Patents

Literature

44results about How to "Easy sawing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

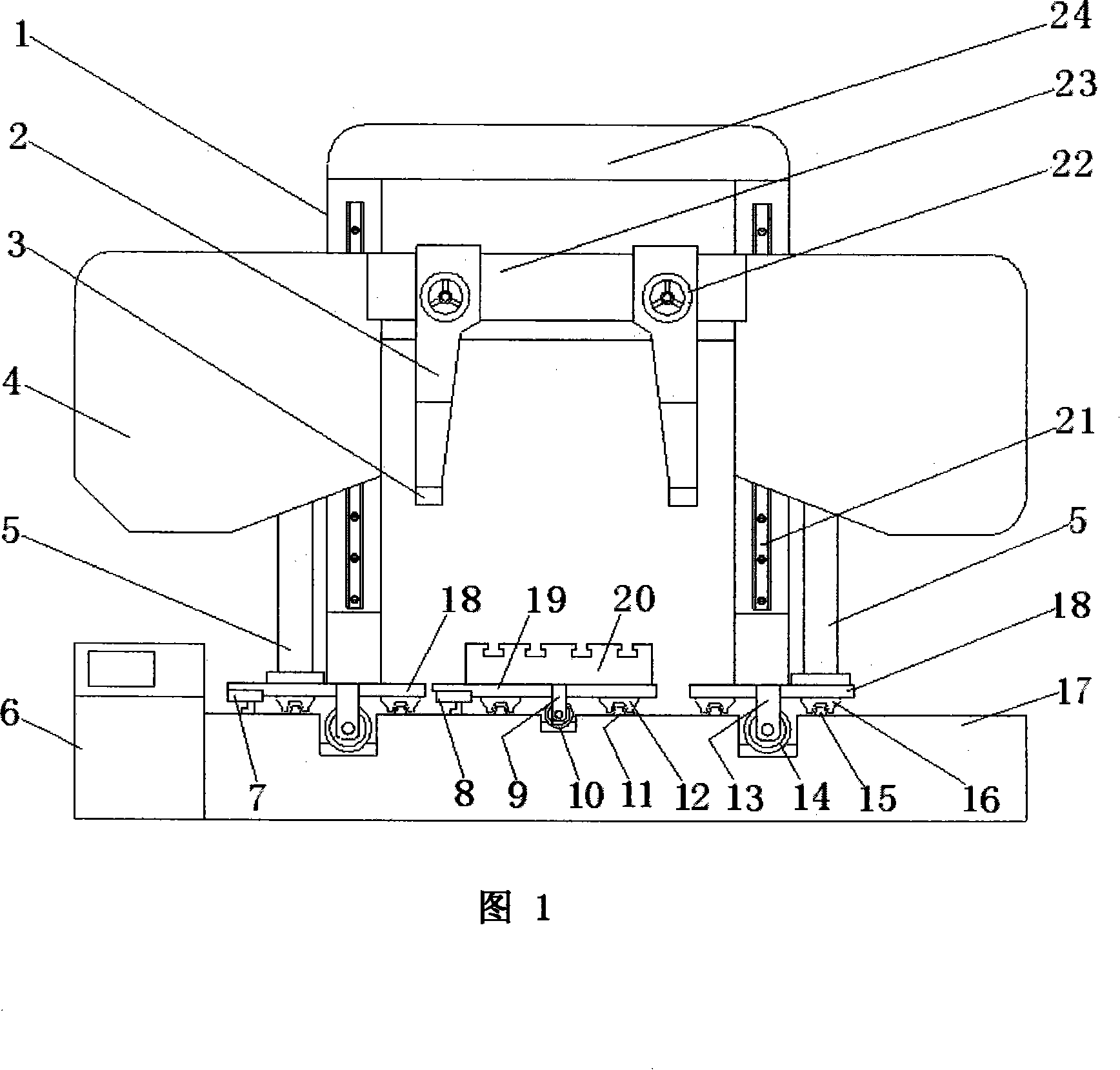

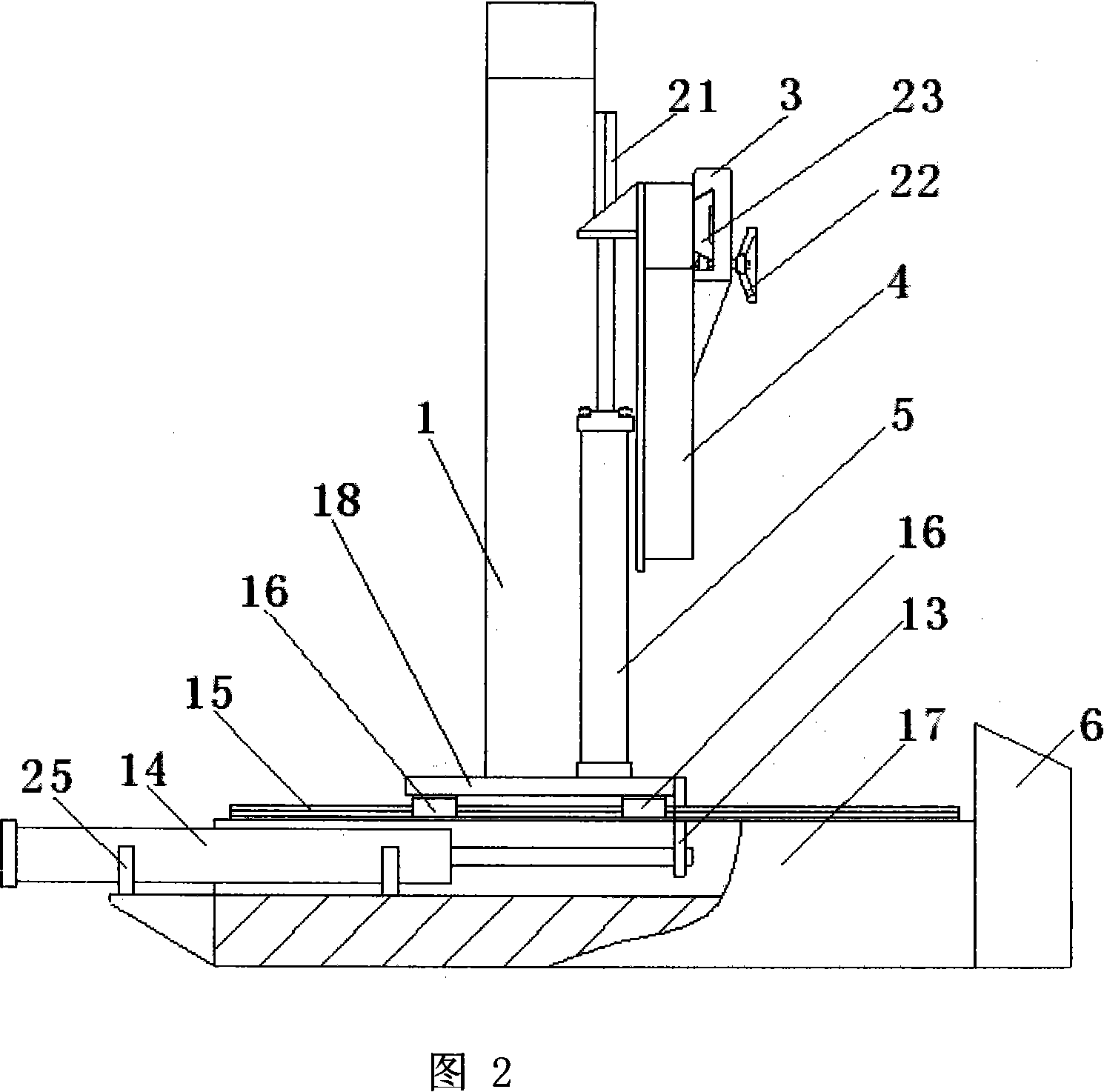

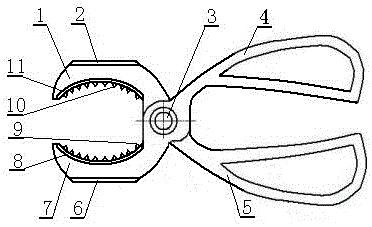

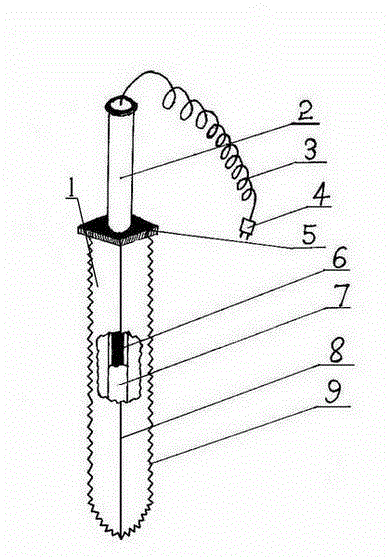

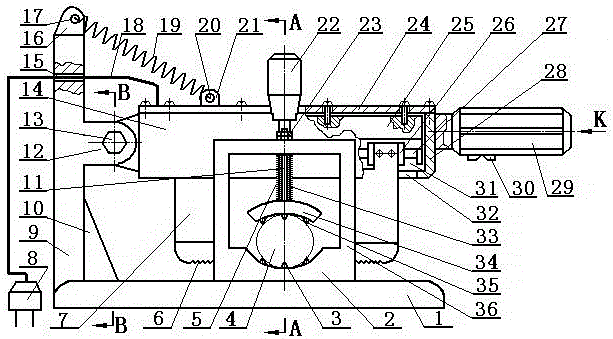

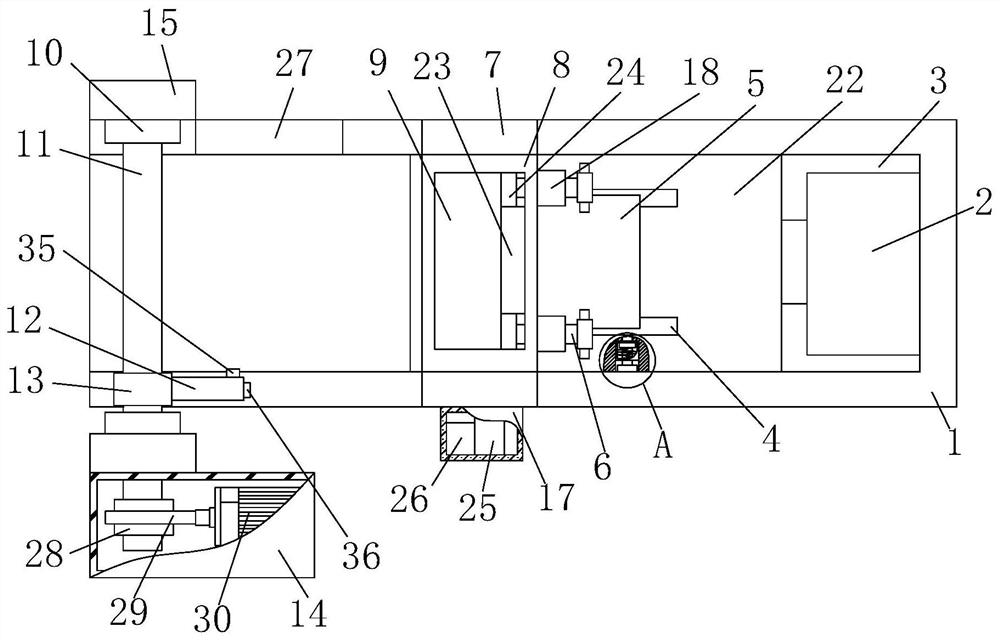

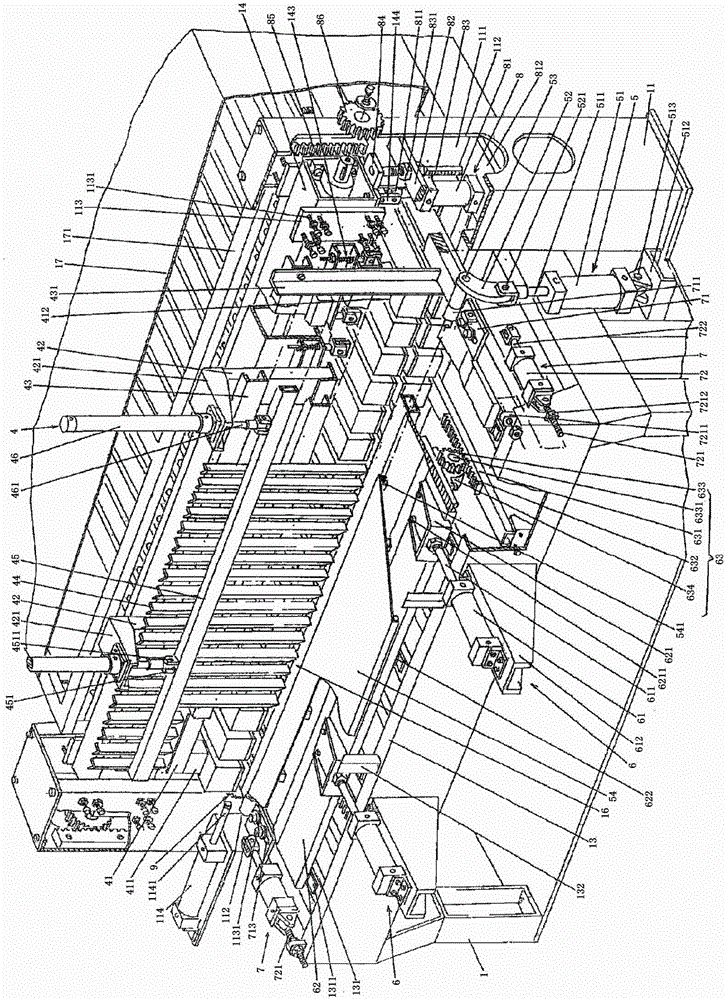

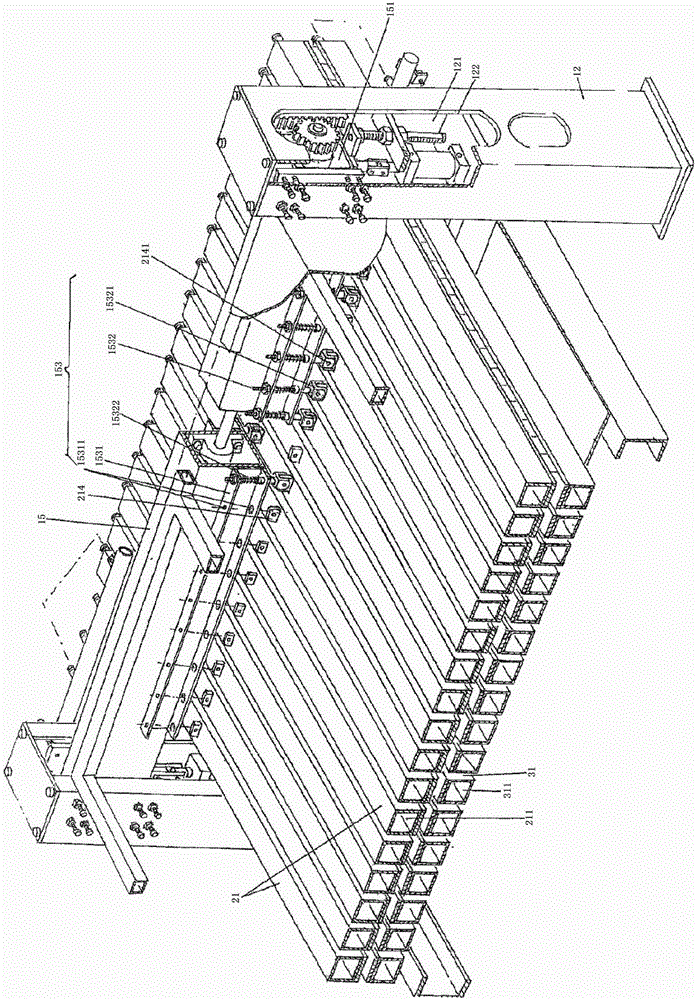

Numerically controlling vertical-horizontal saw cutting metal belt band saw

The invention relates to a numerical control horizontal and vertical metal strip sawing machine, comprising a machine body, two upright pillars arranged on the machine body, a sawing rack, a work table, a guiding mechanism of the sawing strip, a main transmission system, a hydraulic pressure system, an electric system, and a numeral control system. The two upright pillars are driven by an oil tank and can move randomly through a linear guide rail; a guiding head is driven by a guiding drive device and can rotate at 0 to 90 degrees so as to guide the sawing strip to be feed along the horizontal or the vertical direction. The invention not only can vertically feed sawing, but also can realize the horizontal feed sawing through the rotating of the guiding head and the horizontal movement of the two upright pillars, which is convenient in sawing and high work efficiency when processing workpieces with right angles.

