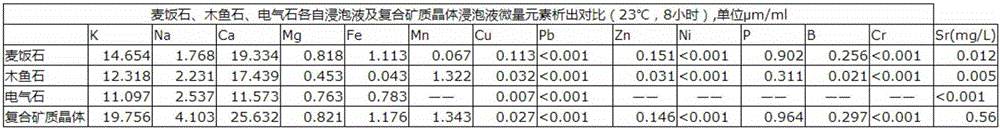

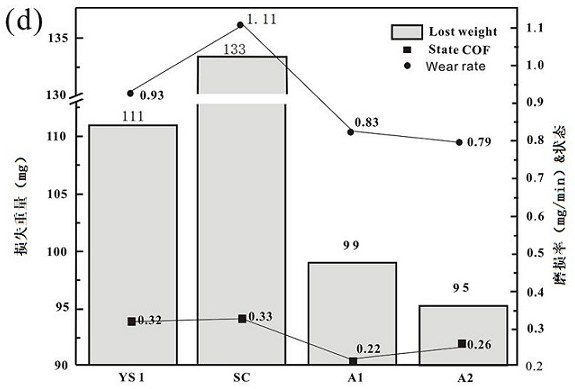

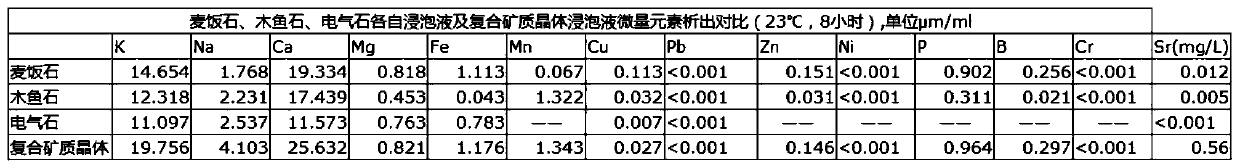

Composite mineral crystal capable of improving water quality, strengthening immunity and facilitating cardiovascular and cerebrovascular diseases and preparation method thereof

InactiveCN106219720AIncrease surface areaImprove adsorption capacityWater contaminantsWater/sewage treatment by substance additionDiseaseWater quality

The invention discloses a composite mineral crystal capable of improving water quality, strengthening immunity and facilitating cardiovascular and cerebrovascular diseases. The composite mineral crystal is prepared from the following components in parts by weight: 10 to 15 parts of medical stone, 5 to 10 parts of wooden fish stone, 5 to 10 parts of tourmaline, 30 to 55 parts of activated zeolite, 5 to 10 parts of celestite and 15 to 40 parts of kaolin. Meanwhile, the invention provides a preparation method of the composite mineral crystal. The surface area of the composite mineral crystal is increased by using supplementary strontium element of the added celestite and a secondary honeycomb wrapping burning technology, and the mineralization speed and effect are greatly improved, so that the precipitation of trace elements, particularly the precipitation of the strontium element, is more abundant, heavy metals are absorbed, and the composite mineral crystal has the effects of promoting metabolism, strengthening immunity, improving water quality and facilitating cardiovascular and cerebrovascular diseases.

Owner:刘乙霄

Processing method for Chinese wampee fruit jam powder

InactiveCN104783026AKeep the natural flavorColor stableFood preparationPre treatmentNutrients substances

The invention discloses a processing method for Chinese wampee fruit jam powder. The Chinese wampee fruit jam powder is processed by taking Chinese wampee fruits as a main raw material, and carrying out the steps of raw material pre-treatment, pulping, enzyme treatment, proportioning, homogenizing, lyophilizing, crushing, filtering and the like. The finished Chinese wampee fruit jam powder produced by the processing method is stable in colour through sulphurous acid treatment, the content of pectin in the raw material can be reduced through enzymolysis, separation for more nutrient substances is benefited, the utilization rate of the raw material is increased, and the natural flavour of the Chinese wampee fruits can be kept without adding any artificial preparation.

Owner:张俊辉

Brewing process of kumquat fruit wine

InactiveCN104830619AAvoid churnImprove utilization efficiencyAlcoholic beverage preparationPteridophyta/filicophyta medical ingredientsNutrientHorticulture

The invention discloses a brewing process of kumquat fruit wine. The brewing process is characterized in that the kumquat fruit wine is brewed by adopting kumquat fruits as a raw material in steps of raw material pretreatment, enzymolysis, mixing, yeast activation, fermentation, mixing, aging, settling and filtering, filling and sterilizing and the like. The blocked kumquat fruit is soaked in high-degree white spirit, so that the loss of nutrients can be avoided; the soaked kumquat fruits are pulped and are subjected to the composite enzyme treatment, so that more kumquat fruit nutrients can be precipitated, the utilization efficiency of the kumquat fruits can be improved, the settling treatment is carried out by adopting a composite settling agent after the aging, the finished product kumquat fruit wine is stable in color, transparent in wine and soft in taste and has health-protection functions for eliminating the indigestion and phlegm, promoting the secretion of saliva or body fluid, relieving sore throat, resolving depression, strengthening the physique and the like.

Owner:张俊辉

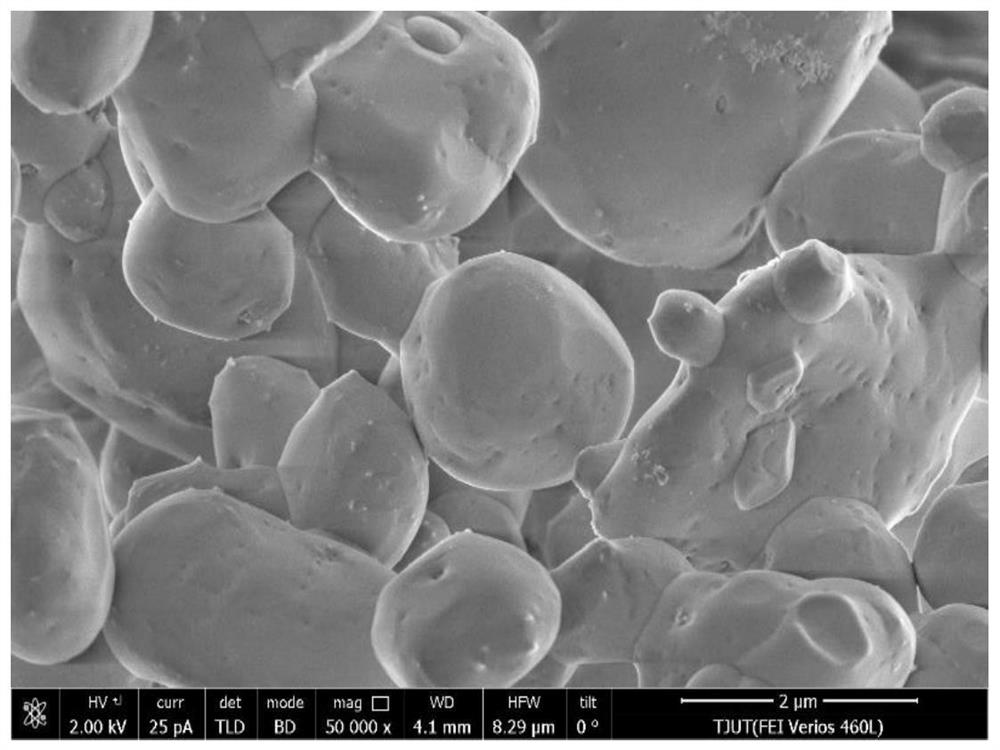

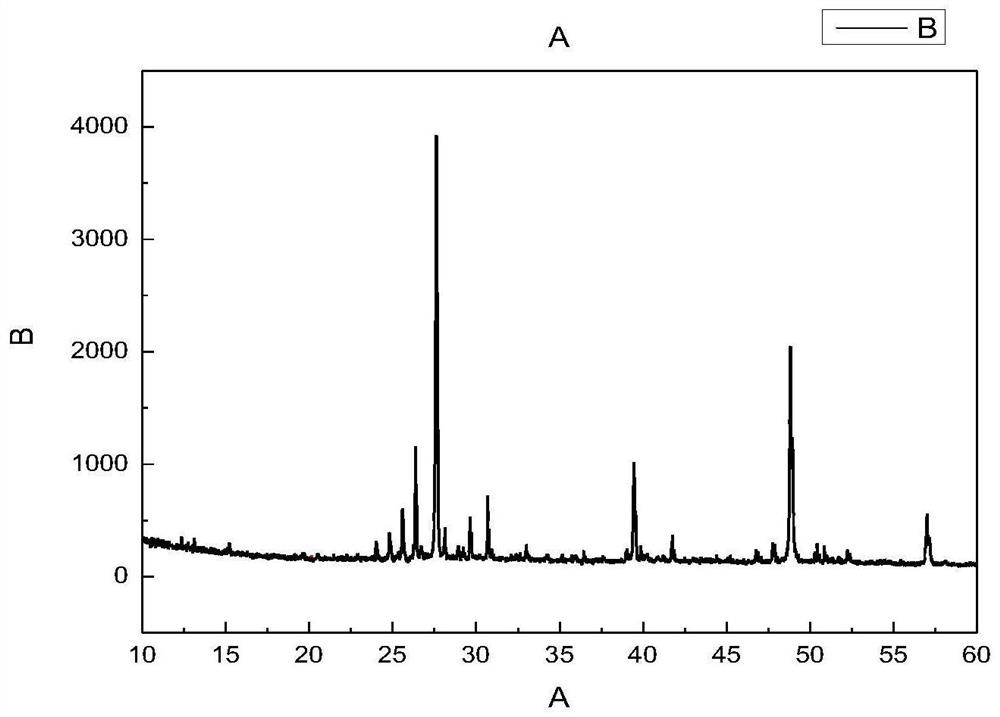

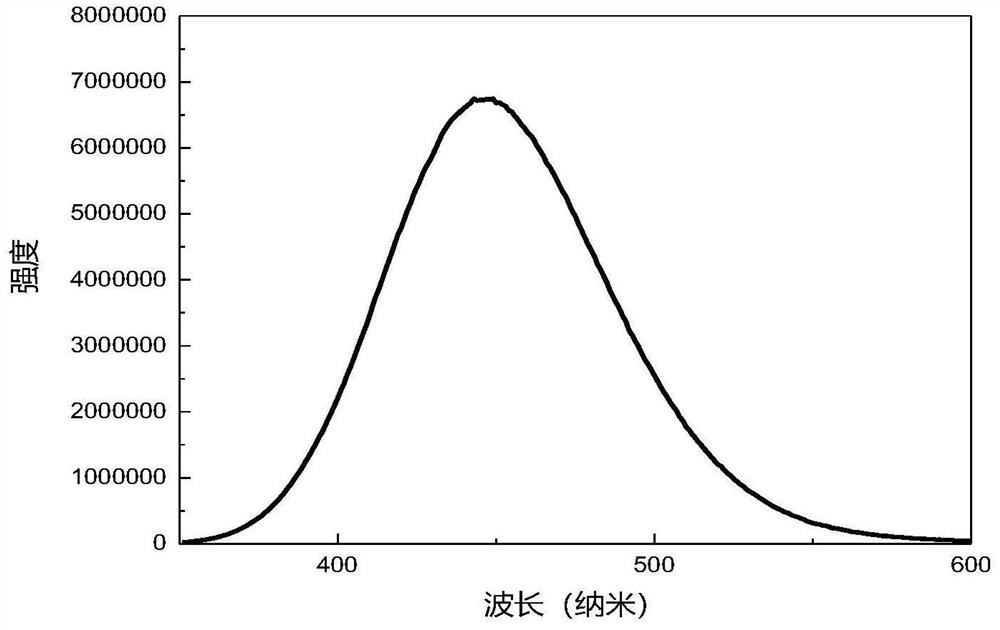

Method for synthesizing copper-based perovskite powder by low-temperature solvent method

InactiveCN112280555ALow costShort preparation cycleCopper compoundsLuminescent compositionsCupric bromideCopper chloride

The invention relates to a method for synthesizing copper-based perovskite powder by a low-temperature solvent method. The method comprises the following steps: adding CsX and CuX into a polar organicmixed solution, and stirring for 4-6 hours at 40-70 DEG C, wherein the polar organic mixed solution is a mixed solution of N, N-dimethylformamide (DMF)and dimethyl sulfoxide (DMSO), the CsX is cesiumchloride, cesium bromide or cesium iodide, and the CuX is copper chloride, copper bromide or copper iodide. According to the synthesis process, constant-temperature growth on a hot plate is not needed, synthesis is directly conducted on a magnetic stirrer, the synthesis process has the advantages of being short in manufacturing period, low in cost, simple in growth step, environmentally friendlyand the like, and Cs3Cu2X5 powder with high crystallization quality is separated out within 5 hours.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Brewing technology of synsepalum dulcificum fruit health-care fruit wine

InactiveCN107488550AAvoid churnImprove utilization efficiencyDigestive systemAlcoholic beverage preparationHorticultureNutrient

The invention provides a brewing technology of synsepalum dulcificum fruit health-care fruit wine. The brewing technology is characterized in that the synsepalum dulcificum fruit health-care fruit wine takes synsepalum dulcificum fruits as raw materials and is brewed through steps of pre-treating the raw materials, carrying out enzymolysis, blending, activating yeast, fermenting, mixing, ageing, clarifying and filtering, filling and sterilizing and the like. According to the brewing technology provided by the invention, the synsepalum dulcificum fruits are chopped and put into high-degree Baijiu for immersing, so that the loss of nutrient substances is avoided; the immersed synsepalum dulcificum fruits are pulped and are subjected to complex enzyme treatment, so that more synsepalum dulcificum fruit nutrient substances are separated out; the utilization efficiency of the synsepalum dulcificum fruits can be improved; after the ageing is carried out, a compound clarifying agent is used for carrying out clarifying treatment, so that the finished-product synsepalum dulcificum fruit health-care fruit wine has the health-care effects of stable color and luster, transparent wine body, soft mouthfeel, facial beautification and the like.

Owner:程龙凤

Brewing technology of Fragaria orientalis Losinsk healthy fruit wine

InactiveCN106318821AImprove utilization efficiencyAvoid churnAlcoholic beverage preparationFruit wineYeast

The invention discloses a brewing technology of Fragaria orientalis Losinsk healthy fruit wine. The technology is characterized in that the Fragaria orientalis Losinsk healthy fruit wine is made from Fragaria orientalis Losinsk and brewed through the steps of raw material preprocessing, enzymolysis, blending, yeast activation, fermentation, mixing, ageing, clarification filtering, filling, sterilization and the like. After being sliced into pieces, the Fragaria orientalis Losinsk is placed into high-alcohol baijiu to be soaked, nutrient substances are prevented from being lost, the soaked Fragaria orientalis Losinsk is pulped and treated through a complex enzyme, more Fragaria orientalis Losinsk nutrient substances can be separated out more easily, the Fragaria orientalis Losinsk utilization efficiency can be improved, after ageing is performed, a composite clarifying agent is adopted for performing clarification treatment, the finished Fragaria orientalis Losinsk healthy fruit wine is stable in color, transparent and soft in taste and has the healthcare effects of helping digestion, reducing phlegm and encouraging production of body fluids to extinguish thirst and the like.

