Golden buckwheat rhizome extract, pharmaceutical preparation containing golden buckwheat rhizome extract and preparation method thereof

A technology of extract and golden buckwheat, which is applied in the field of golden buckwheat extract to achieve the effects of fine shape, good absorption and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

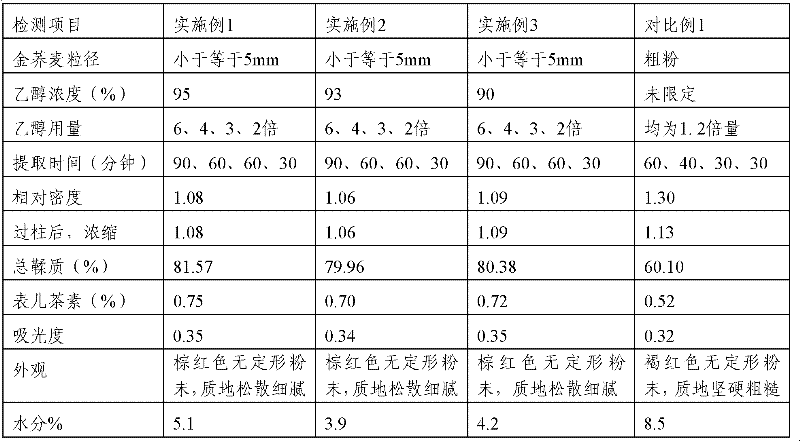

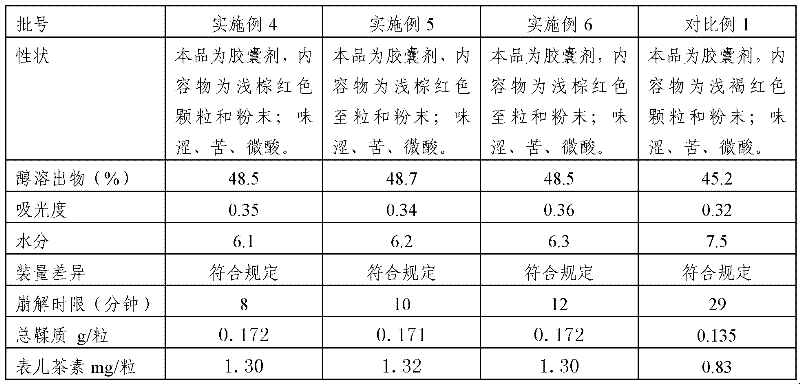

[0058] Example 1: Golden buckwheat extract

[0059] 1. Extraction method: Take 14430g of golden buckwheat, crush it into particles with a particle size less than or equal to 5mm, and extract it with 95% ethanol under reflux for four times, and the quality of the extraction solvent is 6, 4, 3, 2 times, the extraction time is 90, 60, 60, and 30 minutes in sequence, the extracts are combined, filtered, and the filtrate is concentrated under reduced pressure below 60°C to a relative density of 1.08 (55°C); add 20 times the amount of extract with water, mix Suspended and left standing overnight; the supernatant was filtered and separated by macroporous adsorption resin column chromatography; first eluted with water until the effluent was colorless, then eluted with 80% ethanol until the eluent was tested with ferric chloride Until there is no reaction in the solution, the 80% ethanol eluate is collected, concentrated under reduced pressure below 60° C. to a relative density of 1.08...

Embodiment 2

[0084] Example 2: Golden buckwheat extract

[0085]1. Extraction method: Take 14430g of golden buckwheat, crush it into particles with a particle size less than or equal to 5mm, and extract it with 93% ethanol under reflux for four times, and the quality of the extraction solvent is 6, 4, 3, 2 times, the extraction time is 90, 60, 60, and 30 minutes in sequence, the extracts are combined, filtered, and the filtrate is concentrated under reduced pressure below 60°C to a relative density of 1.06 (55°C); add 20 times the amount of extract with water, mix Suspended and left standing overnight; the supernatant was filtered and separated by macroporous adsorption resin column chromatography; first eluted with water until the effluent was colorless, then eluted with 80% ethanol until the eluent was tested with ferric chloride Until there is no reaction in the solution, the 80% ethanol eluate is collected, concentrated under reduced pressure below 60° C. to a relative density of 1.06 ...

Embodiment 3

[0096] Example 3: Golden buckwheat extract

[0097] 1. Extraction method: take 14430g of golden buckwheat, crush it into particles with a particle size less than or equal to 5mm, and extract it with 90% ethanol under reflux for four times, and the quality of the extraction solvent is 6, 4, 3, 2 times, the extraction time is 90, 60, 60, and 30 minutes in sequence, the extracts are combined, filtered, and the filtrate is concentrated under reduced pressure below 60°C to a relative density of 1.09 (55°C); add 20 times the amount of extract with water, mix Suspended and left standing overnight; the supernatant was filtered and separated by macroporous adsorption resin column chromatography; first eluted with water until the effluent was colorless, then eluted with 80% ethanol until the eluent was tested with ferric chloride Until there is no reaction in the solution, the 80% ethanol eluate is collected, concentrated under reduced pressure below 60° C. to a relative density of 1.09...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com