Quick extruding and rolling reduction forming device and method for titanium alloy tube blank

A technology of reducing diameter forming and titanium alloy tubes, which is applied in the direction of metal rolling, metal rolling, metal rolling racks, etc., can solve the problems of low time, economic cost utilization, large material loss and invisible loss, and limit titanium alloy Pipe application and other issues to achieve the effect of improving the overall performance of the product, reducing processing costs and cycles, and facilitating industrial automation and mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

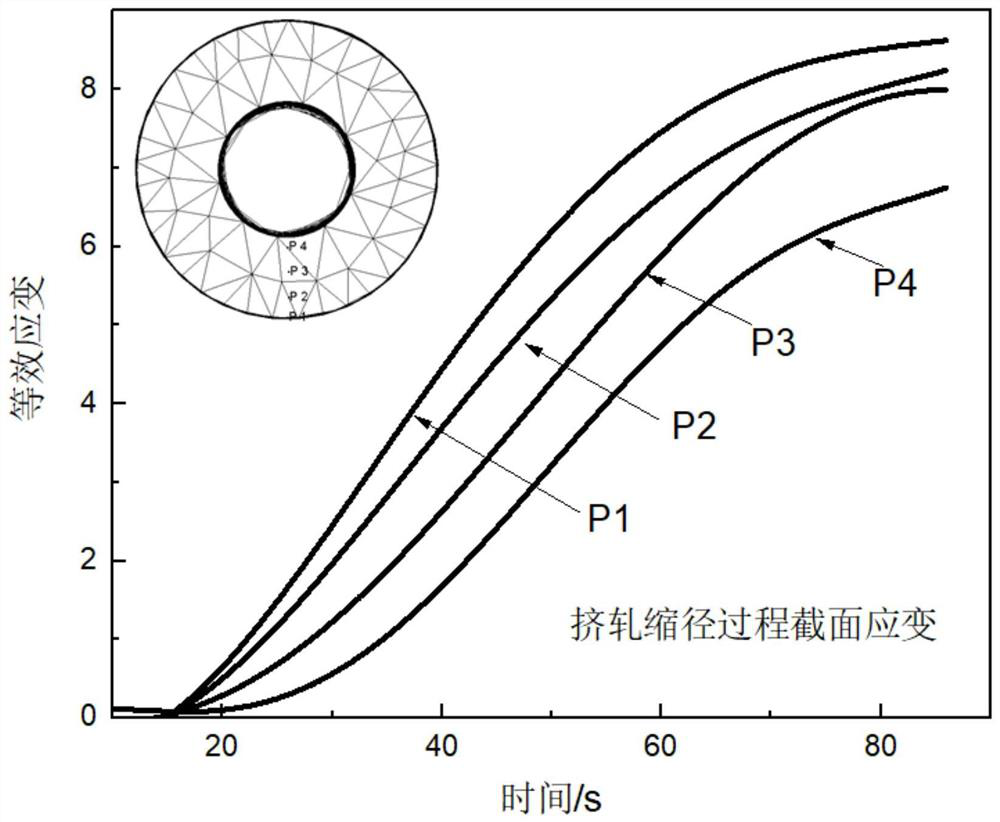

[0058] The size (diameter×wall thickness) of titanium alloy continuous casting tube billet is Φ88×40mm, and the final product size is required to be Φ86×56mm.

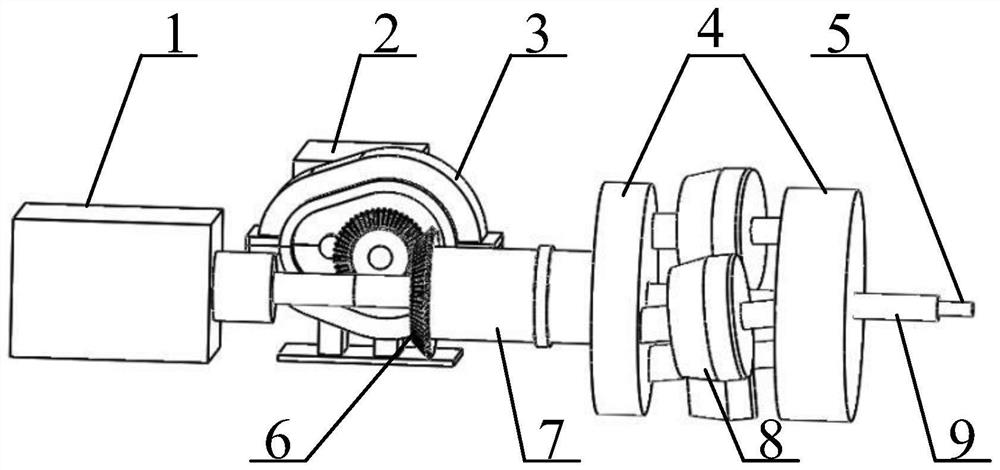

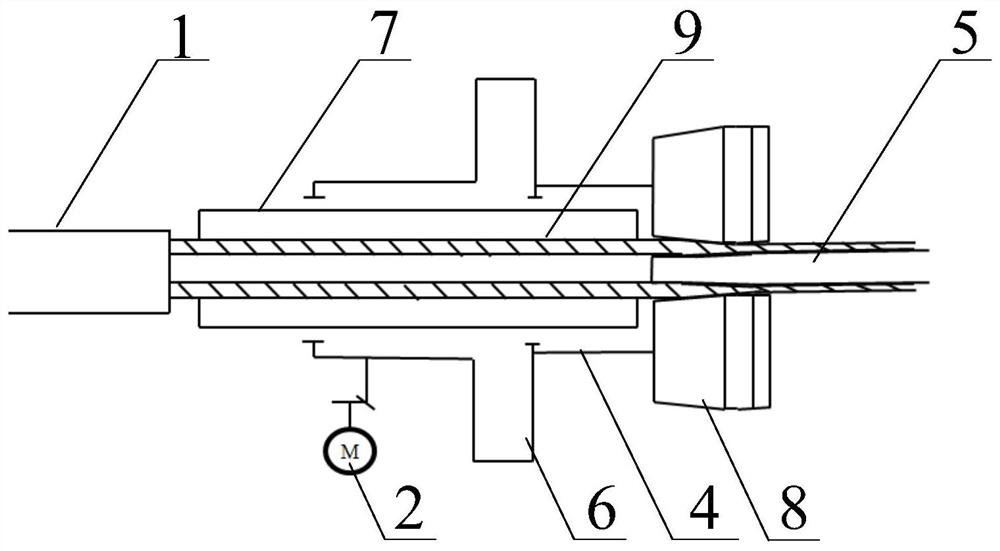

[0059] In order to make the comprehensive performance of the final rolling products meet the requirements of the research objectives, a titanium alloy continuous casting tube billet rapid extrusion and reduction forming device was designed, and the entire process was simulated by the finite element software DEFORM to analyze the feasibility of the technical route provided by the present invention.

[0060] The specific process is as follows:

[0061] The heated continuous casting billet 9 is placed in the sleeve assembly 7, and the continuous casting billet 9 is driven by the left hydraulic assembly 1 to move to the right and enter the first passage surrounded by the sleeve assembly 7, and the skew roll group 8 The second passage surrounded by the mandrel 5 is used to squeeze and reduce the diameter of the continuous c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com