Owner:余芳

Brewing method of mockstrawberry fruit wine

InactiveCN104946483AImprove utilization efficiencyAvoid churnAlcoholic beverage preparationFruit wineHigh concentration

The invention discloses a brewing method of mockstrawberry fruit wine. The brewing method is characterized by being prepared through the steps of taking mockstrawberry fruits as the raw material, pre-treating, enzymatic hydrolysis, blending, activation of yeast, fermenting, mixing, ageing, clarifying and filtering, filling and sterilizing and other steps. According to the brewing method of mockstrawberry fruit wine, mockstrawberry fruits are placed into high-concentration Baijiu for soaking after being diced, loss of nutritive materials is avoided, the soaked mockstrawberry fruits are pulped and then subjected to compound enzyme treatment, precipitation of more nutritive materials of the mockstrawberry fruits is facilitated, the utilization efficiency of mockstrawberry fruits is improved, a compound clarifying agent is adopted for clarification treatment after ageing, therefore the finished mockstrawberry fruit wine is stable in color and luster, transparent in wine body, soft in taste, and has health care effects of reducing sputa to relieve cough, expelling the wind, promoting blood circulation, relieving swelling, stopping pain and improving immunity.

Owner:吴桂丽

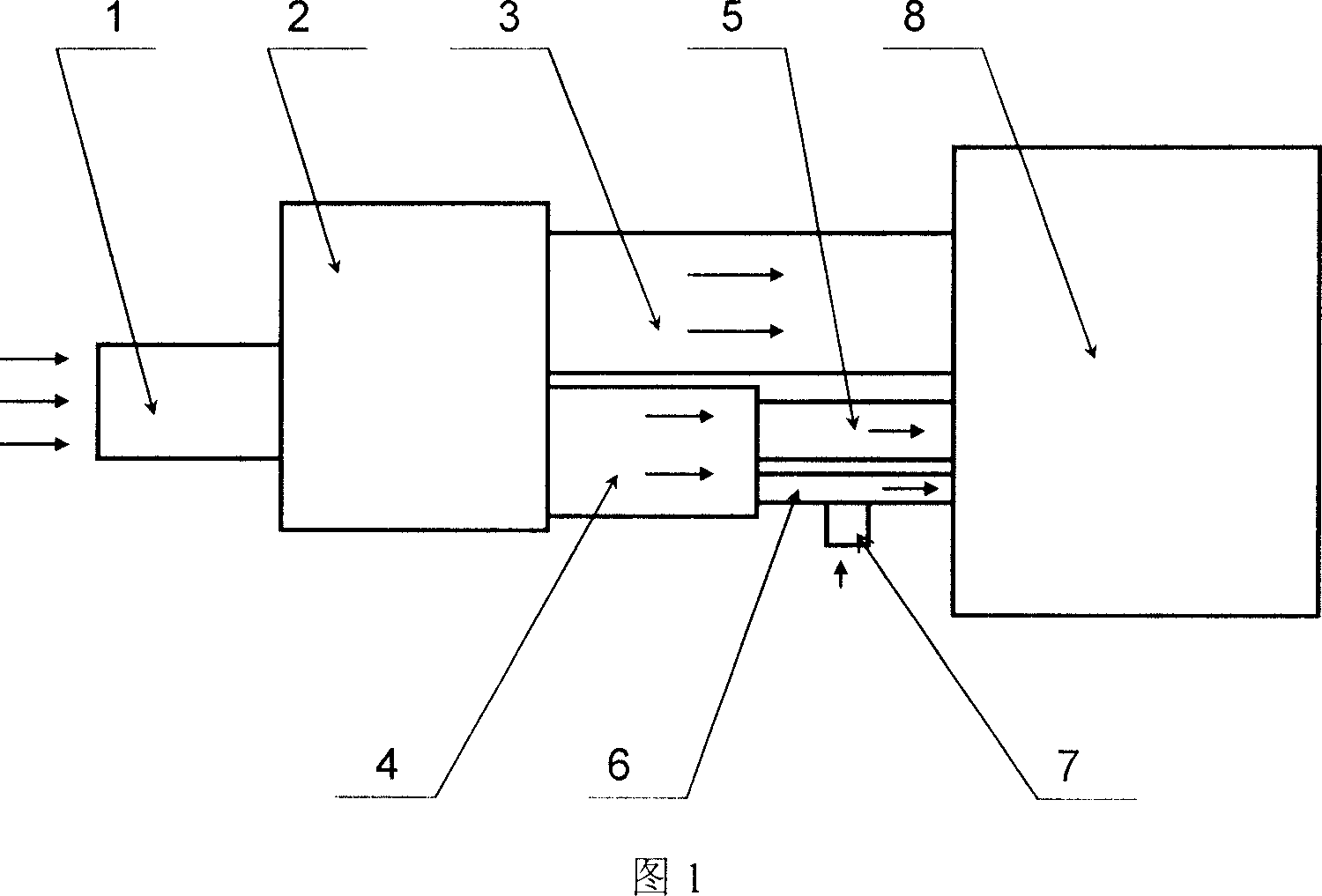

Ignition method and apparatus for fossil fuel

InactiveCN101109517AIncrease oxygen concentrationImprove adaptabilityNon-combustible gases/liquids supplyCombustion chamberLow load

An ignition method and arrangement for fossil fuel is provided, which pertains to the technical field of combustion and equipment. In the invention, before a primary air flow containing powder fuel enters into a combustion chamber, the primary air flow is gradated, then the thick powder air flow is divided into a bigger and a smaller whiff, wherein, the flow area of the channel for the smaller whiff accounts for 15-40% of the total area of the channel for the thick powder air flow. The smaller whiff of thick-powder air flow is mixed with an air flow with high oxygen concentration, so that the oxygen concentration in the smaller whiff of thick-powder air flow is 22-95%, and the stoichiometric ratio of oxygen to the fuel is 0.4-1.2. By improving the pyrolyzation and reaction condition, the invention accelerates and increases the separation out and pre-stage firing of the volatile components of the fossil fuel, improves greatly the firing property of air flow, can realize the firing and low-load steady combustion of fossil energy with low volatile components without using combustion-supporting oil or reducing greatly the use of combustion-supporting oil; in addition, in the invention a steady small flame can be formed, the primary air flow is fired by a way of igniting a big fire through a small flame, this greatly saves the oxygen consumption during the ignition.

