Glass high-temperature kiln flue gas energy conservation and emission reduction purification system and method

A technology for energy saving, emission reduction, and purification system, which is applied in chemical instruments and methods, separation methods, gas treatment, etc., and can solve problems such as scaling, poor system operation, and immature technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

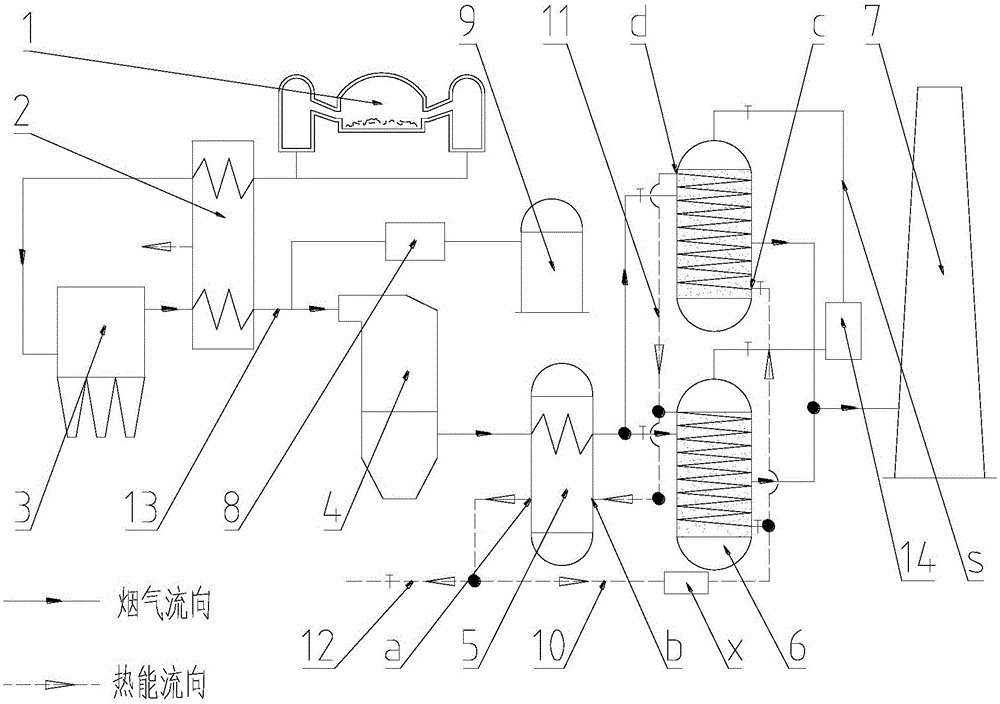

[0025] Embodiment 1: as figure 1 As shown, a glass high-temperature kiln flue gas energy-saving emission reduction purification system includes a glass kiln 1, a catalytic reaction tower 4, and an adsorption system connected in sequence through a flue gas pipeline. The catalytic reaction tower 4 is connected to an ammonia addition device.

[0026] A first heat exchange device 2 and a dust removal device 3 are provided between the glass furnace 1 and the catalytic reaction tower 4, the flue gas outlet of the glass furnace 1 is connected to the high-temperature flue gas inlet of the first heat exchange device 2 The high temperature flue gas outlet of the first heat exchange device 2 is connected to the flue gas inlet of the dust removal device 3, and the flue gas outlet of the dust removal device 3 is connected to the low temperature flue gas inlet of the first heat exchange device 2 connected, the low-temperature flue gas outlet of the first heat exchange device 2 is connected ...

Embodiment 2

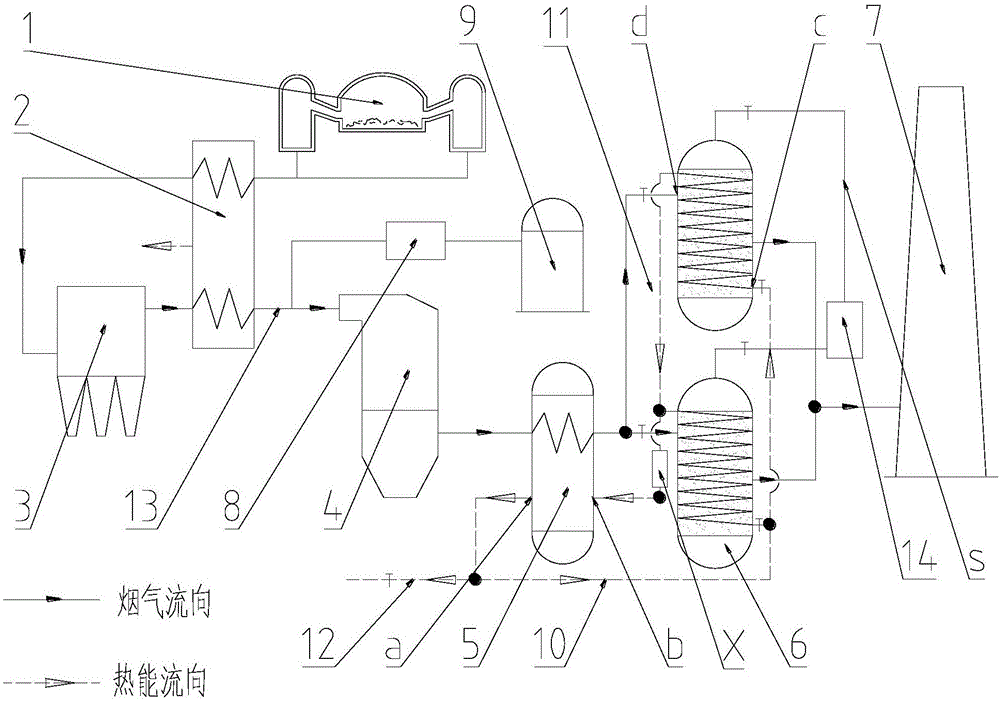

[0032] Embodiment 2: as figure 2 Shown is an energy-saving and emission-reducing purification system for glass high-temperature kiln flue gas. The difference between this embodiment and Embodiment 1 is that the circulation pump x is located on the regenerative heat energy return pipeline 11 .

Embodiment 3

[0033] Embodiment 3: A method for energy-saving and emission-reducing purification of glass high-temperature kiln flue gas. The method is based on a glass high-temperature kiln flue gas energy-saving and emission-reducing purification system and is carried out according to the following steps:

[0034] Step 1: introducing the high-temperature flue gas from the glass kiln 1 into the dust removal device 3 after being cooled by the first heat exchange device 2;

[0035] Step 2: the flue gas treated by the dust removal device 3 is heated up by the first heat exchange device 2 and then introduced into the catalytic reaction tower 4 for desulfurization and denitrification treatment;

[0036] Step 3: The flue gas processed by the catalytic reaction tower 4 is sent to the second heat exchange device 5 for cooling treatment again, and finally sent to any of the adsorption towers 6 for flue gas adsorption, and is adsorbed in the flue gas While regenerating another said adsorption tower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com