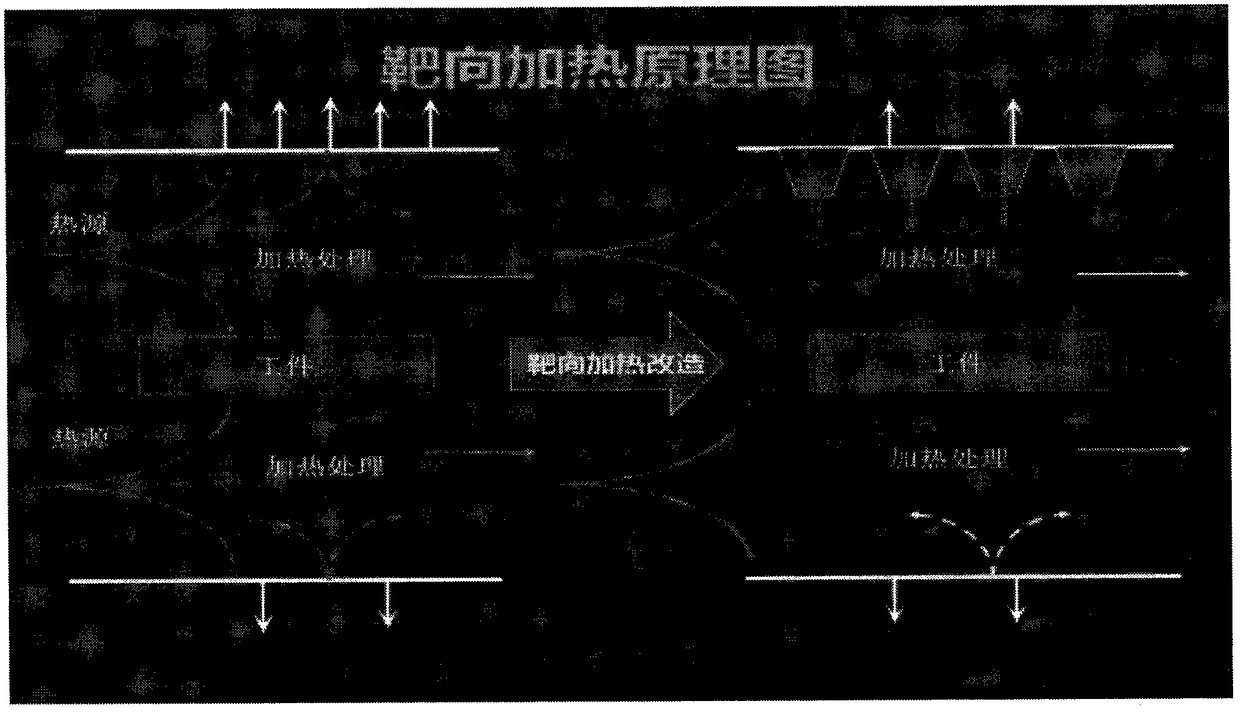

Method for reforming heating furnace with targeted heating elements

A heating element and heating furnace technology, which is applied in the field of energy-saving renovation of heating furnaces and the transformation of heating furnaces by targeting heating elements, can solve the problems of waste of energy consumption of heating furnaces and other problems, and achieve the effect of significant energy-saving effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

