Tantalum capacitor vacuum sintering dewaxing furnace

A technology of vacuum sintering and dewaxing furnaces, which is applied in furnaces, muffle furnaces, cooking furnaces, etc. It can solve the problems of difficult control of product quality, volatilization on the furnace wall, and cumbersome disassembly and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

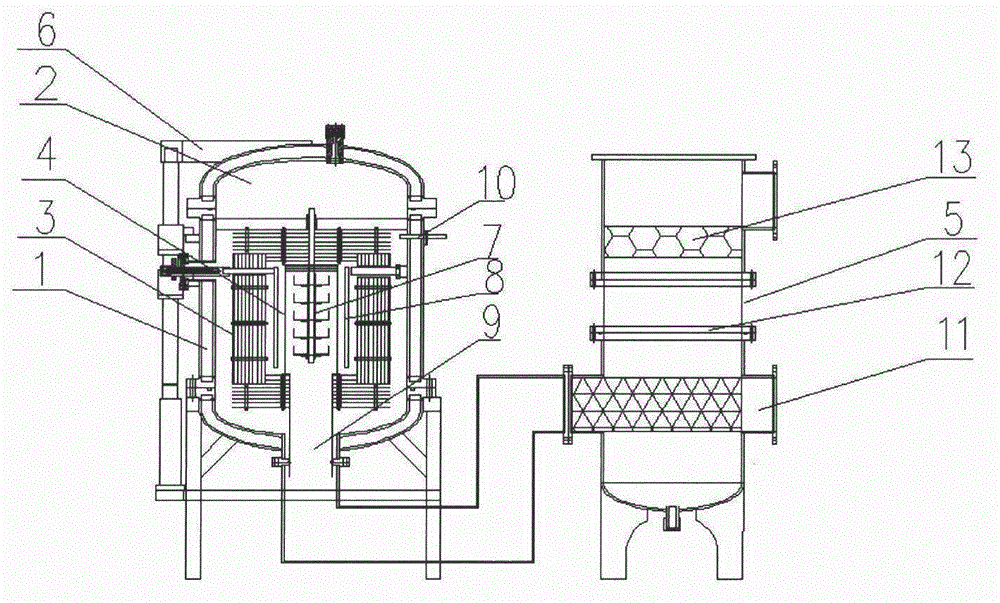

[0010] figure 1 A tantalum capacitor vacuum sintering dewaxing furnace shown includes a furnace body 1, a furnace cover 2, a furnace gall 3, a muffle tank 4, a degreasing collection system 5, a furnace cover lifting mechanism 6, a lifting workpiece basket 7, a heating Device 8, air extraction port 9, gas charging port 10, degreasing trap 11, trapping cold well 12, isolator 13. A tantalum capacitor vacuum sintering dewaxing furnace shown in the figure mainly includes a furnace body, a furnace cover, a furnace tank, a muffle tank and a degreasing collection system. The furnace cover is connected to the furnace body through a furnace cover lifting mechanism and placed directly above the furnace body , The furnace is placed inside the furnace body, and the furnace is provided with hoisting workpiece baskets, muffle tanks and heaters in sequence from the inside to the outside. There is an air extraction port at the bottom of the muffle tank, and an air filling port is set on the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com