Windproof support for greenhouse

A technology of support rods and piston tubes, applied in the field of greenhouses, can solve the problems that the greenhouses are easy to be blown down, and achieve the effects of reducing the force, reducing the blocking, and preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

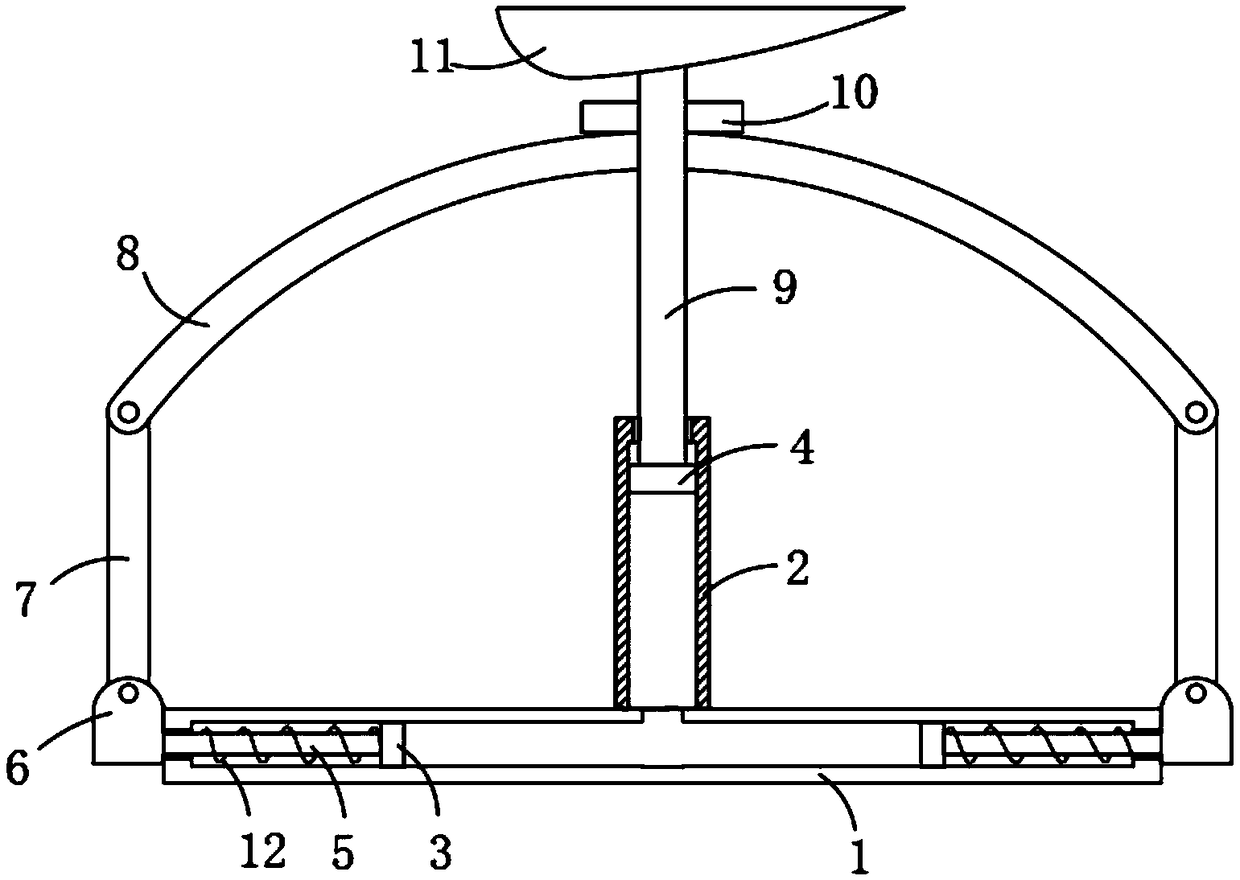

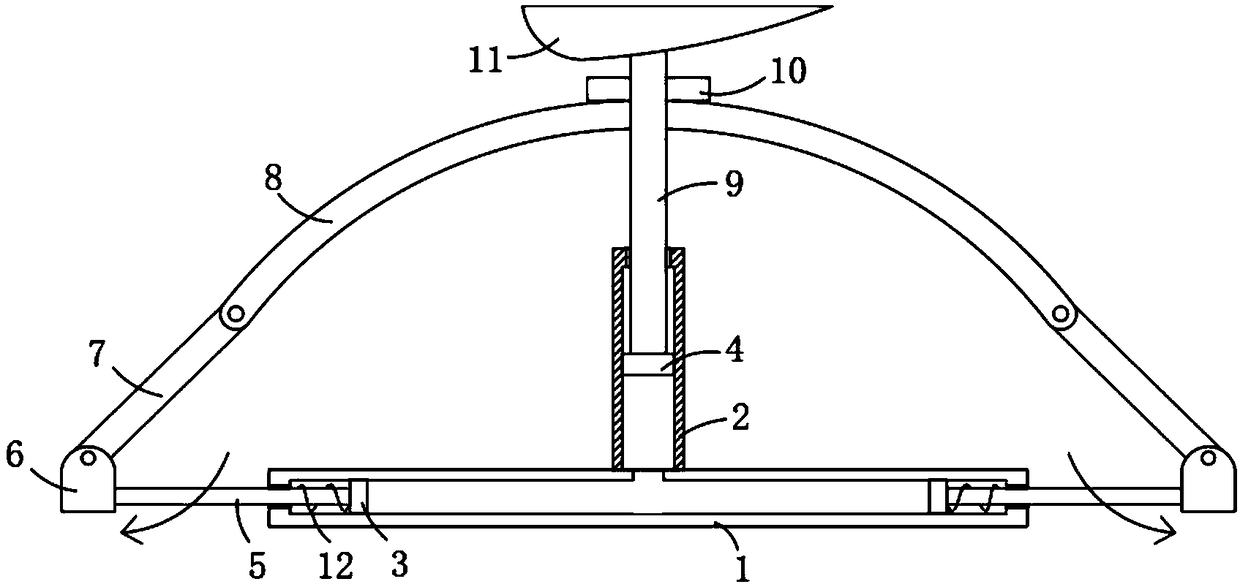

[0019] refer to Figure 1-2 , a wind-resistant greenhouse support, comprising two parallel first piston tubes 1 horizontally fixed on the ground, the two ends of the first piston tube 1 are sealed, and the ends of the two first piston tubes 1 are connected by a connecting rod ( (not shown in the figure) is connected and surrounded into a square frame shape, the middle part of the first piston tube 1 is vertically and fixedly connected with the second piston tube 2, the second piston tube 2 communicates with the first piston tube 1, and the first piston tube 1 is flexibly connected There are two first pistons 3, and the two first pistons 3 are symmetrically distributed on both sides of the second piston tube 2, the second piston tube 2 is movably connected with a second piston 4, and the second piston 4 is connected to the two first pistons. The space formed by the piston 3 is filled with hydraulic oil, the end of the first piston 3 away from the hydraulic oil is fixedly connec...

