Clamp for milling joint face of gearbox shell and use method of clamp

A joint surface and gearbox technology, applied in the direction of clamping, manufacturing tools, supports, etc., can solve the problems of difficult clamping, easy deformation of the workpiece, poor machining accuracy of the joint surface, etc., to avoid vibration, reduce clamping time, improve The effect of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to have a further understanding and recognition of the structural features and the achieved effects of the present invention, the preferred embodiments and accompanying drawings are used for detailed description, as follows:

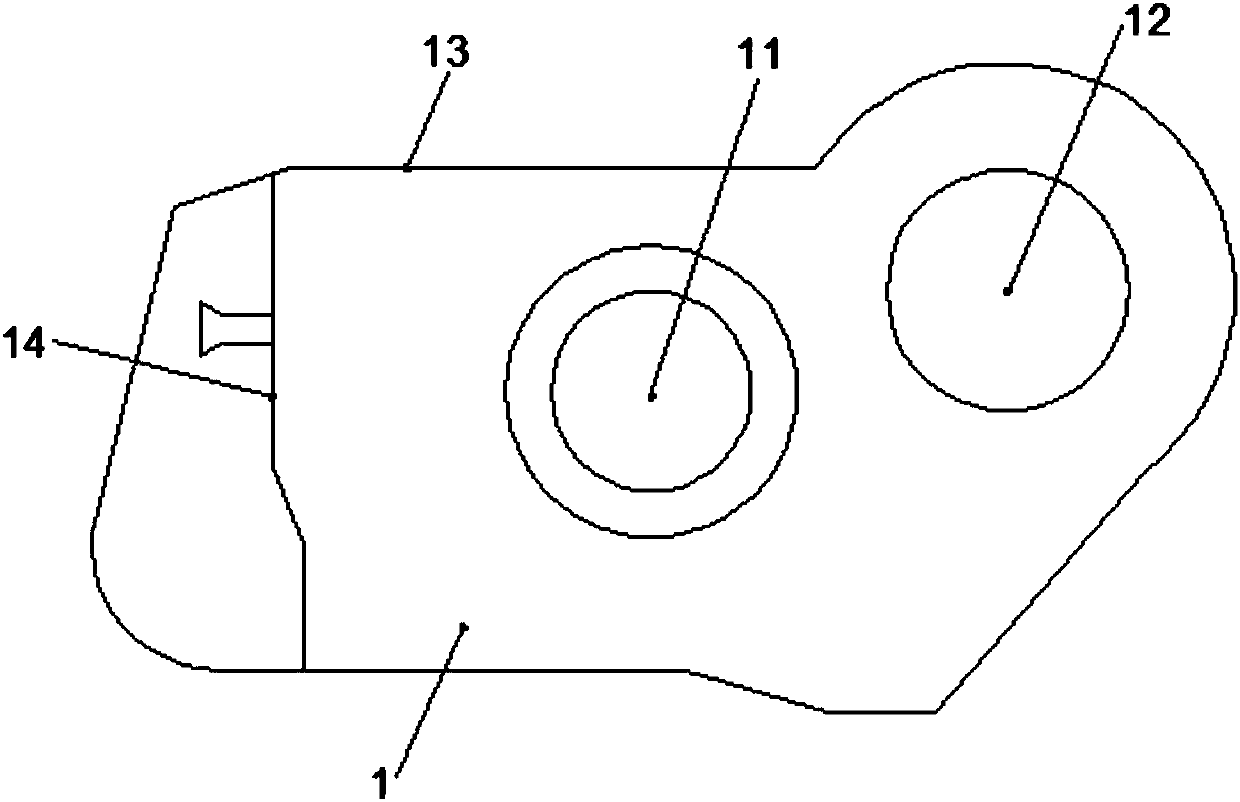

[0027] Such as figure 1 As shown, the gearbox housing 1 is a thin-walled part, and the middle and upper right parts are respectively provided with an assembly hole 11 and an assembly hole 2 12, and the blank surface near the side edge 13 of the housing 1 is smooth and flat. A turning surface 14 is provided at the left middle part of the housing 1 , and the left edge of the housing 1 is the thinnest part of the housing 1 .

