Program control method of pentahedron of numerical control plano milling machine

A gantry milling machine and pentahedron technology, applied in the direction of electrical program control, digital control, etc., can solve problems such as easy quality problems and waste of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

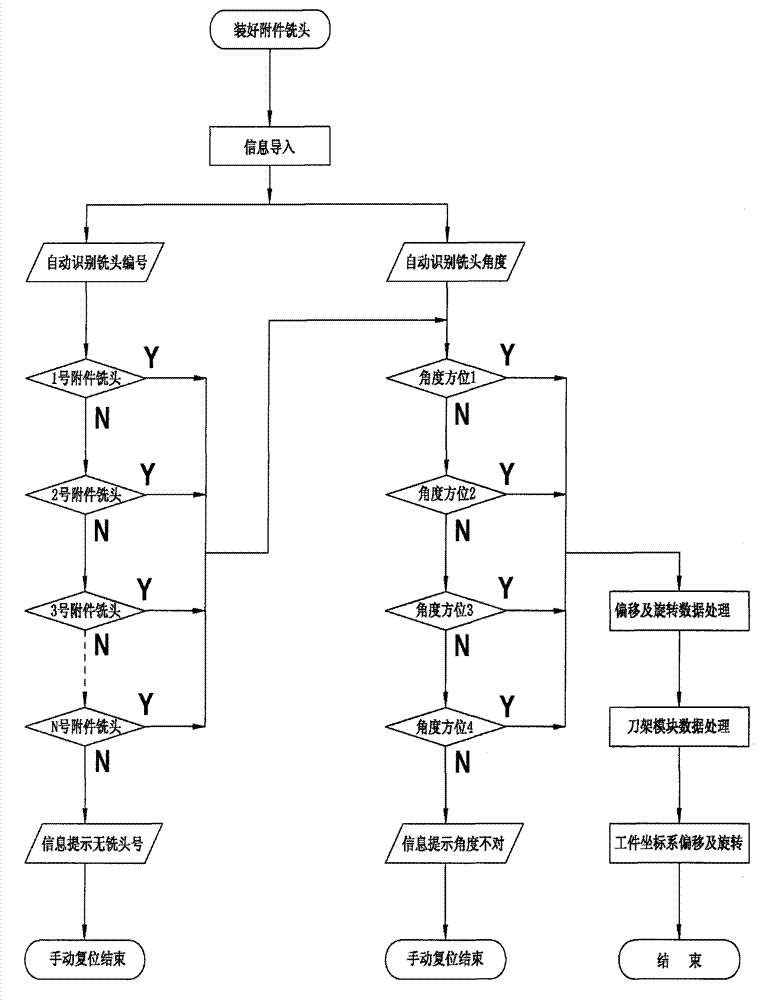

Method used

Image

Examples

Embodiment Construction

[0016] The following examples are used to illustrate the present invention, but are not used to limit the scope of the present invention, all equivalent technical solutions also belong to the category of the present invention, and the patent protection scope of the present invention should be defined by each claim.

