Heat treatment method for 18CrNiMo7-6 steel

A heat treatment method and steel technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of easy spheroidization of pearlite, slow cooling process, low hardness of steel, etc., to facilitate cutting and sawing, and facilitate machining , Furnace gas atmosphere consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] This embodiment is a heat treatment method for 18CrNiMo7-6 steel.

[0049] According to mass percentage, the chemical composition of the above 18CrNiMo7-6 steel is: carbon 0.18%, silicon 0.25%, manganese 0.70%, phosphorus and sulfur both 0.015%, chromium 1.6%, nickel 1.5%, molybdenum 0.30%; the rest is Fe and unavoidable impurities.

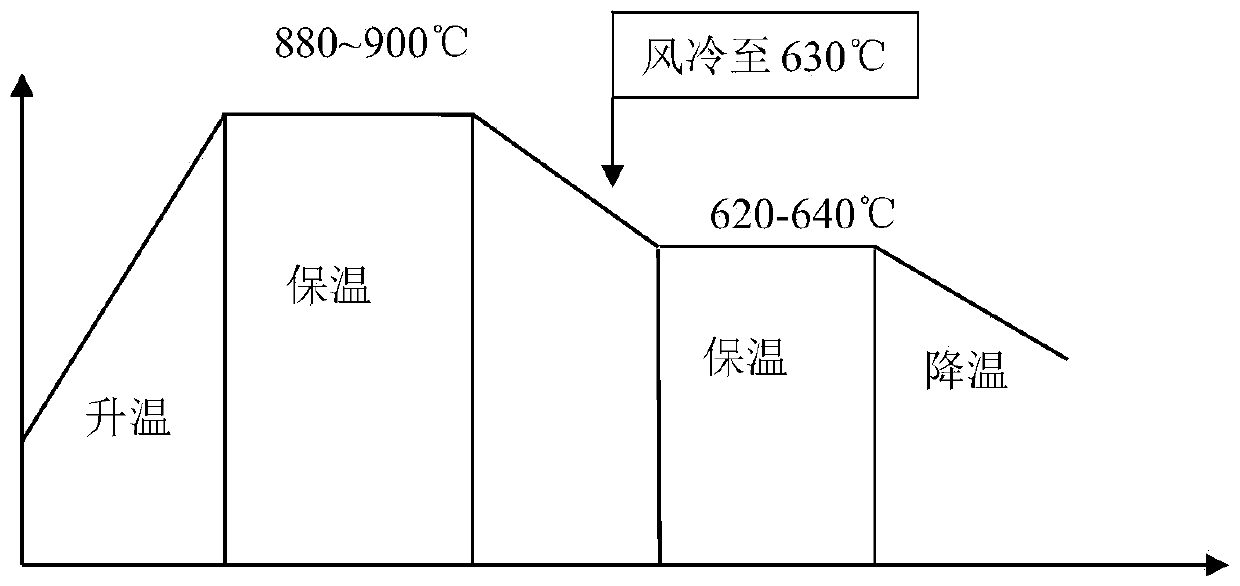

[0050] The annealing treatment that above-mentioned heat treatment method comprises comprises the following steps:

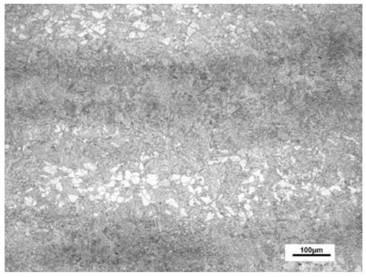

[0051] First, the 18CrNiMo7-6 round bar forged from the 18CrNiMo7-6 steel ingot is heated up at a rate of 80°C / h to the target temperature of 890°C, and then the first heat preservation treatment is carried out at this temperature for 1.5h / 100mm, and then the wind is carried out. Cold treatment (cooling rate 200°C / h) to the target temperature of 630±10°C, and then conduct a second heat preservation treatment at this temperature for 10h / 100mm, and then cool to room temperature with the furnace to obtain an annealed 18CrNiMo7...

Embodiment 2

[0056] In the heat treatment method of the 18CrNiMo7-6 steel product of the present embodiment, the chemical composition of the 18CrNiMo7-6 steel product is identical with embodiment 1; The mode that equipment, fuel, and round rods adopted in the heat treatment process are piled up on the hearth are all identical with embodiment 1, The annealing treatment of heat treatment includes the following steps:

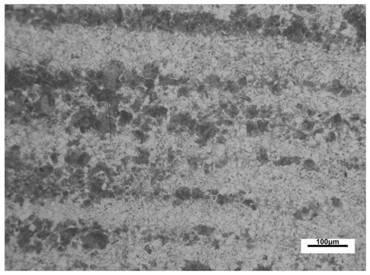

[0057] First, the 18CrNiMo7-6 round bar forged from the 18CrNiMo7-6 steel ingot is heated up at a rate of 80°C / h, and the temperature is raised to the target temperature of 890°C, and then the first heat preservation treatment is carried out at this temperature for 1.5h / 100mm, and then Air cooling (cooling rate 200°C / h) to the target temperature of 650°C, and then conduct a second heat preservation treatment at this temperature for 10h / 100mm, and cool to room temperature with the furnace to obtain an annealed 18CrNiMo7-6 round rod.

[0058] The microstructure of the 18CrNiMo7-...

Embodiment 3

[0061] In this embodiment, except that the partial annealing process of the round bar is different from that of Example 1, other processes and performance testing methods are the same as those of Example 1. The only difference between the annealing process of this embodiment and that of Example 1 is: The cooling method for the temperature to drop to the second heat preservation temperature is air cooling (cooling rate is 100° C. / h). The microstructure of the annealed bar is ferrite (F) + lamellar pearlite (P), the flake pearlite (P) accounts for about 68%, and most of the hardness values in the test samples are in the range of 180-190HBW Inside.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com