A kind of preparation method of sheet metal parts with different thickness of foamed metal

A technology of foam metal and sheet metal parts, which is applied in the field of auto parts processing, can solve the problems of heavy metal sheet metal parts, insufficient grain refinement of metal sheet metal parts, and inability to meet the requirements of lightweight car bodies, etc., to achieve Improvement of tensile strength, improvement of secondary foaming efficiency and production efficiency, and high degree of grain refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below with reference to the drawings and embodiments.

[0025] The invention provides a method for preparing a foamed metal sheet metal with a difference in thickness, which includes the following steps:

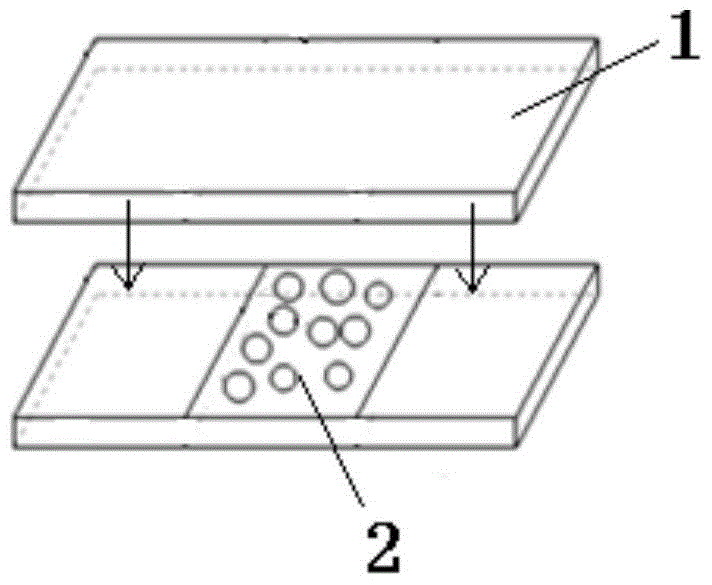

[0026] 1) First stack at least two metal plates 1 and spray foaming agent 2 (such as figure 1 Shown);

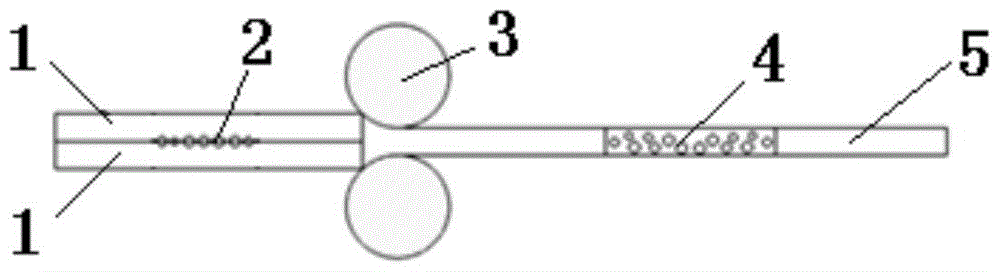

[0027] 2) Then the two metal plates 1 are rolled for the first time through the rolling equipment 3 to obtain a primary rolled metal plate 5 (such as figure 2 Shown);

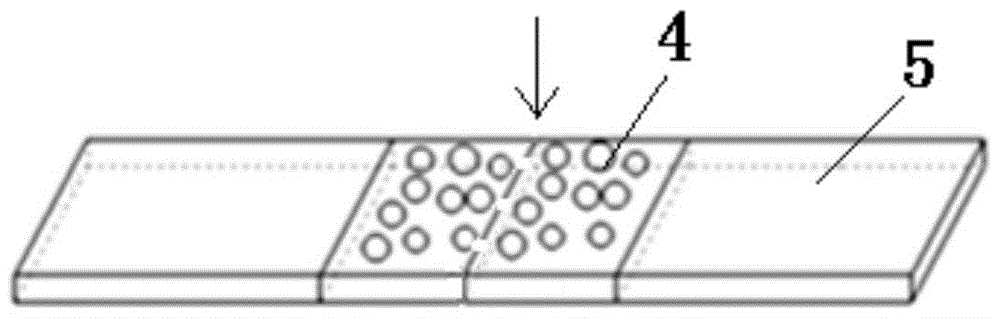

[0028] 3) Separate the once-rolled metal plate 5 from the area 4 to be foamed into two pieces (such as image 3 Shown);

[0029] 4) Stack two primary-rolled metal plates 5 and make the two areas 4 to be foamed face each other, and then perform a second rolling through the rolling equipment 3 to obtain a foamed metal plate 6 (such as Figure 4 Shown);

[0030] 5) Place the foamed metal plate 6 in the heating furnace 7 for preheating, so that the area 4 to be foa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com