Manufacturing method for improving bearing steel ball surface layer performance

A manufacturing method and technology of bearing steel balls, applied in the direction of manufacturing tools, bearing components, shafts and bearings, etc., can solve the problems of metal plastic exhaustion, plastic damage, reduction of steel ball strength, hardness and wear resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

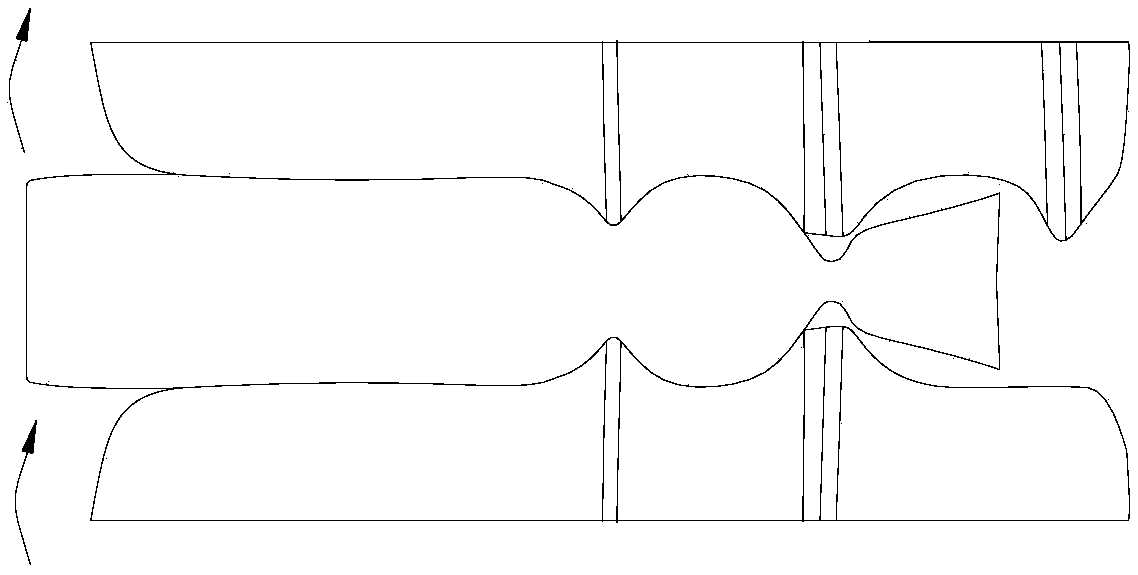

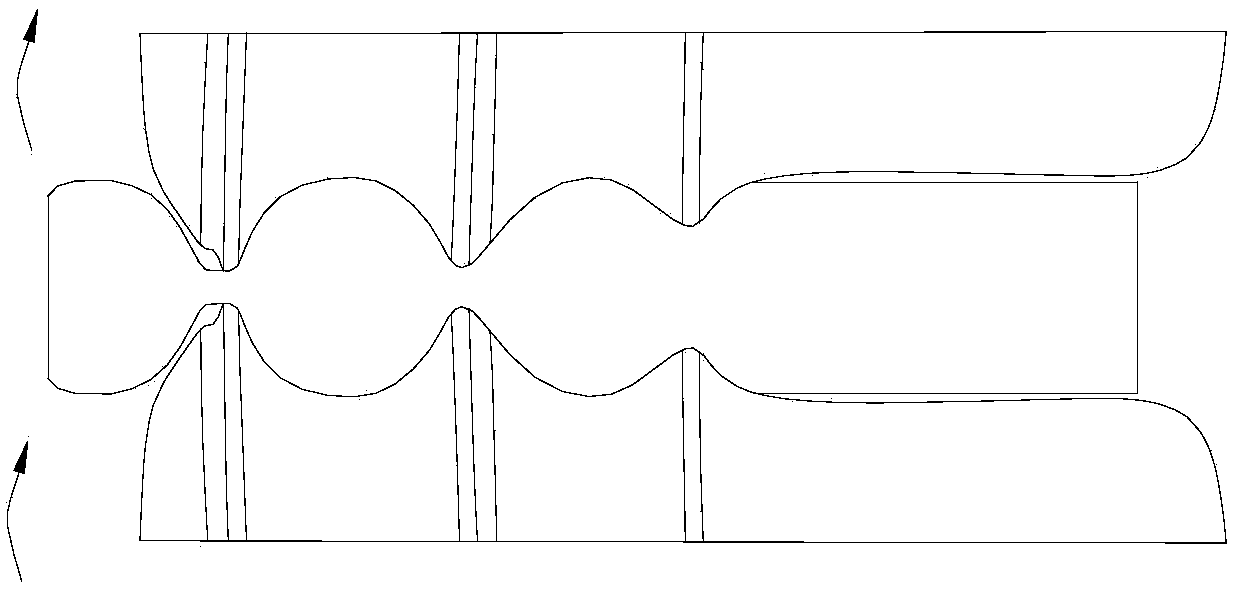

[0021] Such as Figure 1~2 A manufacturing method for improving the performance of bearing steel balls shown includes the following steps:

[0022] Step 1: Heating the steel rod to a temperature above the austenitization temperature, and hot-rolling and forming steel balls by unidirectional rotation of the first skewed rolling roll.

[0023] Step 2: When the steel ball in step 1 is hot-rolled to 50%~70% of deformation, transfer the steel ball bar to the second skewed rolling roll to continue rolling in one direction, so that the metal plastic deformation of the steel ball bar occurs Reverse macro-shear stress zone; the skew rolling direction of the second skew roll is opposite to that of the first skew roll, and the roll inclination angle is the same; if the first skew roll can be selected as a left-handed roll, the second skew roll can be selected as It is a right-handed roll.

[0024] Step 3: Cool the hot-rolled steel ball rapidly, so that the temperature of the core and s...

Embodiment 2

[0027] This embodiment is based on the basis of embodiment 1, and the specific material selection and process requirements of step 1 and step 2 are limited, and the specific scheme is as follows.

[0028] A manufacturing method for improving the performance of bearing steel balls, comprising the steps of:

[0029] Step 1: Heat the GCr15SiMn bearing steel bar with a diameter of 60 mm to 1050 °C, roll the steel ball on the first skew roll to prefabricate the steel ball with a connection neck of 20 mm, and lower the temperature to about 920 °C;

[0030] Step 2; when the steel ball in step 1 is hot-rolled to 50%~70% deformation, transfer the prefabricated steel ball bar with a connection neck of 20 mm to the right-handed rolling roll on the second skew roll to continue rolling Reverse macro-shear stress zone occurs in the metal plastic deformation of the steel ball bar, and the temperature of the steel ball drops to 830˚C after rolling;

[0031] Step 3: Cool the hot-rolled steel ...

Embodiment 3

[0034] This embodiment is based on the basis of embodiment 2, and the specific material selection and process requirements of step 3 and step 4 are limited, and the specific scheme is as follows.

[0035] A manufacturing method for improving the performance of bearing steel balls, comprising the steps of:

[0036] Step 1: Heat the GCr15SiMn bearing steel bar with a diameter of 60 mm to 1050 °C, roll the steel ball on the first skew roll to prefabricate the steel ball with a connection neck of 20 mm, and lower the temperature to about 920 °C;

[0037] Step 2; when the steel ball in step 1 is hot-rolled to 50%~70% deformation, transfer the prefabricated steel ball bar with a connection neck of 20 mm to the right-handed rolling roll on the second skew roll to continue rolling Reverse macro-shear stress zone occurs in steel ball bar metal plastic deformation, improves grain refinement degree of steel ball surface (near surface layer), reduces plastic damage microscopic tear zone, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com