Improved CTP plate base aluminum alloy strip based on 1052# aluminum alloy

An aluminum alloy strip and aluminum alloy technology, which is applied in the field of improved CTP plate-based aluminum alloy strip, can solve the problems of electrolytic corrosion performance that cannot meet the requirements of high-quality printing, poor surface quality, and insufficient flatness, etc. Quality, improved feeding frequency, saving production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] An improved CTP plate-based aluminum alloy strip based on No. 1052 aluminum alloy, characterized in that the specific preparation method comprises the following steps:

[0029] (1) Select No. 1052 aluminum alloy as the raw material, send it into the melting furnace for melting, control the temperature at 750°C, keep nitrogen protection during the melting process, wait until it is completely melted, and keep it warm for 1 hour. During the heat preservation process, remove a small amount of scum on the surface;

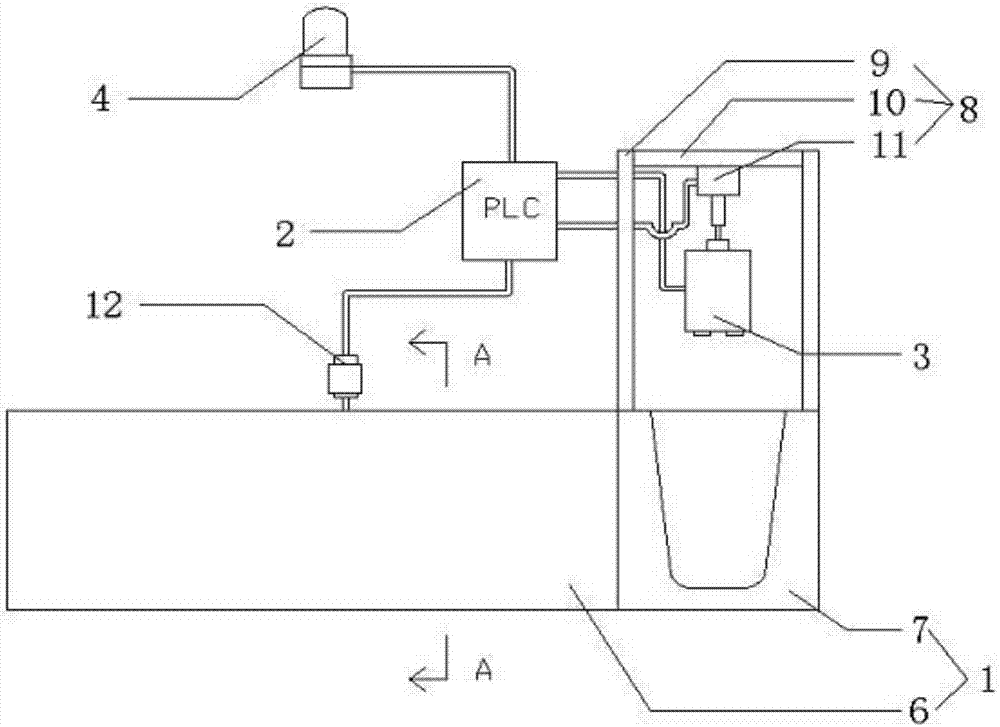

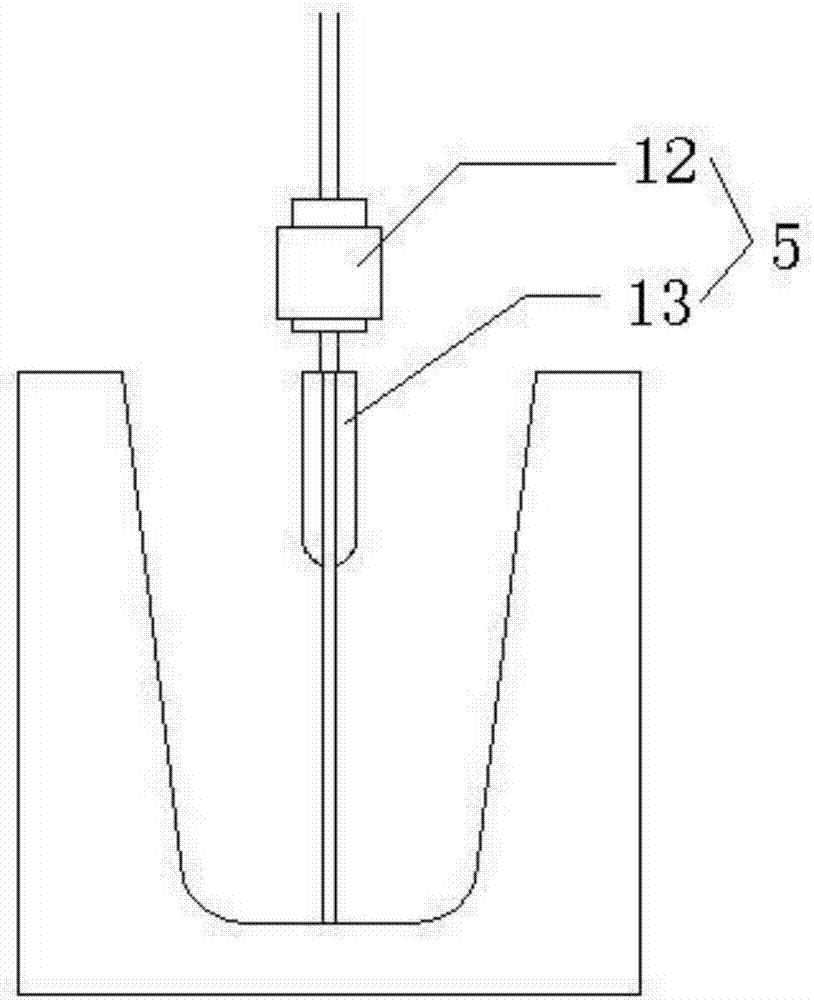

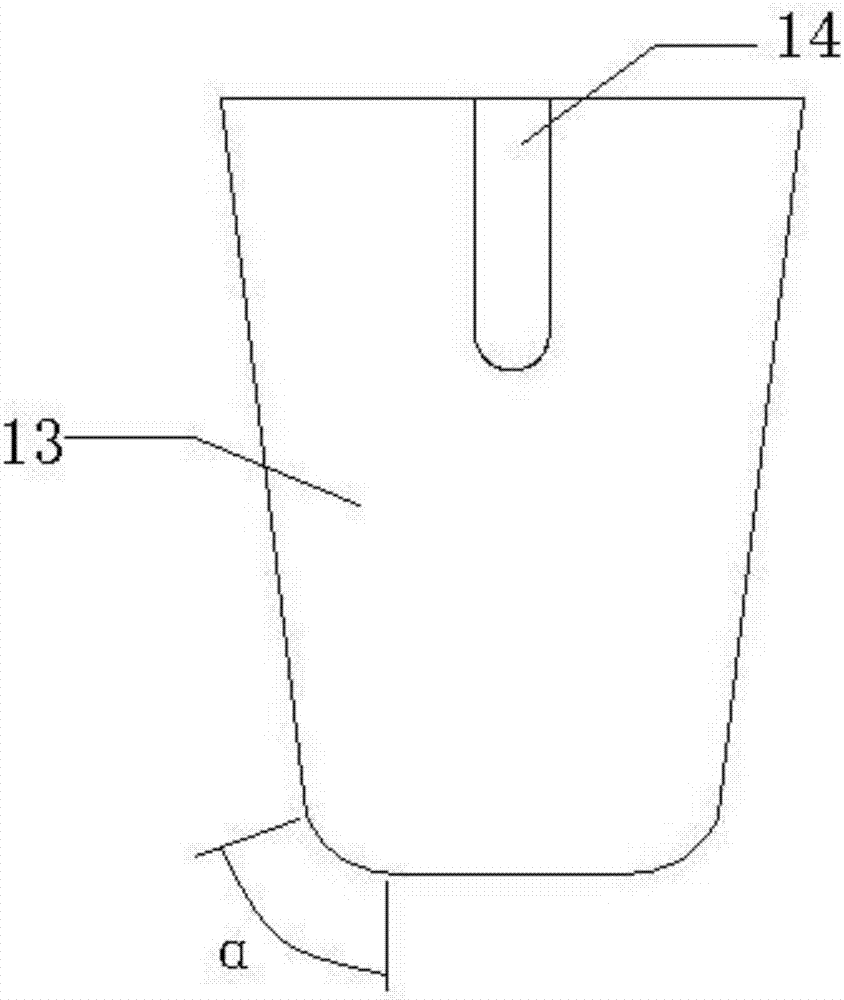

[0030] (2) After step (1) is completed, the molten aluminum is sent into the casting and rolling machine through the front box launder of the casting and rolling machine for casting and rolling;

[0031] (3) After the casting and rolling are completed and the aluminum alloy billet is cooled naturally, four passes of finish rolling are carried out, and the rolling processing rates of the four passes are controlled at 60% to 70%, 60% to 70%, and 45% to 50%, respecti...

Embodiment 2

[0044] The differences between this embodiment and Embodiment 1 are:

[0045] An improved CTP plate-based aluminum alloy strip based on No. 1052 aluminum alloy, characterized in that the specific preparation method comprises the following steps:

[0046] (1) Select 1052 aluminum alloy as the raw material, send it into the melting furnace for melting, control the temperature at 755°C, keep nitrogen protection during the melting process, and keep it at 560°C for 1 hour after it is completely melted. During the heat preservation process, remove the surface a small amount of scum;

[0047] (2) After step (1) is completed, the molten aluminum is sent into the casting and rolling machine through the front box launder of the casting and rolling machine for casting and rolling;

[0048] (3) After the casting and rolling are completed and the aluminum alloy billet is cooled naturally, four passes of finish rolling are carried out, and the rolling processing rates of the four passes ar...

Embodiment 3

[0052] The differences between this embodiment and Embodiments 1 and 2 are:

[0053] An improved CTP plate-based aluminum alloy strip based on No. 1052 aluminum alloy, characterized in that the specific preparation method comprises the following steps:

[0054] (1) Select No. 1052 aluminum alloy as raw material, send it into the melting furnace for melting, control the temperature at 760°C, keep nitrogen protection during the melting process, and keep it at 570°C for 1 hour after it is completely melted. During the heat preservation process, remove the surface a small amount of scum;

[0055] (2) After step (1) is completed, the molten aluminum is sent into the casting and rolling machine through the front box launder of the casting and rolling machine for casting and rolling;

[0056] (3) After the casting and rolling are completed and the aluminum alloy billet is cooled naturally, four passes of finish rolling are carried out, and the rolling processing rates of the four pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com