Owner:TSINGHUA UNIV

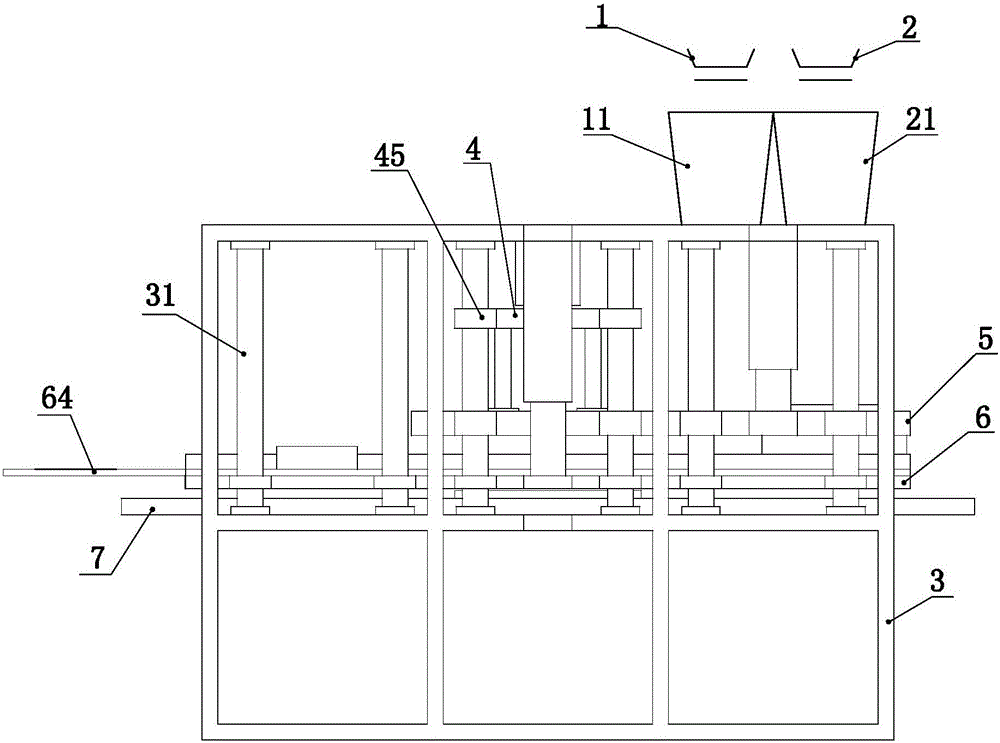

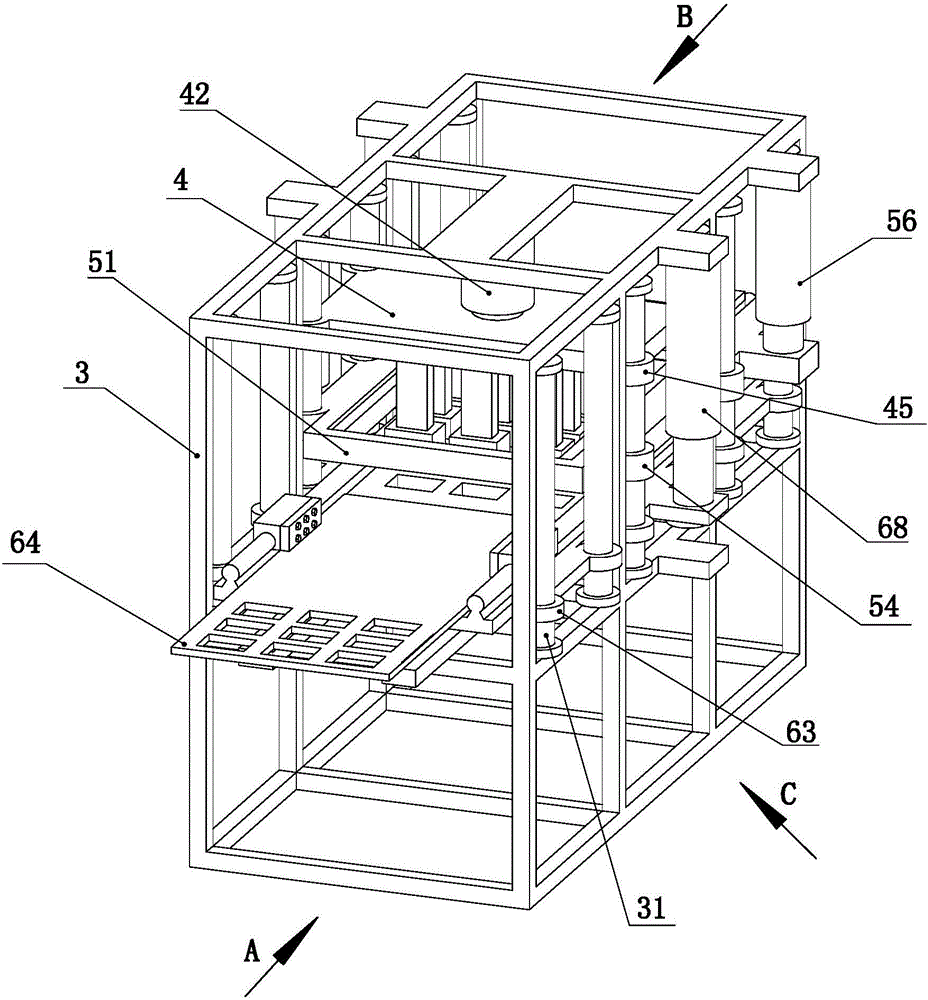

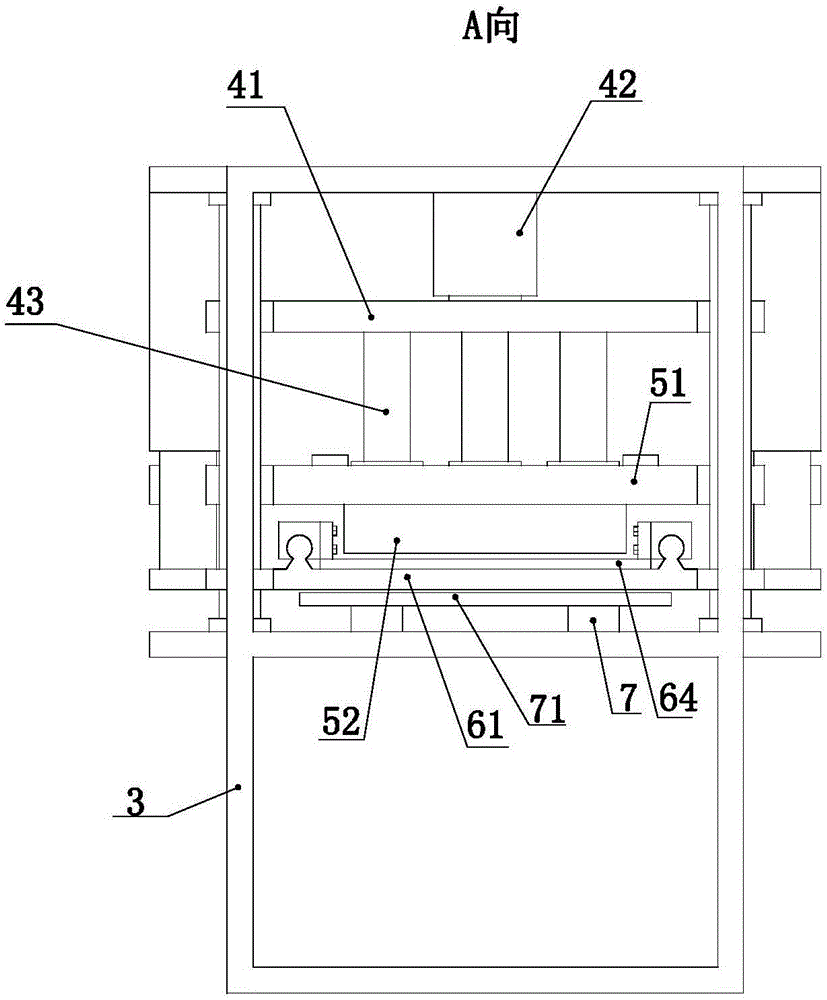

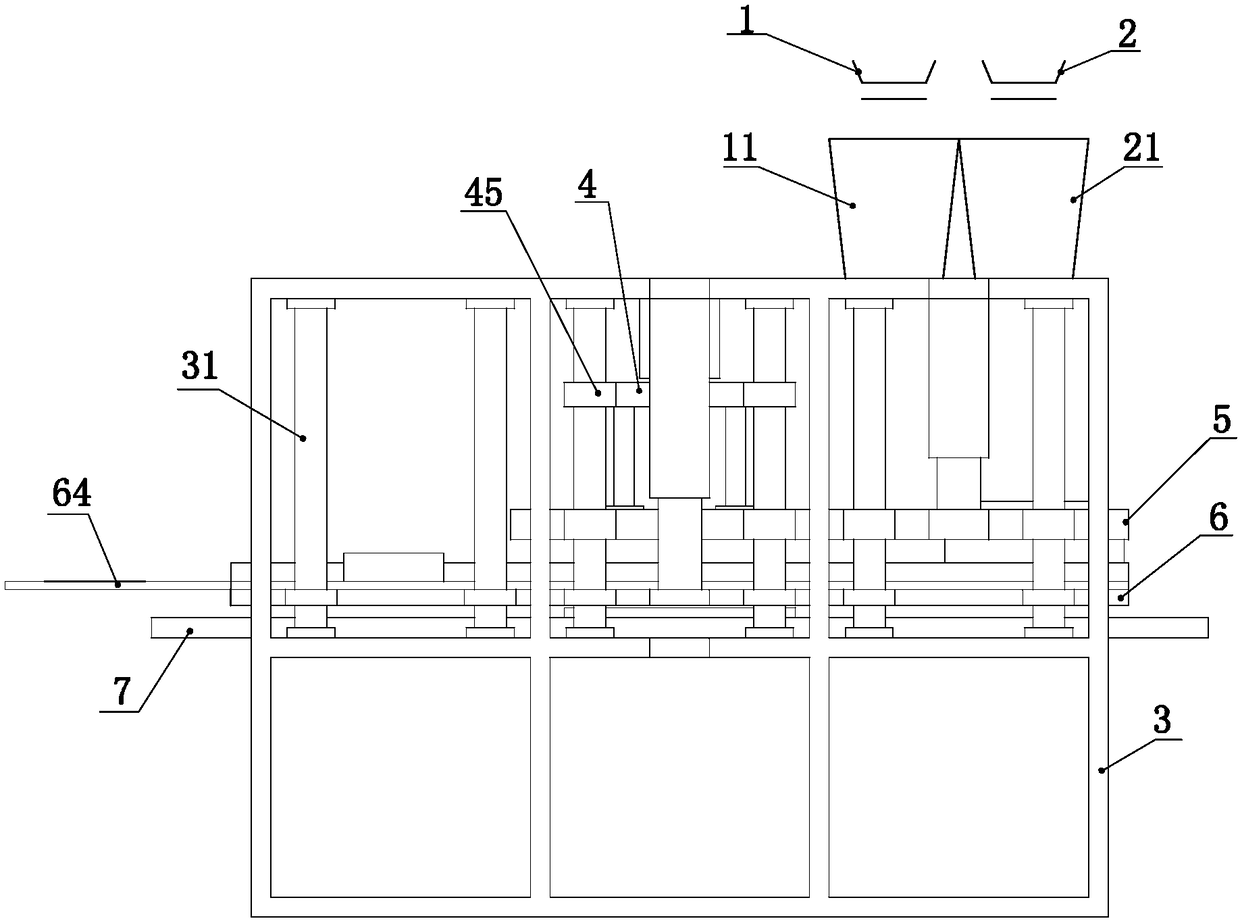

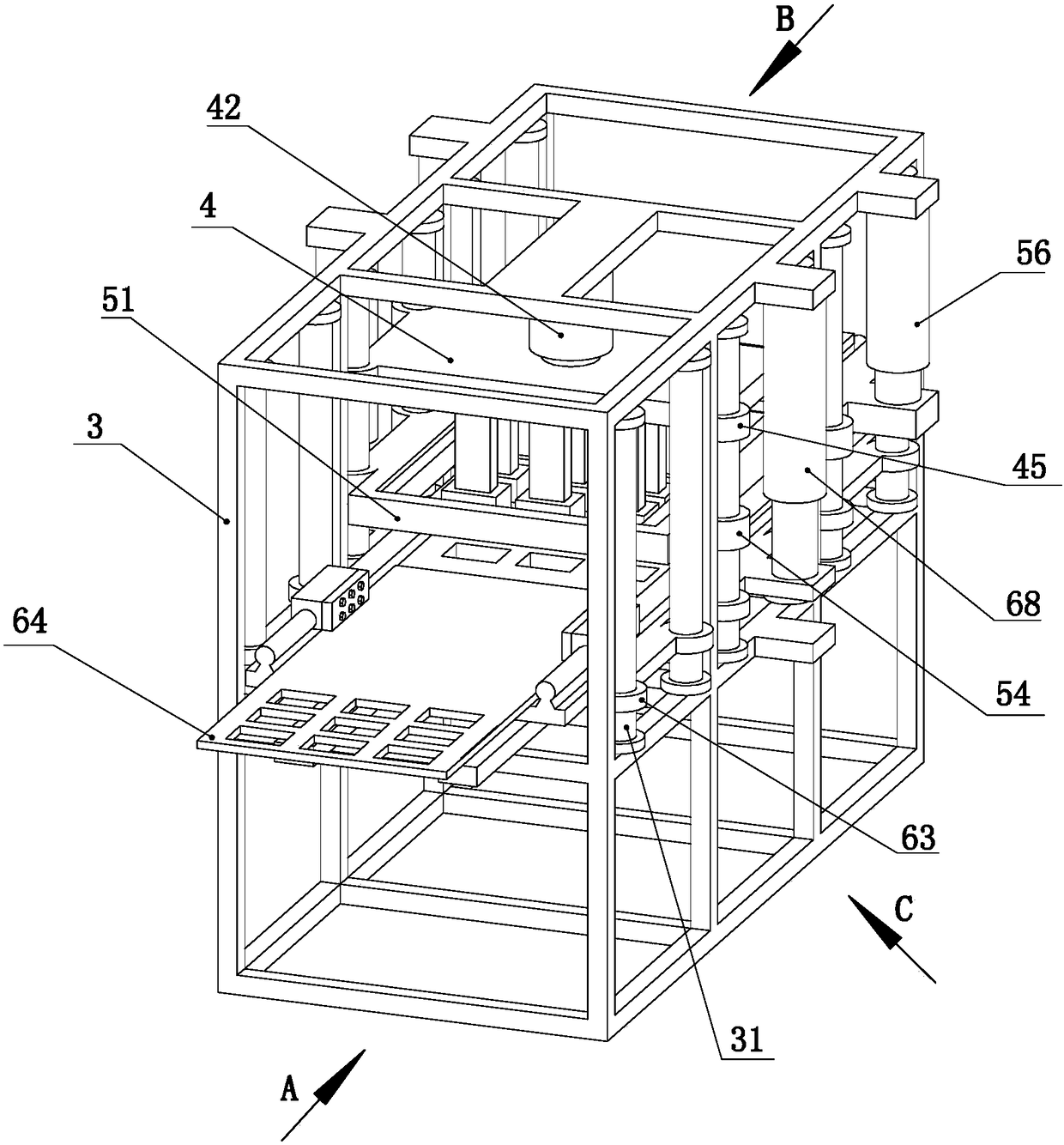

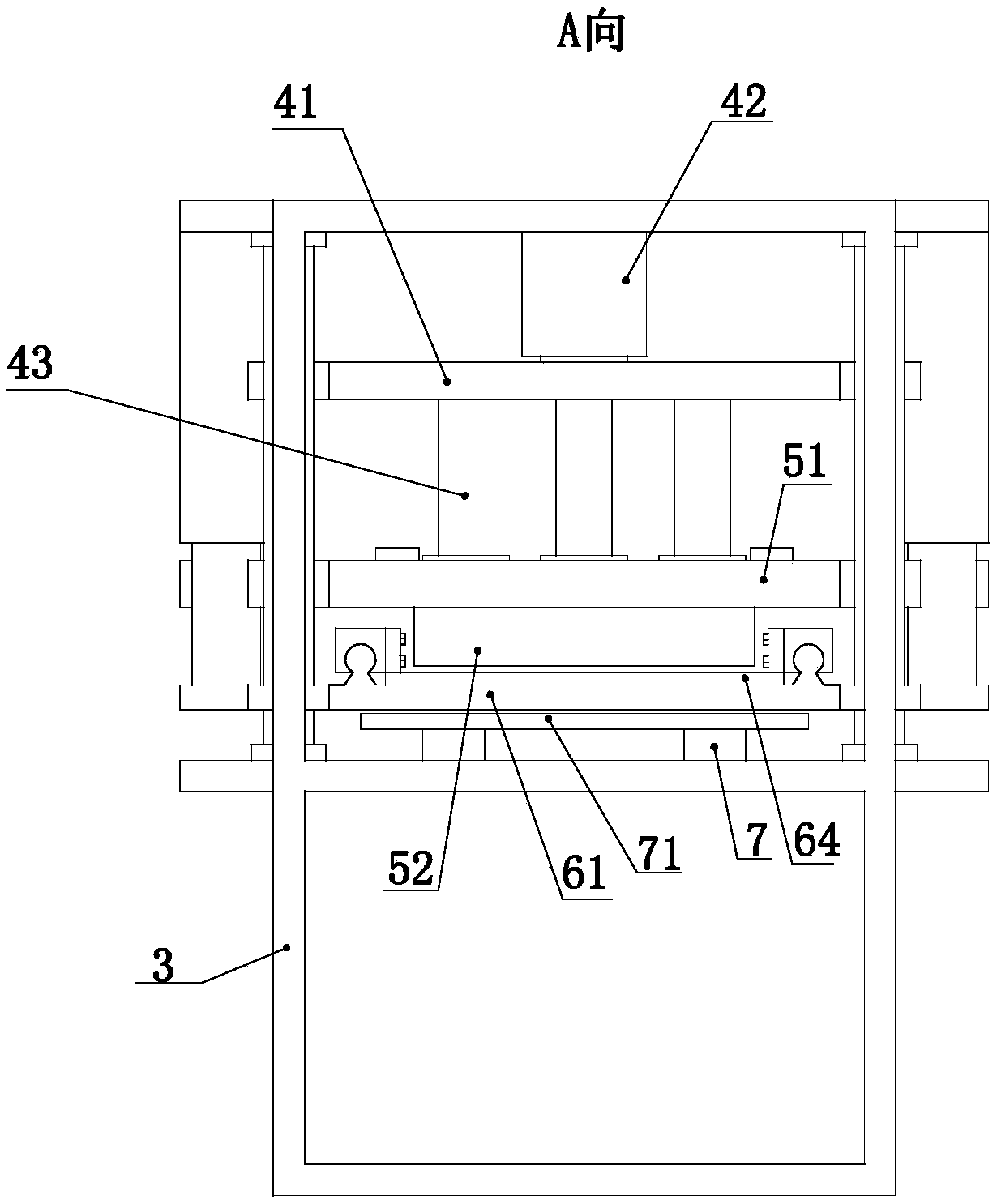

Full-automatic water-permeable brick production line

ActiveCN106272941AUniform thicknessHigh strengthCeramic shaping plantsFeeding arrangmentsProduction lineBrick

The invention provides a full-automatic water-permeable brick production line and relates to the technical field of building material production. The full-automatic water-permeable brick production line is used for producing high-quality double-layer water-permeable bricks. The full-automatic water-permeable brick production line is characterized by comprising a feeding system and a forming system; the feeding system comprises a first conveyor and a second conveyor; the forming system comprises a rack, a stamping device, a distributing device and a die device; the distributing device comprises a distributing frame and a distributor, and the distributing frame is connected to the rack in a sliding mode in the vertical direction; the die device comprises a first die plate and a second die plate, the first die plate is connected to the rack in a sliding mode in the vertical direction, and the second die plate is connected to the upper side of the first die plate in a sliding mode in the horizontal direction. The full-automatic water-permeable brick production line has the advantages that it can be guaranteed that the thicknesses of all layers of the produced double-layer water-permeable bricks are uniform, it is guaranteed that the upper layers and the lower layers are clearly separated, therefore, the strength and the water-permeable performance of the double-layer water-permeable bricks are improved, the service life of the double-layer water-permeable bricks is prolonged, and the advantage that one machine achieves multiple purposes is achieved.

Owner:SHANDONG JINYI GARDEN SHARES CO LTD

Method for extracting coumarin compound from kidney beans

InactiveCN107126455AMore precipitationPromote precipitationOrganic chemistryPlant ingredientsFiltration membraneNiacinamide

The invention provides a method for extracting a coumarin compound from kidney beans. The method comprises the following steps: grinding kidney bean seeds into paste and adding magnesium sulfate, sodium citrate and niacinamide; heating and extracting to separate out more effective substances from the paste; absorbing and eluting an extracting solution through ion exchange resin to remove impurities; concentrating by adopting a nano-filtration membrane and extracting a concentrated solution with an ethanol water solution; finally, concentrating and crystallizing an extracting solution to obtain the coumarin compound. According to the extraction method provided by the invention, the purity of the coumarin compound can be extremely improved; cellulase is added in an extracting process and the effective substances can also be separated out, so that the yield of the coumarin compound is improved.

