Work transfer apparatus, and work mounting method

A technology for conveying devices and workpieces, applied in metal processing equipment, assembly machines, manufacturing tools, etc., can solve the problems of guarantee, inability, and insufficient extrusion of the adhesive 106, so as to improve the setting accuracy and ensure the bonding strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

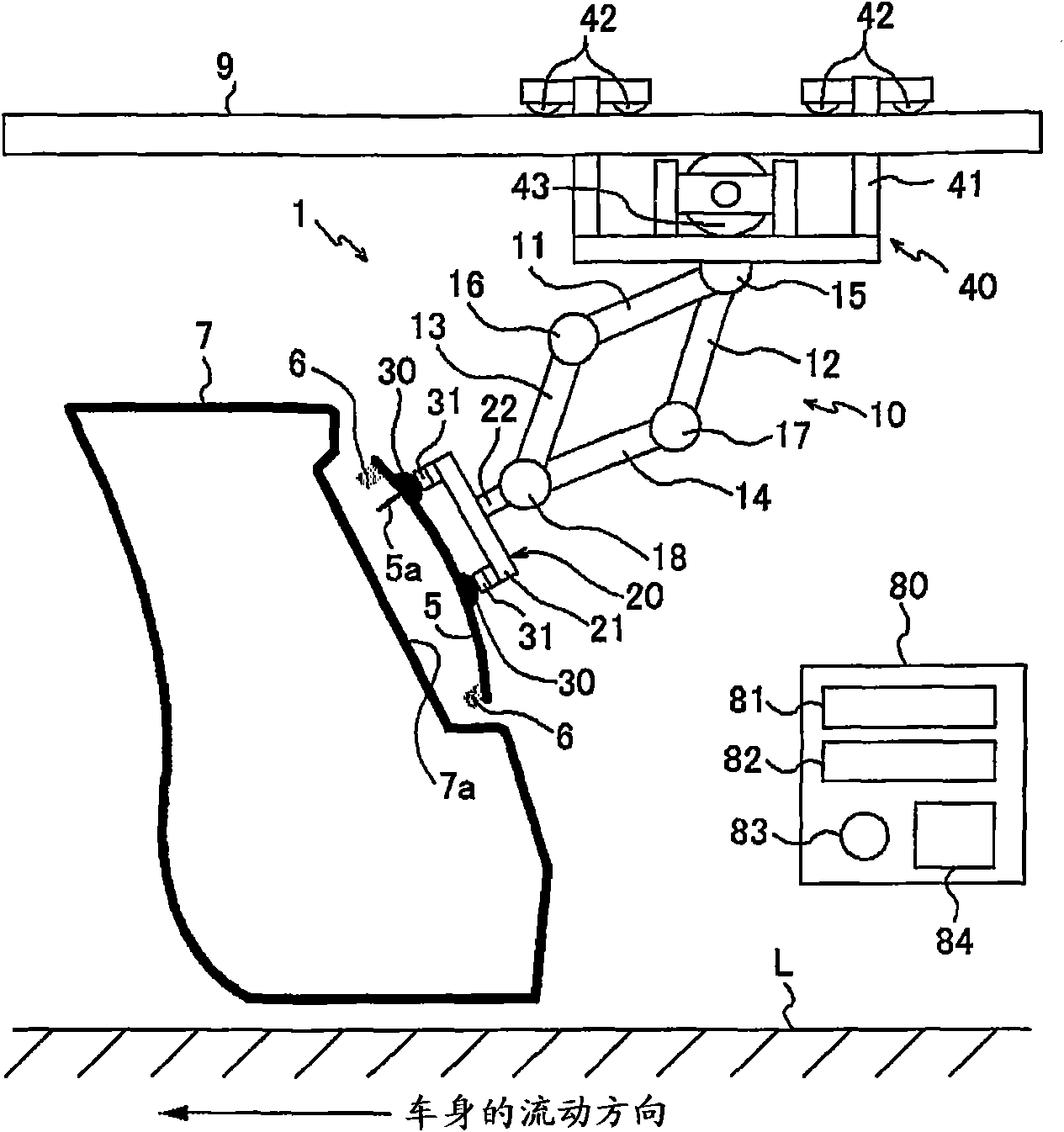

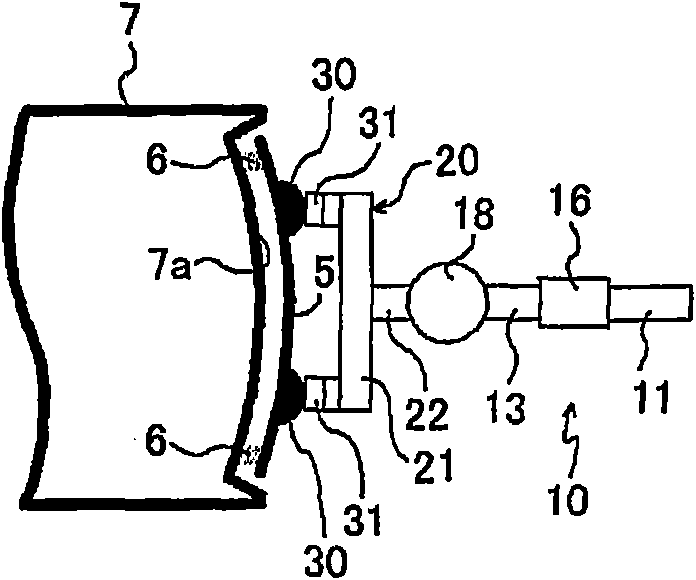

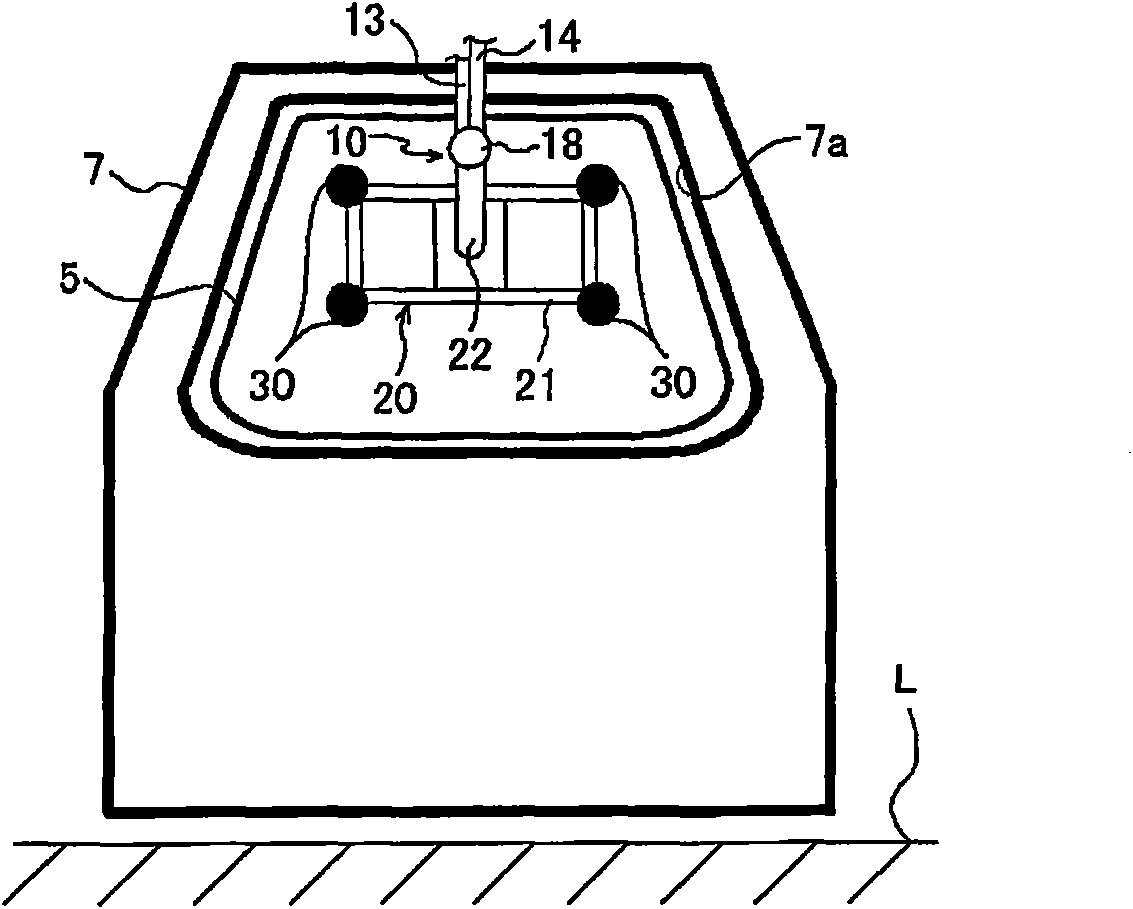

[0064] Figure 1 to Figure 3 The workpiece conveying device 1 shown is the following device: a workpiece (so-called "large workpiece" such as a front windshield glass and a rear windshield glass) that is difficult to carry, position and install with respect to an installed object by one worker, According to the intention of the worker, the workpiece is transported in a three-dimensional manner by cooperating with the worker or independently by the workpiece transport device 1, and is set after being positioned at a predetermined position.

[0065] In this embodiment, the workpiece conveying device 1 is relatively figure 1 The window frame 7 a of the vehicle body 7 , which is the object to be installed on the left side of the center, is installed after positioning the rear windshield 5 as a workpiece. The workpiece transfer device 1 has a holding tool 20 , a support arm 10 , a driving cart 40 and a control device 80 . The holding tool 20 holds the rear windshield 5 . The su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com