Double-layer wine storage pot

A wine storage tank, double-layer technology, applied in the field of wine tank storage equipment, can solve the problems of container pressure instability, lower operating height, etc., to achieve the effect of saving the use area, preventing bacterial infection, and meeting the needs of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

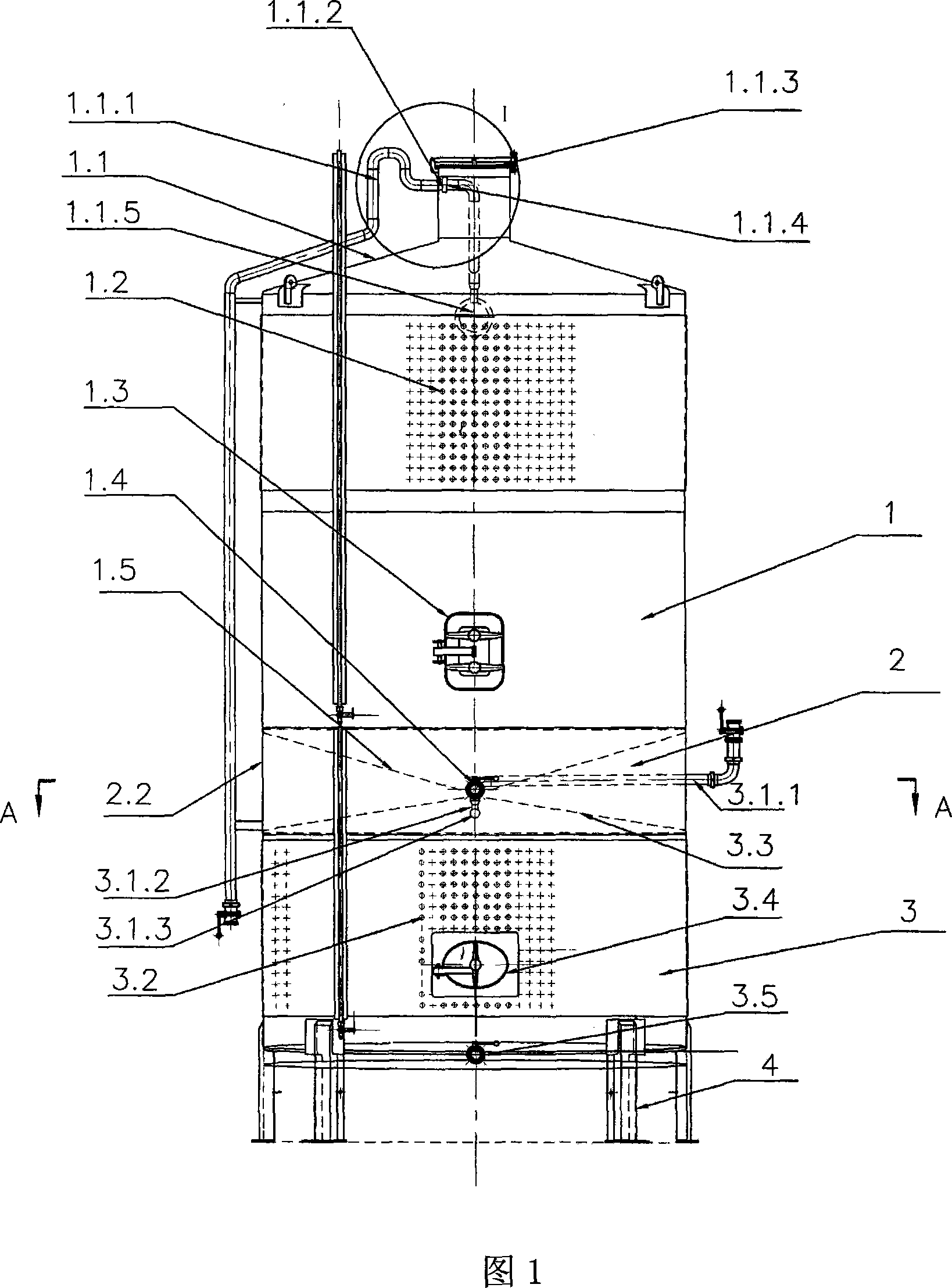

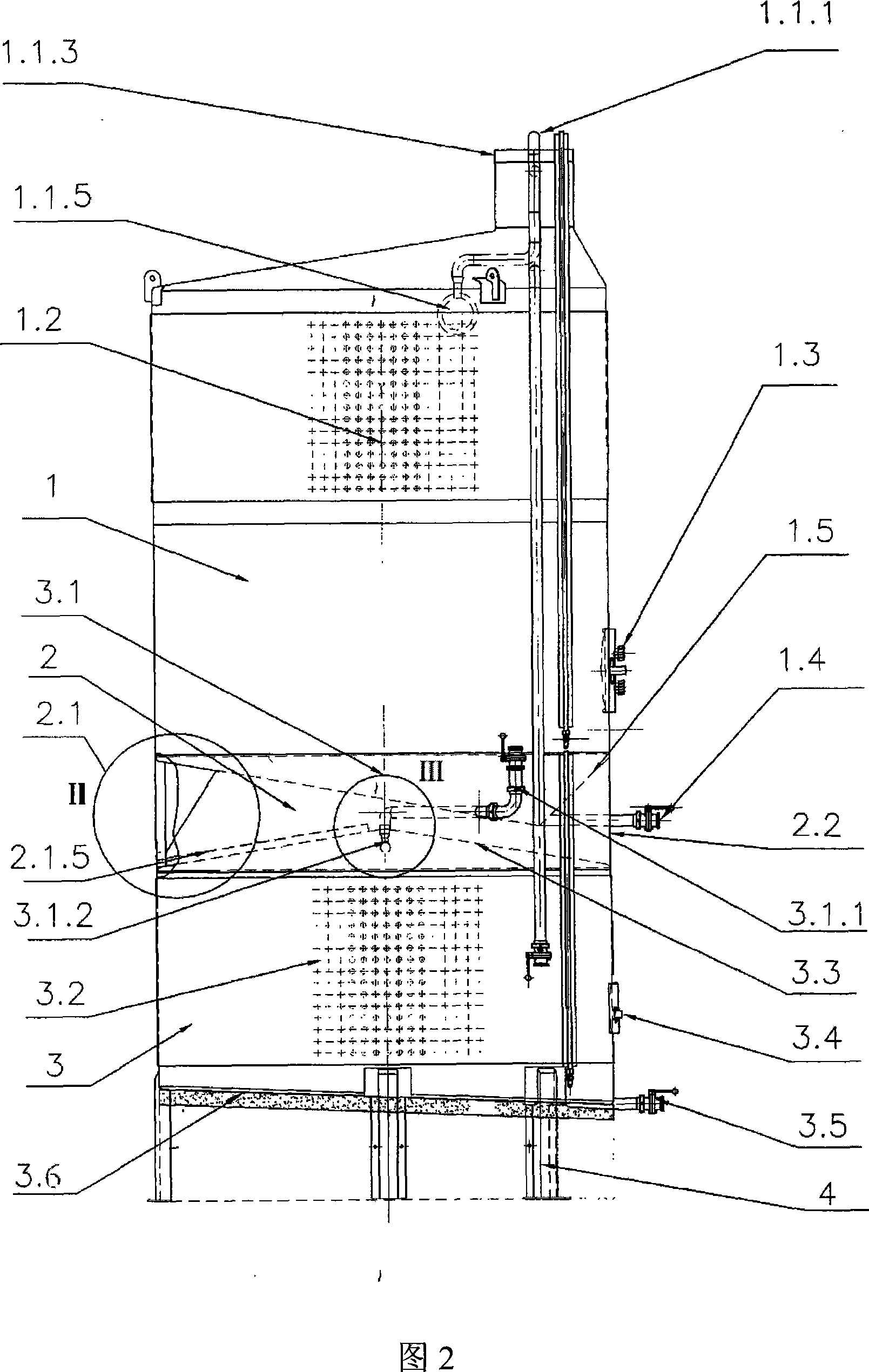

[0050] Embodiment 1: a kind of double-deck wine storage tank, comprises the nitrogen-flush system of access, is characterized in that wine storage tank is to be made of overlapping two wine storage tanks 1 and 3 up and down (see Figure 1-2 ), the volume of the upper wine storage tank 1 is greater than the volume of the lower wine storage tank 3, the tank top 1.1 and the tank bottom 1.5 of the upper wine storage tank 1 are partial cones, and the tank top 3.3 of the lower wine storage tank 3 is a positive cone, The bottom of the tank 3.6 is a sloping bottom and connected to the outrigger 4 at the bottom of the tank, and the connection part 2 between the upper and lower wine storage tanks has a reinforced structure; the upper and lower wine storage tanks are respectively equipped with manholes 1.1. Upper tank lower manhole 1.3 and lower tank lower manhole 3.4, upper tank inlet and outlet 1.4 and lower tank inlet and outlet 3.5, and upper tank flushing-nitrogen pipeline that has t...

Embodiment 2

[0057] Embodiment 2: a double-layer wine storage tank, other structures are the same as in Example 1.