Owner:于世金

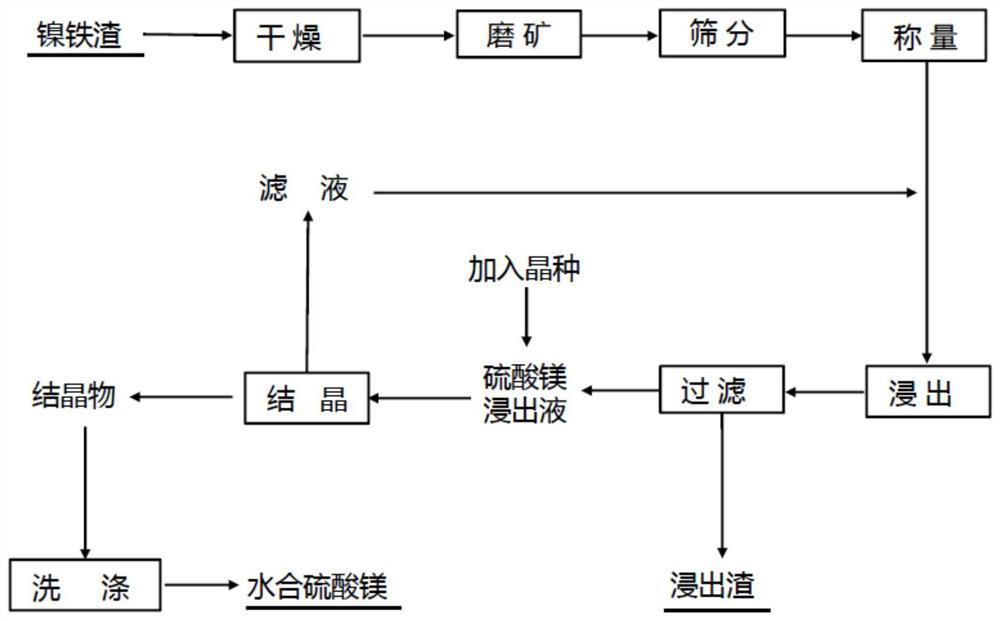

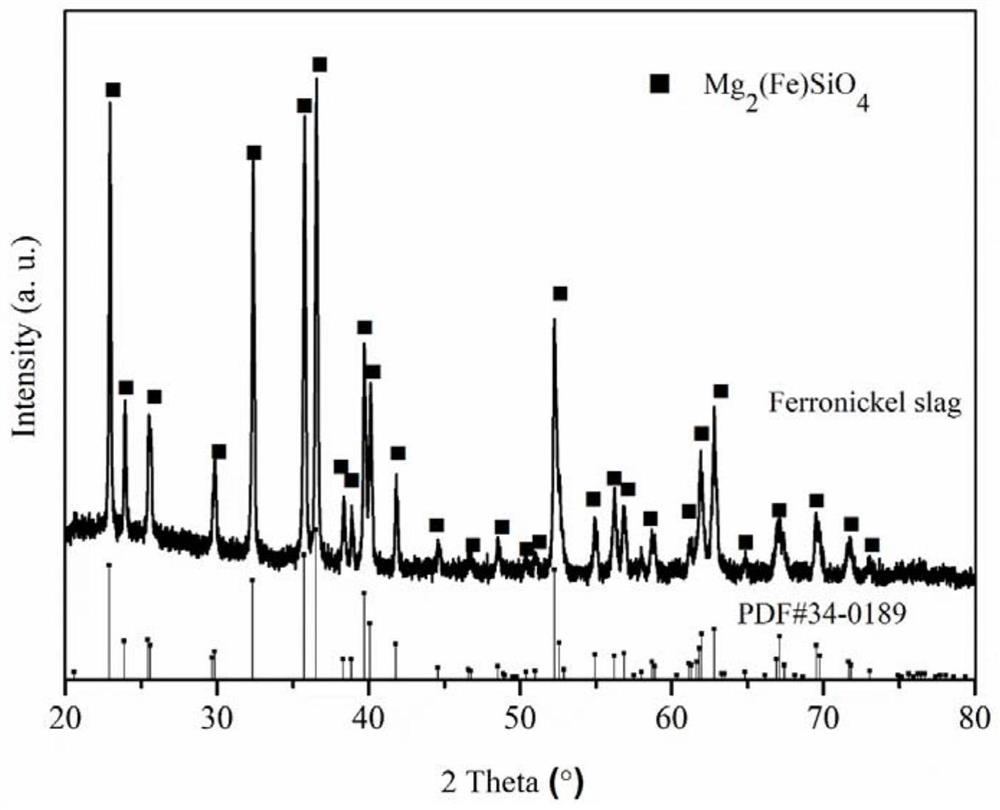

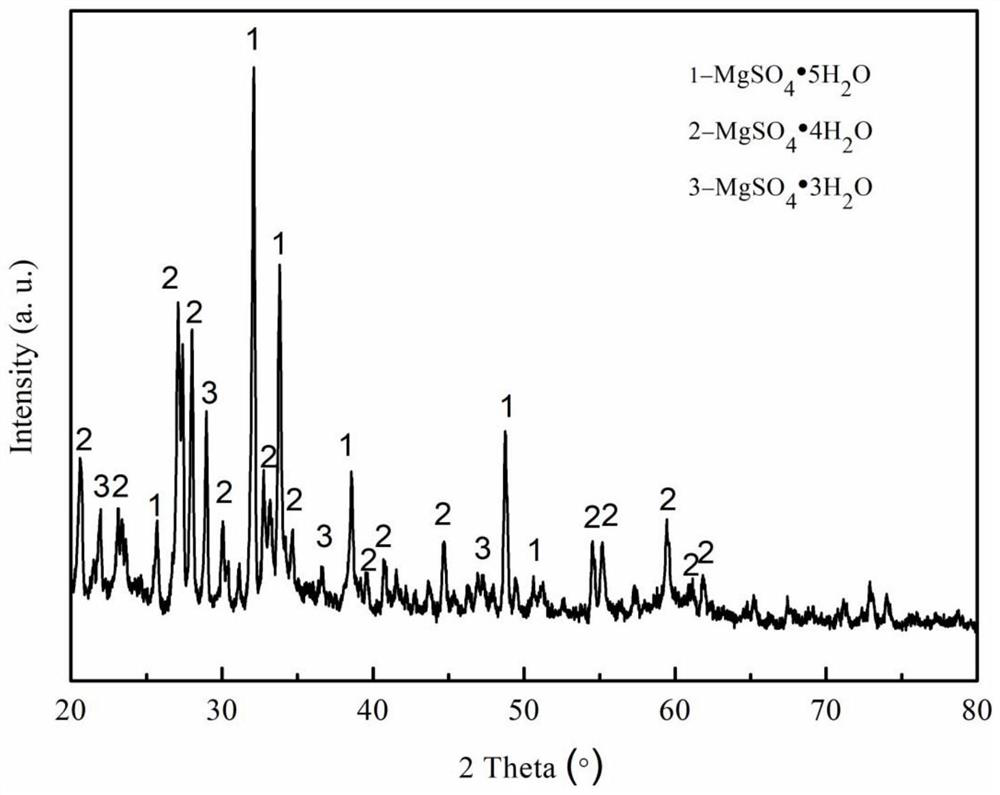

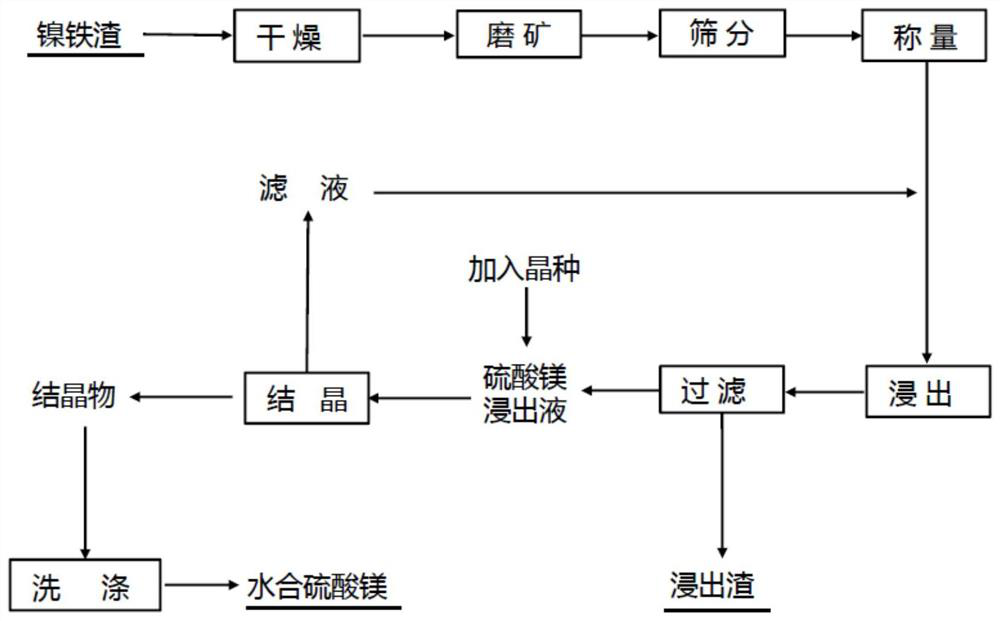

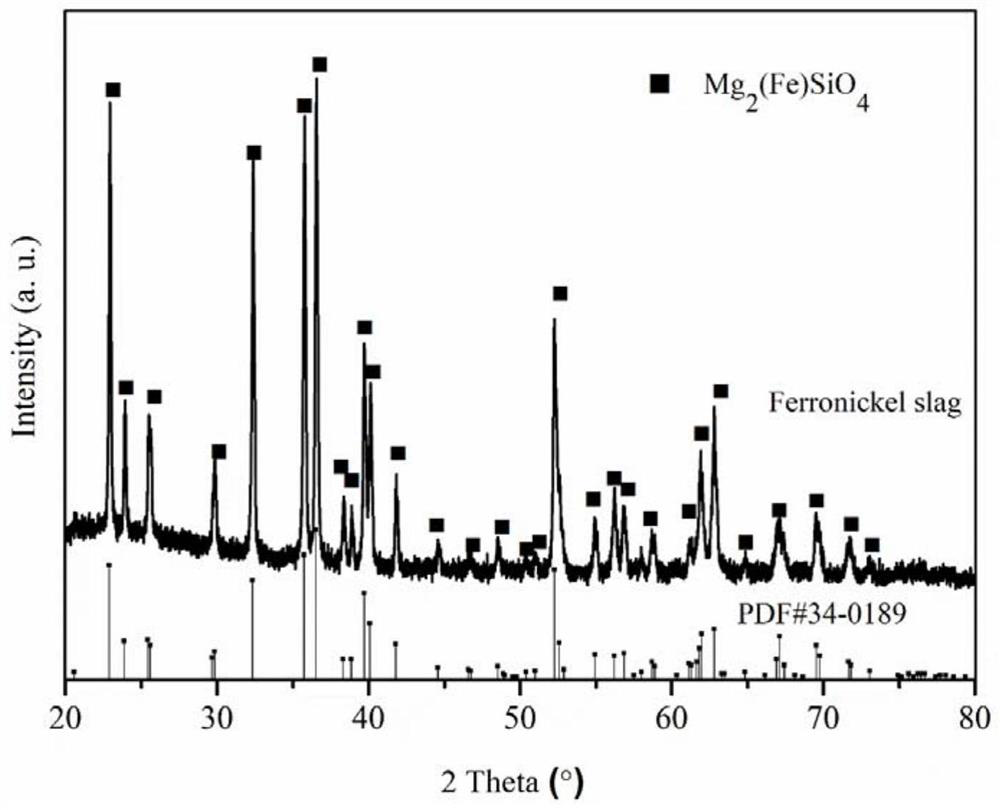

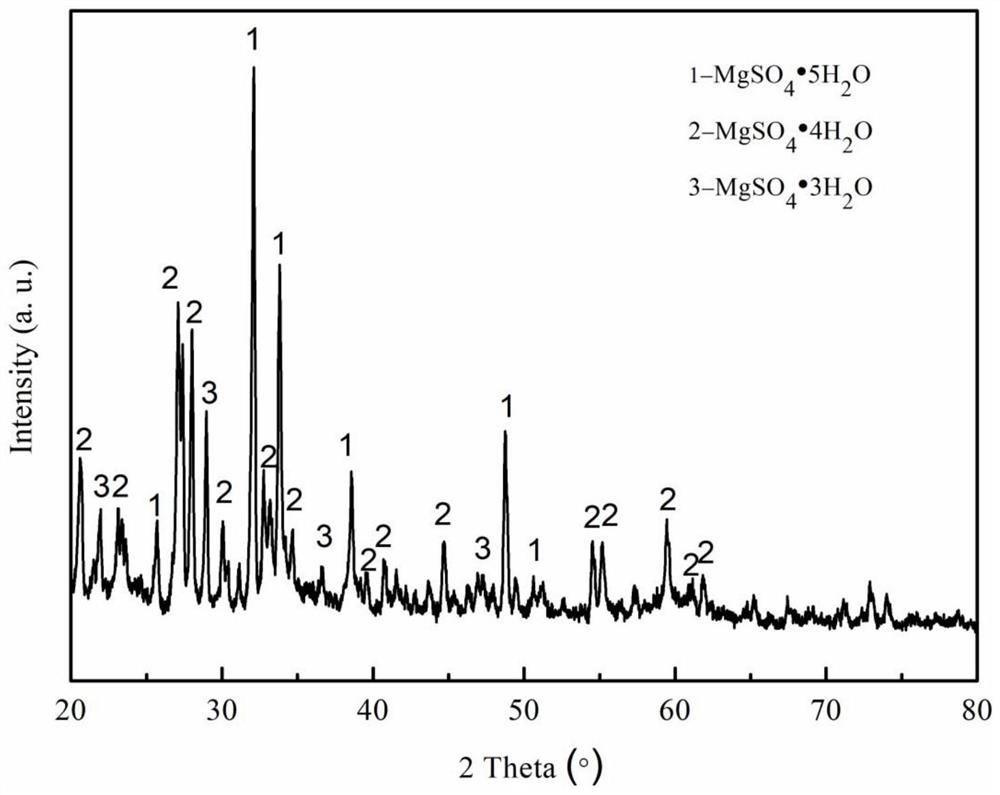

Method for recovering magnesium from ferronickel slag

ActiveCN111926193ASimple processEasy to operatePolycrystalline material growthFrom normal temperature solutionsChemical industrySeed crystal

The invention relates to the field of chemical industry, in particular to a method for recovering magnesium from ferronickel slag. The method comprises the following steps of impregnating the ferronickel slag in concentrated sulfuric acid at normal pressure, adding a seed crystal, and crystallizing to precipitate magnesium sulfate. The magnesium in the ferronickel slag is converted into magnesiumsulfate for magnesium recovery through a full-wet process, the process is simple, operation is easy, the requirement for equipment is low, the magnesium recovery rate is high, the application range ofmagnesium sulfate is wide, the added value of products is high, and the comprehensive utilization rate of the ferronickel slag can be increased.

Owner:GUANGXI UNIV

Brewing technology of scilla scilloides wine

InactiveCN104946484AImprove utilization efficiencyAvoid churnAlcoholic beverage preparationFiltrationScilla scilloides

The invention discloses a brewing technology of scilla scilloides wine. The brewing technology is characterized in that: scilla scilloides is adopted as the raw material, and the scilla scilloides wine is brewed from the steps of raw material pretreatment, enzymolysis, blending, yeast activation, fermentation, mixing, ageing, clarification and filtration, filling and sterilization, and the like; after being diced, scilla scilloides is put in high-degree Baijiu to be soaked, so that nutrient substance loss is avoided; the soaked scilla scilloides is pulped and subjected to complex phosphoesterasum treatment, so that more nutrient substances of scilla scilloides are precipitated, and the utilization efficiency of scilla scilloides can be improved; after being aged, the scilla scilloides wine is clarified with a compound clarifier, so that the finished product, namely, the scilla scilloides wine, is stable in color and luster, transparent in wine body and soft in mouthfeel, and has various health care efficiencies of invigorating spleen-stomach and benefiting the liver, treating insomnia, strengthening muscles and bones, strengthening brain and benefiting thinking, activating blood circulation and reducing swelling, detoxifying and relieving pain, and the like.

Owner:李琪

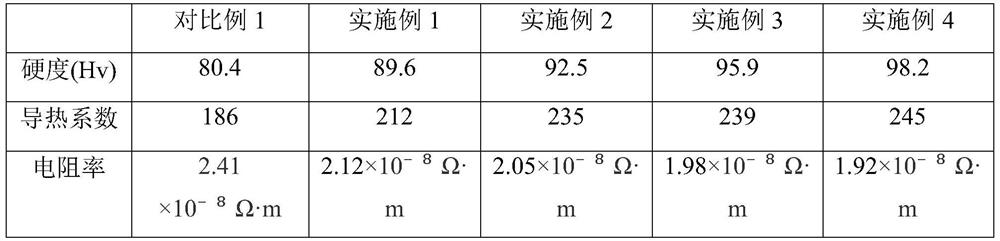

Aluminum alloy material with good conductivity and production method thereof

The invention discloses an aluminum alloy material with good conductivity and a production method thereof. Aluminum, an Al-B intermediate alloy, copper and silver are melted together, heat preservation treatment-rapid cooling is carried out, then heating-heat preservation treatment is carried out twice, a first treatment material is prepared, in the rapid cooling treatment and the heating-heat preservation treatment twice, more supersaturated solid solutions in an aluminum matrix are separated out, crystal lattices are distorted and recovered more thoroughly, the heat conduction performance and the electric conduction performance of the alloy are enhanced, a trace amount of titanium element is doped in the alloy, a small amount of TiAl2 is generated at an interface, a casting structure and a weld structure are refined, the mechanical property of the aluminum alloy material containing silver and a small amount of boron is improved, meanwhile, a trace amount of vanadium is added, the comprehensive mechanical property is improved, rhenium is added for secondarily refining crystal grains, precipitation of vanadium in crystals is reduced, boron, rhenium and vanadium achieve the composite effect, the conductivity of aluminum is promoted to be recovered in the annealing process of the alloy, a second phase of rhenium is enhanced, and therefore the influence on the conductivity of the alloy when the mechanical property is improved is reduced.

Owner:鹰潭市林兴建材有限公司

A fully automatic permeable brick production line

ActiveCN106272941BUniform thicknessHigh strengthCeramic shaping plantsFeeding arrangmentsProduction lineBrick

The invention provides a full-automatic water-permeable brick production line and relates to the technical field of building material production. The full-automatic water-permeable brick production line is used for producing high-quality double-layer water-permeable bricks. The full-automatic water-permeable brick production line is characterized by comprising a feeding system and a forming system; the feeding system comprises a first conveyor and a second conveyor; the forming system comprises a rack, a stamping device, a distributing device and a die device; the distributing device comprises a distributing frame and a distributor, and the distributing frame is connected to the rack in a sliding mode in the vertical direction; the die device comprises a first die plate and a second die plate, the first die plate is connected to the rack in a sliding mode in the vertical direction, and the second die plate is connected to the upper side of the first die plate in a sliding mode in the horizontal direction. The full-automatic water-permeable brick production line has the advantages that it can be guaranteed that the thicknesses of all layers of the produced double-layer water-permeable bricks are uniform, it is guaranteed that the upper layers and the lower layers are clearly separated, therefore, the strength and the water-permeable performance of the double-layer water-permeable bricks are improved, the service life of the double-layer water-permeable bricks is prolonged, and the advantage that one machine achieves multiple purposes is achieved.

