Special-purpose equipment for plant fibre tray bidirectional extrusion forming method

A plant fiber, two-way extrusion technology, applied in the pretreatment of molding materials, application, household components, etc., can solve the problems of not being suitable for packaging and transportation of paper items, failing to meet the use requirements, and small bearing capacity of finished products. Achieve the effects of small damage rate, simple structure and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

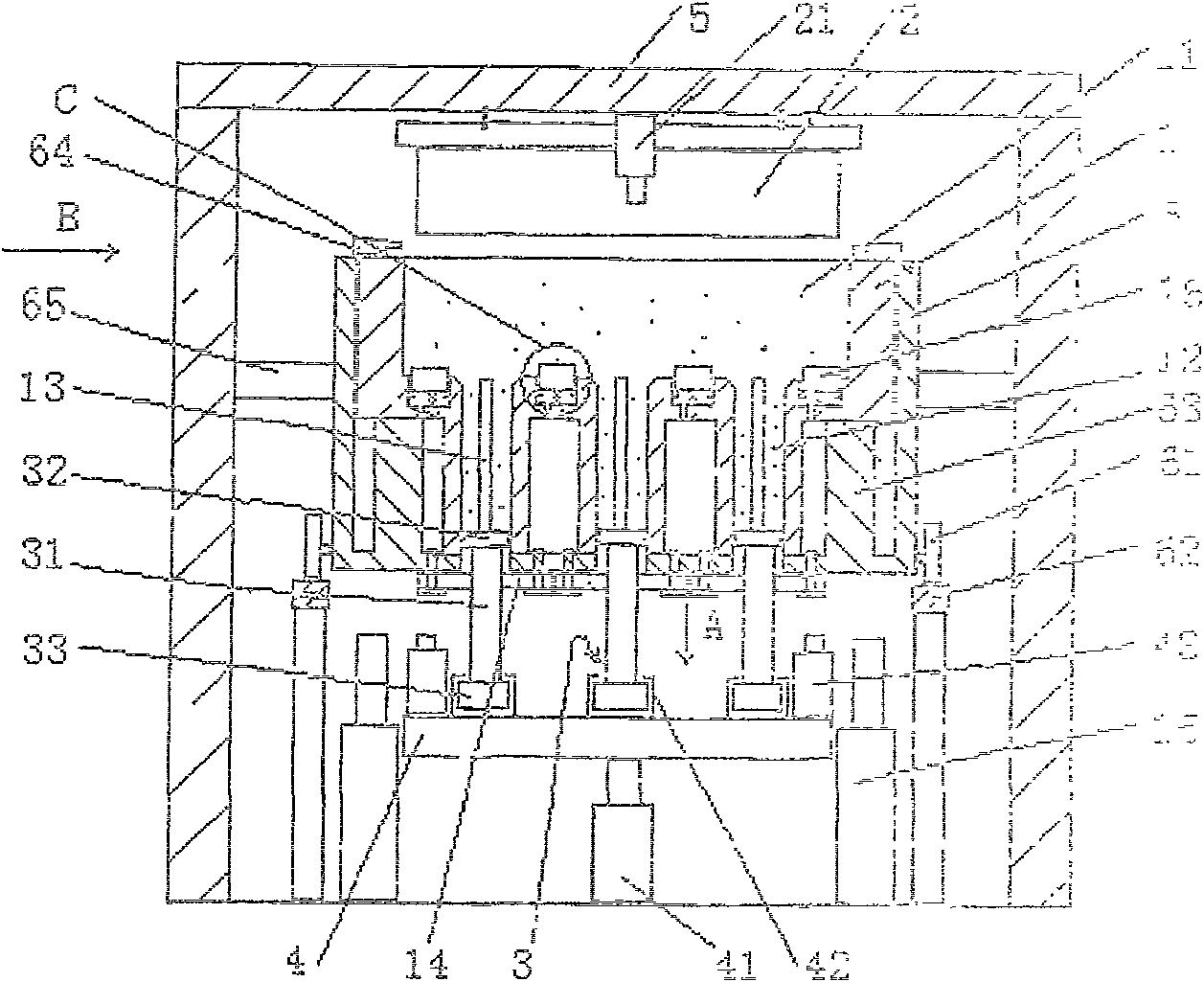

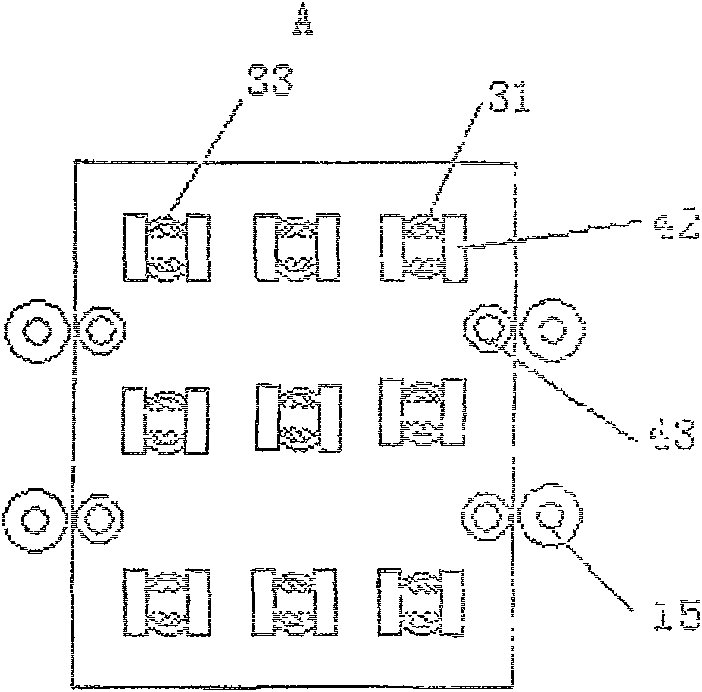

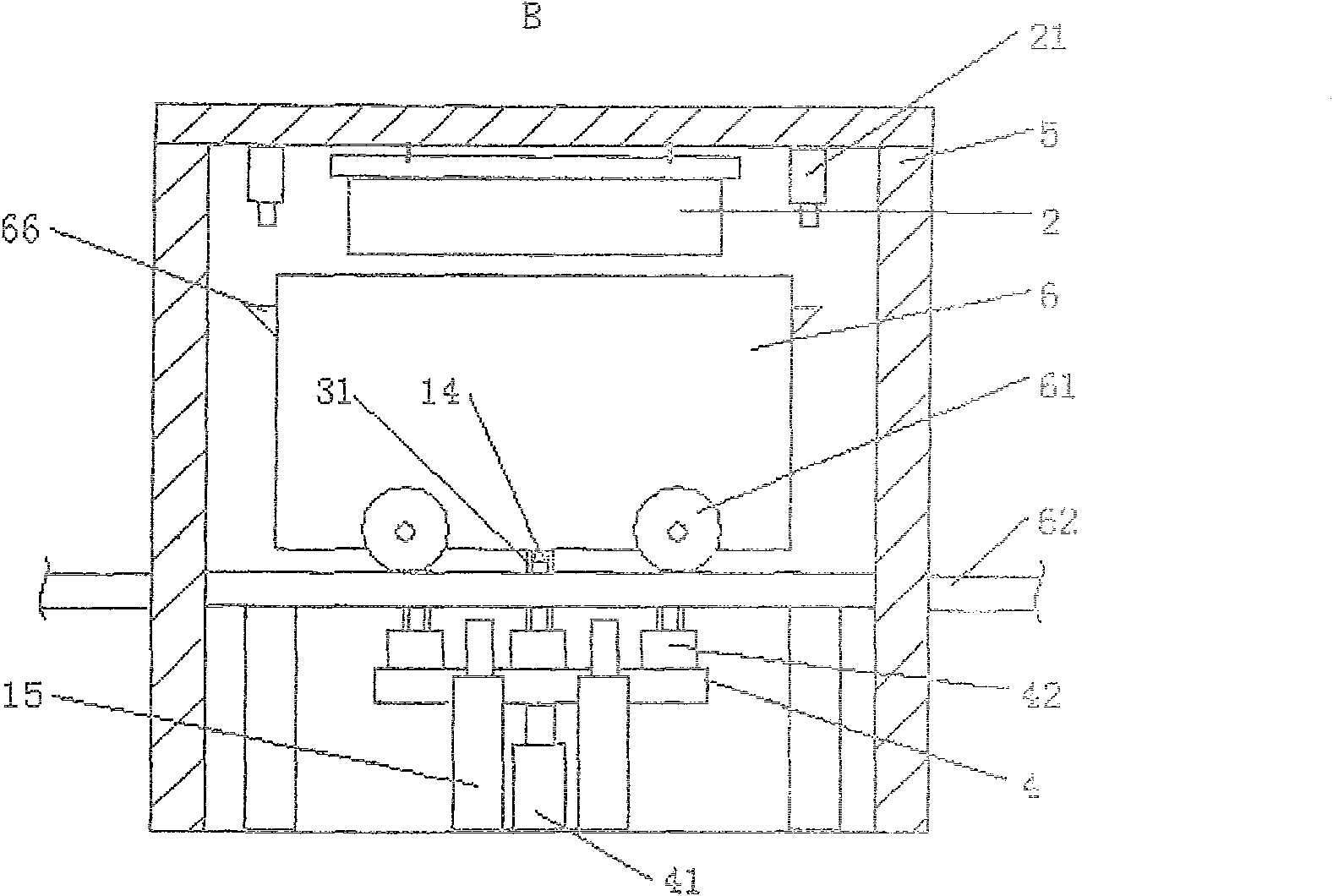

[0032] Such as figure 1 As shown, the special equipment for the plant fiber tray bidirectional extrusion molding method of the present utility model includes a female die 1, an upper die punch 2, a lower die punch 3, a movable frame 4, a frame 5 and a hydraulic power unit.

[0033] Such as figure 1 , 3 As shown, the female mold 1 is located in the box body 6, the bottom of the plate cavity 11 of the female mold 1 communicates with the tray support foot cavity 12, and the bottom of the box body 6 is provided with holes matching the support foot cavity 12 . Such as figure 1 As shown, a core rod 13 is provided with the same circle center in the supporting foot cavity 12, and after the lower end of the core rod 13 stretches out from the hole at the bottom of the box body 6, it is fixedly connected with a positioning plate 14, and the two ends of the positioning plate 14 are fixedly connected to the box body. The bottom of the body 6, the upper end of the core rod 13 is horizon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com