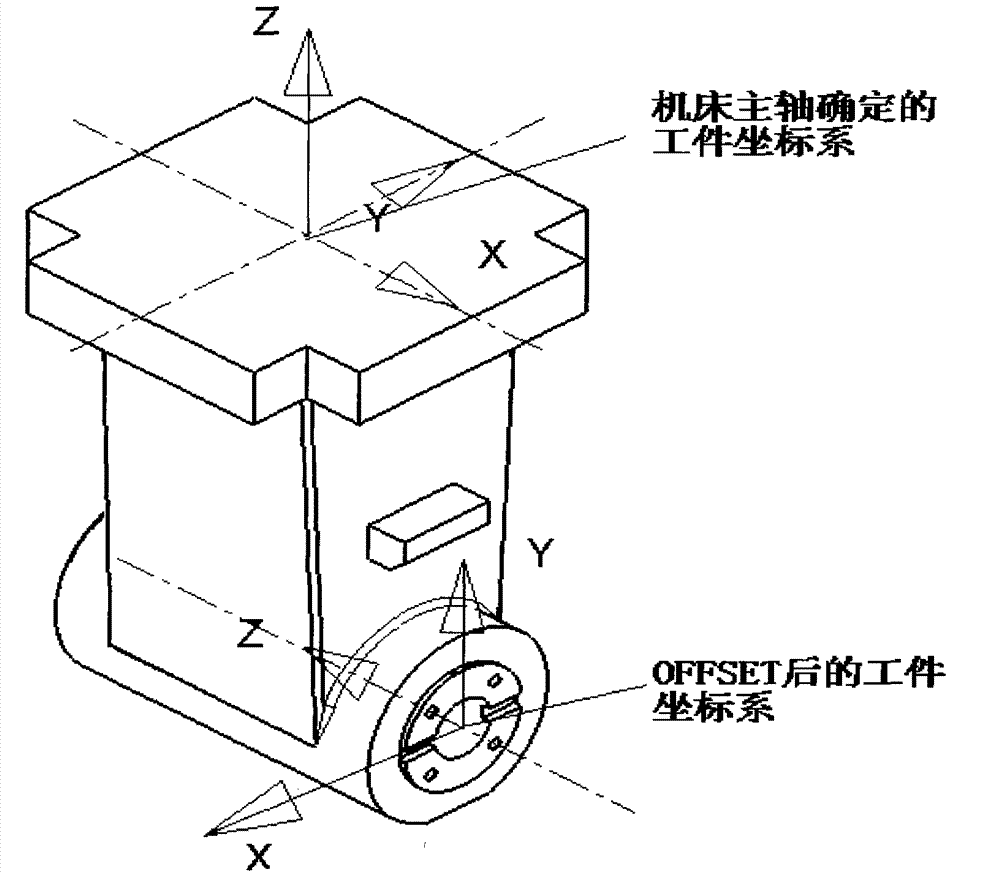

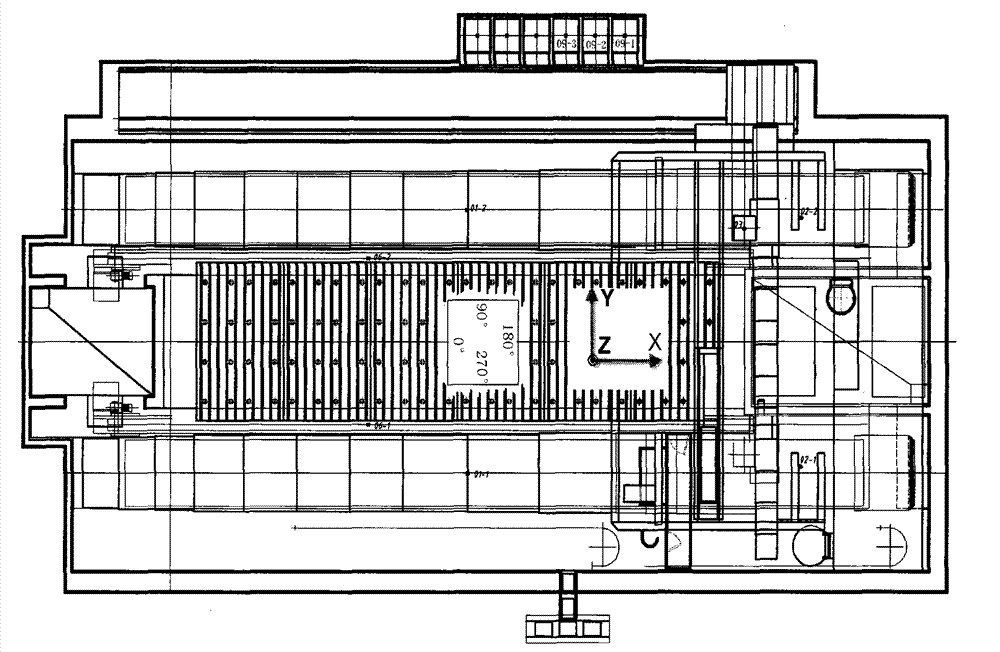

[0017] In order to explain more clearly how the program OFFSET realizes its function during execution, the working process and results of the software will be illustrated in the form of a view. Assume that the milling head is at 0° orientation. That is, the spindle end of the milling head faces image 3 The positive direction of the X axis of the machine tool.

[0018] First: After the gantry milling machine is installed with the accessory milling head, it will be as follows figure 2 As shown, the center above the milling head is the center of the machine tool spindle. When the workpiece is installed, the zero point of the workpiece coordinate syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com