Bimetallic sintering process of spheroidal graphite cast iron and copper

A technology of nodular cast iron and bimetal, which is applied in the field of bimetal sintering technology of nodular cast iron and copper, which can solve the problems of surface inclusions and poor bonding strength of the joint surface, achieve good distribution and ensure the effect of sintering quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

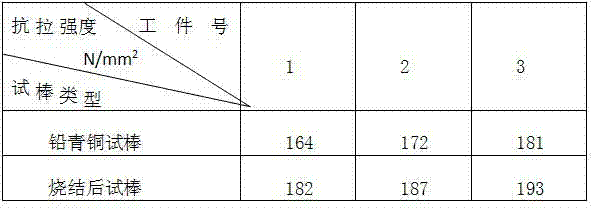

Embodiment 1

[0018] Embodiment 1: a kind of bimetallic sintering process of ductile iron and copper, its step comprises:

[0019] a. Raw material selection:

[0020] Substrate: Nodular cast iron QT700 is used. According to the design process requirements, without affecting the subsequent processing, the structure of the substrate parts is improved to ensure effective control of the generation of sintered pores.

[0021] Copper rod: lead bronze is selected, the mass percentage of which is Pb120g, Sn60g, Ni10g, Fe5g, and the remaining content is Cu730g. After descaling, it is turned to meet the process requirements.

[0022] b. Ultrasonic cleaning:

[0023] Before sintering, use water-based cleaning liquid to thoroughly clean the washing cylinder and copper rods of ductile iron, and reliably and economically clean and remove debris, oil, and emulsion on the workpiece to ensure the sintering quality.

[0024] c. Vacuum cleaning:

[0025] Under the condition of vacuum and negative pressure,...

Embodiment 2

[0033] Embodiment 2: a kind of bimetallic sintering process of nodular cast iron and copper, its step comprises:

[0034] a. Raw material selection:

[0035] Substrate: Nodular cast iron QT700 is used. According to the design process requirements, without affecting the subsequent processing, the structure of the substrate parts is improved to ensure effective control of the generation of sintered pores.

[0036] Copper rod: lead bronze is selected, and the mass percentage is Pb150g, Sn80g, Ni30g, Fe10g, and the remaining content is Cu815g. After descaling, it is turned to meet the process requirements.

[0037] b. Ultrasonic cleaning:

[0038] Before sintering, use water-based cleaning liquid to thoroughly clean the washing cylinder and copper rods of ductile iron, and reliably and economically clean and remove debris, oil, and emulsion on the workpiece to ensure the sintering quality.

[0039] c. Vacuum cleaning:

[0040] Under the condition of vacuum and negative pressure...

Embodiment 3

[0048] Embodiment 3: a kind of bimetallic sintering process of nodular cast iron and copper, its step comprises:

[0049] a. Raw material selection:

[0050] Substrate: Nodular cast iron QT700 is used. According to the design process requirements, without affecting the subsequent processing, the structure of the substrate parts is improved to ensure effective control of the generation of sintered pores.

[0051] Copper rod: lead bronze is selected, of which the mass percentage is Pb130g, Sn70g, Ni20g, Fe7g, and the remaining content is Cu780g. After descaling, it is turned to meet the process requirements.

[0052] b. Ultrasonic cleaning:

[0053] Before sintering, use water-based cleaning liquid to thoroughly clean the washing cylinder and copper rods of ductile iron, and reliably and economically clean and remove debris, oil, and emulsion on the workpiece to ensure the sintering quality.

[0054] c. Vacuum cleaning:

[0055] Under the condition of vacuum and negative pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com