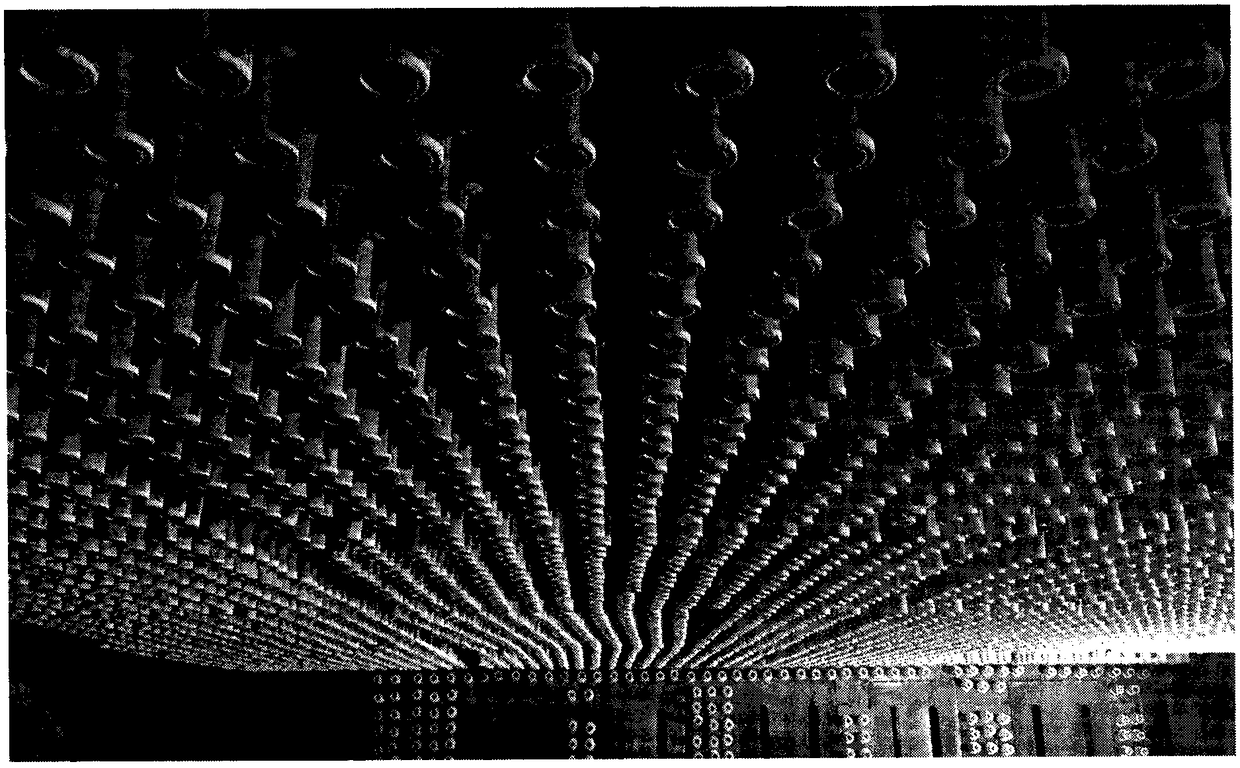

[0078] 1.1 This energy-saving technological transformation project includes the overall energy-saving transformation project of the heating furnace of the rolling mill. The basic parameters are as follows:

[0079] content

data

Furnace type

Conventional

Furnace effective size

31050mm×6500mm×3000mm

Furnace long-term use temperature

1350℃

Calorific value of fuel

3350Kcal / m3

fuel unit price

0.015 yuan / m

Fuel consumption (unit gas consumption)

507.46m / t steel

Annual output

1 million tons

Type and quantity of heating burner

48 pairs of regenerative side burners

Lining material

Castable

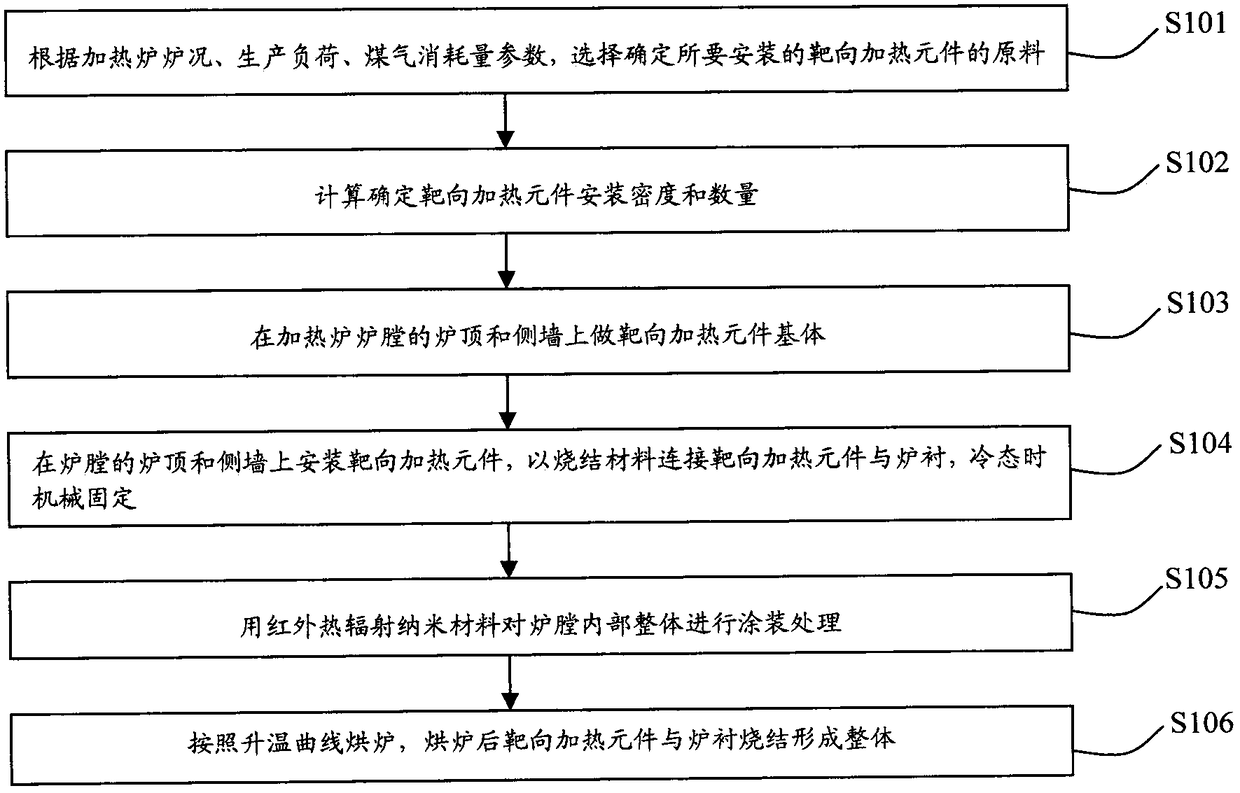

[0080] 1.2 Overall solution

[0081] Through the analysis of the heating furnace conditions, the reasons for the current loss of steel rolling gas consumption and energy waste are obtained. Aiming at these problems, an energy-saving technical transformati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com