A Forming Process of Large-diameter, Medium-Strength, and Heat-resistant Magnesium Alloy Thick-walled Cylindrical Parts

A forming process and thick-walled tube technology, which is applied in the deformation processing of magnesium alloys, forging and ring rolling deformation of Mg-Al-Ag series magnesium alloys, and can solve the problems of fast heat dissipation, narrow thermal deformation temperature range, and difficulty in blank preparation, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

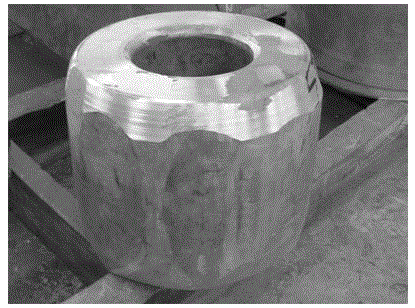

[0023] Example 1: Using a large furnace to melt raw materials, a Mg-8.0Al-0.5Ag-0.4Zn-0.1Mn-0.1RE-0.01Ca (wt.%) magnesium alloy ingot with a diameter of Ф530mm was cast by semi-continuous casting. The ingot is processed by mechanical car skin, cutting, chamfering, etc., and finally an ingot with a diameter of Ф480mm and a length of 700mm is processed, such as figure 1 shown. The ingot is subjected to bipolar homogenization annealing. The annealing process is as follows: after holding at 250-300 °C for 10-12 hours, the temperature is raised to 380-410 °C for 20-30 hours, and air-cooled to room temperature. The ingot is heated to 410°C for 10 hours, and the ingot is forged by upsetting and multi-directional forging on a hydraulic press. The amount is 5-10%, and the temperature of the upper and lower cutting boards is 150-200 °C. During the forging process, when the surface temperature of the ingot is lower than 350 ℃, it is annealed back to the furnace, and the annealing tempe...

Embodiment 2

[0024] Example 2: First, use a large furnace to melt the alloy raw materials, and then semi-continuously cast a Mg-8.0Al-0.5Ag-0.4Zn-0.1Mn-0.1RE-0.02Ca (wt.%) alloy ingot with a diameter of Ф550mm. The ingot is processed by mechanical turning, cutting, chamfering, etc., and finally an ingot with a diameter of Ф500mm and a length of 780mm is processed. The ingot is subjected to bipolar homogenization annealing. The annealing process is as follows: after holding at 250-300 °C for 10-12 hours, the temperature is raised to 380-410 °C for 20-30 hours, and air-cooled to room temperature. The ingot was kept at 400°C for 16 hours, and the ingot was forged by upsetting and multi-directional forging on a hydraulic press. -10%, the temperature of the upper and lower cutting boards is 150-200℃. During the forging process, when the surface temperature of the ingot is lower than 350 ℃, it is annealed back to the furnace, and the annealing temperature is 390 ℃ and the holding time is 8h. E...

Embodiment 3

[0025] Example 3: First, use a large furnace to melt the alloy raw materials, and then semi-continuously cast a Mg-9.0Al-0.8Ag-0.4Zn-0.1Mn-0.1RE-0.01Ca (wt.%) magnesium alloy ingot with a diameter of Ф600mm. The ingot is processed by mechanical car skin, cutting, chamfering, etc., and the final ingot size is Ф550mm in diameter and 650mm in length. The ingot is subjected to bipolar homogenization annealing. The annealing process is as follows: after holding at 250-300 °C for 10-12 hours, the temperature is raised to 380-410 °C for 20-30 hours, and air-cooled to room temperature. Upsetting and drawing multi-directional forging is performed on the ingot on a hydraulic press, with a reduction speed of 200-400mm / min, a reduction of 30-40% for upsetting passes, a reduction of 5-10% for elongated passes, and the temperature of the upper and lower anvils. 150-300℃. The ingot was heated to 410°C for 8h before forging. During the forging process, when the surface temperature of the in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com