Concentrated low-nitrogen dual channel swirl burner with central air

A low-nitrogen burner, concentrated technology, which is applied to burners, burners, combustion methods and other directions of burning powder fuel, can solve the problem of coking, boiler fly ash and large slag carbon content increased, poor combustion structure, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0034] It should be understood that terms such as "having", "comprising" and "including" as used herein do not entail the presence or addition of one or more other elements or combinations thereof.

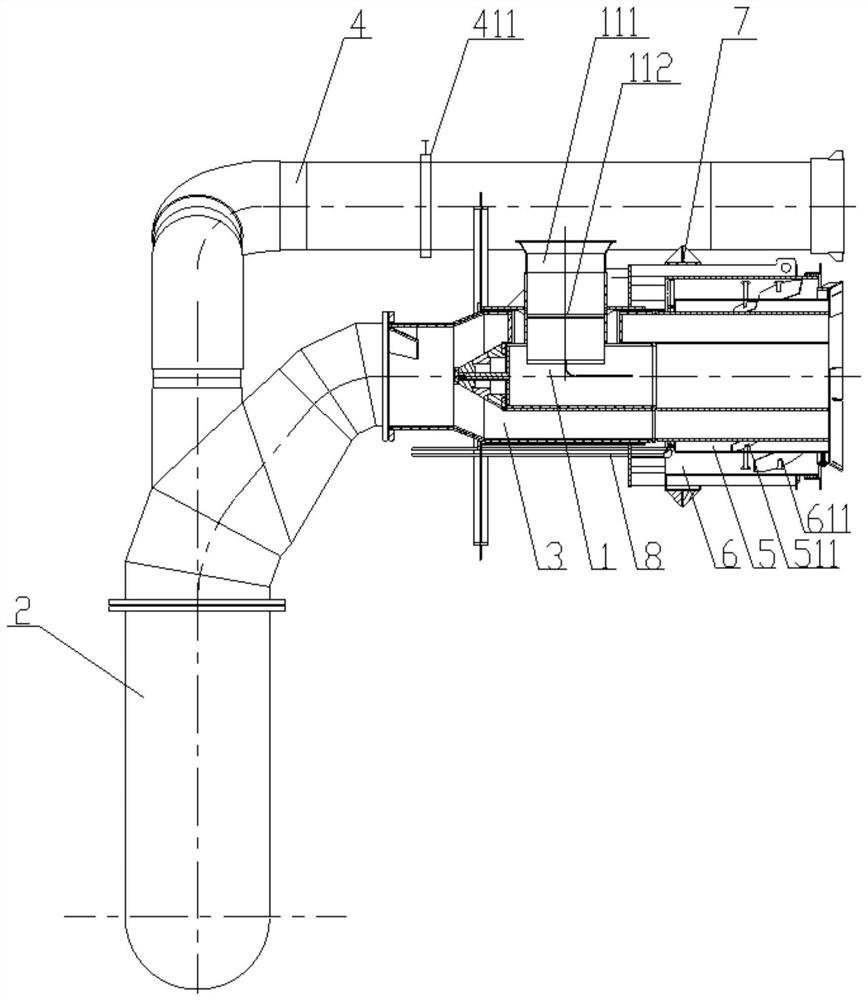

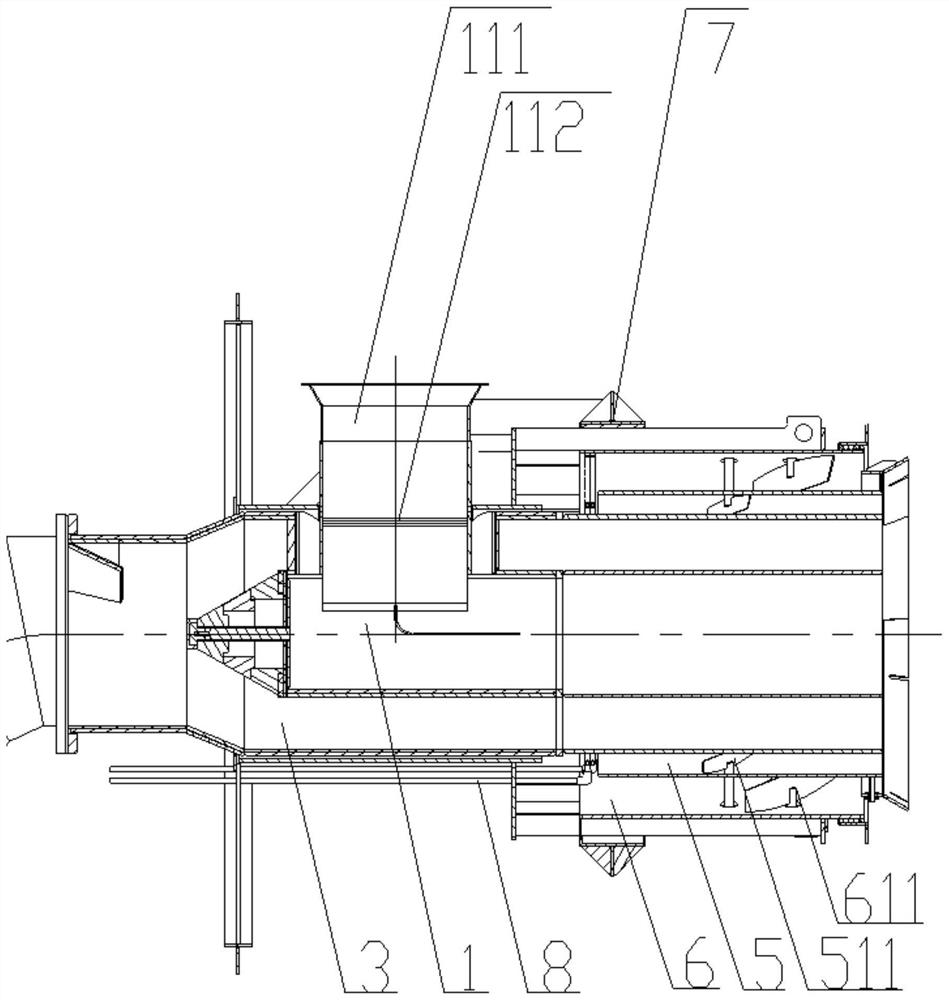

