Hot rolling process for soft-state aluminum alloy for anodic oxidation

An anodic oxidation and aluminum alloy technology, applied in the field of aluminum alloy processing, can solve the problems of increased investment risk and stagnant pace of 1090 high-end anodized materials, and achieve products with obvious market competitiveness, significant economic benefits, and simple methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

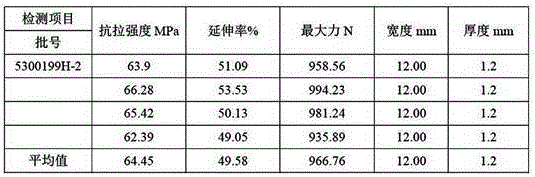

[0028] Example 1 Hot rolling of aluminum alloy (soft state) product for anodic oxidation

[0029] The hot-rolling equipment adopts domestic common single-stand hot-rolling mill. First, the soft 1090 aluminum alloy ingot (purity 99.90%) is homogenized at 450°C at low temperature. After holding for 8 hours, the low-temperature start rolling is carried out at 410-430°C. In the 17th pass, the temperature of the slab dropped to 350-370°C. At this time, a small reduction with a reduction rate of 7% was carried out, followed by an overpressure with a reduction rate of 45% in the following 18 passes. and then continue to adopt the principle of equal reduction distribution for plate and strip rolling, and control the rolling speed during the 21st, 22nd and 23rd three-pass rolling process, and accurately control the hot rolling finish temperature at 235 ~ 250°C range. Under this hot rolling process, the brightness of the reflector product after anodic oxidation reaches a level of ≥90%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com