Sealed recovery and operation pressure stabilizing control method for tank top tail gas of refinery enterprise atmospheric storage tank

A technology for atmospheric storage tanks and tank roofs, which is applied in the field of recovery of exhaust gas from the roof of atmospheric storage tanks in refining and chemical enterprises and operation and pressure stabilization control. Recycling and other issues to achieve the effect of eliminating odor pollution sources, solving pollution problems, and eliminating volatile organic compound (VOC) emission sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

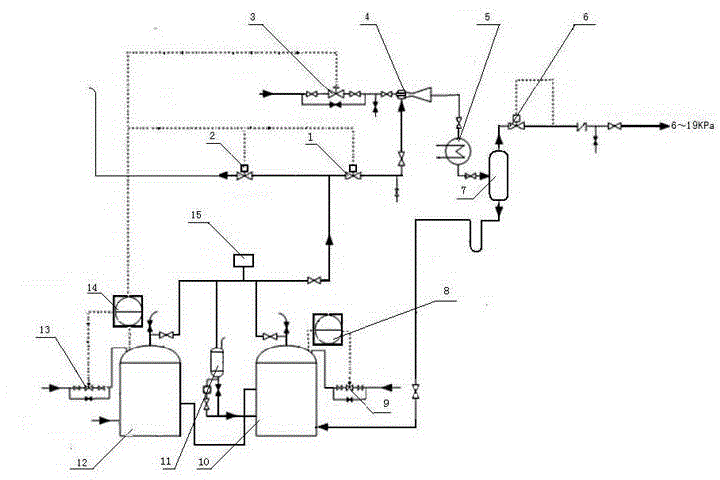

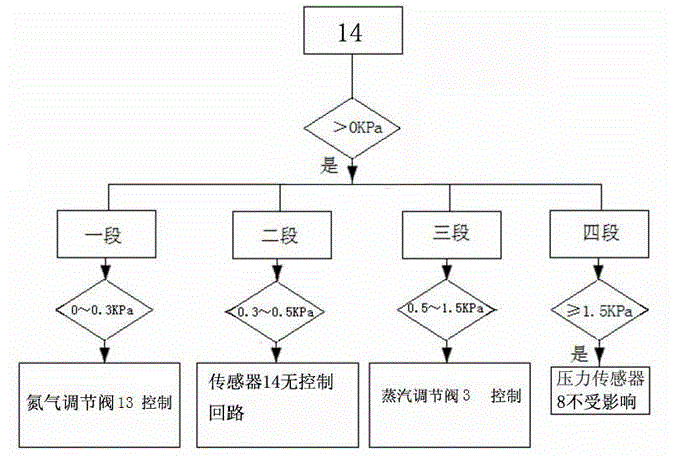

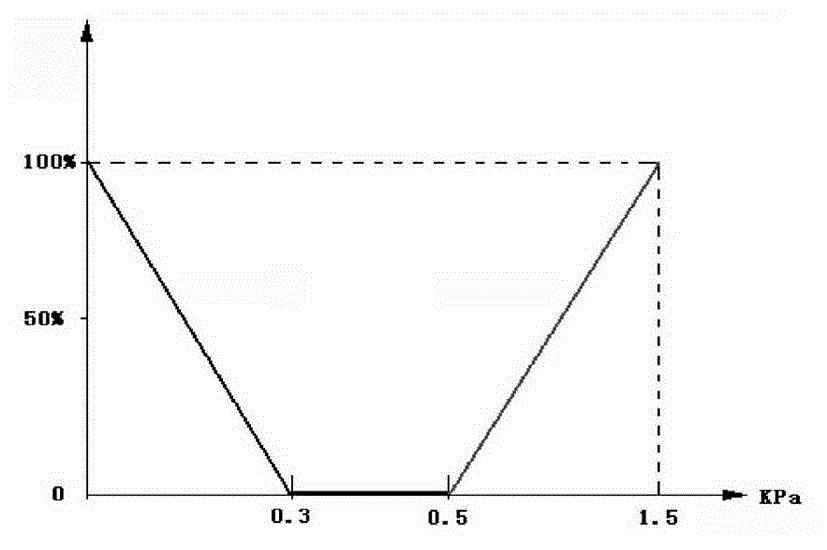

[0028] according to figure 1 As shown, a method for airtight recovery of exhaust gas on the roof of atmospheric storage tanks in refining and chemical enterprises

[0029] There is a sewage storage tank, the air pressure in the sewage storage tank 12 is 0~1.8kPa, the 1.0MPa steam sent by the tank top exhaust gas of the sewage storage tank through the pipeline and the steam regulating valve 3 enters the steam injection compressor 4, and passes through the gas-steam On-line pressurization, the mixed gas of tail gas and steam is sent to the circulating water cooler 5 to cool to 45°C, and after entering the gas-liquid separator 7 for separation, when the pressure in the gas-liquid separator (7) is greater than When the system is used, the non-condensable gas enters the low-pressure gas flare system of the refinery under self-pressure, and the pressure of the low-pressure gas flare system of the refinery is 6-19kpa, and the condensate flows back to the sewage storage tank 10 under ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com