Rack for testing anti-sinking rigidity of side surface of vehicle body

A test bench, side surface technology, applied in the direction of testing material hardness, measuring device, strength characteristics, etc., to achieve the effect of improving test accuracy, stable and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings.

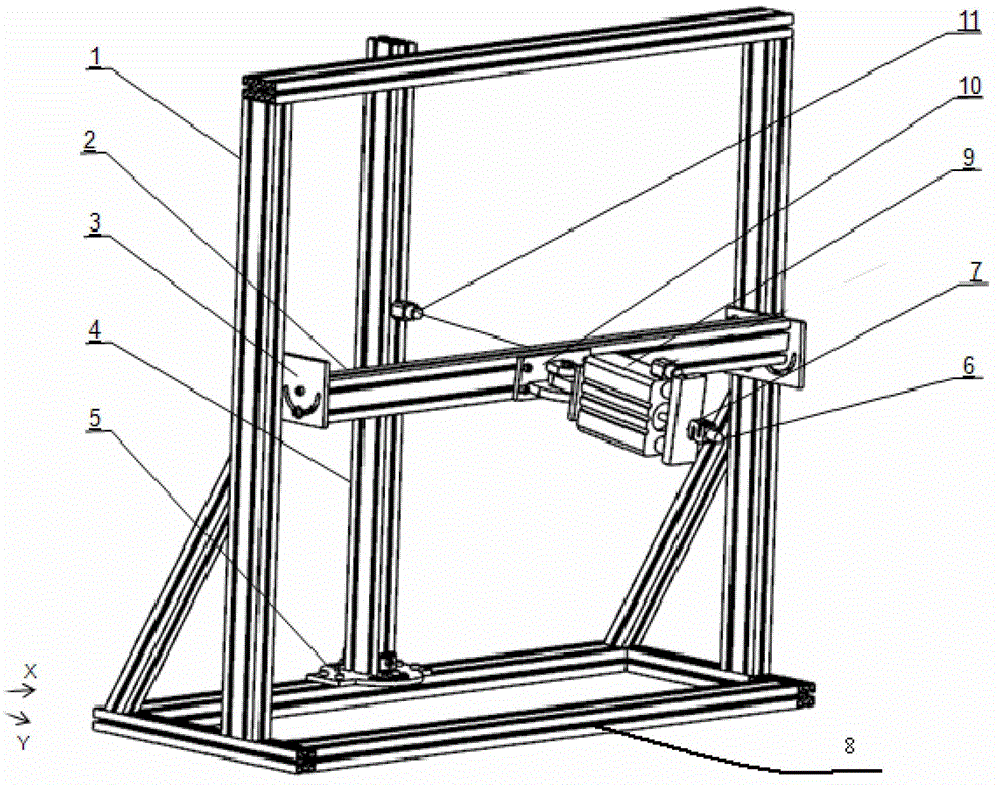

[0039] Such as Figure 1-7 A kind of vehicle body side surface anti-concave rigidity test stand of the present invention shown, comprises underframe 8 and vertical frame 1 and column 4 that are vertical to underframe and is fixedly connected with underframe and is arranged in parallel with each other; This structure is stable and reliable .

