Selective hydrogenation catalyst for carbon five fraction and preparation and use thereof

A hydrogenation catalyst and selectivity technology, which is applied in the chemical industry, can solve the problems of small load, poor selectivity, and short life, and achieve the effects of convenient operation, long selectivity, and reduced investment costs and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

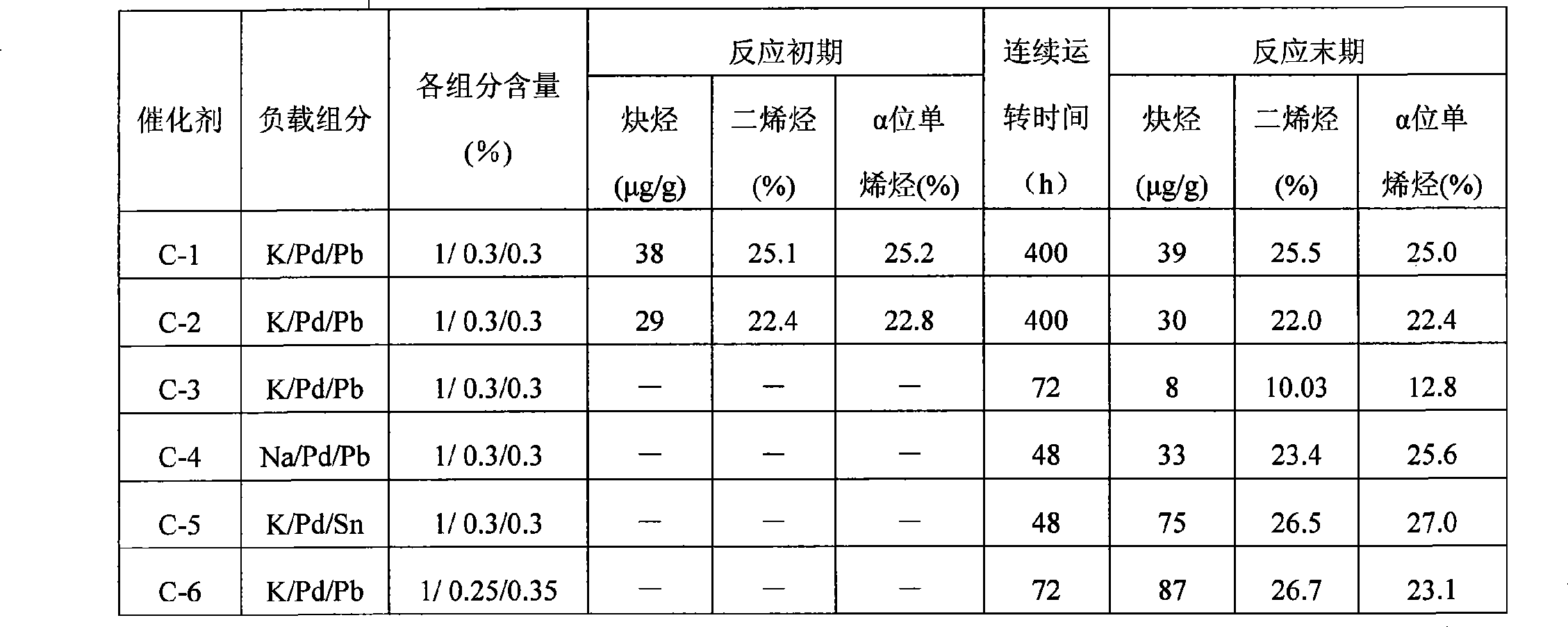

Examples

Embodiment 1

[0048] 1. Preparation of carrier S-1

[0049] 1000 grams of α-gibbsite (Shandong Aluminum Factory adopts Bayer method to produce, solid content 60~65wt%) and Y zeolite mixture are packed in the container of 2 liters of vibrations, and wherein Y zeolite quality accounts for 5% of powder mass, Make the container quickly pass through the 700°C high temperature zone for dehydration, the residence time is 0.5 seconds, then put the obtained powder into a small granulator and spray water while rolling, roll into small balls with a diameter of 2 to 4 mm, and then put the small balls in the Place in a sealed bag at room temperature, that is, keep healthy for 24 hours, then hydrate in water at 90°C and pH 7 for 8 hours, dry at 120°C for 4 hours, and roast at 1000°C to obtain alumina-zeolite composite carrier balls, which are expressed as carrier S -1.

[0050] 2. Preparation of Catalyst C-1

[0051] Take 100 grams of carrier S-1, and impregnate the alumina carrier (BET surface area 75...

Embodiment 2

[0053] 1. Preparation of carrier S-2

[0054] Weigh the mixture of 100g of SB powder and Y zeolite, wherein the quality of Y zeolite accounts for 5% of the powder mass, and use 100ml of water and 3.0g of HNO 3 Mix evenly, extrude into strips with a diameter of 1.6mm on a catalyst extrusion molding machine, dry under an infrared lamp for 5 hours, place in an oven to dry at 120°C for 12 hours, bake in a muffle furnace at 1000°C for 5 hours, and cut into 3 A thin strip of -8 mm, denoted as carrier S-2.

[0055] 2. Preparation of Catalyst C-2

[0056] Get 100 grams of carrier S-2 (BET surface area 70m 2 / g), at room temperature, with potassium nitrate aqueous solution (0.1M) impregnated alumina support (BET surface area 75m 2 / g), dried at 120°C for 12 hours, then calcined at 500°C for 4 hours, taken out and cooled to room temperature; impregnated with aqueous hydrochloric acid solution of palladium chloride (pH value is 3.5), and then dried at 120°C for 12 hours , and then ba...

Embodiment 3

[0058] 1. Preparation of carrier S-3

[0059] Put 1000 grams of α-gibbsite (produced by Bayer method in Shandong Aluminum Plant, solid content 60-65% by weight) into a 2-liter vibrating container, and make it quickly pass through the 700°C high-temperature zone for dehydration, with a residence time of 0.5 Seconds, then put the obtained powder into a small granulator and spray water while rolling, roll into small balls with a diameter of 2 to 4 mm, then put the small balls in a sealed bag at room temperature, that is, keep healthy for 24 hours, and then Hydrate in water at 90°C and pH 7 for 8 hours, dry at 120°C for 4 hours, and bake at 1000°C to obtain alumina balls, which are represented as carrier S-3.

[0060] 2. Preparation of Catalyst C-3

[0061] Get 100 grams of carrier S-3 (BET surface area 55m 2 / g), repeat the preparation process of catalyst C-1 in Example 1. The catalyst prepared in this way is designated Catalyst C-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com