Owner:SHANDONG JINYI GARDEN SHARES CO LTD

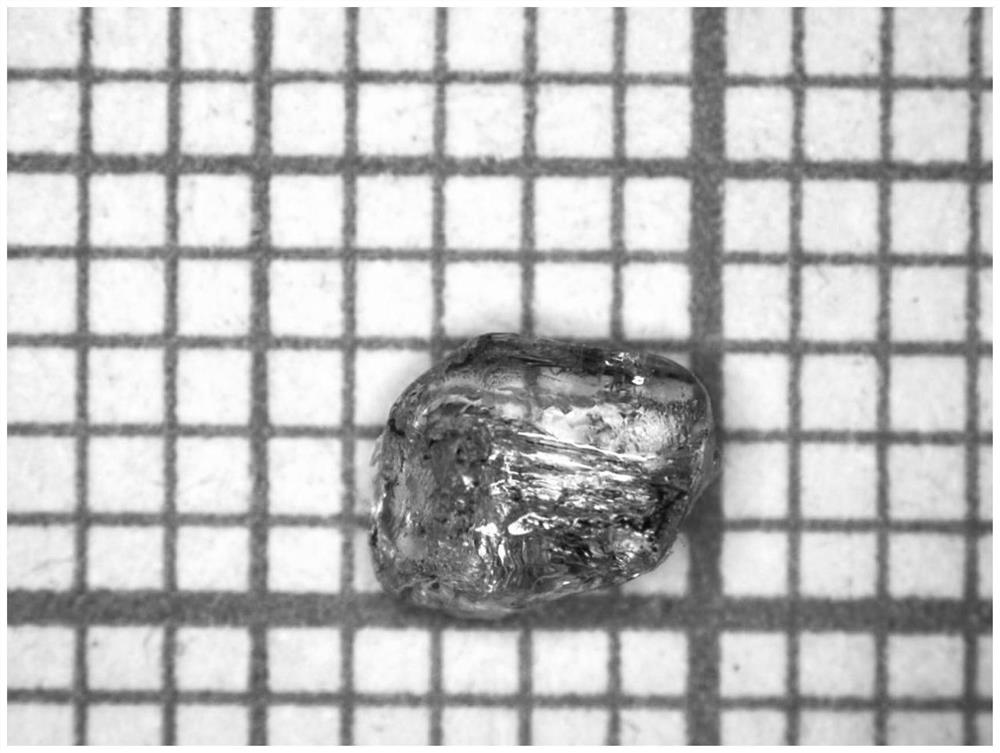

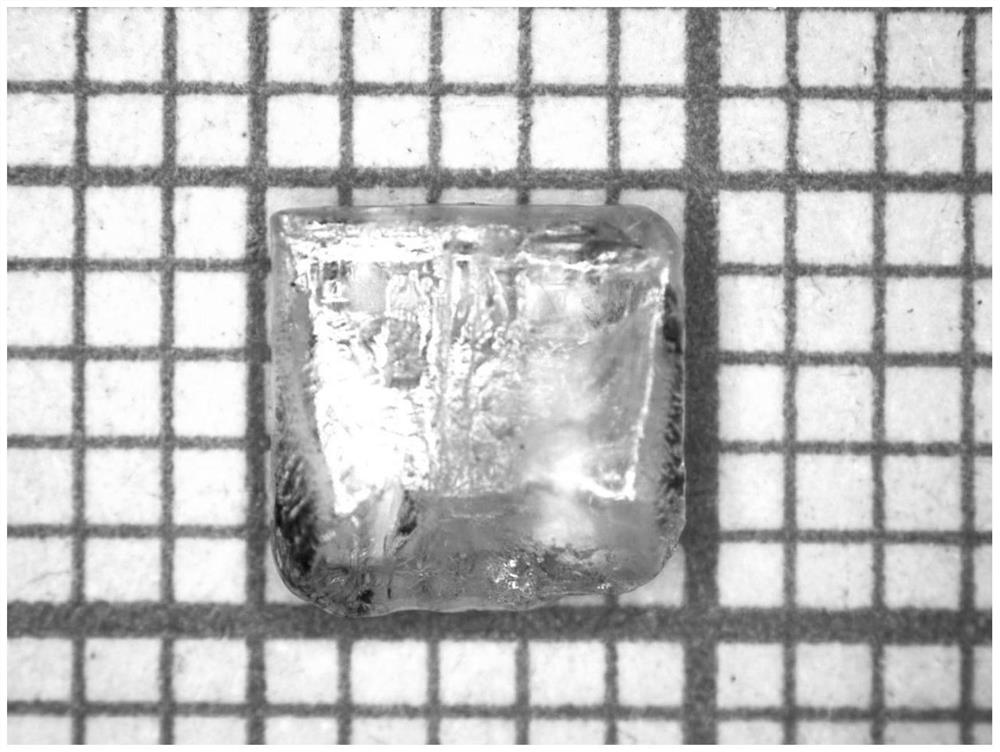

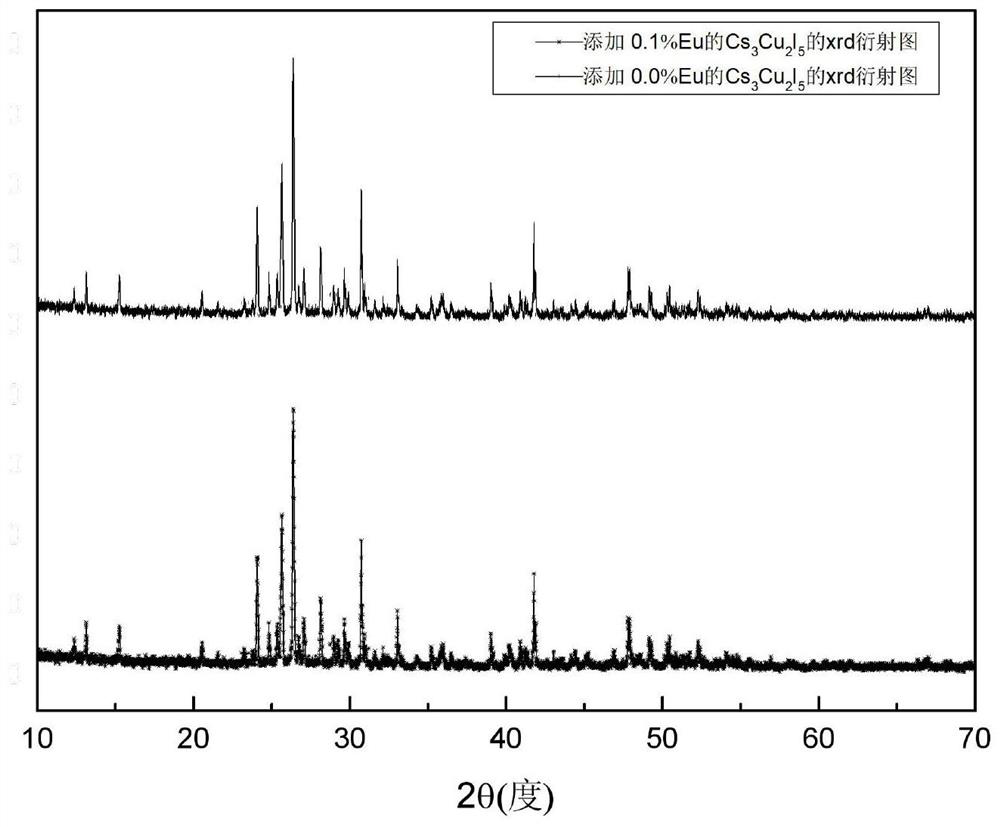

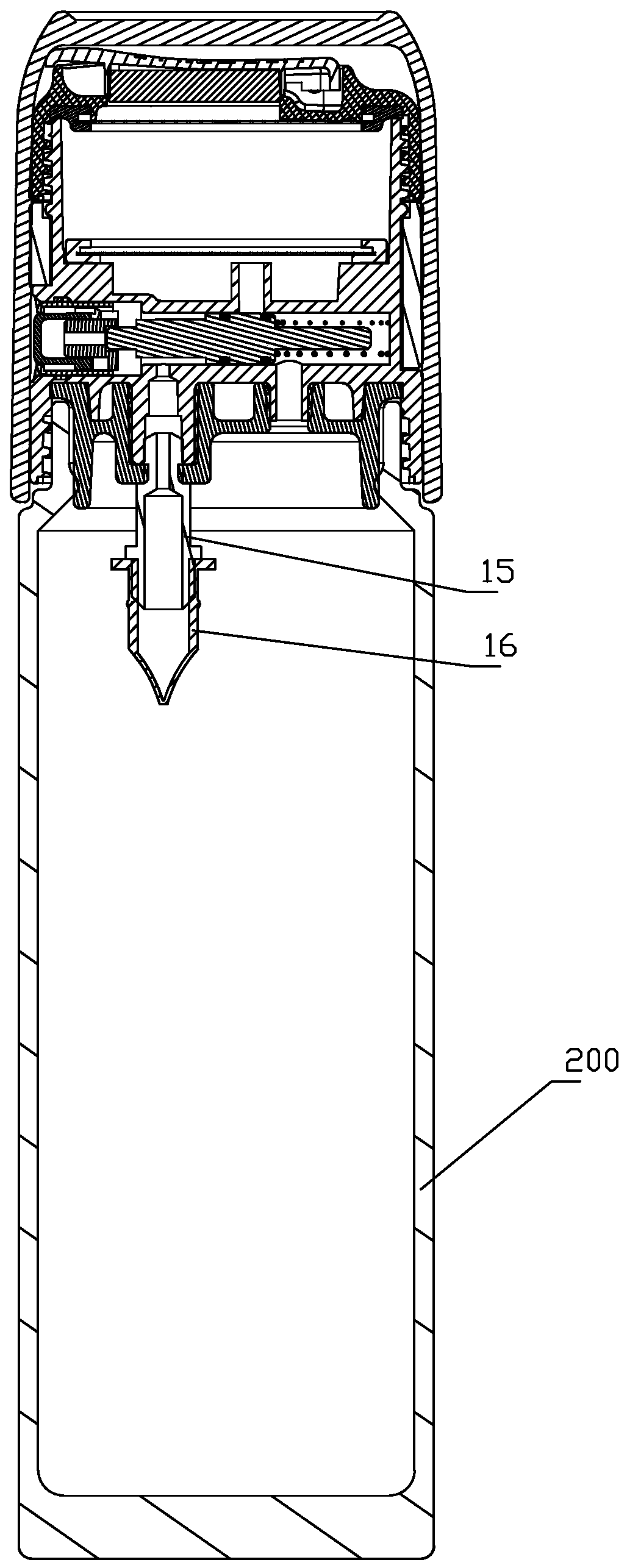

EuCl3-assisted growth method of Cs3Cu2X5 perovskite single crystal

InactiveCN113373501ASpeed up synthesis timePrecipitation stablePolycrystalline material growthFrom normal temperature solutionsSingle crystalLuminescence

The invention relates to an EuCl3-assisted growth method of a Cs3Cu2X5 perovskite single crystal. According to the method, CuX and CsX serve as raw materials, an organic mixed solution composed of methylformamide, dimethyl sulfoxide and methyl acetate serves as a crystal synthesis environment, EuCl3 is added at the temperature lower than 70 DEG C to assist growth, and high-quality Cs3Cu2X5 which is square in shape and remarkably improved in quantum efficiency is separated out. The Cs3Cu2X5 crystal grows on a hot plate at a constant temperature, has the characteristics of good crystal luminescence property, short manufacturing period, low cost, simple growth process, environmental friendliness and the like, and can be separated out within 24 hours.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

