Plastic pipe electrofusion connector with mesh structure electric heating element and preparation method thereof

A technology of electric heating elements and plastic pipes, which is applied in the direction of pipe connection layout, pipe elements, siphon pipes, etc., can solve the problems of mismatching size of connectors and pipes, easy short circuit, high temperature, etc., to avoid unstable quality, avoid circuit breakage, reduce The effect of surface load power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Prepare the electrofusion connector of the plastic pipe whose specification is straight through Dn200, select the brand in Table 1 as GH140, the thickness is 1mm, the alloy resistance sheet material with a resistivity of 1.04, this material contains 20% chromium (Cr), 0.35% aluminum (Al), and the rest are iron (Fe) and rhenium (Re), and the specific implementation process is as follows:

[0058] 1. According to the specification of the connector of Dn200, cut the above material into a strip material with a width of 48mm according to the required width of the welding strip;

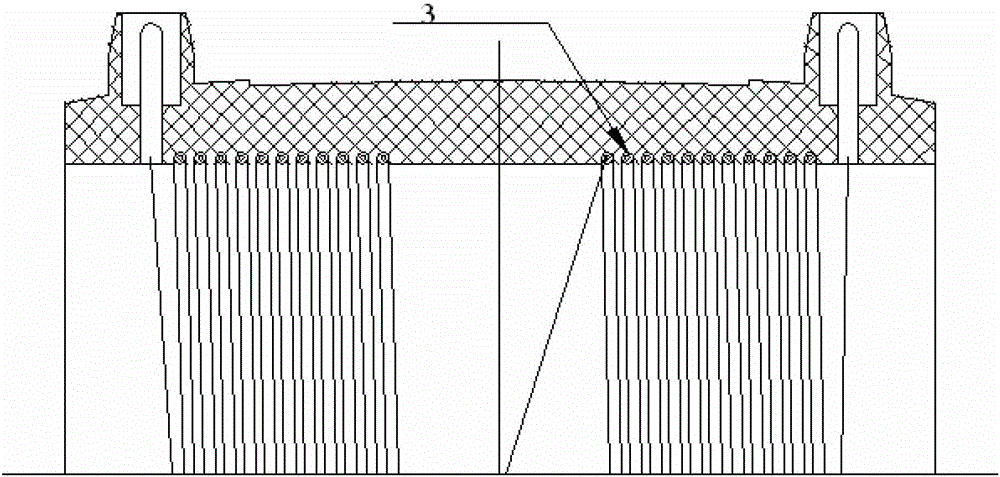

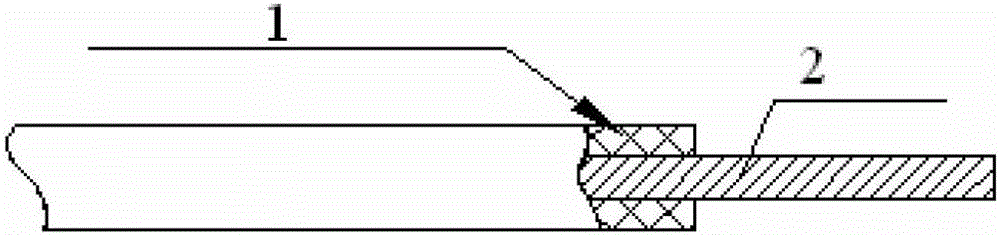

[0059] 2. Continuously punch 5x5mm prismatic holes on the belt with the stamping process of feeding the punching die, the width of the side ribs constituting each mesh is 2mm, and the obtained hole mesh belt is pressed according to the electric fusion connector. The inner diameter perimeter minus 5mm die blanking, the inner diameter perimeter length of the Dn200 electrofusion connector is 631.5-5=62...

Embodiment 2

[0065] Prepare the electrofusion connector of the plastic pipe whose specifications are straight through Dn630, select the grade in Table 1 to be Cr15Ni60, the resistivity is 1.1, and the thickness is an alloy resistance sheet of 1.5mm. This material contains 15% chromium (Cr), and the rest is rhenium ( Re), the specific implementation process is as follows:

[0066] 1. Cut the material specified above into strips of resistance material with a width of 140mm;

[0067] 2. Then punch a hole in the middle of the resistance material strip, the average distance between any non-adjacent vertices in each hole is 8mm, and the width of the side ribs constituting each mesh is 2mm. The melting surface of the plastic pipe electrofusion connector with the mesh structure electric heating element and the plastic pipe is twice the area of the pipe wall in the cross section of the Dn630 plastic pipe. The mesh structure is formed by arranging rhombus meshes of the same shape side by side alo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com