Method for manufacturing oil by using tea oil residues

A technology of oil and oil press, which is applied in the direction of recycling technology, recovery of fat oil/fatty acid from waste materials, and fat generation, etc. It can solve the problems of reducing the use of tea cakes, breeding bacteria, and large changes, so as to improve production and processing efficiency. , Improve oil yield and low moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Take 55 kg of tea oil residue, 35 kg of tea cake, and 10 kg of camellia husk;

[0035] Tea cakes and camellia husks are broken manually or mechanically, so that the maximum diameter of tea cake particles (may be lumpy) is less than five centimeters, and the maximum diameter of camellia husk particles is less than two centimeters; then the broken tea Cake, camellia husk and camellia oil residue are mixed and stirred evenly to obtain compound raw materials;

[0036] Add water to the evenly stirred compound raw materials so that the water content is 7-10%; continue to stir evenly;

[0037] Put the compound raw material after replenishing water into the screw oil press for pressing to obtain 24.03 kg of Camellia oleifera seed oil and newly produced tea cake.

Embodiment 2-11, comparative example 2-11

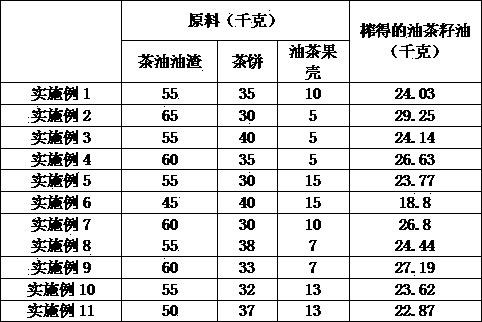

[0042] Examples 2-11 are the same as Example 1 except that the ratio of raw materials and process parameters are different from those of Example 1. Table 1 below lists the raw materials used in each example and the pressed Camellia oleifera seed oil.

[0043] Table 1

[0044]

[0045] The camellia oil dregs that comparative examples 2-11 adopts have the same quality as the camellia oil dregs of the corresponding embodiments, and its preparation method is the same as that of comparative example 1. Table 2 below has listed in detail the raw materials and pressed extracts used in each comparative example. Camellia oleifera seed oil obtained. It can be seen that it is about 3% less (relative to the quality of camellia oil residue) than the Camellia oleifera seed oil squeezed out by each embodiment.

[0046] Table 2

[0047]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com