Aluminum alloy material with good conductivity and production method thereof

A technology of aluminum alloy materials and electrical conductivity, applied in the field of aluminum alloy materials, can solve the problems of low hardness, brittleness and easy breakage of aluminum alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

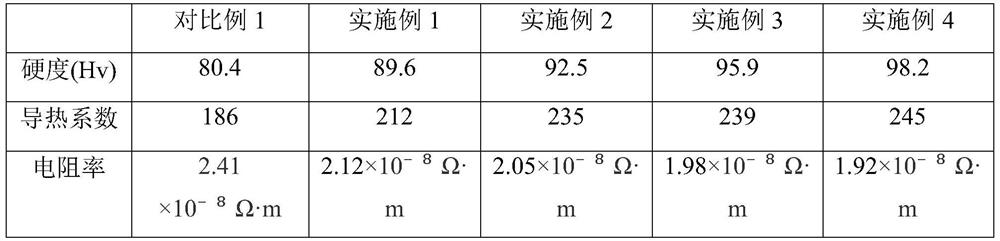

Examples

Embodiment 1

[0030] An aluminum alloy material with good electrical conductivity, the basic components are 4% Cu, 0.5% Ag, 0.2% Al-B master alloy, 0.002% Ti, 0.001% V, 2.3% Re, the balance is Al;

[0031] The preparation method of the aluminum alloy material comprises the following steps:

[0032] S1. Melt the raw material Al at 650°C to obtain an Al melt, put the Al-B intermediate alloy, Cu raw material and Ag raw material into the Al melt, keep it at 600°C for 1.5h, let it stand for precipitation to remove borides, and then put into the coolant for rapid cooling to obtain the first treated material;

[0033] S2. Put the first treatment material at a temperature of 200° C., keep it warm for 2 hours, then raise the temperature to 300° C., hold it for a second time for 3 hours, and pulverize it after cooling to obtain the second treatment material;

[0034] S3. Put the second treatment material, Ti powder, V powder and Re powder into the high-energy ball mill together, add ball milling me...

Embodiment 2

[0037] An aluminum alloy material with good electrical conductivity, the basic components are 4% Cu, 0.5% Ag, 0.2% Al-B master alloy, 0.002% Ti, 0.001% V, 2.3% Re, the balance is Al;

[0038] The preparation method of the aluminum alloy material comprises the following steps:

[0039] S1. 99.7% pure aluminum is heated and melted into molten aluminum. When the temperature reaches 700°C, add sodium tetraborate with a weight of 2% of the weight of the molten aluminum into the molten aluminum. At the same time, carry out electromagnetic stirring for 8 minutes, and then heat up to 1000°C for 15 minutes. Electromagnetic stirring was performed for 5 minutes during the heat preservation process to obtain the first treatment solution;

[0040] Cooling the ingot from the first treatment solution to obtain an Al-B master alloy;

[0041] The raw material Al is melted at 650°C to obtain the Al melt, and the Al-B intermediate alloy, Cu raw material and Ag raw material are put into the Al ...

Embodiment 3

[0046] An aluminum alloy material with good electrical conductivity, the basic components are 4% Cu, 0.5% Ag, 0.2% Al-B master alloy, 0.002% Ti, 0.001% V, 2.3% Re, the balance is Al;

[0047] The preparation method of the aluminum alloy material comprises the following steps:

[0048] S1. 99.7% pure aluminum is heated and melted into molten aluminum. When the temperature reaches 700°C, add sodium tetraborate with a weight of 2% of the weight of the molten aluminum into the molten aluminum. At the same time, carry out electromagnetic stirring for 8 minutes, and then heat up to 1000°C for 15 minutes. Electromagnetic stirring was performed for 5 minutes during the heat preservation process to obtain the first treatment solution;

[0049]Cooling the ingot from the first treatment solution to obtain an Al-B master alloy;

[0050] The raw material Al was melted at 650°C to obtain the Al melt, the Al-B intermediate alloy, the Cu raw material and the Ag raw material were put into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com