A kind of method of recovering magnesium from nickel iron slag

A technology of ferronickel slag and seed crystals, which is applied in the field of magnesium recovery, can solve the problems of high requirements for equipment, reduction conditions and safety, and the impossibility of industrial application, so as to achieve improved comprehensive utilization rate, high added value of products, and wide application range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

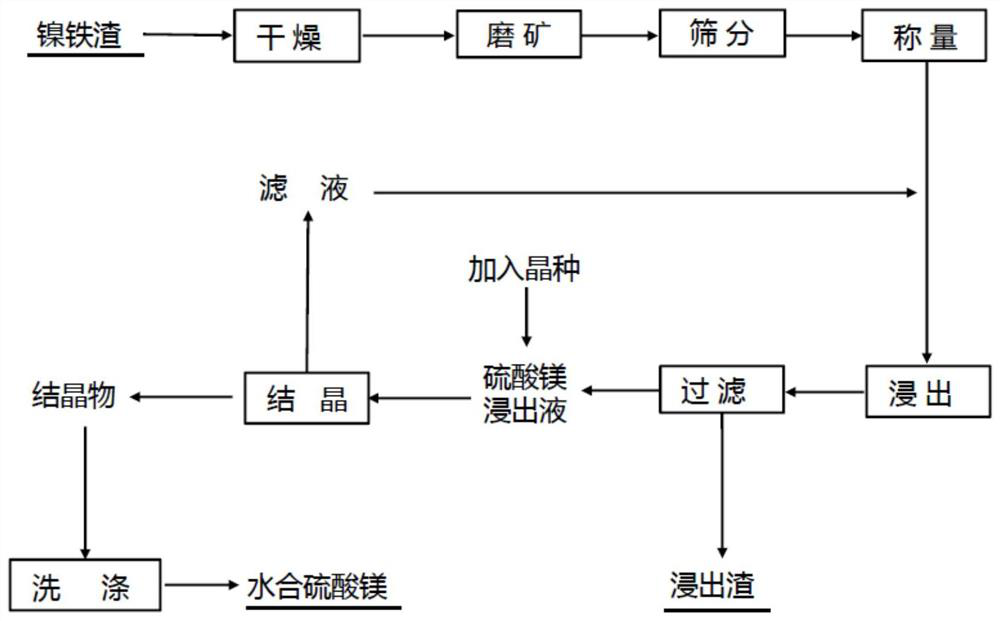

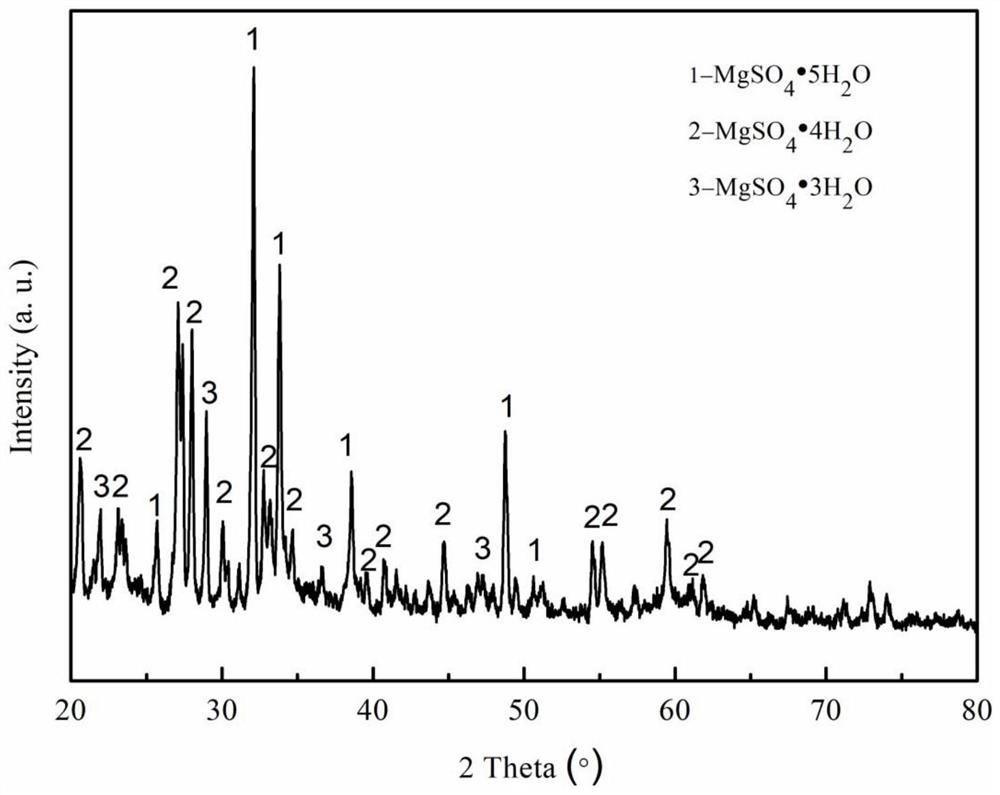

[0050] like figure 1 As shown, the present embodiment relates to a method for recovering magnesium from ferronickel slag, comprising the following steps:

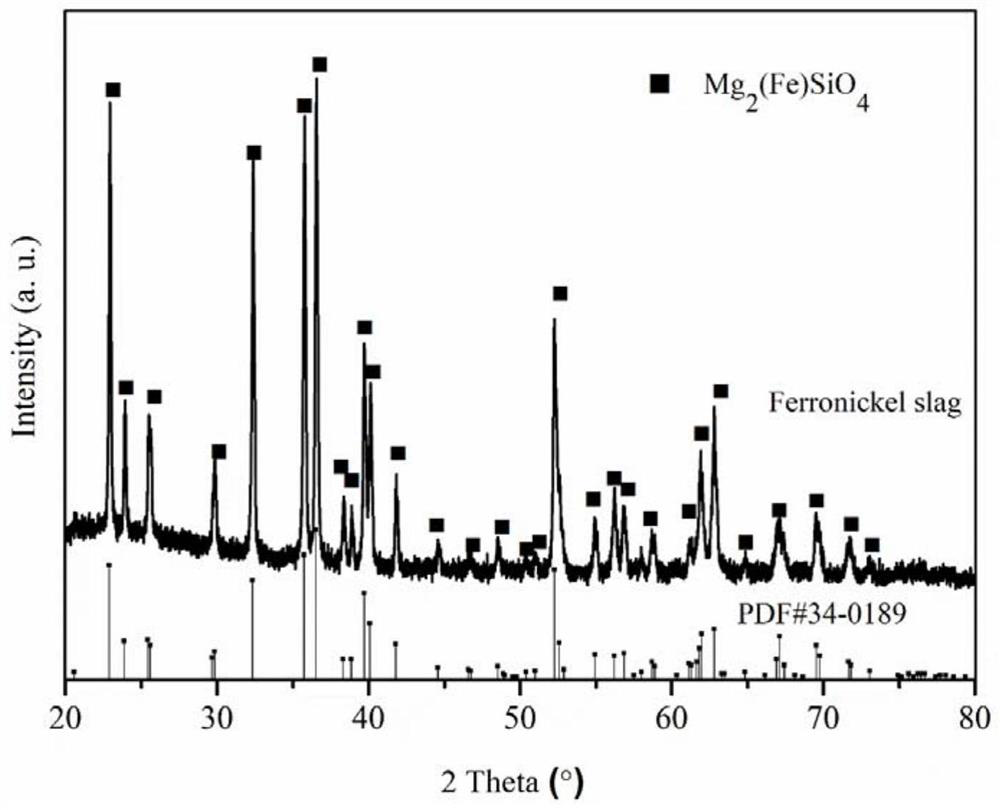

[0051] S1. Pretreatment: Dry the nickel-iron slag at 105°C for 12h, set the rotation speed on the planetary ball mill to 300r / min, the revolution speed to 600r / min, the grinding time is 3h, pass through a 300-mesh sieve after ball milling, and obtain the particle size For the nickel-iron slag powder smaller than 38 μm, in order to ensure that the nickel slag used in each group of tests has the same composition, the particles larger than 38 μm are returned to the next batch of ball mills, and the process is repeated. The fine powder of nickel iron slag is used as the solute.

[0052] S2, leaching: Weigh 20g of nickel-iron slag fine powder and place it in a three-necked flask, under the condition that the liquid-solid ratio is 20:1 (ml / g), add a sulfuric acid solution with a concentration of 15N (N represents the equivalent ...

Embodiment 2

[0058] The present embodiment relates to a method for recovering magnesium from ferronickel slag, comprising the following steps:

[0059] S1. Pretreatment: Dry the nickel-iron slag at 105°C for 8h, set the rotation speed on the planetary ball mill to 250r / min, the revolution speed to 500r / min, the grinding time is 6h, pass through a 300-mesh sieve after ball milling, and obtain the particle size For the nickel-iron slag powder smaller than 38 μm, in order to ensure that the nickel slag used in each group of tests has the same composition, the particles larger than 38 μm are returned to the next batch of ball mills, and the process is repeated. The fine powder of nickel iron slag is used as the solute.

[0060] S2, leaching: Weigh 20g of nickel-iron slag fine powder and place it in a three-necked flask. Under the condition that the liquid-solid ratio is 10:1 (ml / g), add a sulfuric acid solution with a concentration of 11N, without adding a cosolvent, and then add The flask wa...

Embodiment 3

[0064] The present embodiment relates to a method for recovering magnesium from ferronickel slag, comprising the following steps:

[0065] S1. Pretreatment: Dry the nickel-iron slag at 130°C for 6h, set the rotation speed on the planetary ball mill to 200r / min, the revolution speed to 400r / min, the grinding time is 5h, pass through a 300-mesh sieve after ball milling, and obtain a particle size smaller than 38μm nickel-iron slag powder, in order to ensure that the nickel slag used in each group of tests has the same composition, the particles larger than 38μm are returned to the next batch of ball mills, and the process is repeated. Finally, all batches of sieved materials are mixed uniformly. Iron slag fines are used as the solute.

[0066] S2, leaching: Weigh 20g of nickel-iron slag fine powder and place it in a three-necked flask, under the condition that the liquid-solid ratio is 20:1 (ml / g), add a 15N sulfuric acid solution with a concentration of 15N, without adding a co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com