Method for cooling and secondary blowing-in of converter

A converter and furnace lining technology is applied in the field of converter cooling and secondary furnace opening, which can solve the problems of peeling, magnesia-carbon brick pulverization, and inability to guarantee safety, and achieves the effect of meeting process requirements and reducing the cost of refractory materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

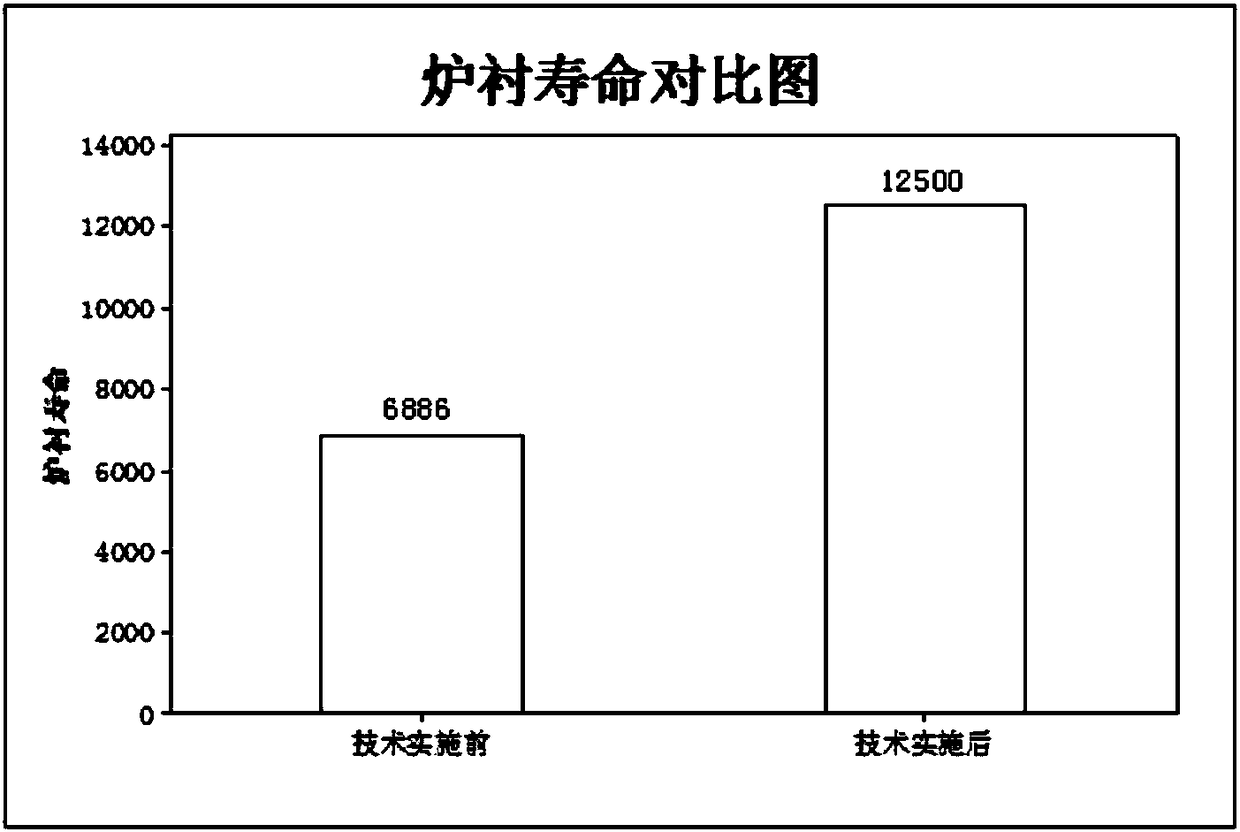

[0028] The converter is shut down when the age of the converter is 6886, and the second time the furnace is turned on after the shutdown for 30 days, including the following specific steps:

[0029] 1. Converter shutdown treatment

[0030] 1. The effect of slag splashing must be guaranteed for 20 furnaces before shutdown. When the furnace is shut down, the thickness of the slag layer of the furnace lining reaches 50mm, and the furnace lining cannot see bricks; it plays the role of isolating the lining bricks from the air and preventing the oxidation of magnesia carbon bricks from intensifying.

[0031] 2. When the furnace is shut down, the furnace bottom operation will not be carried out;

[0032] 3. Slow heat dissipation makes the furnace lining bricks cool slowly; prevents the thermal vibration stability of the lining bricks from deteriorating due to excessive temperature gradient changes.

[0033] 4. During the cooling period, it is forbidden to leak water into the furnace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com