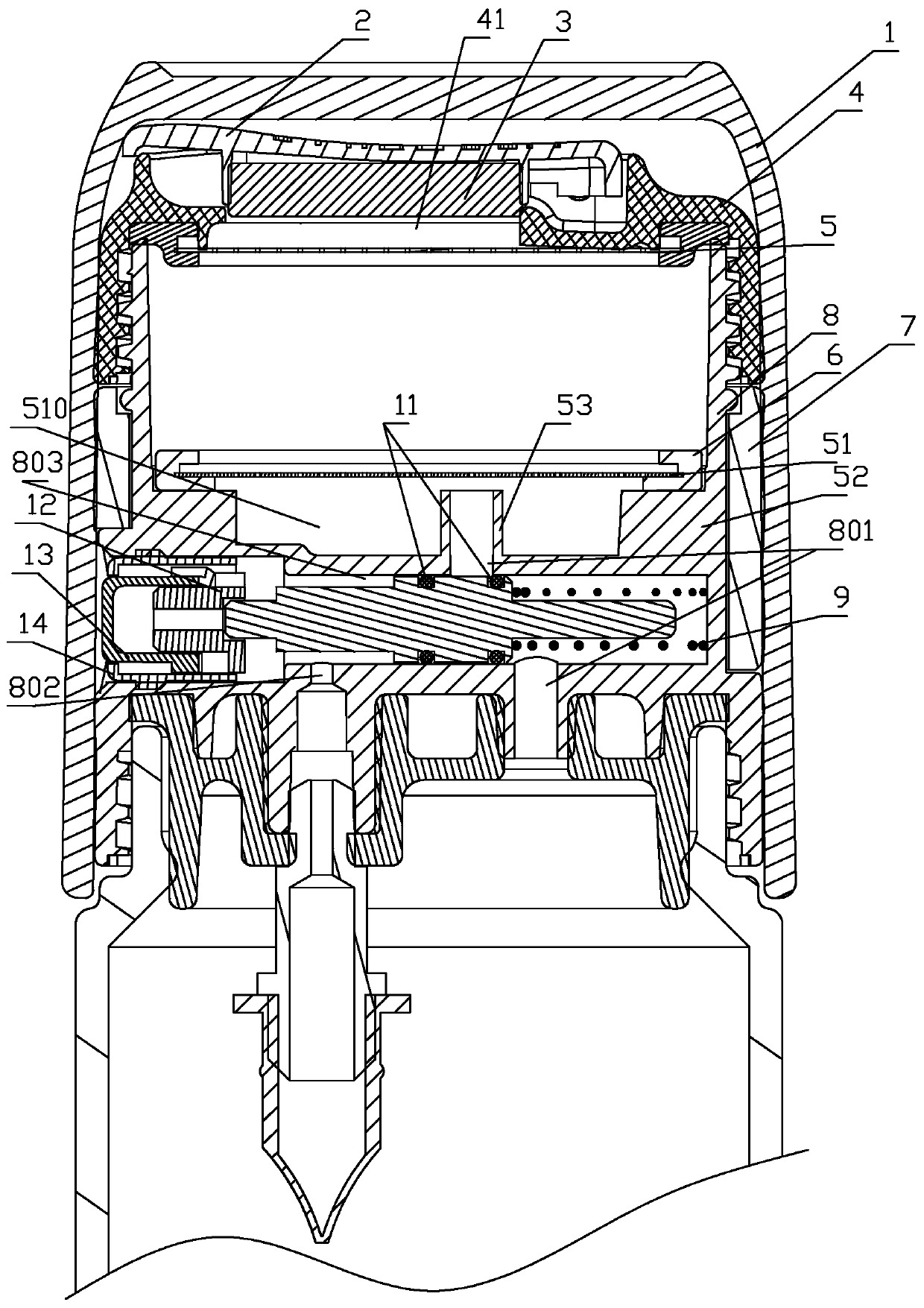

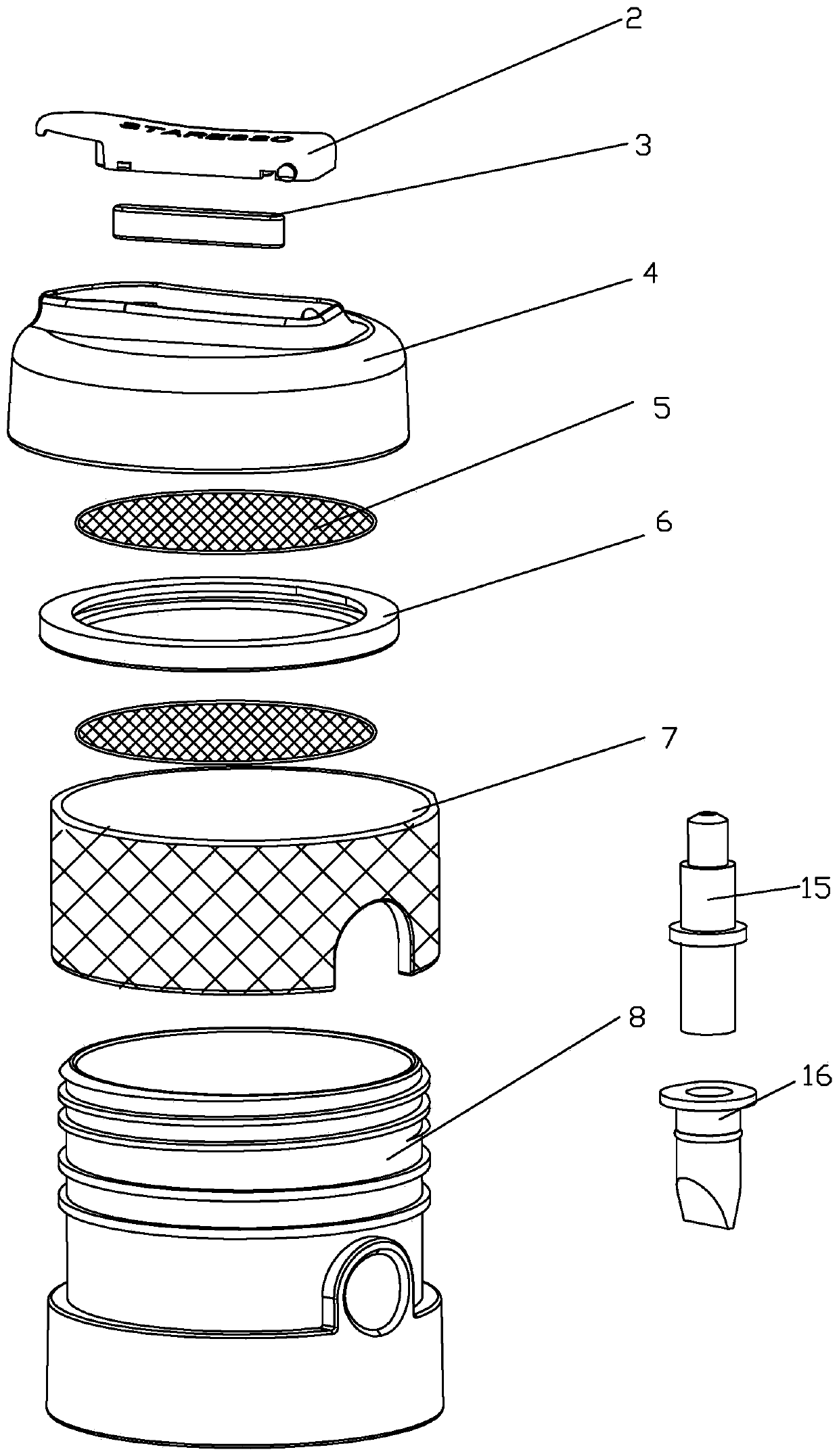

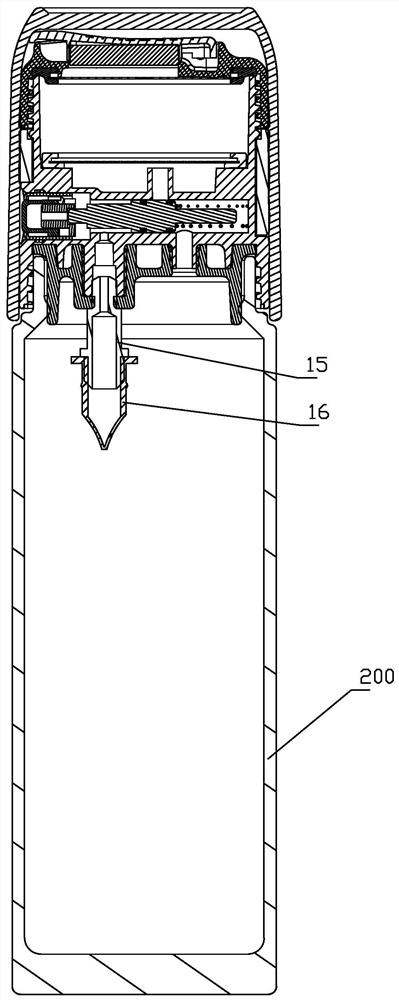

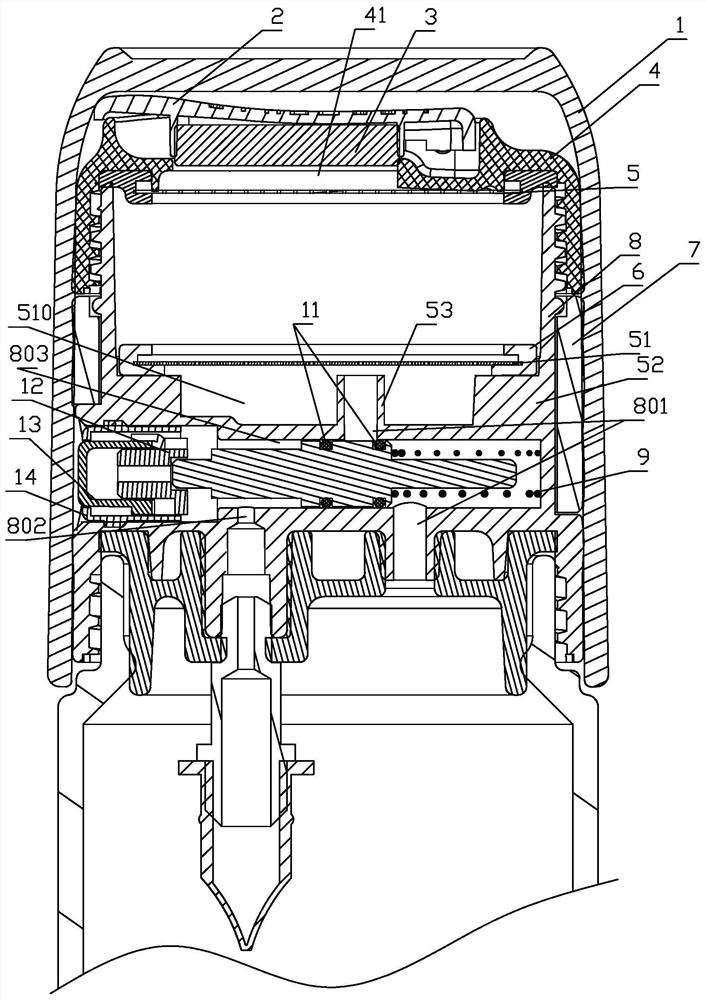

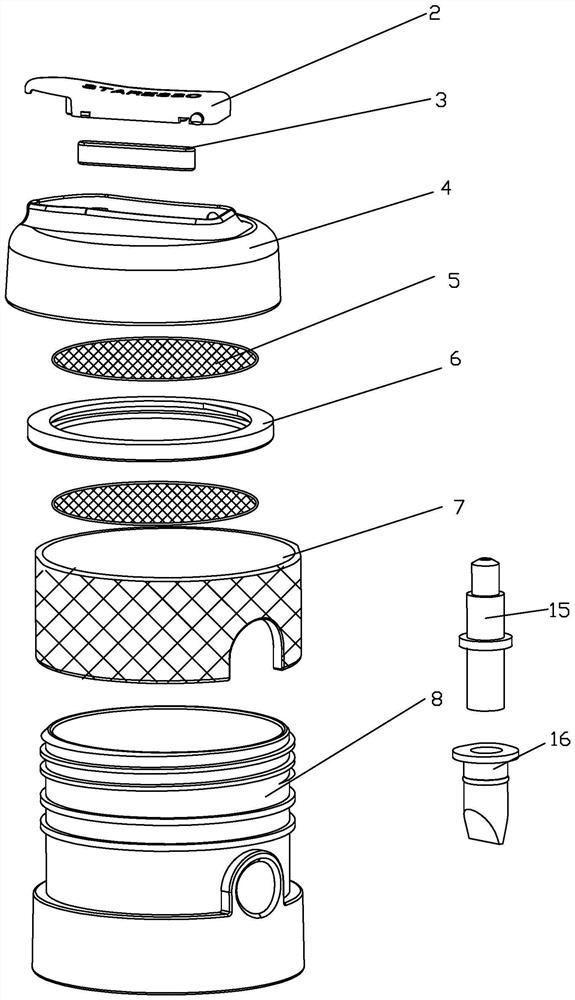

Running water form teacrema or coffee brewing pot

ActiveCN110664246ABarometric balanceGuaranteed no tea stainsBeverage vesselsDomestic vesselsHazardous substanceWater flow

The invention discloses a running water form teacrema or coffee brewing pot comprising a pot body, a pot cover body and a tea powder cover, and a control mechanism capable of closing or opening a water flow channel is arranged on the pot cover body; the control mechanism controls the water flow channel and air inflow of an air inlet system separately; a first layer of filter screen is arranged ina container space; a water dispersion component capable of dispersing water entering the container space through the water flow channel is arranged in the container space; a tea outlet is located above the first layer of filter screen; and the end, located in the pot body, of a conduit is connected with a one-way valve capable of allowing air to flow into the pot body only, and automatic air inflow of the air inlet system is realized. The balance of air pressure in the pot body can be maintained, no negative pressure is generated, and the water outflows smoothly. Residual water can be prevented from remaining in the container space. The air inlet system, the water flow control structure and the tea outlet structure form a smooth running-water teacrema system, the excellent flavor components in the tea or coffee are extracted effectively and accurately, and excessive foreign flavor and harmful substances are avoided from being separated out.