Embodiment 2

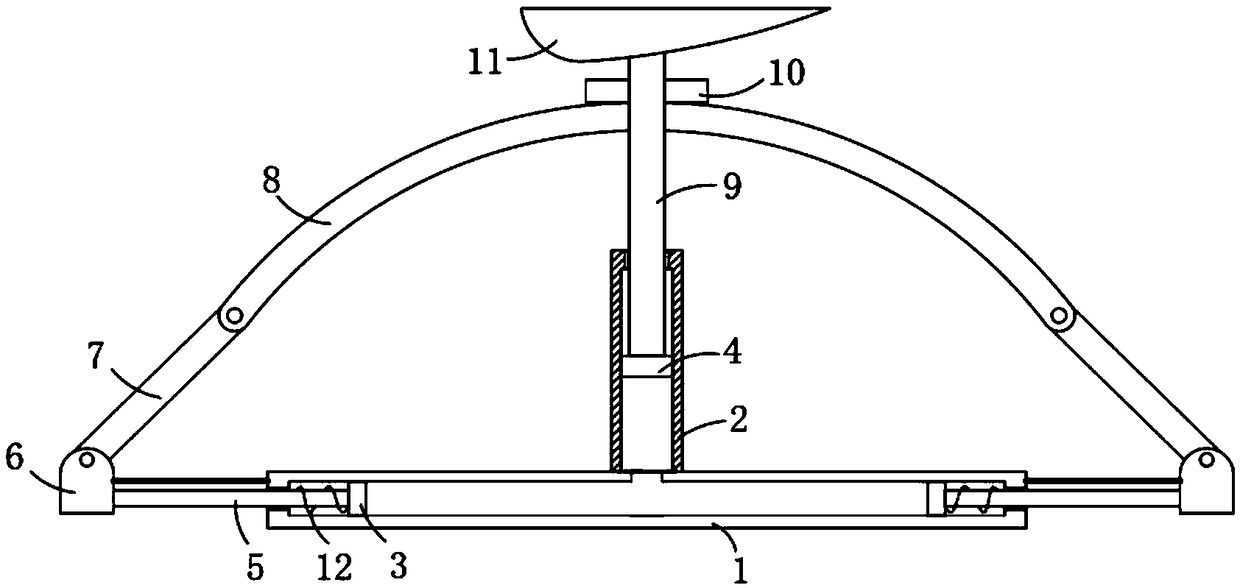

[0025] refer to Figure 3-4 , the mounting plate 6 is provided with a cavity, and a winding roller 13 is installed inside the cavity, and a sealing film 14 is wound on the winding roller, and the free end of the sealing film 14 runs through the strip hole on the side wall of the cavity and is connected with the The end face of the connecting rod and the first piston tube 1 is connected in a sealed manner.

[0026] The difference between this embodiment and Embodiment 1 is that a cavity is provided in the mounting plate 6, and a winding roller 13 is installed inside the cavity, and a sealing film 14 is wound on the winding roller, and the free end of the sealing film 14 penetrates The strip hole on the side wall of the cavity is sealed and connected with the connecting rod and the end face of the first piston tube 1. When the growth of the plants in the greenhouse requires a closed space to maintain temperature and humidity, the greenhouse cannot be closed in windy weather. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com