Double-laser forging remanufacturing and repairing device for damaged mortises of high-temperature alloy small-size structure turbine disc and application method thereof

A technology of superalloy and turbine disk, applied in the direction of metal material coating process, coating, etc., can solve the problems of time-consuming, human and financial resources, poor working conditions, complex shapes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

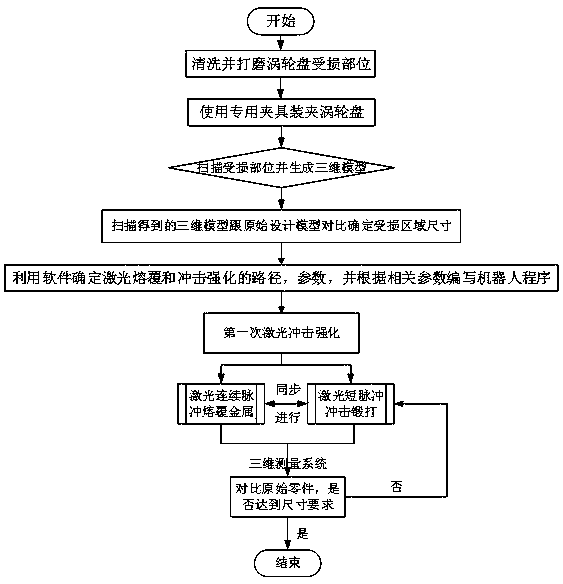

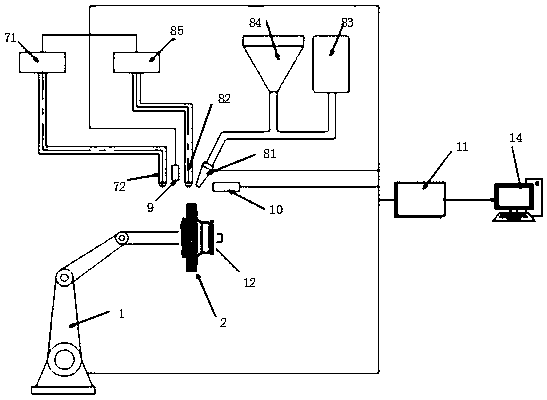

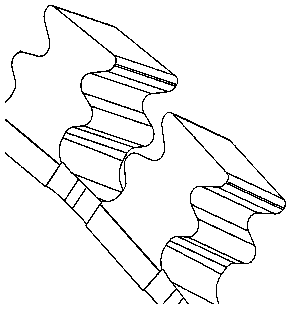

[0032] Such as Figures 1 to 4 It is an embodiment of a device for remanufacturing and repairing damaged mortise and groove double laser forging of a superalloy small-sized turbine disk. The device includes a turbine disk 2 for repair, a mechanical arm 1, a processor 14, a laser shock strengthening module 7, Cladding module 8, temperature sensing module 9, on-line monitoring system 10 and general controller 11, general controller 11 and processor 14, laser shock strengthening module 7, cladding module 8, temperature sensing module 9, with measuring system The online monitoring system 10 is electrically connected, the processor 14 is electrically connected to the online monitoring system 10 , and the turbine disk 2 is installed on the mechanical arm 1 . Specifically, the online monitoring system 10 is provided with a three-dimensional measurement system, and the processor 14 is a computer.

[0033]Wherein, the laser shock strengthening module 7 includes a forging laser 71 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com