Domestic oil press with blanking control mechanism

A control mechanism and oil press technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of blockage of the press mechanism, waste of materials, waste, etc., and achieve the effect of avoiding blockage, enhancing versatility, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

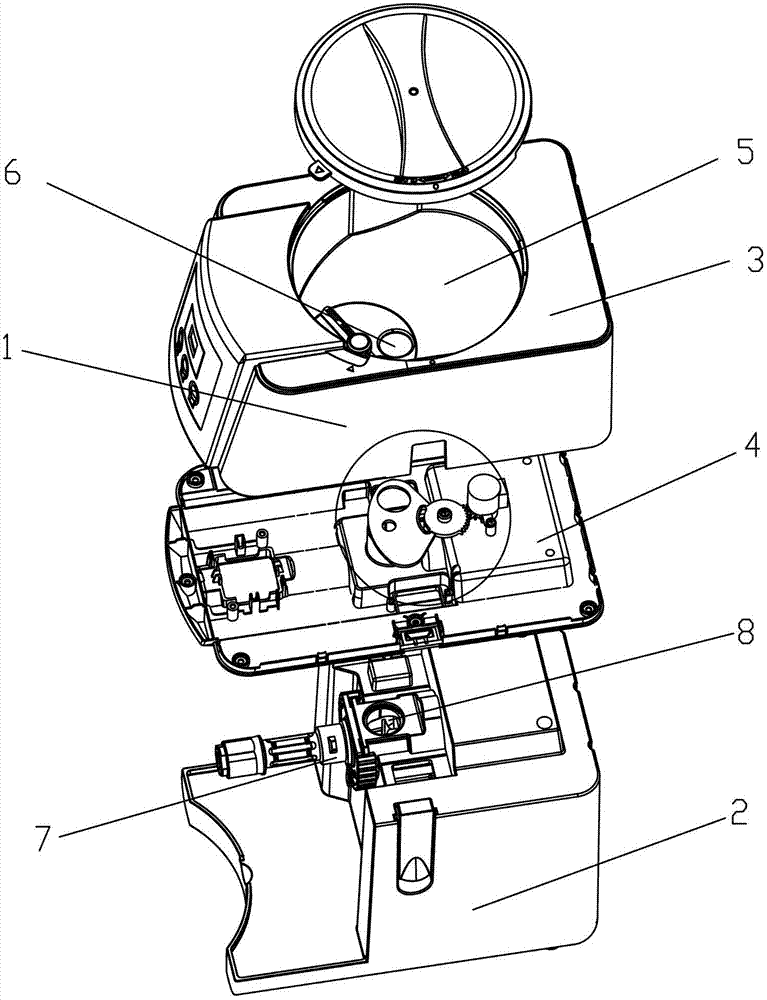

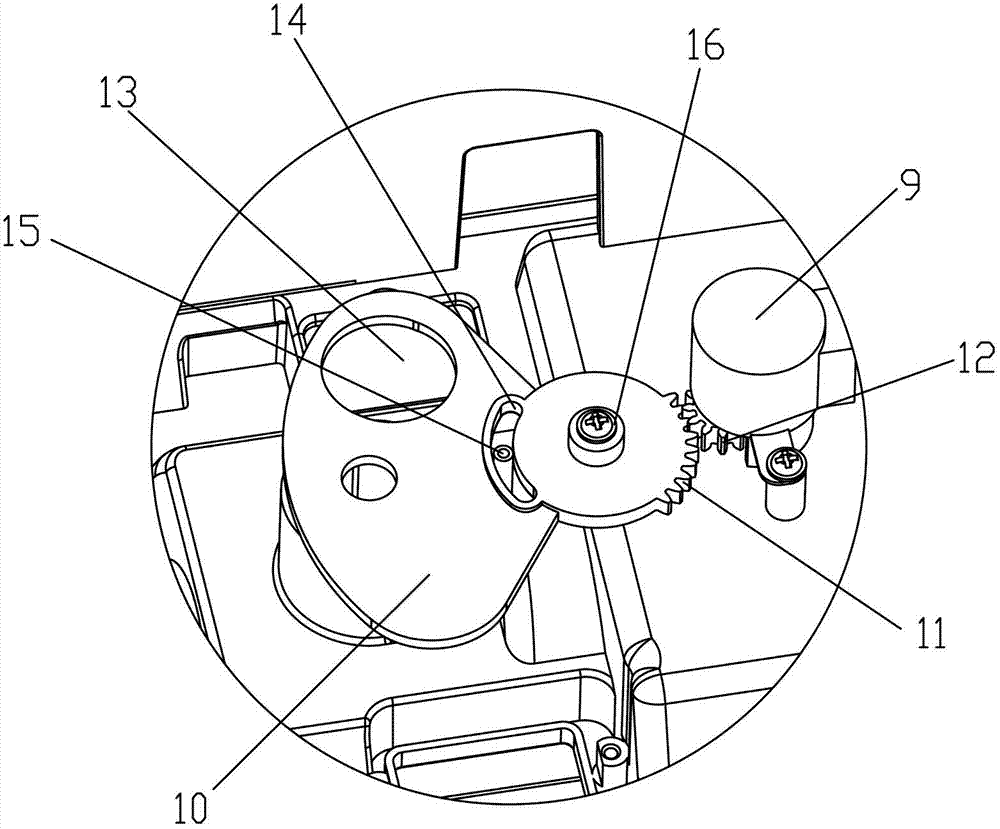

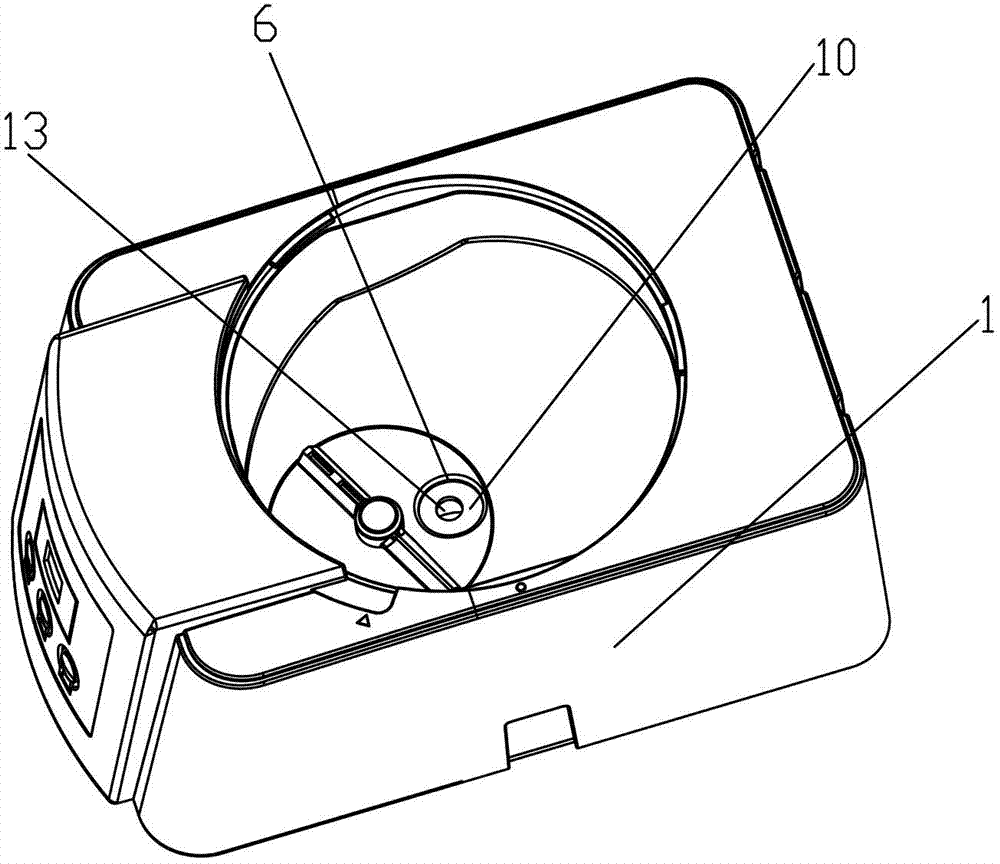

[0015] refer to figure 1 , figure 2 , a household oil press with a feeding control mechanism, including upper and lower machine bases 1, 2, the upper machine base 1 includes a casing 3 and a bottom plate 4, and the casing 3 is provided with a material storage chamber 5 , the storage chamber 5 is provided with a discharge hole 6, the discharge hole 6 is connected with the feed port 8 of the pressing mechanism 7 on the lower machine base 2, the bottom plate 4 is provided with a discharge control mechanism, and the discharge control The mechanism includes a motor 9 and a rotating block 10 linked with the motor shaft. The motor shaft and the rotating block 10 are driven by gears. The rotating block 10 is close to the bottom of the discharge hole 6 and can cover or open the discharge hole 6. .

[0016] The bottom plate 4 of the upper frame of the present invention is provided with a blanking control mechanism, and the rotating blocking plate 10 in the mechanism can cover or open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com