Owner:卢建飞

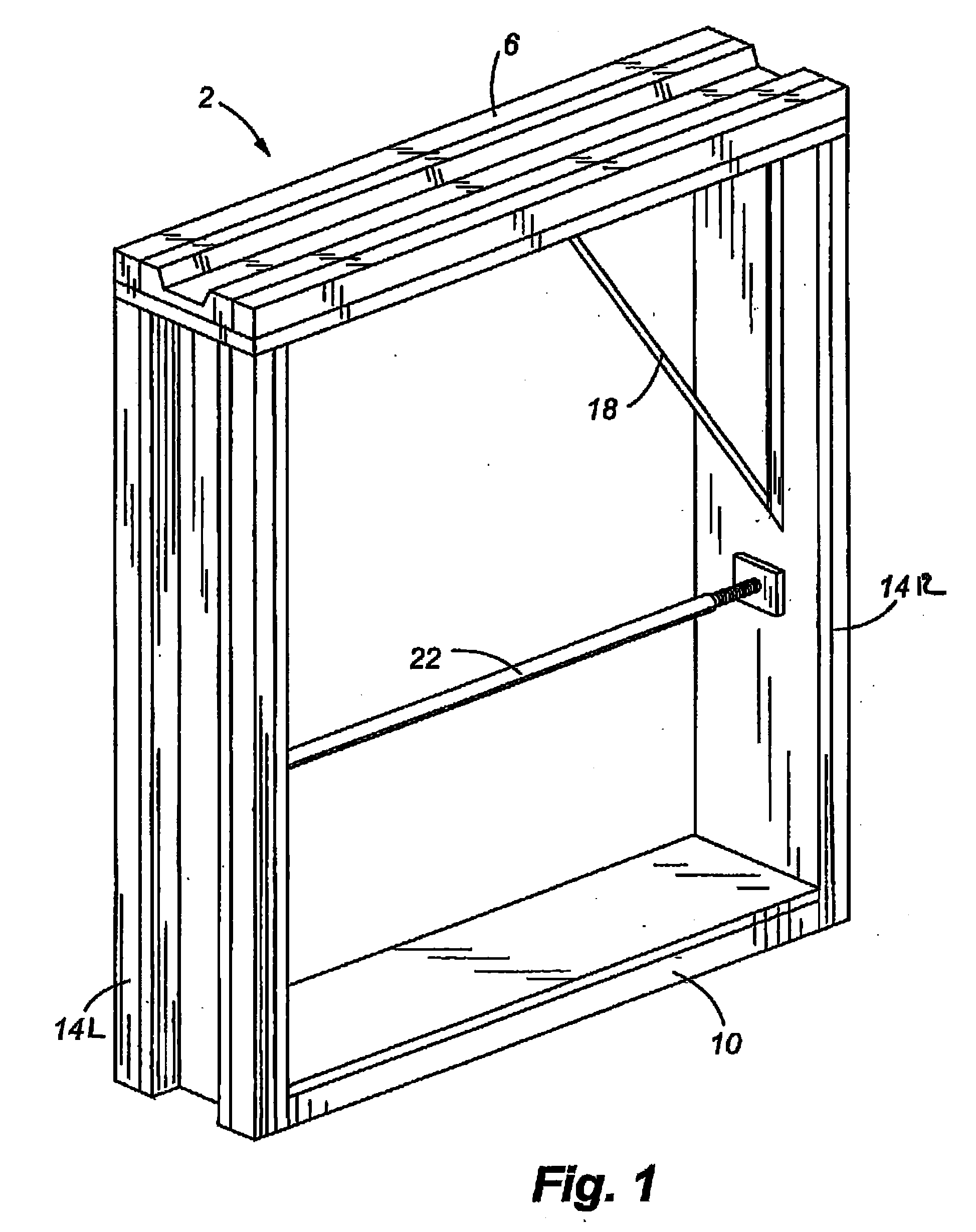

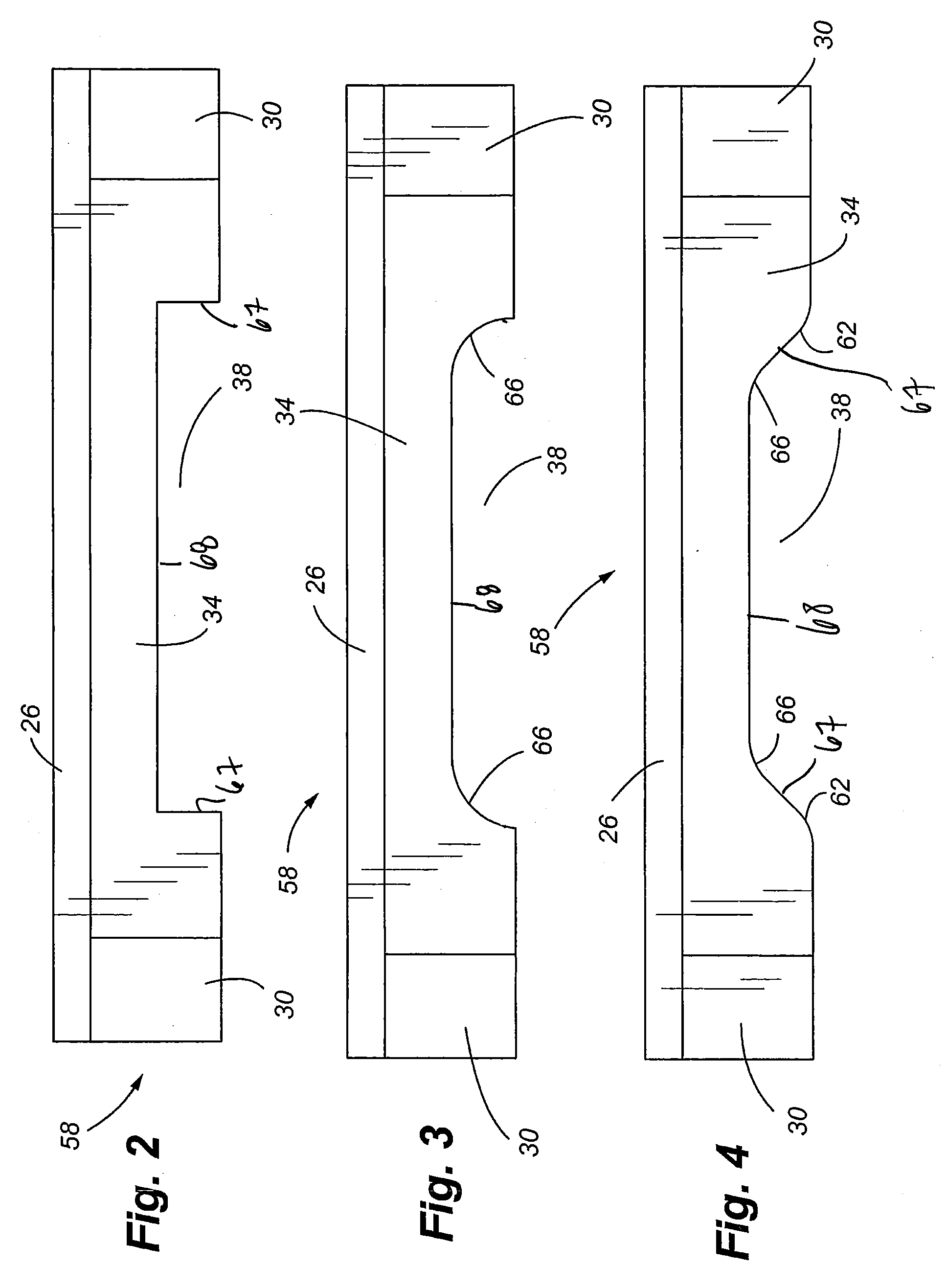

Apparatus and method for forming an opening in a concrete wall system

InactiveUS20080115431A1Reduce wasteImprove design flexibilityWindow/door framesBuilding material handlingStructural engineering

A method and apparatus for forming an opening in a concrete wall is provided. More specifically, interlocking concrete forms comprising parallel spaced insulation panels are provided for receipt of concrete. Any openings, i.e. such as for windows and doors, are accommodated within the insulated concrete forms by way of a customizable buck. The buck members utilize less material than those of the prior art, and are easily customized to yield a required opening size. The placement of concrete into the form yields a concrete wall with the desired window or door opening.

