Heat accumulating type furnace gas forced circulation device of industrial furnace

A technology of circulation device and forced circulation, applied in heat storage equipment, furnace, waste heat treatment and other directions, can solve problems such as poor furnace temperature uniformity, achieve smooth furnace gas circulation, improve cycle strength, and improve furnace temperature uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

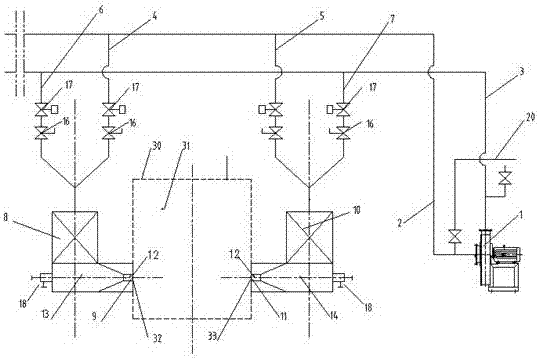

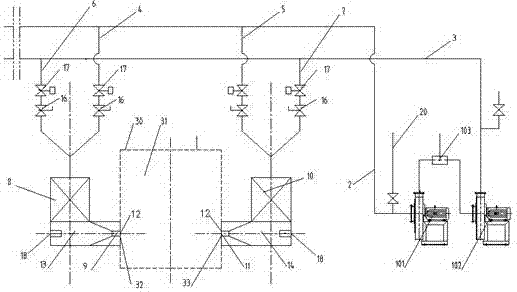

[0021] Such as figure 1 As shown, the industrial furnace regenerative forced furnace gas circulation device of the present invention includes a heating furnace body 30, and the cavity in the middle of the heating furnace body 30 forms a furnace 31, and the workpiece to be heated is placed in the furnace 31 to be heated to raise the temperature; the heating furnace body 30 Usually industrial furnaces such as electric furnaces and fuel furnaces. On the furnace 31, at least a pair of the first opening 32 of the furnace and the second opening 33 of the furnace are arranged, that is, the first opening 32 of the furnace and the second opening 33 of the furnace are arranged in pairs, and the first opening 32 of the furnace and the second opening 33 of the furnace are respectively connected with The furnace 31 is connected, and when one of them is used as an air blowing port for intake air, the other is used as a suction port for exhaust gas, which takes turns to intake and exhaust ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com