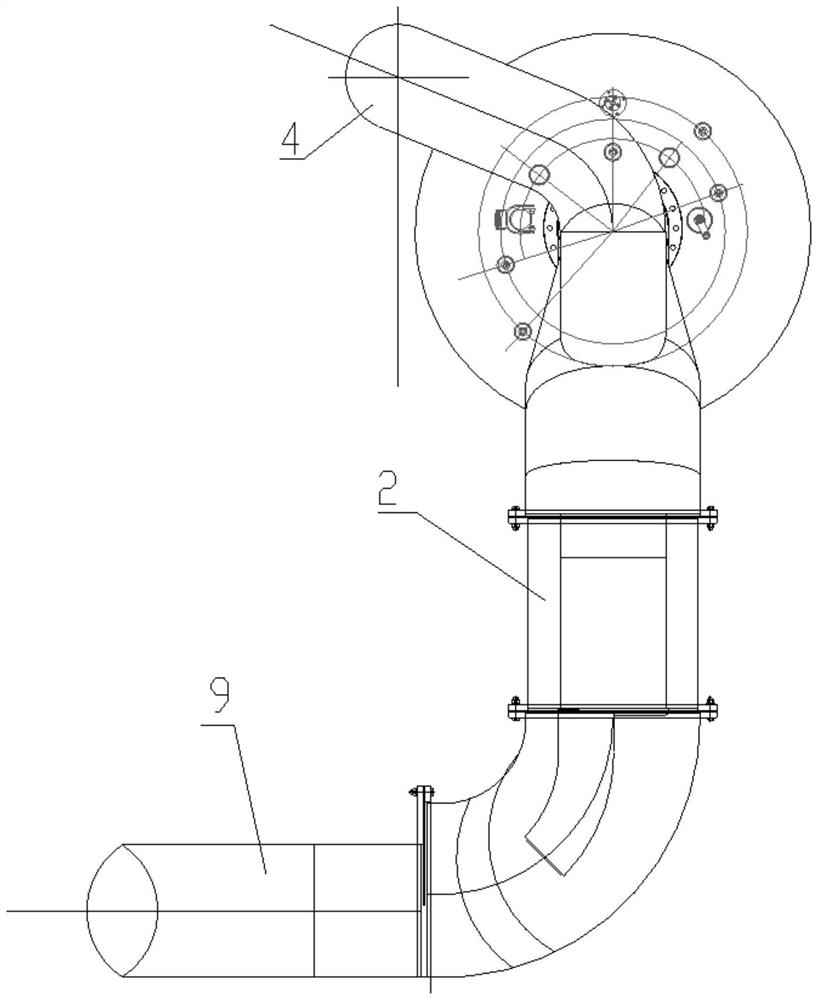

[0035] Such as figure 1 , 2 Shown in and 3, the present invention provides a kind of enrichment type double regulating wind swirl low nitrogen burner that is provided with central wind, comprises:

[0036] The double-adjusting air swirl nozzle area, one end of which is connected to the combustion furnace, the double-adjusting air swirl nozzle area includes a central air channel 1, a primary air channel 3, an inner secondary air channel 5 and The outer secondary air channel 6, and the central air channel 1 and the primary air channel 3 are respectively provided with their own ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com