Aluminum alloy for bicycle frame tube and preparation method thereof

A technology for bicycles and aluminum alloys, which is applied in the field of aluminum alloys for bicycle frame pipes and its preparation, can solve the problems of insufficient welding process performance, insufficient strength, and difficulty in passing the frame, and achieve fine grain size, improved safety and reliability, and extrusion The effect of smooth pressing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

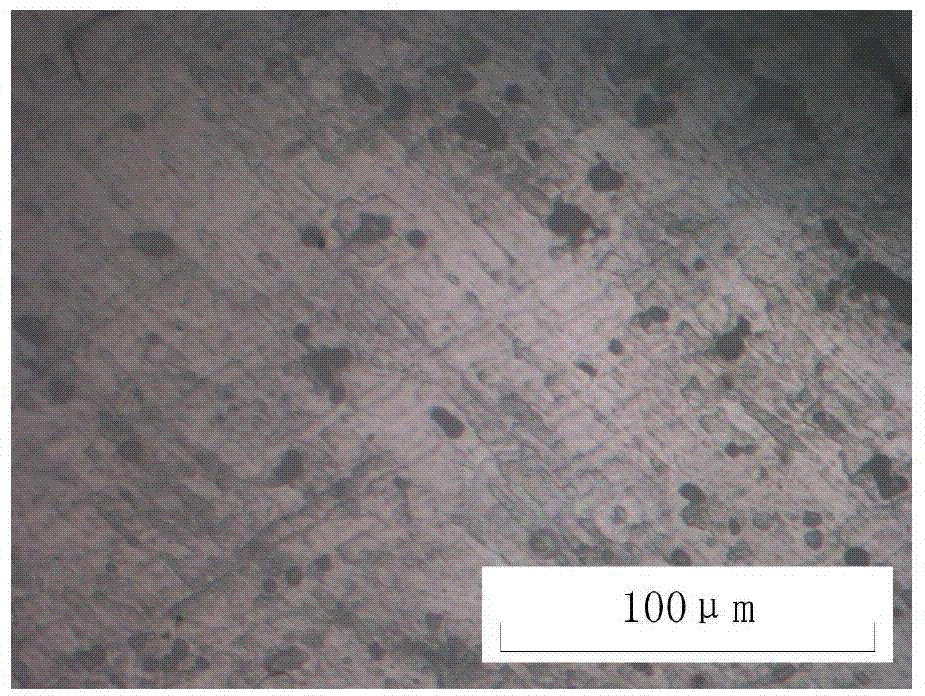

Image

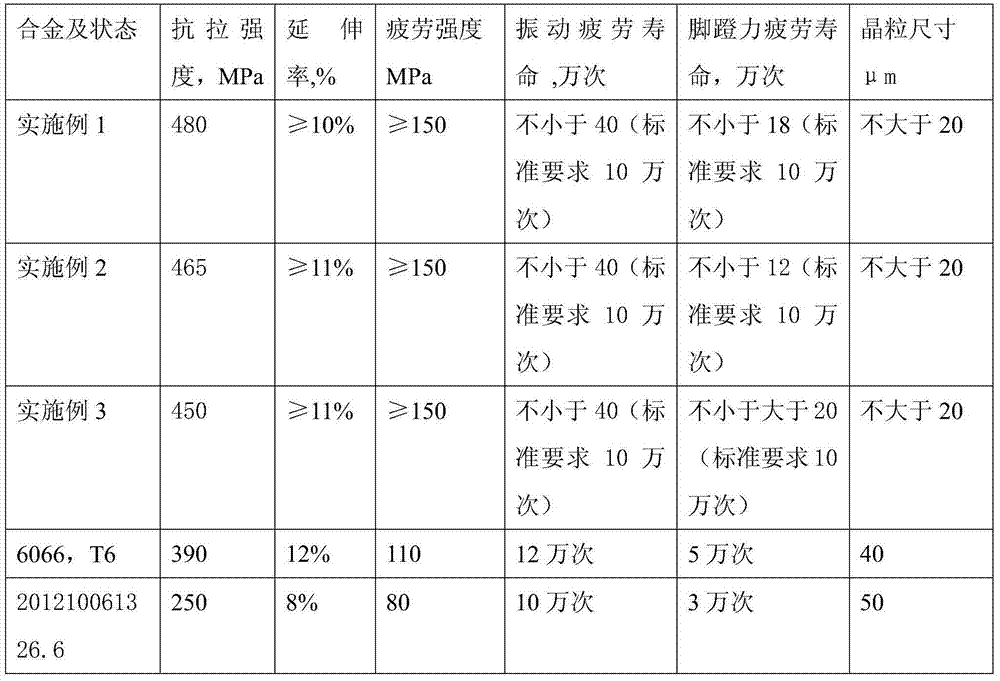

Examples

Embodiment 1

[0023] An aluminum alloy for a bicycle frame tube, which consists of the following components by weight percentage:

[0024] 1.6%Mg, 1.8%Si, 1.2%Cu, 1.4%Mn, 0.30%Cr, 0.60%Er, 0.20%Zr, the balance is Al and unavoidable impurities. Its preparation method comprises the following steps:

[0025] Step 1, transfer the electrolytic pure aluminum liquid into the smelting furnace, add the silicon, manganese, chromium, and copper to the content requirements respectively with crystalline silicon, metal manganese, metal copper, and metal chromium pure substances according to the weight percentage, heat and melt and Stir evenly to obtain alloy melt;

[0026] Step 2, control the temperature of the alloy melt at 750°C, add metal magnesium ingots into the melt, make it melt and stir evenly;

[0027] Step 3, control the temperature of the alloy melt to 740°C, add 1.5% aluminum alloy refining agent or blow in aluminum alloy refining gas and stir and refine for 30 minutes, after removing scum,...

Embodiment 2

[0040] An aluminum alloy for bicycle frame tubes, which consists of the following components by weight percentage: 1.1%Mg, 1.3%Si, 0.9%Cu, 1.0%Mn, 0.2%Cr, 0.3%ER, 0.15%Zr, and the balance is Al and unavoidable impurities. Its preparation method comprises the following steps:

[0041] Step 1, heat and melt the electrolytic aluminum ingot to 750°C, and add the silicon, manganese, chromium, and copper to the content in the form of aluminum-silicon, aluminum-manganese, aluminum-chromium, and aluminum-copper master alloys according to weight percentages. Requirements, heat and melt to obtain alloy melt and stir evenly;

[0042] Step 2, control the temperature of the alloy melt within the range of 740°C, add metal magnesium ingots into the melt, make it melt and stir evenly;

[0043] Step 3, control the temperature of the alloy melt to 730°C, add 1% aluminum alloy refining agent or blow in aluminum alloy refining gas and stir and refine for 20 minutes, after removing scum, cover w...

Embodiment 3

[0056] An aluminum alloy for bicycle frame tubes, which consists of the following components by weight percentage: 0.8%Mg, 0.8%Si, 0.7%Cu, 0.6%Mn, 0.10%Cr, 0.1%Er, 0.08%Zr, and the balance is Al and unavoidable impurities. Its preparation method comprises the following steps:

[0057] Step 1: Heat the pure aluminum ingot to 720°C, and add the silicon, manganese, chromium, and copper to the content requirements in the form of aluminum-silicon, aluminum-manganese, aluminum-chromium, and aluminum-copper master alloys according to weight percentages. , heated and melted to obtain alloy melt and stirred evenly;

[0058] Step 2, controlling the temperature of the alloy melt in the range of 730°C, adding metal magnesium ingots into the melt to melt and stir evenly;

[0059] Step 3. Control the temperature of the alloy melt to 720°C, add 1%-2% of aluminum alloy refining agent or blow in aluminum alloy refining gas and stir and refine for 10 minutes. After removing scum, cover with c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com