Smoke gathering device used for electric arc furnace and refining furnace and smoke gathering method

A technology for refining furnaces and electric arc furnaces, which is applied in soot collection devices, fixed soot collection closed rooms, and soot collection fields. The effect of high degree of automation and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

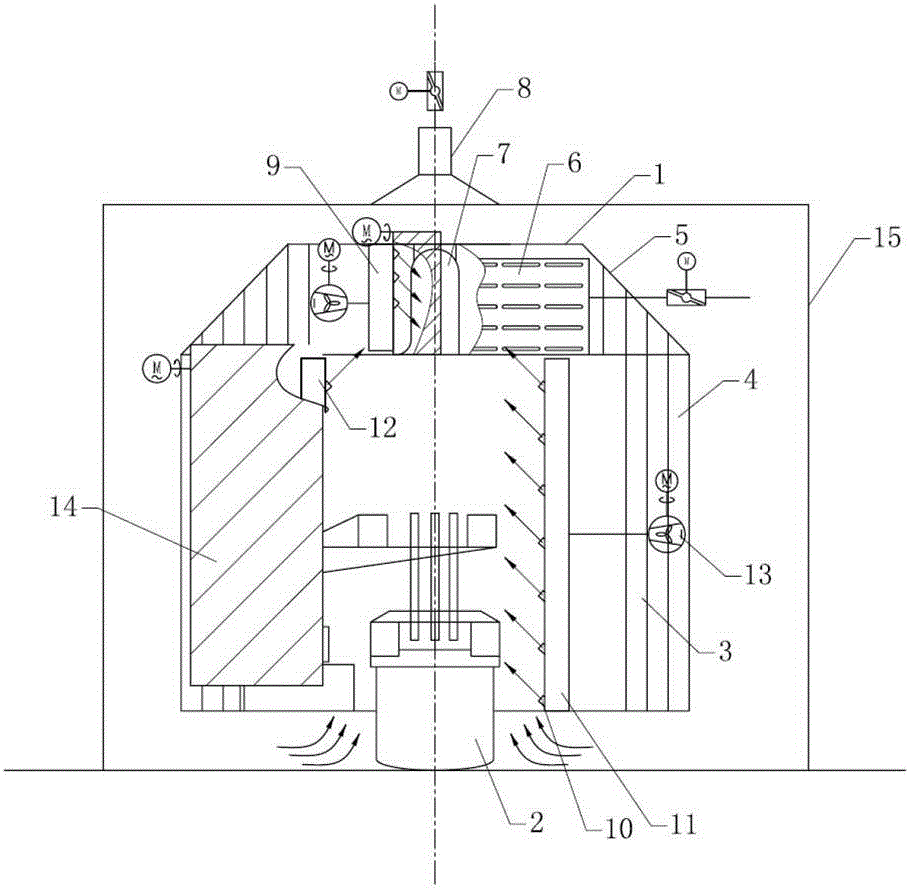

[0039] Take electric arc furnace as an example

[0040] Such as figure 1As shown, a dust collection device for electric arc furnaces and refining furnaces includes a sealed chamber 1 that seals and surrounds an electric arc furnace 2, and the sealed chamber 1 includes a steel structure frame 3 that plays a supporting role , the steel structure frame 3 is fixedly installed, and the sound-absorbing and heat-insulating layer 4 is installed on the steel structure frame 3 as a wallboard, thereby forming the sealed chamber 1 with high airtightness. The outermost layer of the sound-absorbing and heat-insulating layer 4 is a 1mm color steel plate, then a layer of 2mm galvanized sheet, and then a layer of 100mm aluminum silicate that can withstand high temperatures of 600°C, and the inner layer is a layer of 1.5mm high temperature resistant glass fiber Cloth, the innermost layer is a layer of 1.5mm stainless steel perforated plate. The stainless steel perforated plate can effectively...

Embodiment 2

[0048] Taking the refining furnace as an example, the structure is basically the same as that of Embodiment 1, so no illustration is given.

[0049] The difference from Embodiment 1 is that the sealed chamber seals and surrounds the refining furnace. In addition, the air curtain adopts the following structure: the opening is provided with a flat air outlet, and there are several flat air outlets, which are all connected to the air duct, and the opening side of the top of the closed chamber 1 is provided with a first air duct , the angle between the flat air outlet arranged on the first air duct and the horizontal direction is 16°, and the blowing direction is downward and towards the inside of the closed chamber, and the two sides of the opening at the front of the closed chamber are respectively set There are a second air duct and a third air duct, the angle between the flat air outlet of the second air duct and the third air duct and the horizontal direction is 8°, and the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com