Horizontal adjustment stranded wire pre-twisting device and method thereof

A level adjustment and pre-twisting technology, which is applied in the manufacture of electrical components, circuits, cables/conductors, etc., can solve the problems of increasing aluminum alloy single wire damage, increasing single wire friction damage, single wire rebound loose, etc., to achieve loose rebound and consistent deformation , the effect of preventing the accumulation of pre-torsion stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

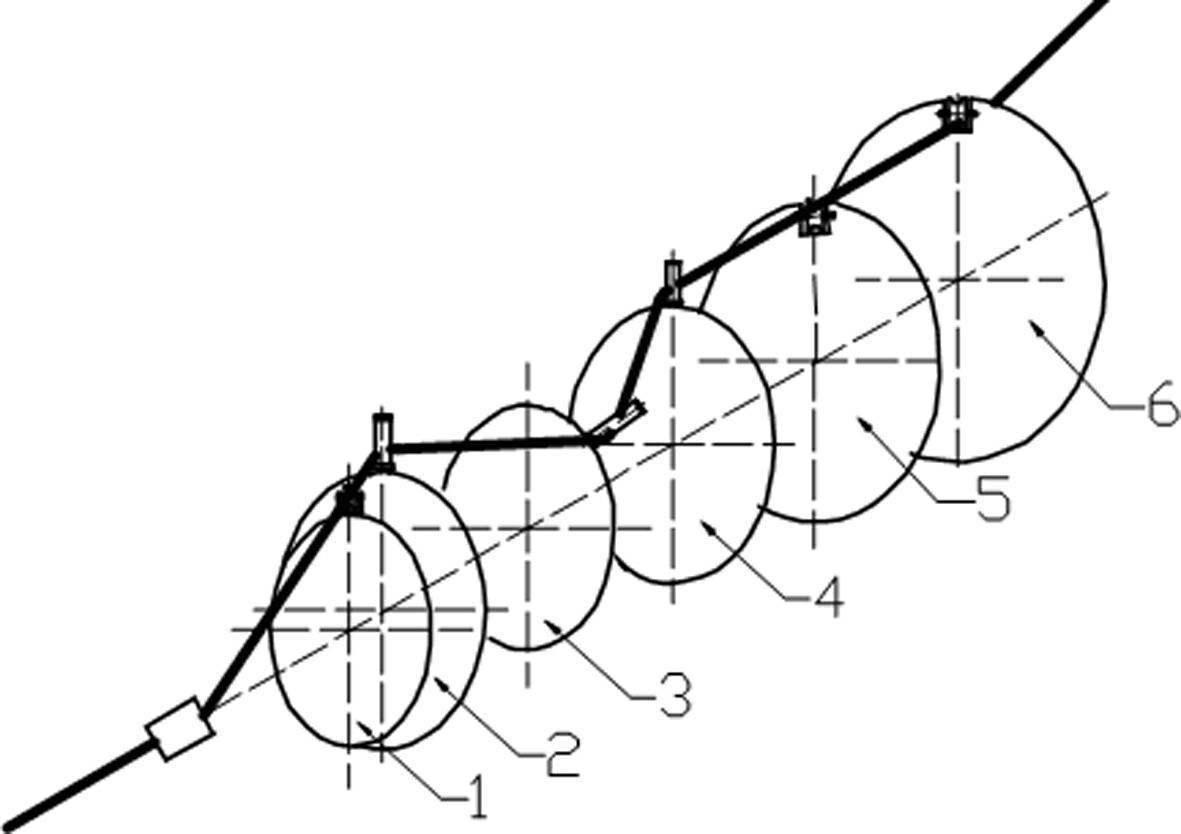

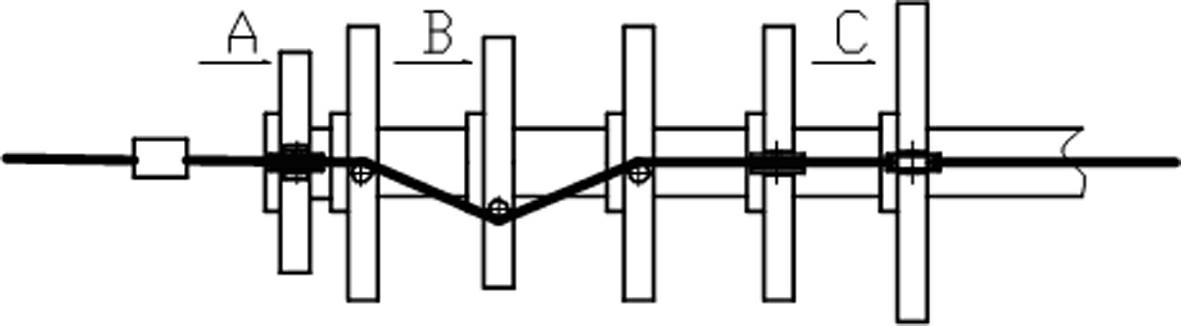

[0048] The "horizontal pre-twisting" device using the pulley as the pre-twisting guide wheel is used to produce large-section high-strength aluminum alloy conductors for the Yellow River large-span on the non-backward twisting machine, which solves the problem of loose rebound of aluminum alloy single wires. Because the equipment pay-off guide wheel and the pre-twisted guide wheel have the same outer diameter, there is no need to increase auxiliary guide wheels 5 and 6. When using the pre-twist device, select the top group of pre-twist guide wheels as the representative of the pre-twist adjustment, and the steps are as follows:

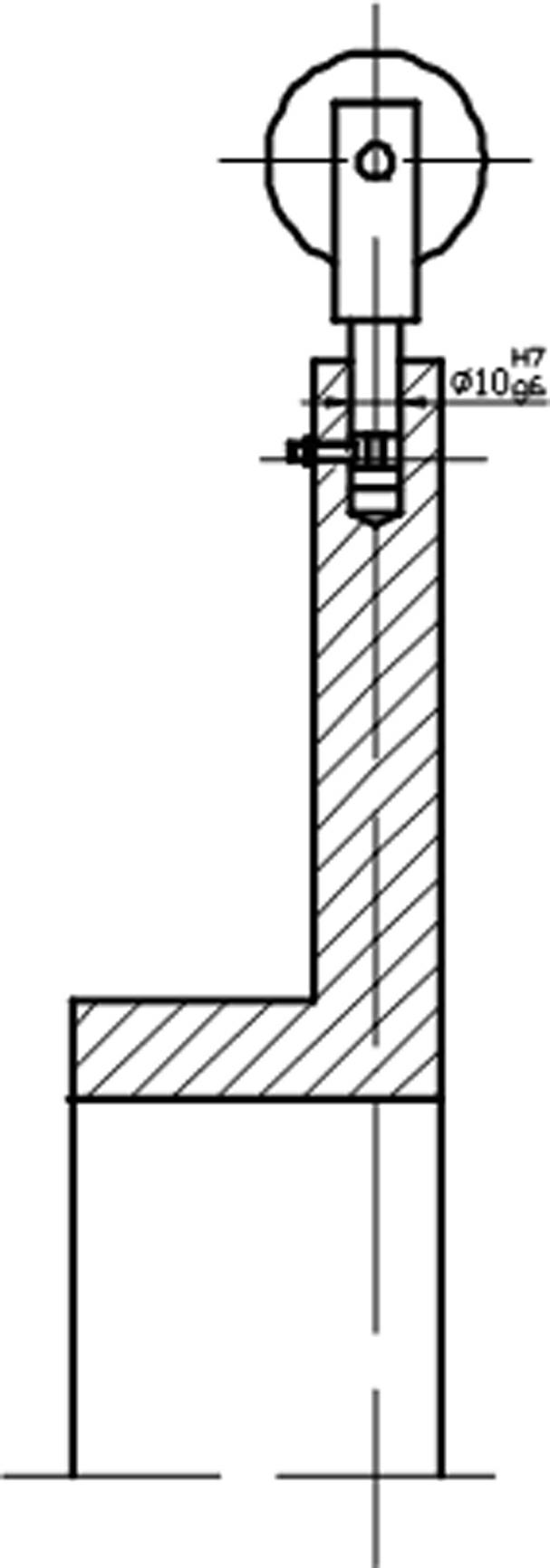

[0049] 1. First, fix disc 1 to an appropriate position to play the role of splitting the wires and prevent misalignment when the single wires are twisted. The up and down position adjustment of the supporting wheel meets the requirements of the natural lifting of the single wire from the guide wheel of disc 2 to prevent damage to the single wire;

[00...

Embodiment 2

[0055] The "horizontal pre-twisting" device using the cylindrical wheel as the pre-twisting guide wheel is used for the steel wire armor stranding production of "special armored cables for oil well exploration and ultrasonic oil augmentation" on the back-twisting stranding machine, which solves the problem of steel wire rebounding and loosening. The structure of the oil well cable is: conductor + inner insulation + metal braided conductor + outer insulation + steel wire armor layer 1 + steel wire armor layer 2. The stranding process of steel wire armor is the same as the stranding process of aluminum alloy conductors. When using the pre-twist device, select the top group of pre-twist guide wheels as the representative of the pre-twist adjustment, and the steps are as follows:

[0056] 1. First, fix disc 1 to an appropriate position to play the role of splitting the wires and prevent misalignment when the single wires are twisted. The up and down position adjustment of the sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com