Owner:2M SQUARED

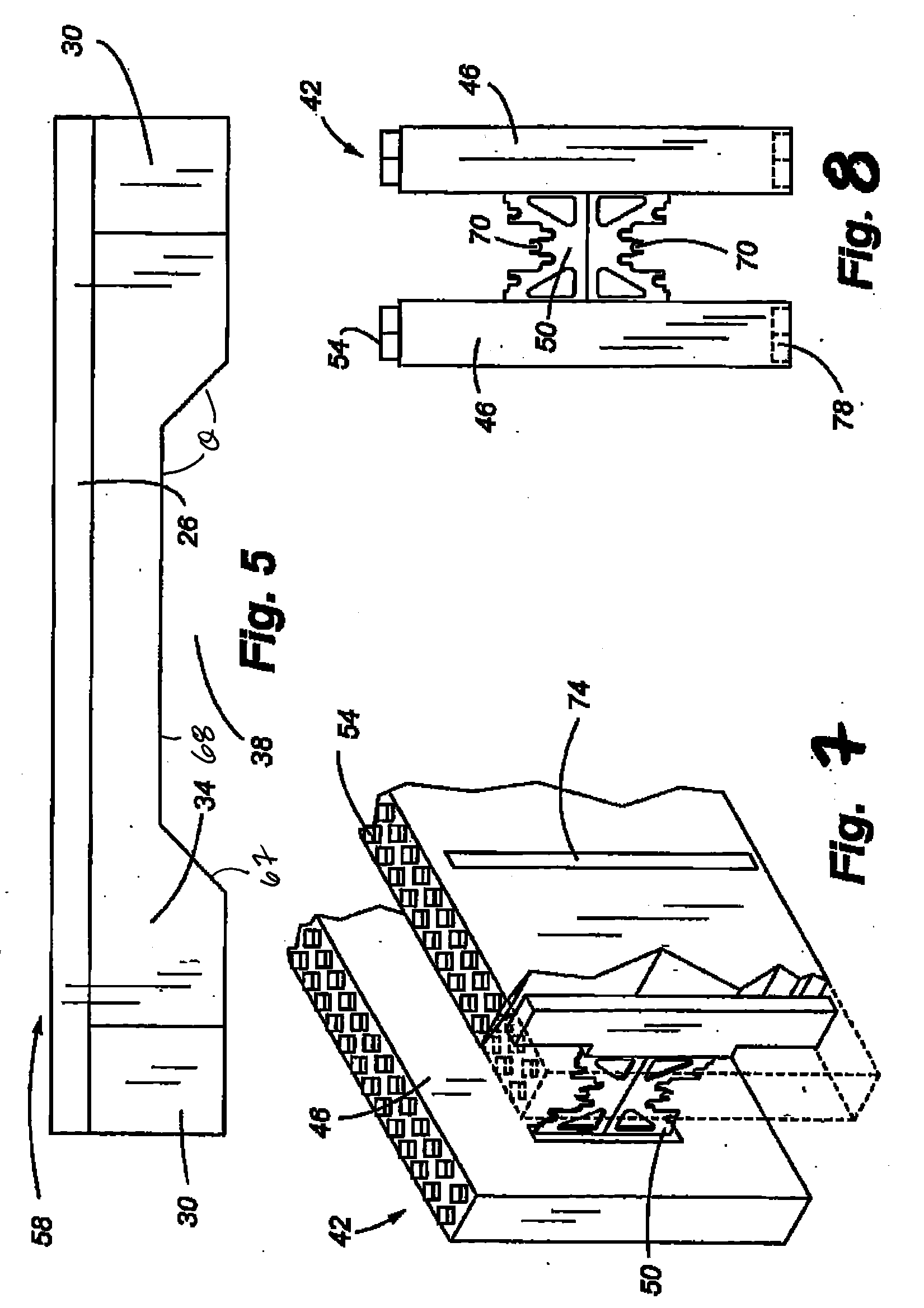

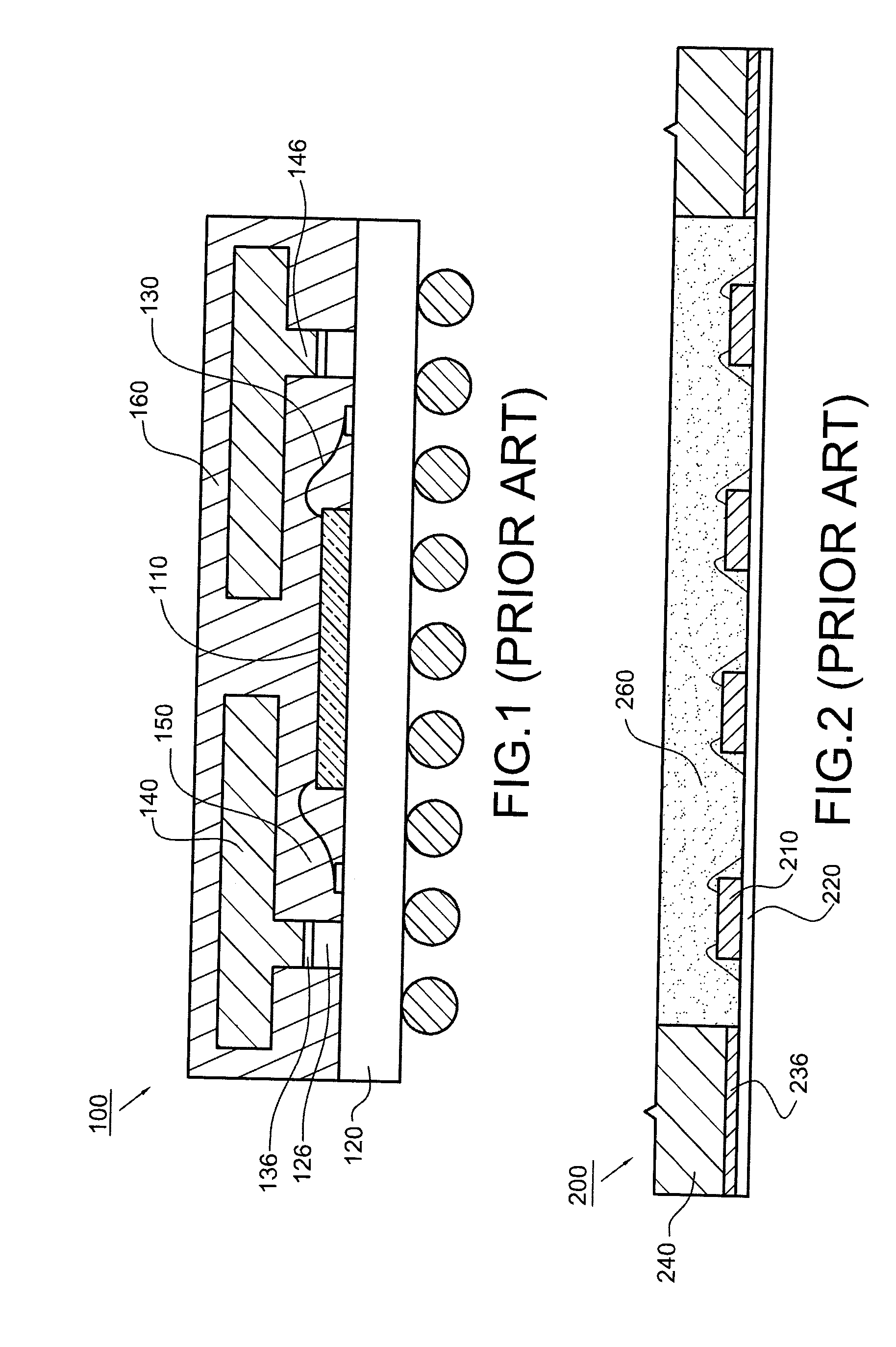

