A production process of high-strength and high-elongation ductile iron castings

A technology with high elongation and production technology, which is applied in the direction of improving process efficiency, can solve problems such as low performance, and achieve the effects of improving molten iron quality, preventing burning loss, and increasing elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

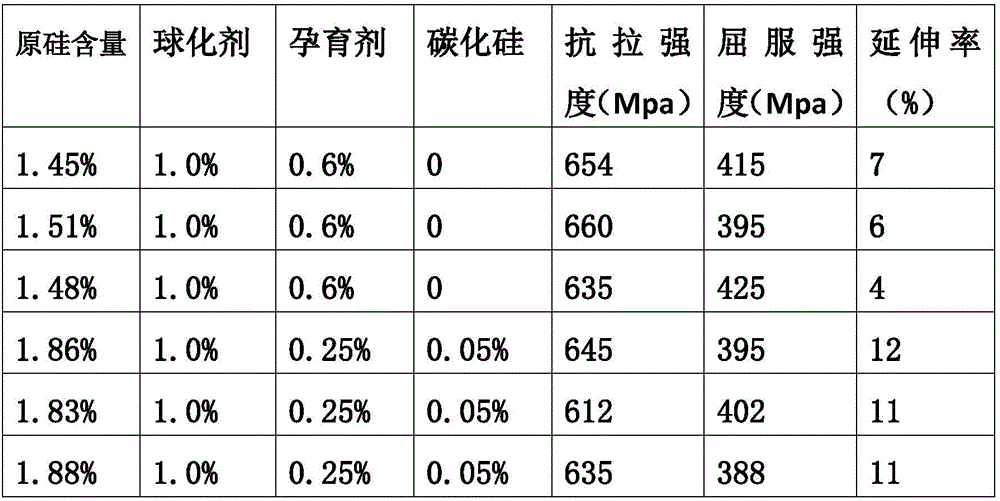

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the examples, but not as a basis for limiting the present invention.

[0021] Example. A production process of high-strength and high-elongation ductile iron castings is carried out according to the following steps:

[0022] ① Add 18-22 parts of scrap steel to the electric furnace for smelting, then add 58-62 parts of returned materials, and finally add 0.5 parts of tissue modifier and 18-22 parts of pig iron for smelting to form the original molten iron;

[0023] ② Add the spheroidizing agent into the spheroidizing chamber of the spheroidizing bag, then cover the inoculant on the spheroidizing agent, then cover the silicon steel sheet on the inoculant, and finally add the tissue modifier into the spheroidizing bag;

[0024] ③ Pour the original molten iron whose temperature is controlled at 1460-1480°C in the electric furnace into the spheroidizing ladle for reaction to form the final molten iron...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com