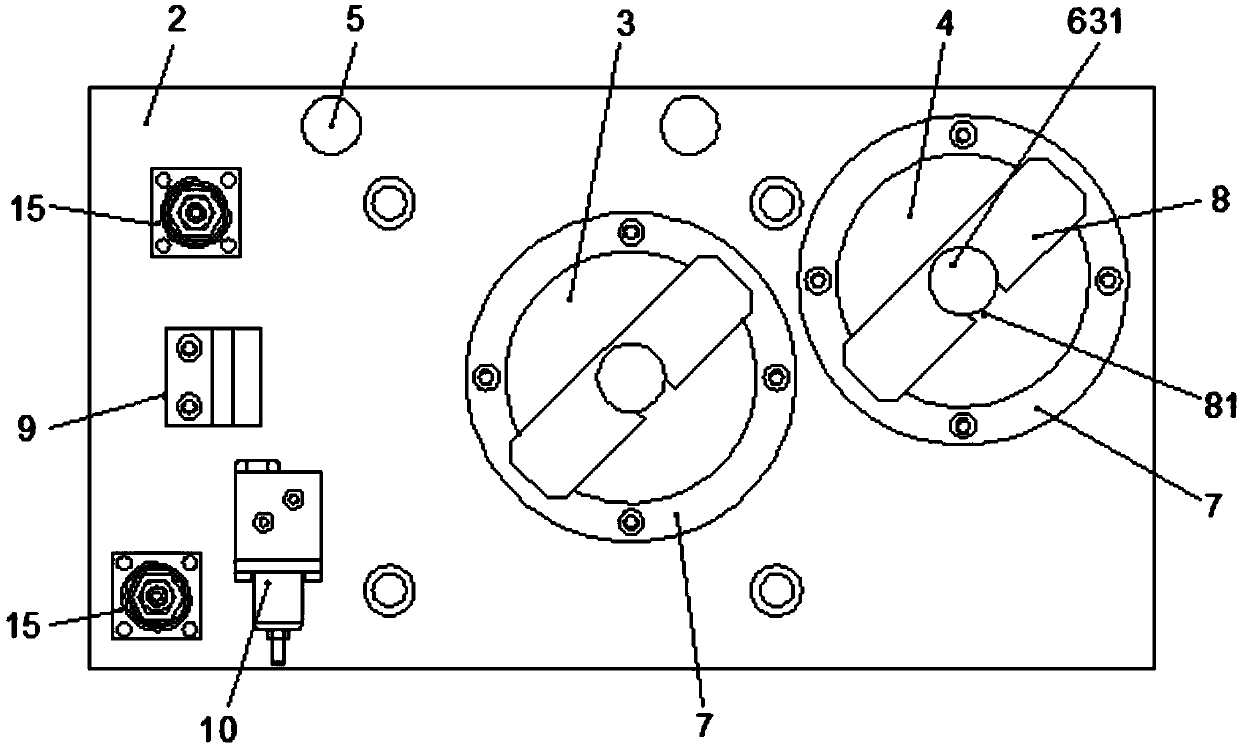

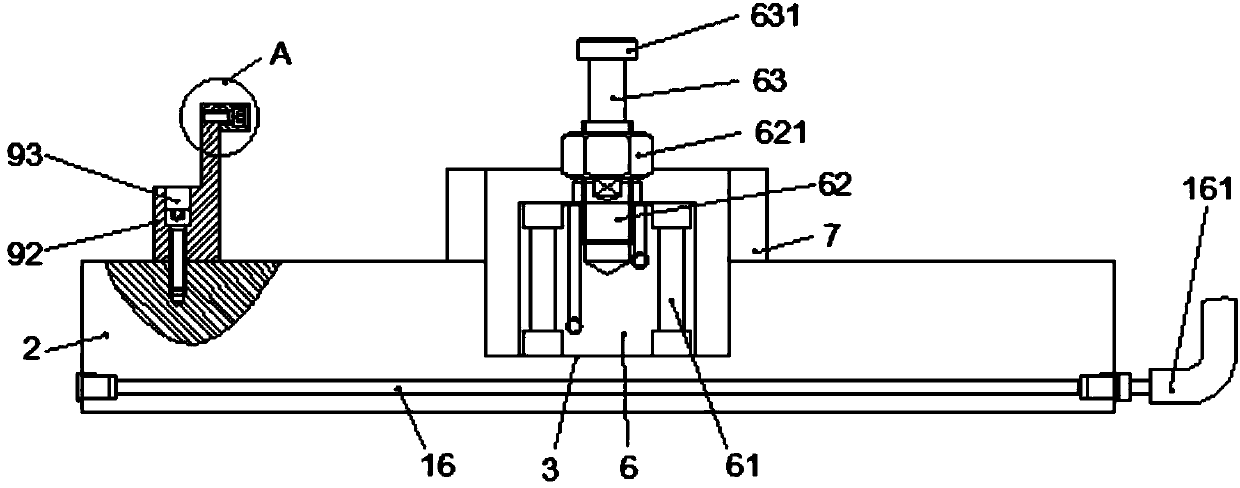

[0028] Such as figure 2 , image 3 As shown, the jig for milling the joint surface of the transmission case includes a base plate 2, and the base plate 2 is provided with a counterbore corresponding to the position of the assembly hole on the housing 1, wherein the counterbore 3 is connected to the assembly hole 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com