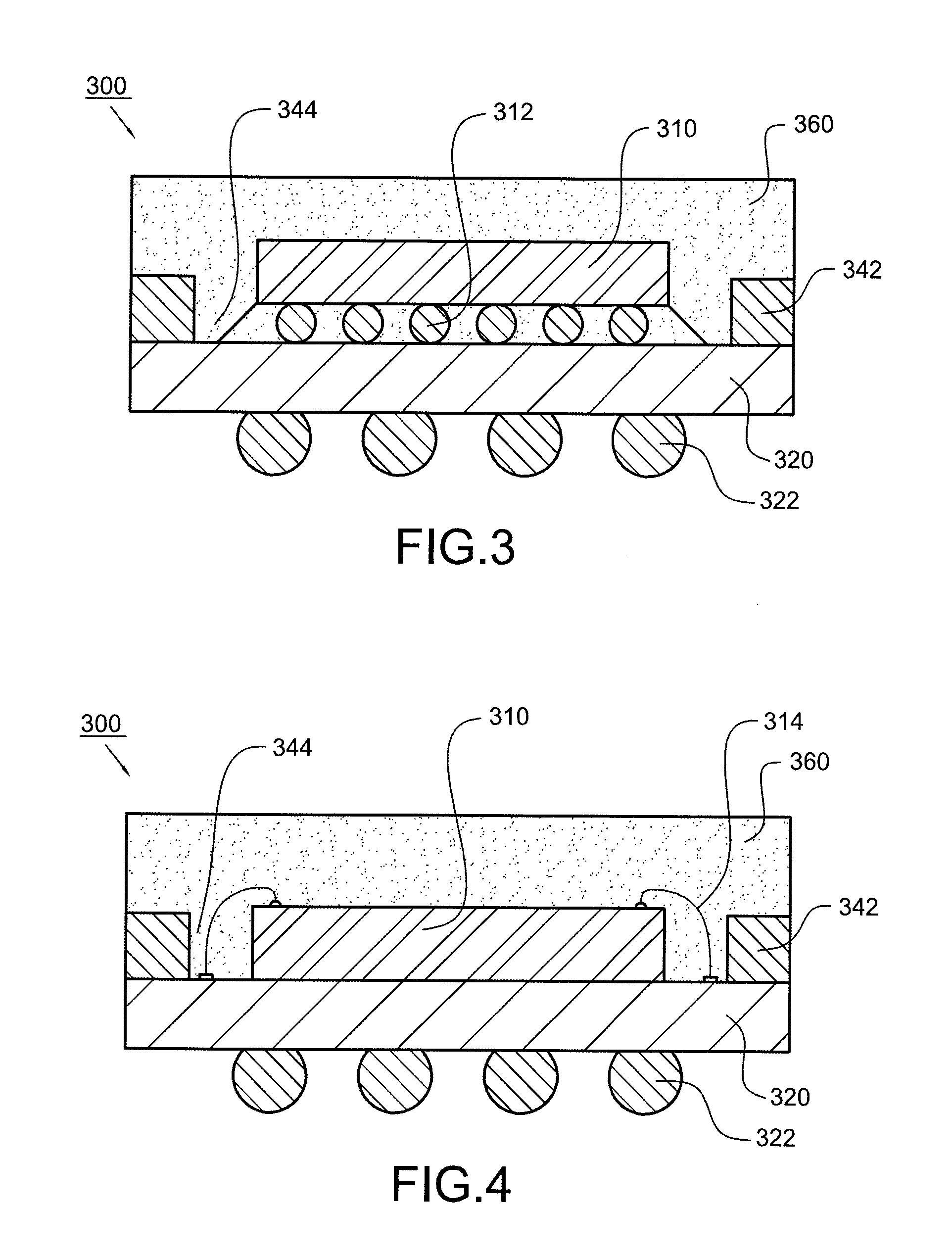

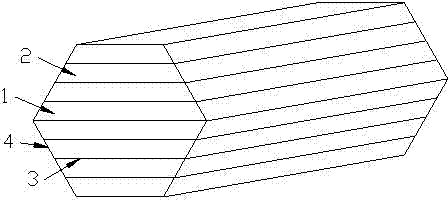