[0058] The sprinkler head at the top of the upper and lower tanks is easy to disassemble and does not leave a welding dead angle The connector is an embedded and quick-loading connection, and the spray head 1.1.5 on the top of the upper wine tank barrel is connected with the flushing-nitrogen pipeline mouth 1.1.2 according to the quick-loading connector 1.1.4.

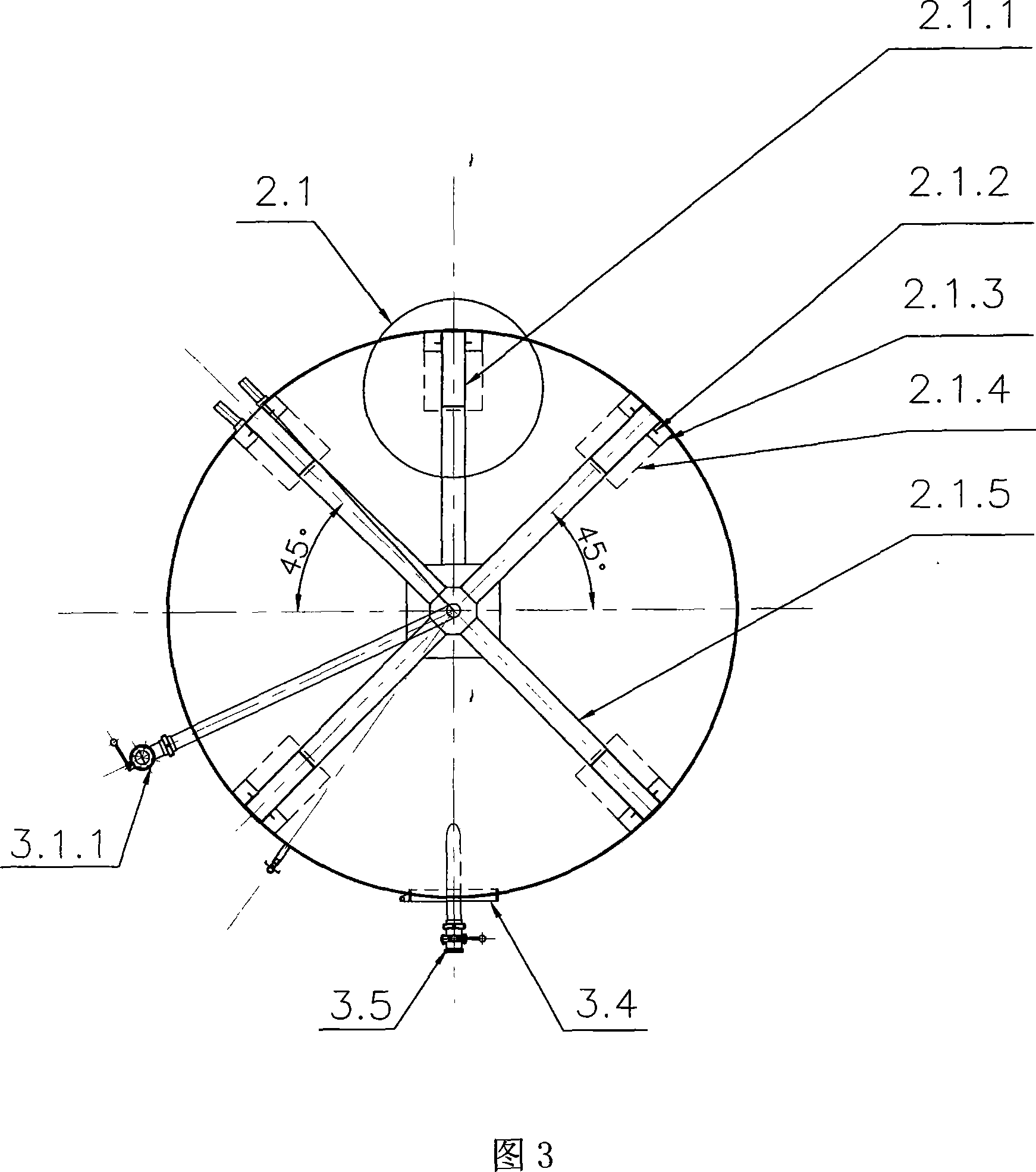

[0059] The reinforcement structure of the connecting part 2 between the upper and lower layers of wine storage tanks is composed of a cylindrical connecting part formed by connecting the upper tank bottom 1.5 with the lower tank roof 3.3 and the tank wall 2.2. 4 outriggers, and two symmetrical outriggers are added at the bottom of the upper tank, that is, 6 outriggers 2.1 are set at the connection part 2 between the upper and lower layers of wine storage tanks, and the upper tank bottom 1.5 and the lower tank top 3.3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com