Flowing tea or coffee maker

A flow-through, coffee pot technology, applied in kitchen utensils, household utensils, household containers, etc., can solve problems such as unsmooth water outlet from the pot body, damage to the quality of tea soup, personal safety issues, etc., to achieve improved air intake sensitivity, stable flow rate, smooth water effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

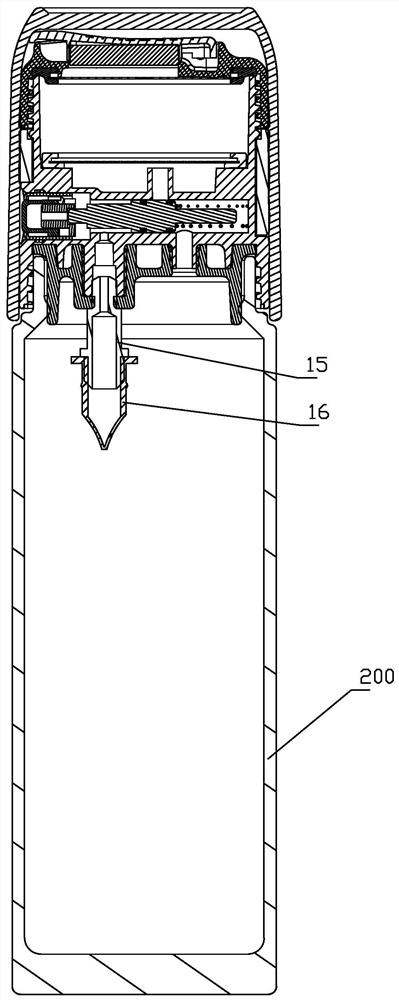

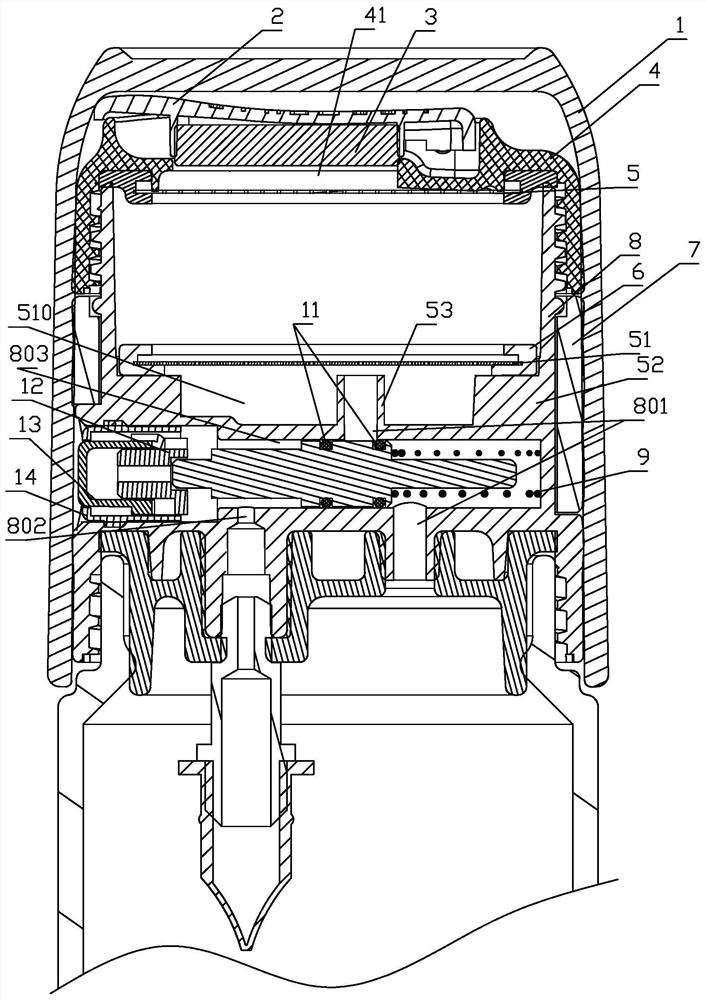

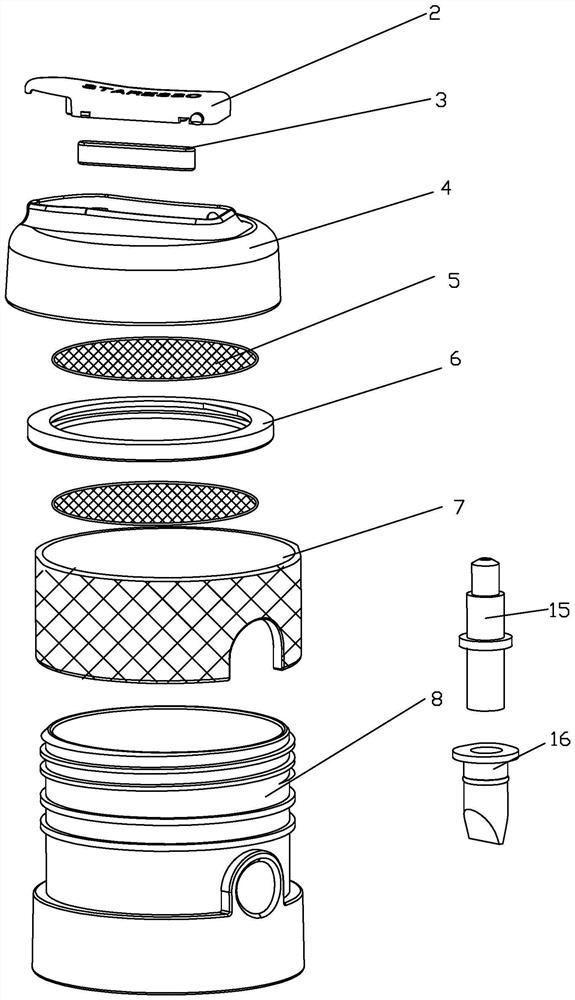

[0032] Example 1: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a flowing water type tea extraction or coffee brewing pot includes a pot body 200, a pot lid body 8, and a tea powder lid 4. The bottom of the pot lid body is detachably sealed with the bottle mouth of the pot body. The top is detachably sealed with the tea powder cover, and a container space is provided between the tea powder cover and the pot cover body; the container space is formed by the inner cavity of the pot cover body and the tea powder cover covering the upper opening of the inner cavity.

[0033] The lid body is provided with a water flow channel 801, which connects the pot body and the above-mentioned container space; the lid body is provided with an air inlet channel 802; the tea powder cover is provided with a tea outlet 41; the air inlet channel faces the pot body The mouth is provided with a conduit 15 extending into the body of the kettle.

[0034] The lid body is provi...

Embodiment 2

[0042] Example 2: The tea outlet hole is provided with a corresponding openable flip cover 2, the flip cover is provided with a sealing strip 3 and the tea outlet hole realizes dynamic sealing, the sealing strip is fixed under the flip cover, and the flip cover is hinged to the tea powder cover.

Embodiment 3

[0043] Embodiment 3: The control mechanism includes a valve core 10, a valve hole 803 arranged in the body of the pot lid, the valve hole 803 traverses the flowing water channel, and the valve hole communicates with the air intake channel; the valve core is provided with a first sealing ring 11, a second Two sealing rings, the first sealing ring and the second sealing ring have a gap with each other; the first sealing ring and the second sealing ring make the valve core 10 and the inner wall of the valve hole realize dynamic sealing; when the control mechanism is closed, the upper part of the water channel is closed. The opening is located in the gap between the first sealing ring and the second sealing ring, so that the water flow channel is closed; after the valve core moves, the opening of the upper section of the water flow channel is located outside the gap between the first sealing ring and the second sealing ring, and the valve hole The inner bottom section of the water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com