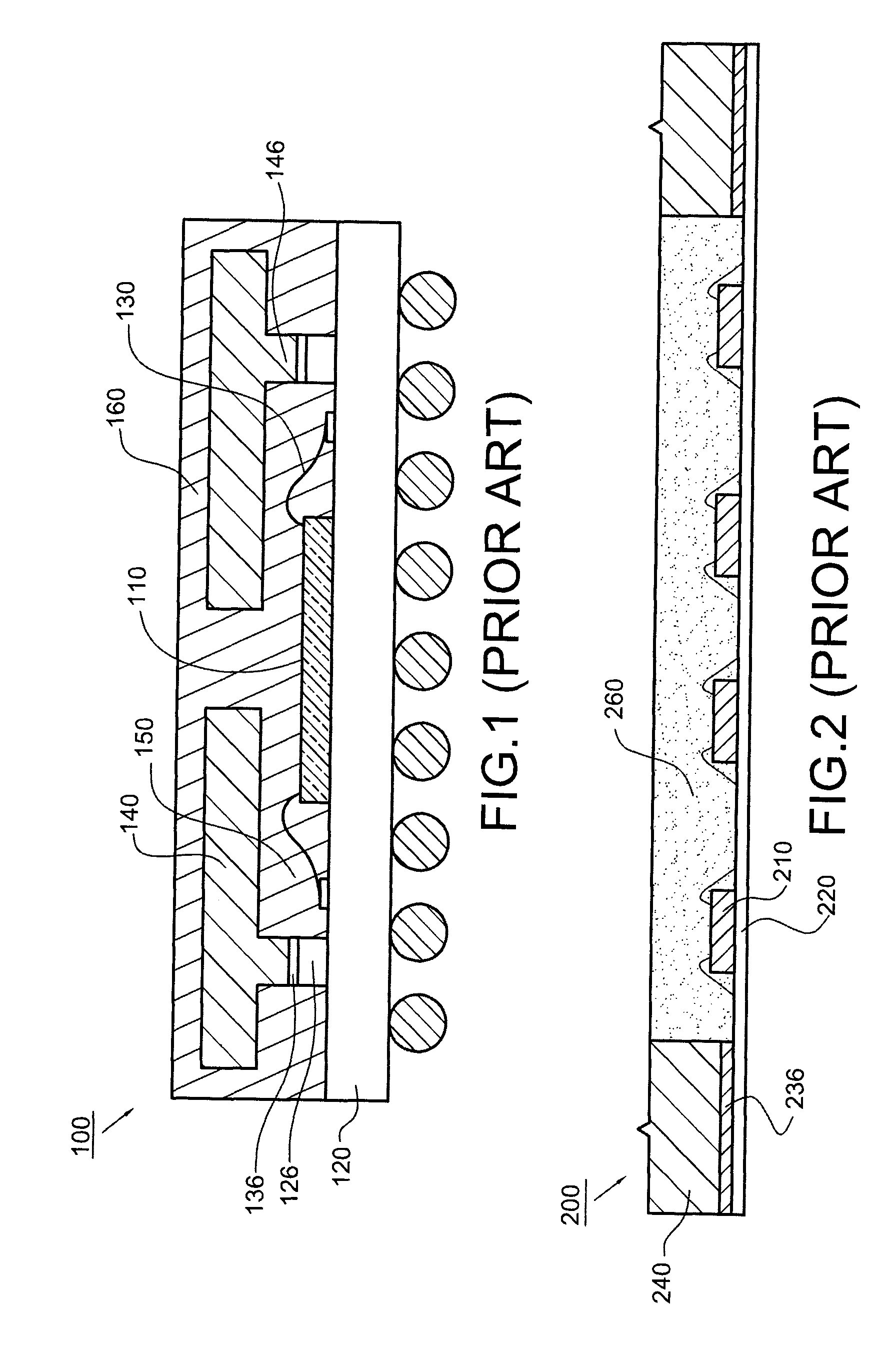

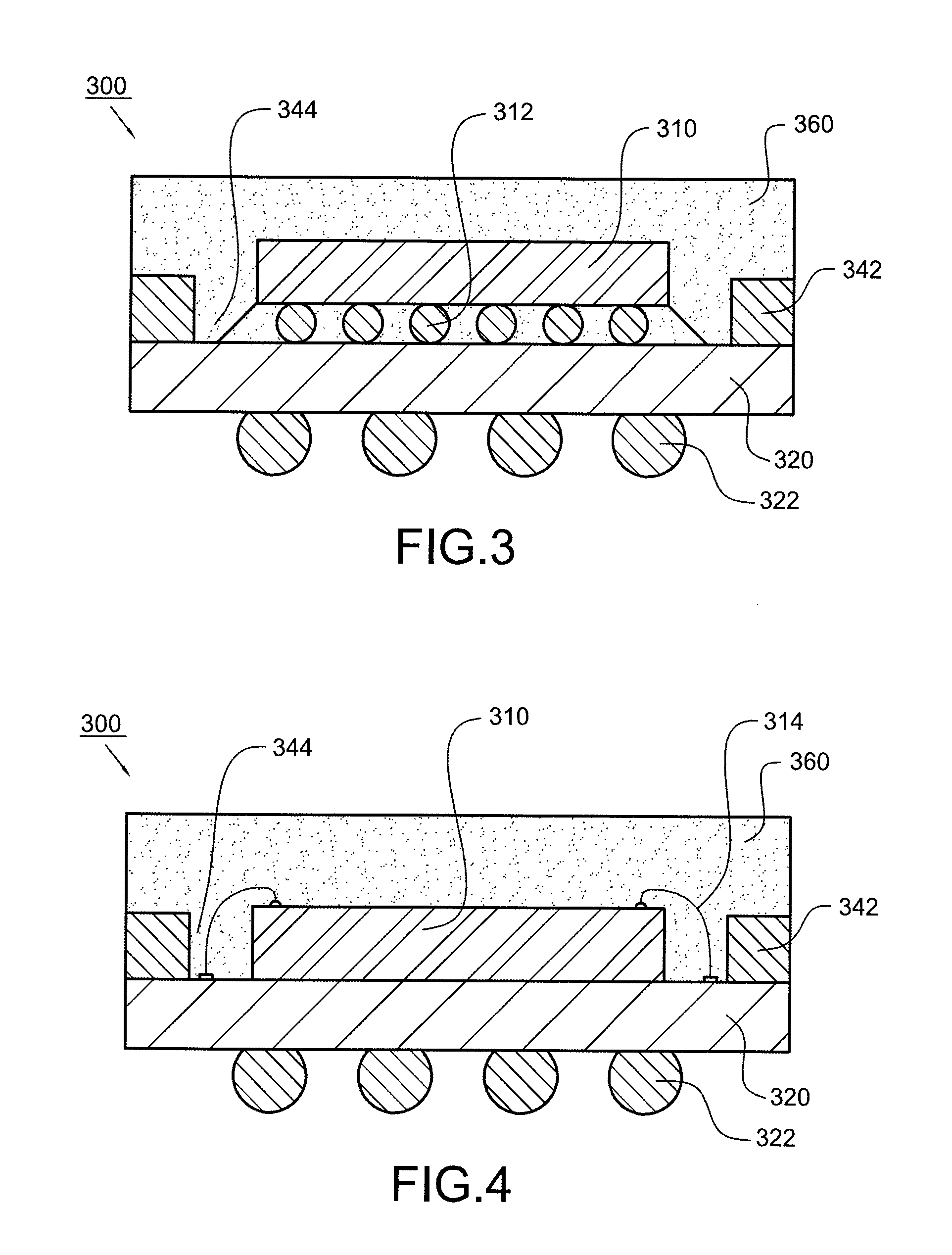

