Ultra thin reed forming die

A molding die, ultra-thin technology, applied in molding tools, manufacturing tools, metal processing equipment and other directions, can solve the problems of poor overall rigidity, high product cost, large elastic deformation of reeds, etc., to reduce product cost and improve geometry Accuracy and geometric tolerance, the effect of improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

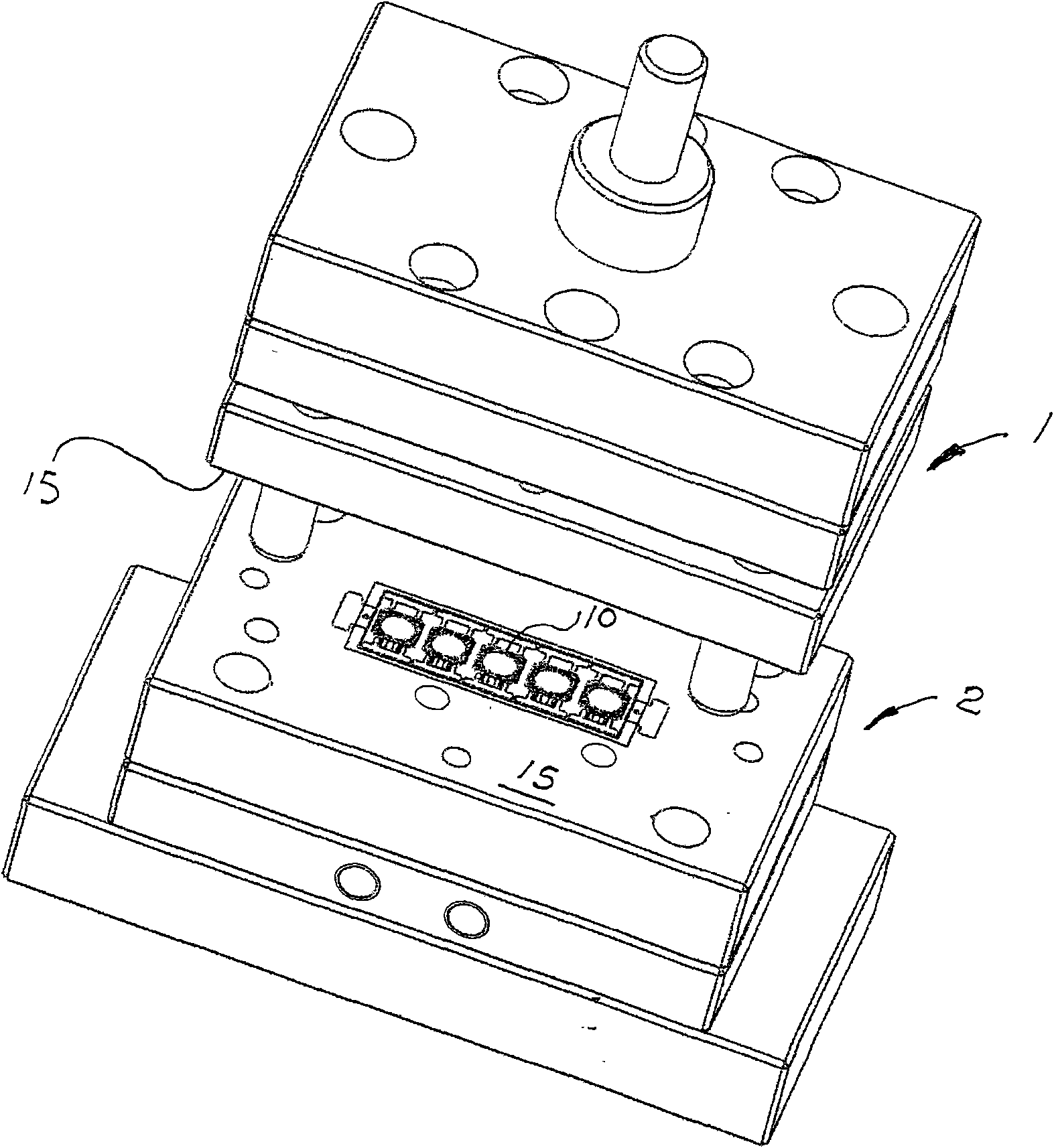

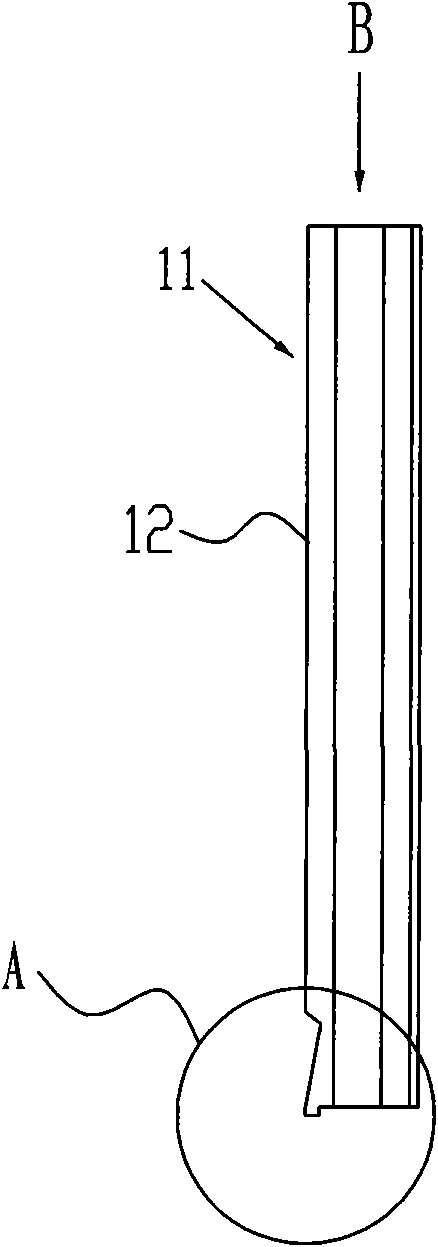

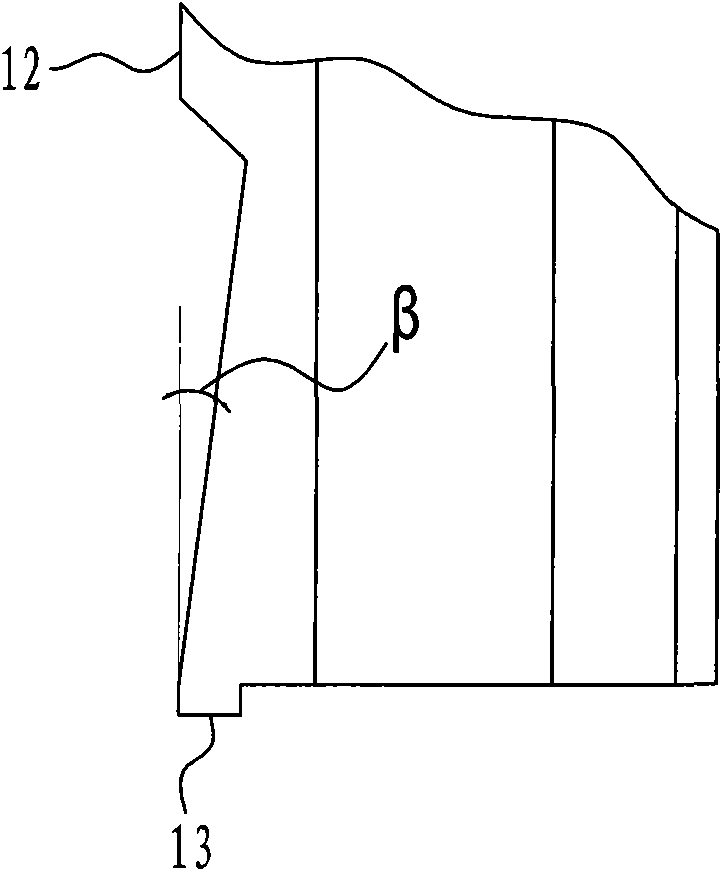

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0026] Figure 1 to Figure 10 An embodiment of the present invention is shown, the ultra-thin reed 10 of the present invention is made of high-quality spring steel sheet, its thickness is only about 0.05 mm, the diameter of the annular outer profile is about Φ9 mm, and the diameter of the circular inner profile is Φ7 mm or so; it is also used as a conductive terminal and is provided with left and right power supply pins 3 of the same thickness on the side of its outline, such as figure 1 , 9 , shown in 10; the power supply pin 3 and the reed plane 4 are in a vertical state, and the pin and the coil in the lens driving mechanism form an electrical circuit and generate electromagnetic force to push the lens to move back and forth in the direction of the optical axis, and the reed The reactionary damping force produced by 10 can keep the lens i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com