Ignition method and apparatus for fossil fuel

A technology for fossil fuels and fuels, applied in combustion methods, non-flammable liquid/gas transportation, combustion equipment, etc., can solve the problems of large oxygen consumption, poor economy, and unsatisfactory fuel-saving effect, and achieve low oxygen consumption. , Increase the effect of early ignition, improve pyrolysis and reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The principle, working process and implementation of the present invention will be further described below in conjunction with the accompanying drawings.

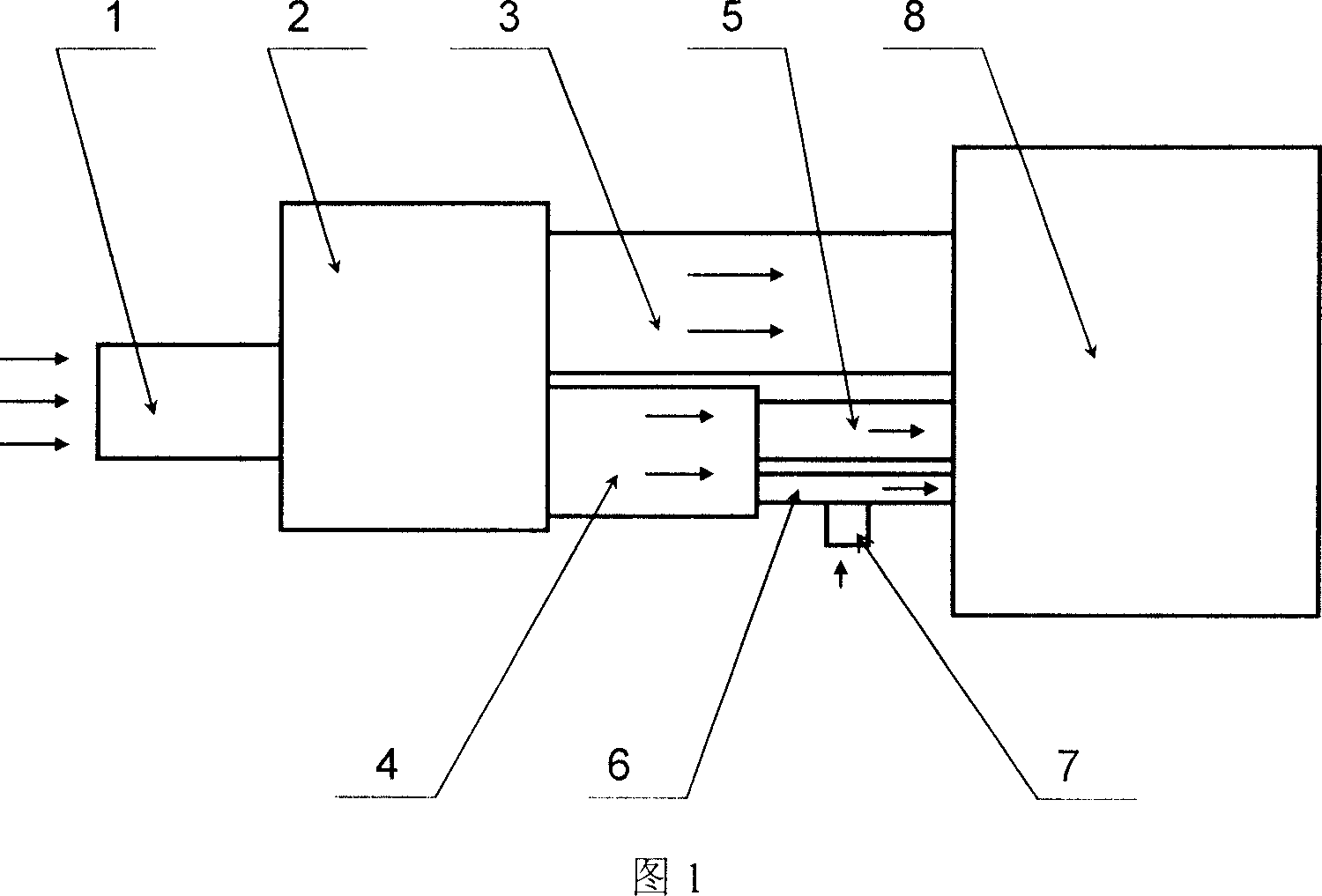

[0015] Fig. 1 is a schematic diagram of the structure and principle of the embodiment provided by the present invention. It mainly includes a primary air duct 1, a thick and light separation device 2, a light powder airflow channel 3, a concentrated powder airflow main channel 4, a large concentrated powder airflow channel 5, a small concentrated powder airflow channel 6, and a small concentrated powder airflow channel 6 Connected oxygen inlet channel 7 and combustion chamber 8 .

[0016] Working process of the present invention is as follows:

[0017] Before the primary air flow carrying powdered fuel enters the combustion chamber 8, it is properly separated by the concentration separation device 2, and is divided into two strands of thick and thin. Generally, the amount of pulverized coal in the thick strand accou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com