Owner:SHENZHEN STARESSO CULTURE CO LTD

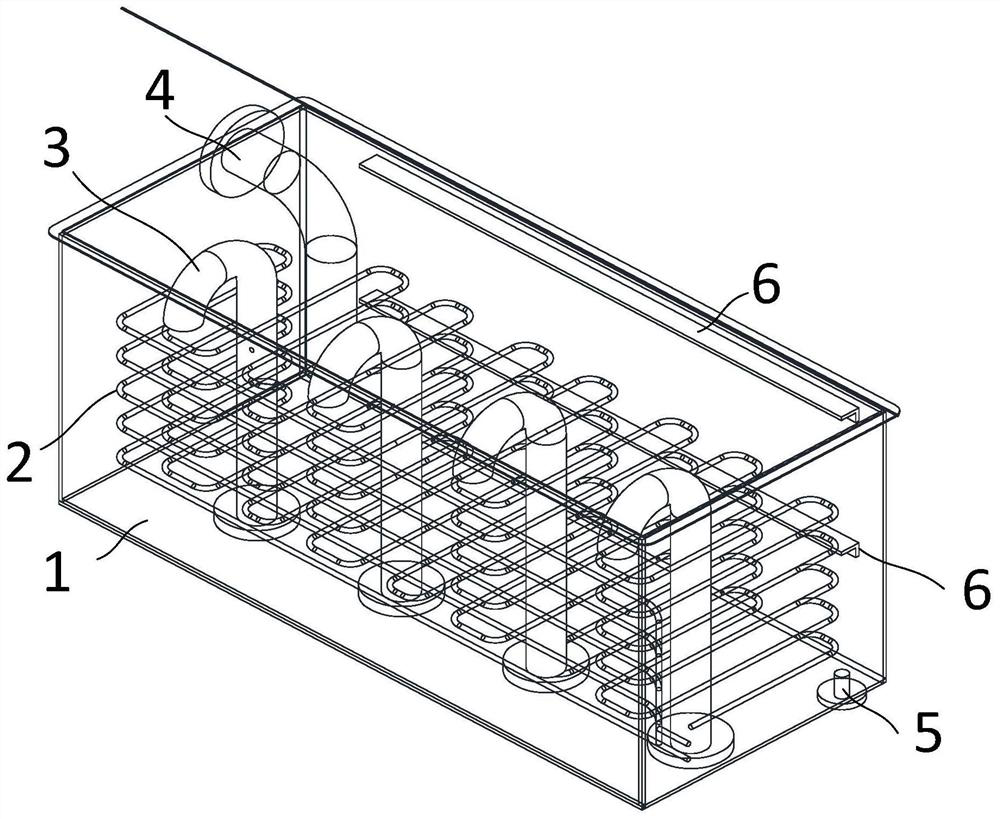

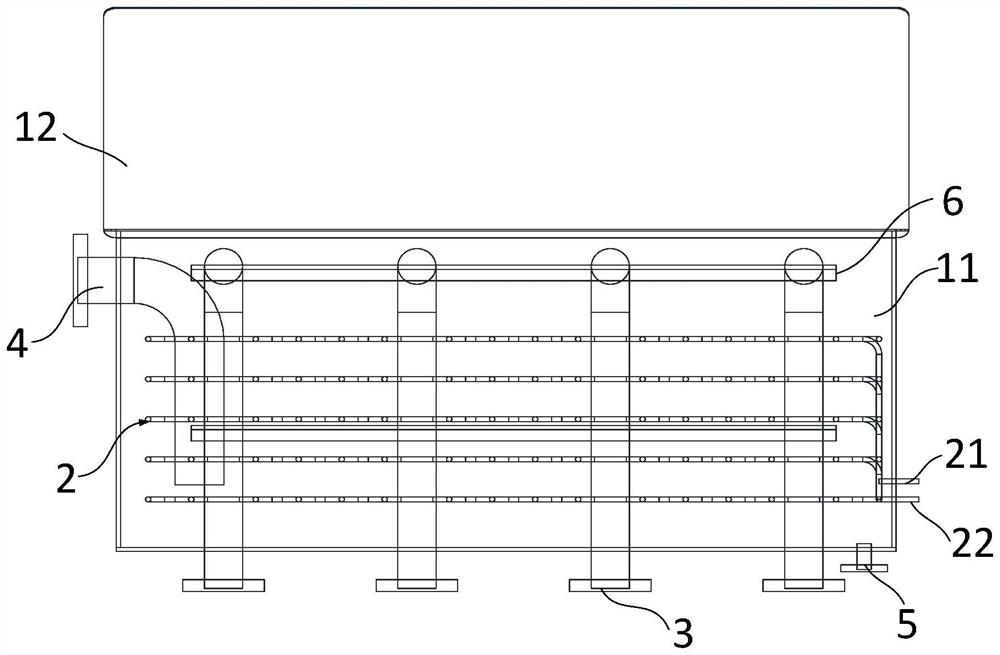

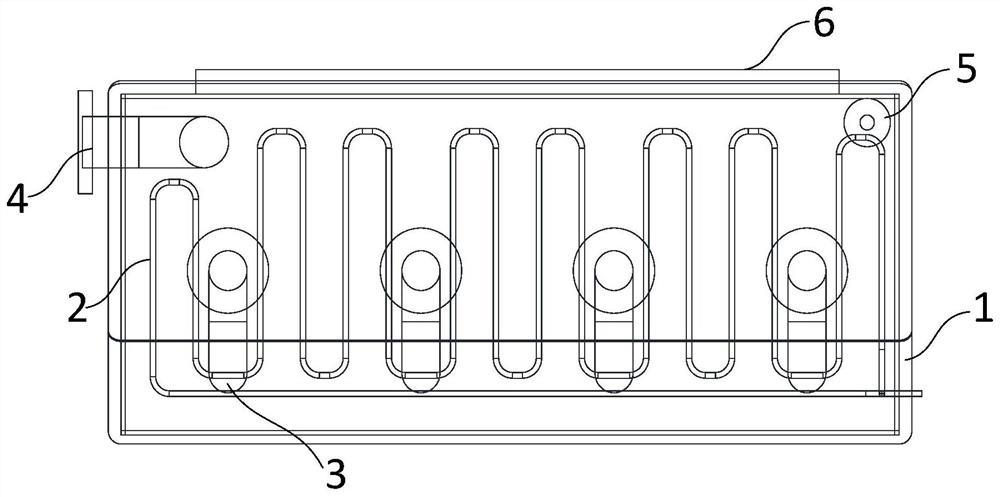

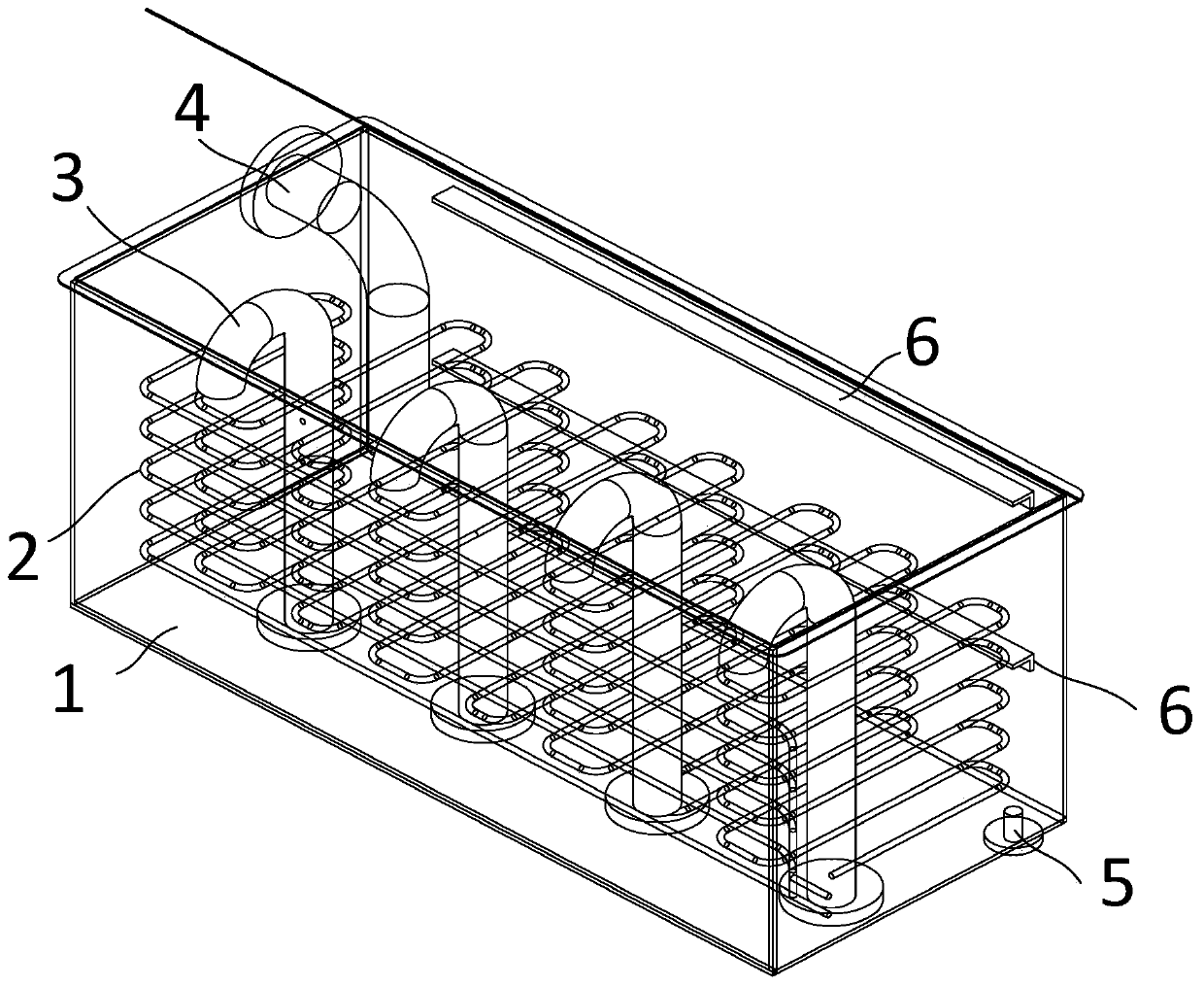

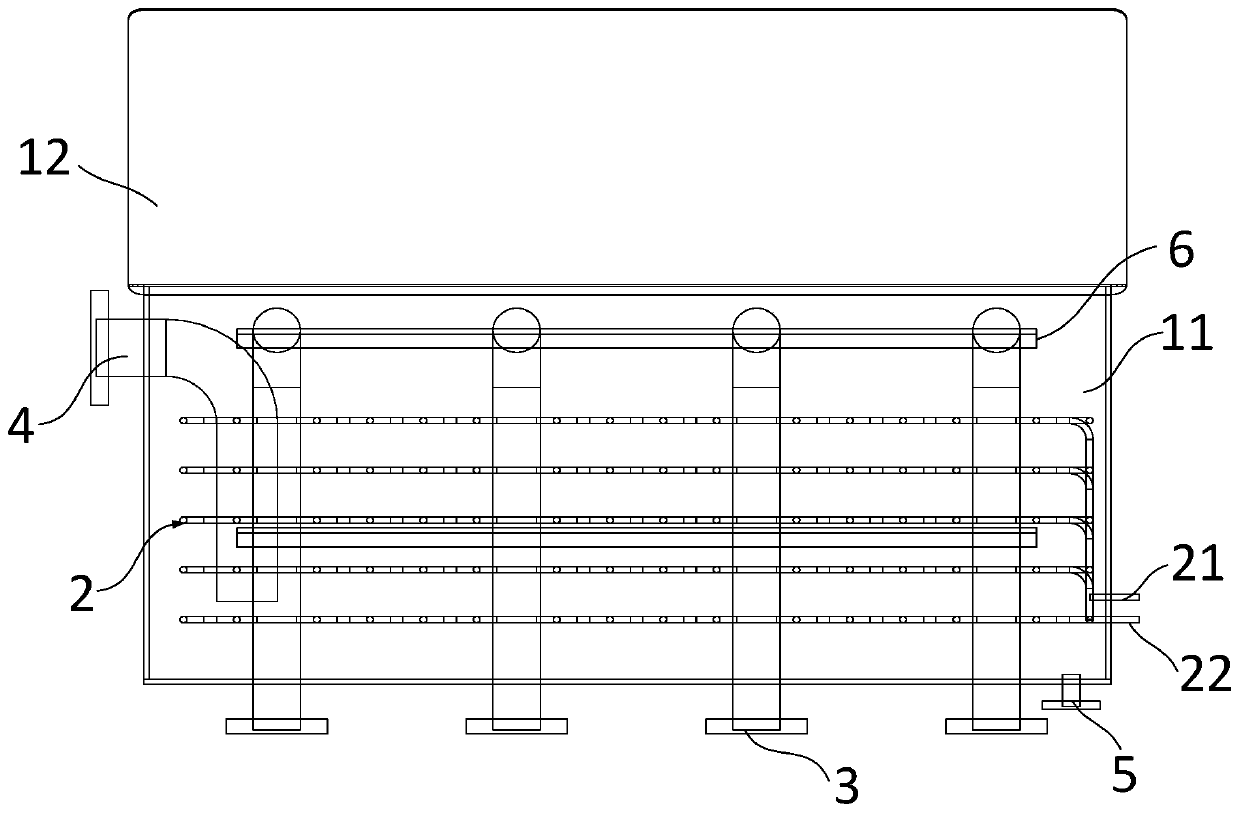

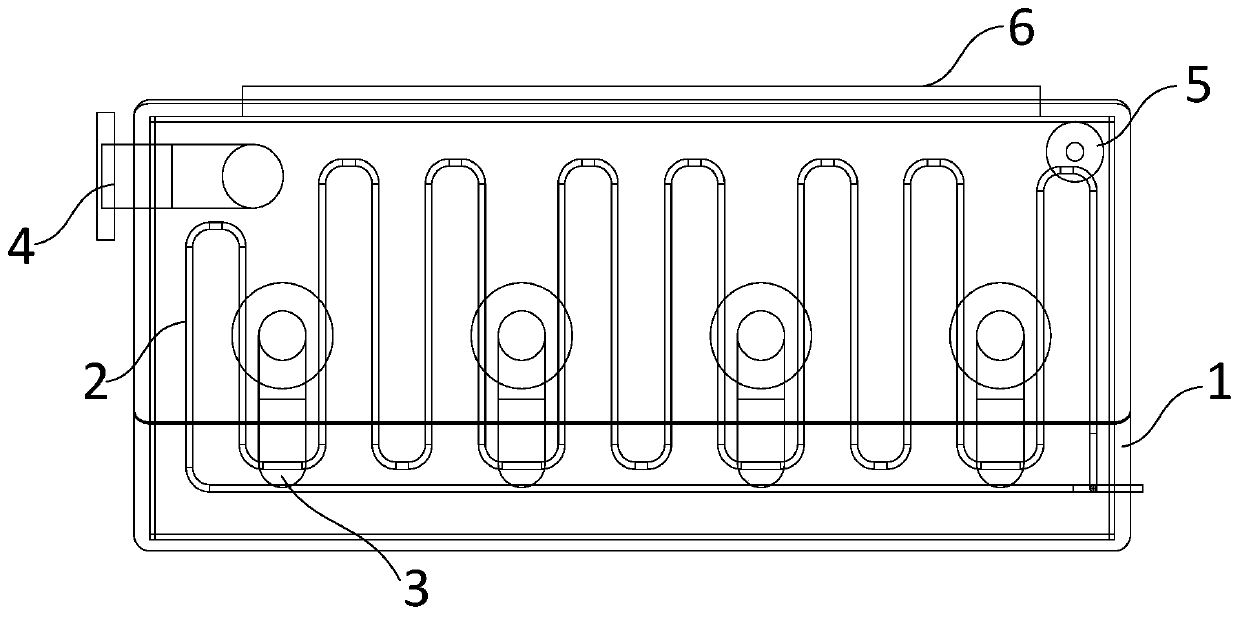

Condenser

ActiveCN109966772BReduce the temperatureImprove cooling effectVapor condensationThermodynamicsEngineering

Owner:SHANGHAI WAIGAOQIAO SHIP BUILDING CO LTD

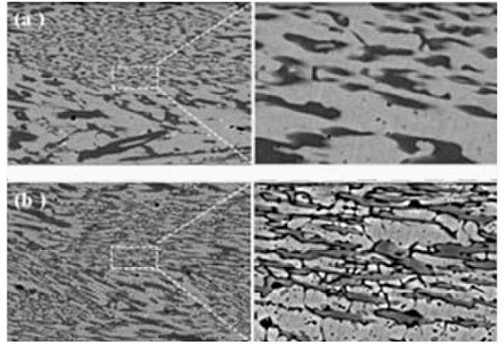

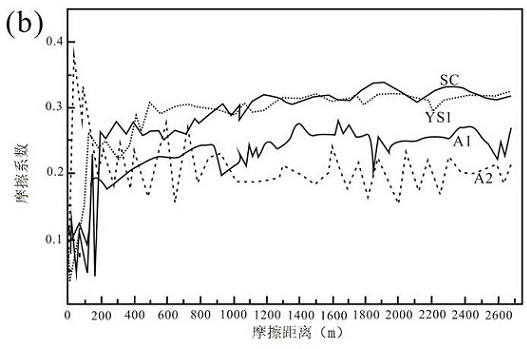

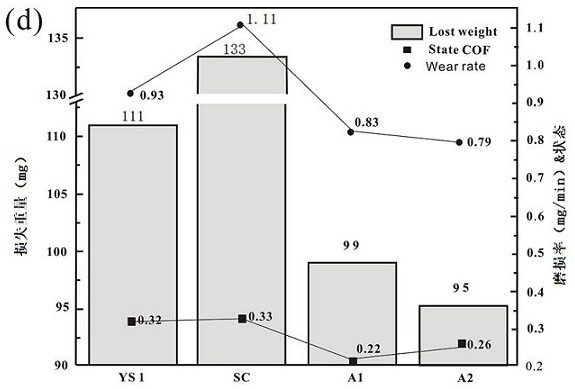

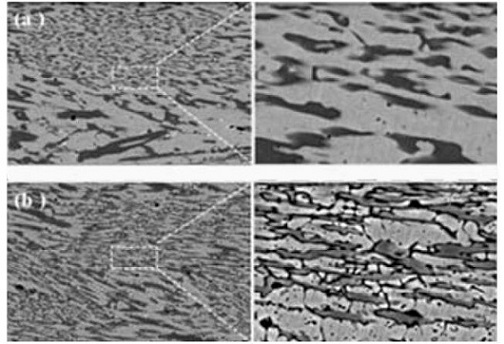

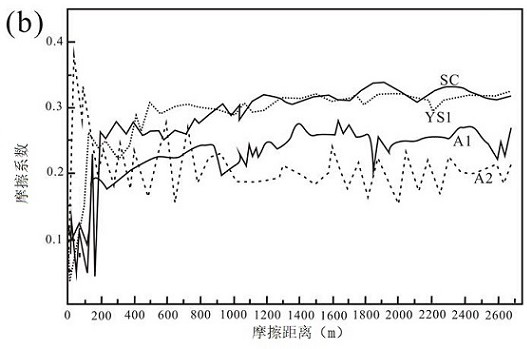

Preparation method of slurry pump cylinder sleeve

ActiveCN114164318AIncreased inner surface hardnessReduce toughnessPositive displacement pump componentsFurnace typesWear resistanceMachining

The invention relates to the technical field of cylinder sleeve machining, in particular to a slurry pump cylinder sleeve manufacturing method which comprises the steps that firstly, a cylinder sleeve inner container is subjected to rough machining; secondly, the cylinder sleeve inner container obtained after rough machining is subjected to heat treatment; thirdly, the cylinder sleeve inner container subjected to magnetic field heat treatment in the second step is machined and polished; and fourthly, after the cylinder sleeve outer sleeve is heated to 400-500 DEG C, the cylinder sleeve outer sleeve and the polished cylinder sleeve inner container are subjected to embedding and machining, and then the slurry pump cylinder sleeve is obtained. The surface hardness and wear resistance of the prepared inner container are improved, the hardness of the double-metal cylinder sleeve is improved from 58-61 HRC to 63-64 HRC, and meanwhile the toughness and other mechanical properties of the prepared cylinder sleeve are improved.