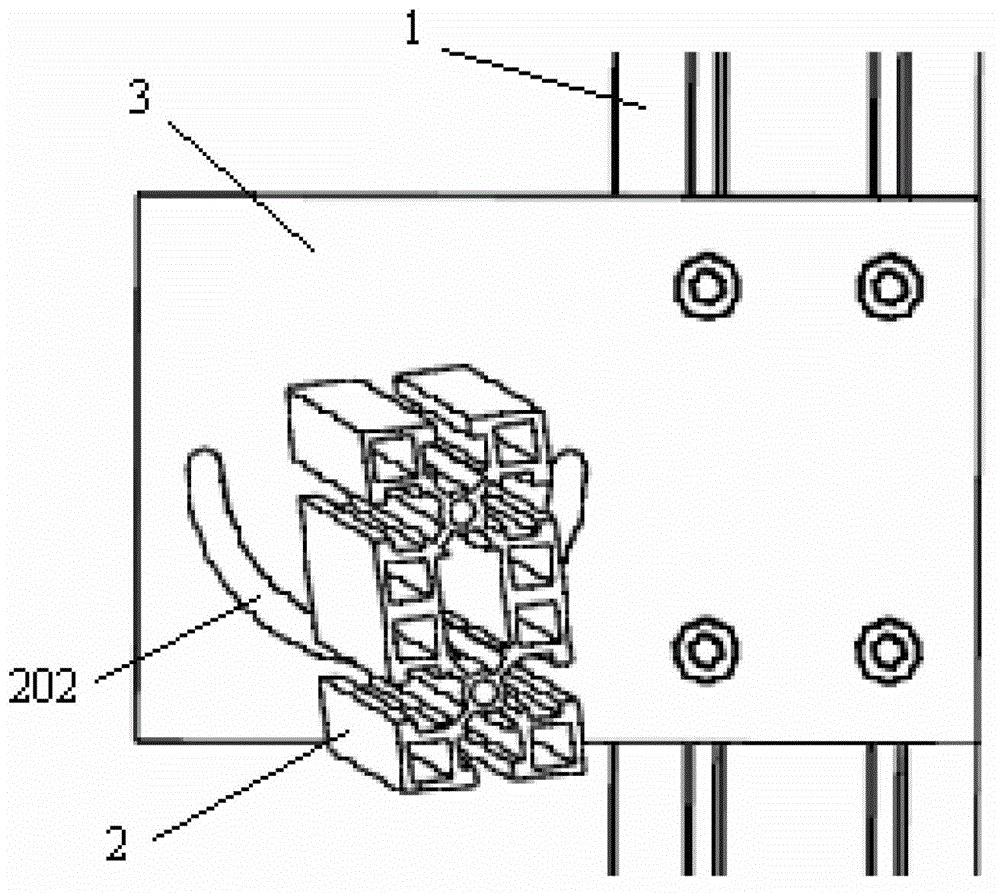

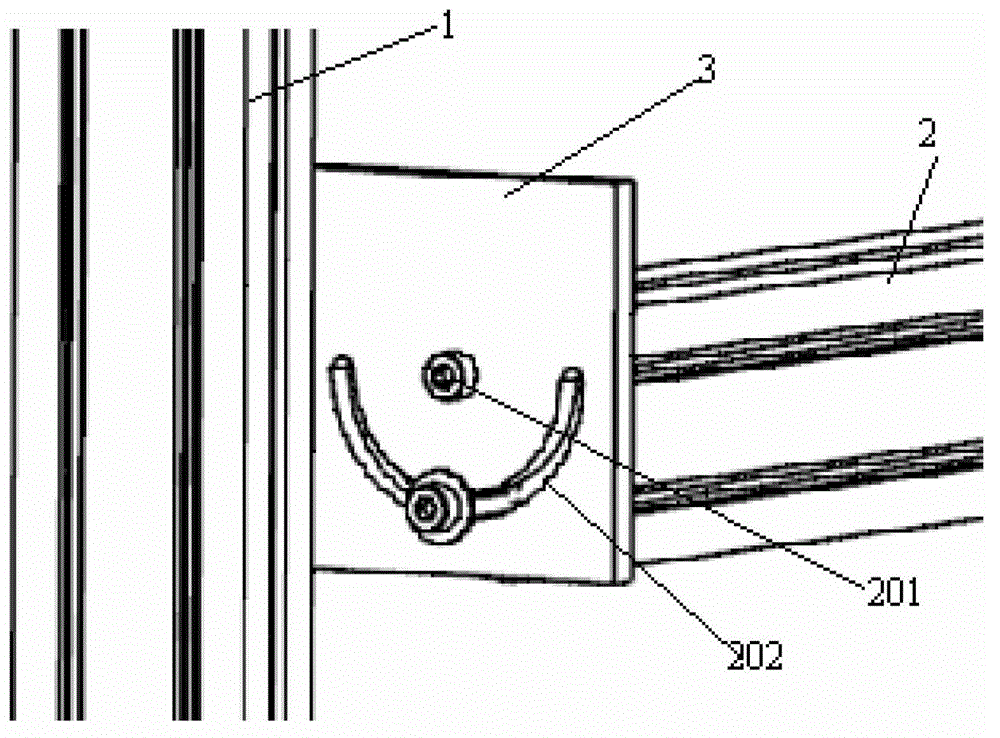

[0040] The two symmetrical mullions of the vertical frame are respectively connected with the beam mounting plate 3; the position of the beam mounting plate relative to the vertical frame can be adjusted up and down; the mounting position of the beam mounting plate can be adjusted along the Z direction of the vertical frame, and then screw The nut is fixed to realize the Z-direction adjustment and locking function of the test head.

[0041] The two ends of the horizontal beam 2 are connected to the vertical frame 1 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com