A large-scale fine-grained tungsten rod and its two-roll rolling preparation method

A large-scale, tungsten rod technology, which is applied in the field of large-scale fine-grained tungsten rods and their two-roll rolling preparation, can solve the problems of difficulty in fully guaranteeing fine grains, uneven grains of tungsten rods, and large fluctuations in product quality. Long pressure holding time, good dimensional consistency, and the effect of reducing product cost and production difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to highlight the purpose, technical solutions and advantages of the present invention, the present invention will be further described below in conjunction with the examples, and the examples are expressed by way of explanation of the present invention rather than limiting the present invention.

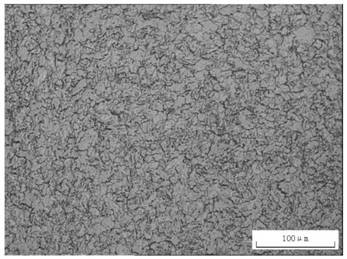

[0040] Example 1 φ26*1000mm fine-grained tungsten rod

[0041] 1. Powder preparation

[0042] Customized FW-1 type pure tungsten powder that meets the national standard of GB / T3458-2006, with a Fischer particle size of 3.0μm and a bulk density of 6.7g / cm 3 , and passed through a 200-mesh sieve to screen out large agglomerated particles, and then put it into a special polyurethane mold for compaction and flattening.

[0043] 2. Cold isostatic pressing

[0044] The tungsten powder is pressed by a cold isostatic press. The working pressure is 150MPa. After holding the pressure for 10 minutes, the pressure is slowly released to the normal atmospheric pressure. vibratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com