Owner:东营天工石油工程技术有限公司

A kind of method of recovering magnesium from nickel iron slag

ActiveCN111926193BIncrease profitHigh recovery ratePolycrystalline material growthFrom normal temperature solutionsChemical industrySlag

The invention relates to the field of chemical industry, in particular to a method for recovering magnesium from ferronickel slag, which comprises the steps of immersing the ferronickel slag in concentrated sulfuric acid at atmospheric pressure, adding crystal seeds, and crystallizing out magnesium sulfate. The magnesium in the ferronickel slag is converted into magnesium sulfate for recovery of magnesium by adopting the all-wet process. The process is simple, easy to operate, requires low equipment, and has a high recovery rate of magnesium. Magnesium sulfate has a wide range of applications and high added value. It can improve the comprehensive utilization rate of nickel-iron slag.

Owner:GUANGXI UNIV

A production process of high-strength and high-elongation ductile iron castings

ActiveCN104878275BAvoid burnsQuality improvementProcess efficiency improvementElectric arc furnaceHigh intensity

The invention discloses a production technology for a ductile iron casting with high strength and high ductility. The production technology comprises the following steps: 1, adding 18-22 parts of steel scrap into an electric furnace for smelting, adding 58-62 parts of foundry returns, and finally, adding 0.5 part of a structure modifier and 18-22 parts of pig iron at the same time for smelting, so as to obtain raw molten iron; 2, adding a nodulizing agent into a nodulizing chamber of a nodulizing ladle, and coating the nodulizing agent with a nucleating agent, covering the nucleating agent with a silicon steel sheet, and finally, adding the structure modifier into the nodulizing ladle; 3, enabling the raw molten iron of which the temperature is controlled to be 1460-1480 DEG C in the electric furnace to react in the nodulizing ladle, so as to obtain final molten iron; 4, pouring the final molten iron for casting, and cooling, so as to obtain the ductile iron casting. According to the invention, the burning loss of crystal cores in molten iron can be prevented, the quality of molten iron is improved, and the ductility and strength can be greatly improved.

Owner:江苏力源金河铸造有限公司

Condensation device

ActiveCN109966772AReduce manual operationsReduce the temperatureVapor condensationEngineeringBuoyancy

The invention discloses a condensation device. The device comprises a condensation box, a condensation coil pipe and a ventilation pipeline; the condensation box comprises a box body and a cover plate, the condensation coil pipe is located in the condensation box, a condensation liquid fills the condensation coil pipe for cooling oil mist in the condensation box, and the ventilation pipeline is located in the condensation box for making the oil mist enter the condensation box and discharged from the condensation box; and the condensation device further comprises a release valve for dischargingcondensed oil in the condensation box, the release valve is a float ball stop valve, and when buoyancy of a float ball by the condensed oil is greater than gravity, the release valve is opened. The condensation device provided by the invention can keep the temperature in the condensation box lower, accelerate cooling of the oil mist, and enable oil gas to be precipitated more and faster; a mutualposition between the ventilation pipeline and the condensation pipeline also allows the oil mist to be more contact with the condensation pipe; and when the condensed oil is accumulated to a certainheight, the condensed oil can be automatically discharged through the release valve, so that manpower is saved, and the device is more convenient.

Owner:SHANGHAI WAIGAOQIAO SHIP BUILDING CO LTD

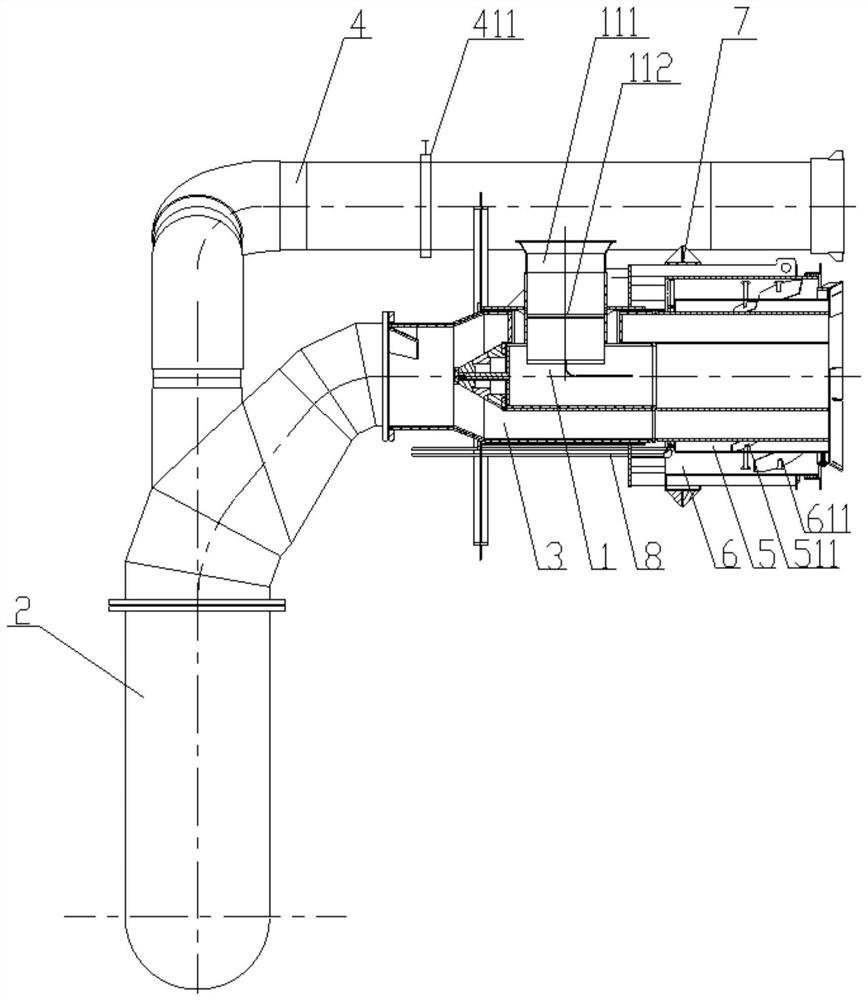

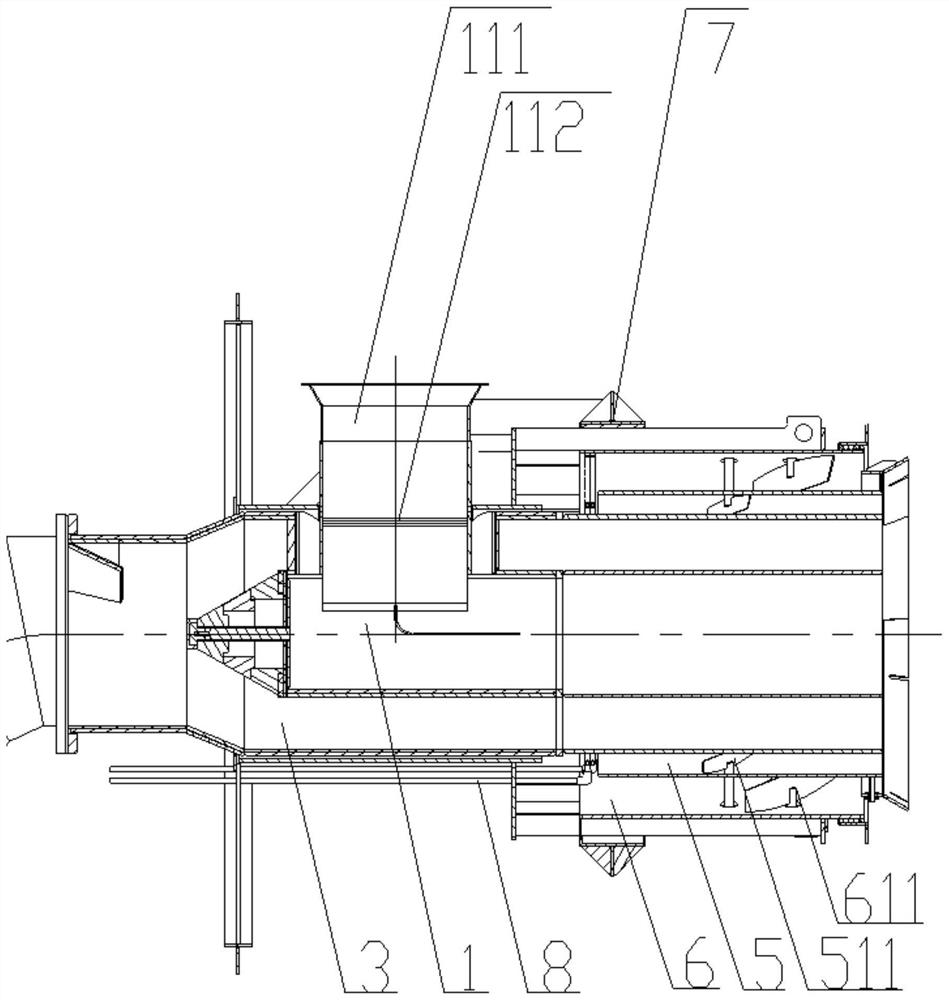

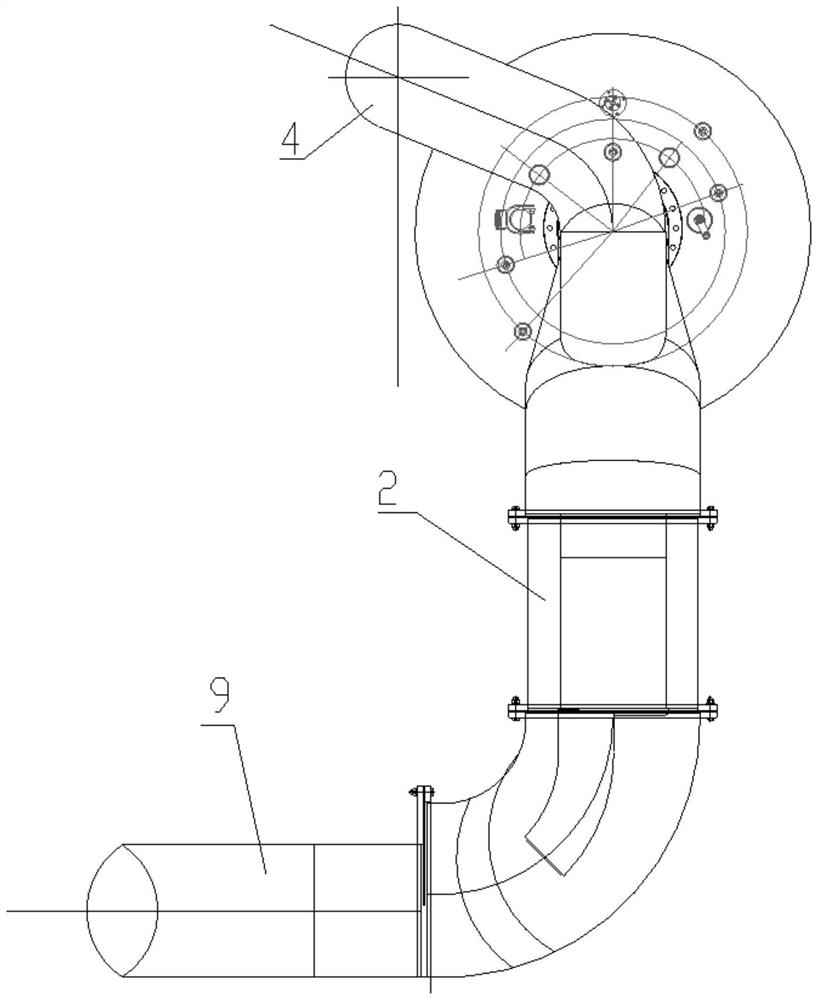

Concentrated low-nitrogen dual channel swirl burner with central air

PendingCN112781036AImprove adaptabilityGood adaptability across coal typesPulverulent fuel combustion burnersProcess engineeringCoal

The invention discloses a concentrated low-nitrogen dual channel swirl burner with central air. The burner comprises a dual channel swirl nozzle area with one communicating with a combustion furnace and comprising a central air channel, a primary air channel, an inner secondary air channel and an outer secondary air channel which are sequentially sleeved from inside to outside, an exhaust air channel with one end further communicating with the combustion furnace, and further provided with an air volume adjusting valve, and a pulverized coal concentration part, wherein a common inlet of pulverized coal primary air is formed in one end of the pulverized coal concentration part, and the other end of the pulverized coal concentration part communicates with the other ends of the primary air channel and the exhaust air channel separately. The burner disclosed by the invention is high in adaptability across coal types, high in combustion efficiency, good in stable combustion effect, good in low-nitrogen effect and good in anti-coking performance, and the win-win of environment and economic benefits is achieved.

Owner:TRANSTEK IND HK LTD KOWLOON

Manufacturing process of a high-strength aluminum alloy ring forging

ActiveCN106363352BImprove the problem of low mechanical propertiesAchieve productionNumerical controlHigh intensity

The invention relates to a manufacturing process of a high-strength aluminum alloy ring forge. The manufacturing process comprises the following operation steps of blank purchasing, blank cut-off, heating of the forge, blank forming, machining of an inner hole, heating, broaching of a mandrel supporter, return heating, ring milling, cooling, curing, cold deformation, aging and machining to the required dimension. Through combination of the multiway improving forging technology, the mandrel supporter broaching technology, the lubricating technology, the numerical control ring-milling technology, the high-intensity thermal treatment technology and the cold deformation technology, the problems that an existing aluminum alloy ring forge is low in overall performance, nonuniform in mechanical property, obvious in anisotropism and the like.

Owner:WUXI PAIKE HEAVY CASTING & FORGING

A kind of preparation method of mud pump cylinder liner

ActiveCN114164318BIncreased inner surface hardnessToughness does not decreasePositive displacement pump componentsFurnace typesThermodynamicsEngineering

The invention relates to the technical field of cylinder liner processing, in particular to a method for preparing a mud pump cylinder liner. Step 1: Roughly process the cylinder liner liner; Step 2: Perform heat treatment on the rough-processed cylinder liner liner; Step 3 1. Process and polish the cylinder liner liner after the magnetic field heat treatment in step 2; step 4, heat the cylinder liner coat to 400-500°C and install and machine the polished cylinder liner liner to obtain the mud pump cylinder liner. The surface hardness and wear resistance of the liner prepared by the present invention are improved, and the hardness of the bimetallic cylinder liner is increased from the existing 58-61HRC to 63-64HRC. At the same time, the toughness and other mechanical properties of the cylinder liner prepared by the present invention are improved. .

Owner:东营天工石油工程技术有限公司

Compound mineral crystals for improving water quality, enhancing immunity, and benefiting cardiovascular and cerebrovascular diseases and preparation method thereof

InactiveCN106219720BIncrease surface areaImprove adsorption capacityWater contaminantsWater/sewage treatment by substance additionWater qualityMaterials science

The invention discloses a composite mineral crystal capable of improving water quality, strengthening immunity and facilitating cardiovascular and cerebrovascular diseases. The composite mineral crystal is prepared from the following components in parts by weight: 10 to 15 parts of medical stone, 5 to 10 parts of wooden fish stone, 5 to 10 parts of tourmaline, 30 to 55 parts of activated zeolite, 5 to 10 parts of celestite and 15 to 40 parts of kaolin. Meanwhile, the invention provides a preparation method of the composite mineral crystal. The surface area of the composite mineral crystal is increased by using supplementary strontium element of the added celestite and a secondary honeycomb wrapping burning technology, and the mineralization speed and effect are greatly improved, so that the precipitation of trace elements, particularly the precipitation of the strontium element, is more abundant, heavy metals are absorbed, and the composite mineral crystal has the effects of promoting metabolism, strengthening immunity, improving water quality and facilitating cardiovascular and cerebrovascular diseases.

Owner:刘乙霄

Flowing tea or coffee maker

ActiveCN110664246BBarometric balanceGuaranteed no tea stainsBeverage vesselsDomestic vesselsHazardous substanceWater flow

Owner:SHENZHEN STARESSO CULTURE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com