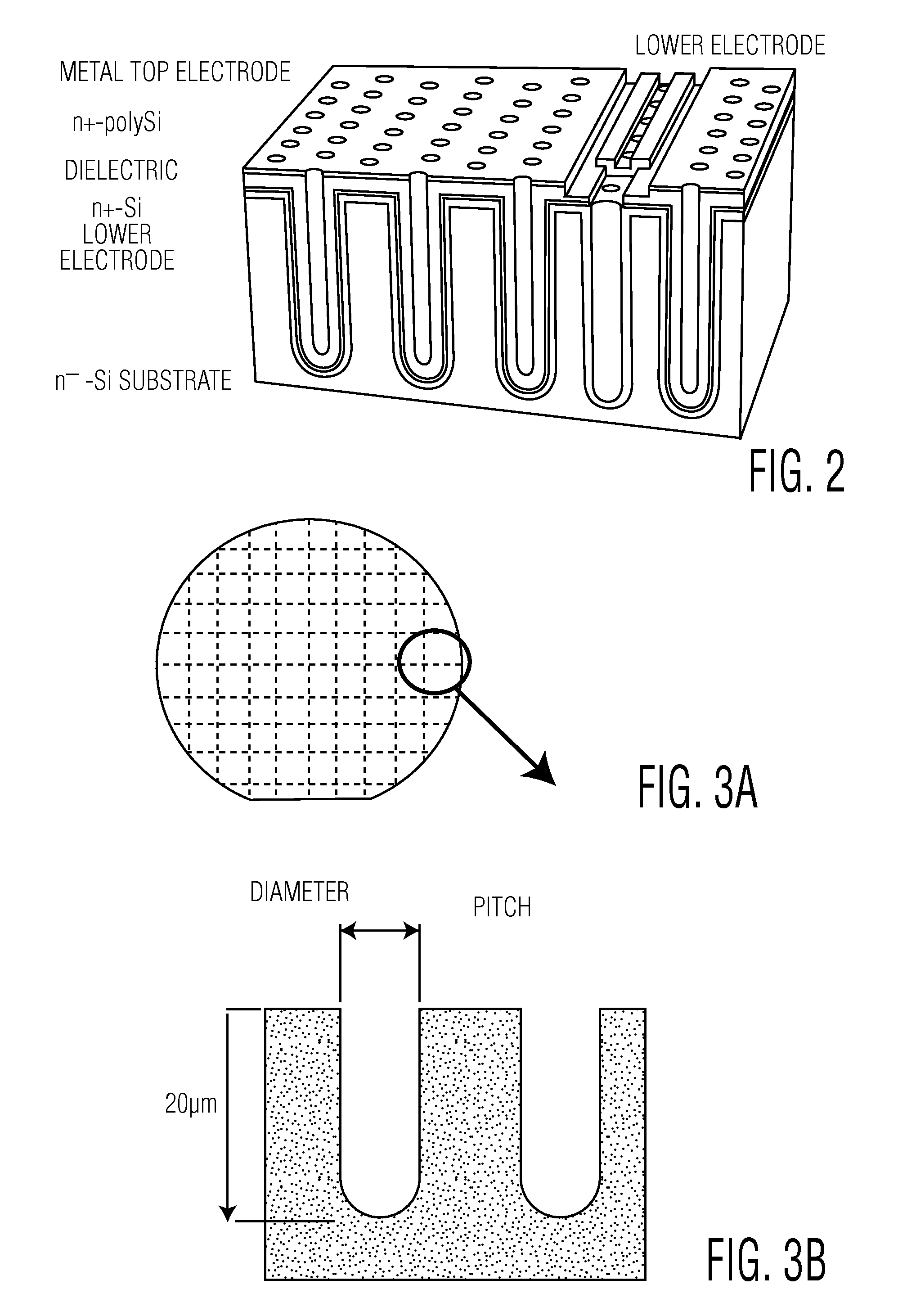

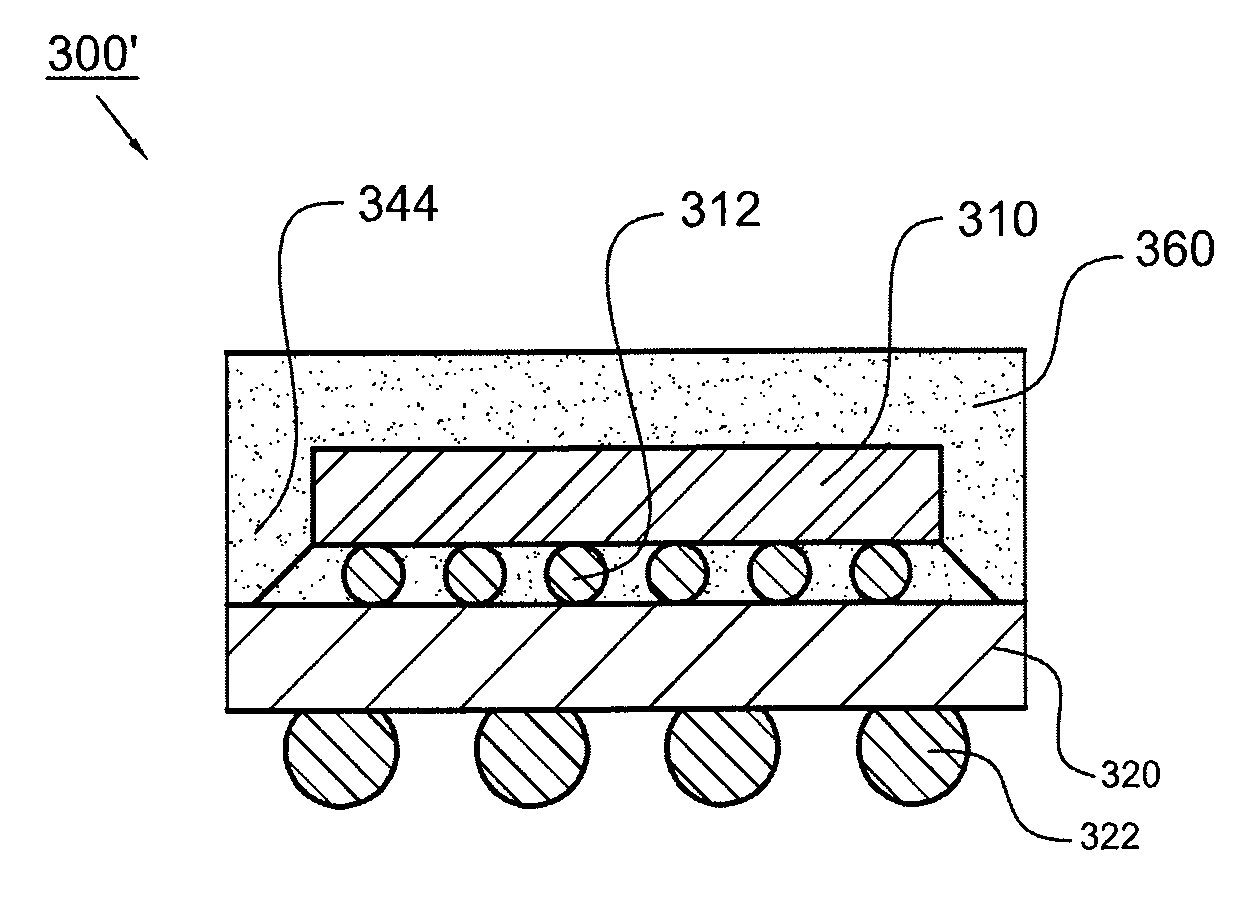

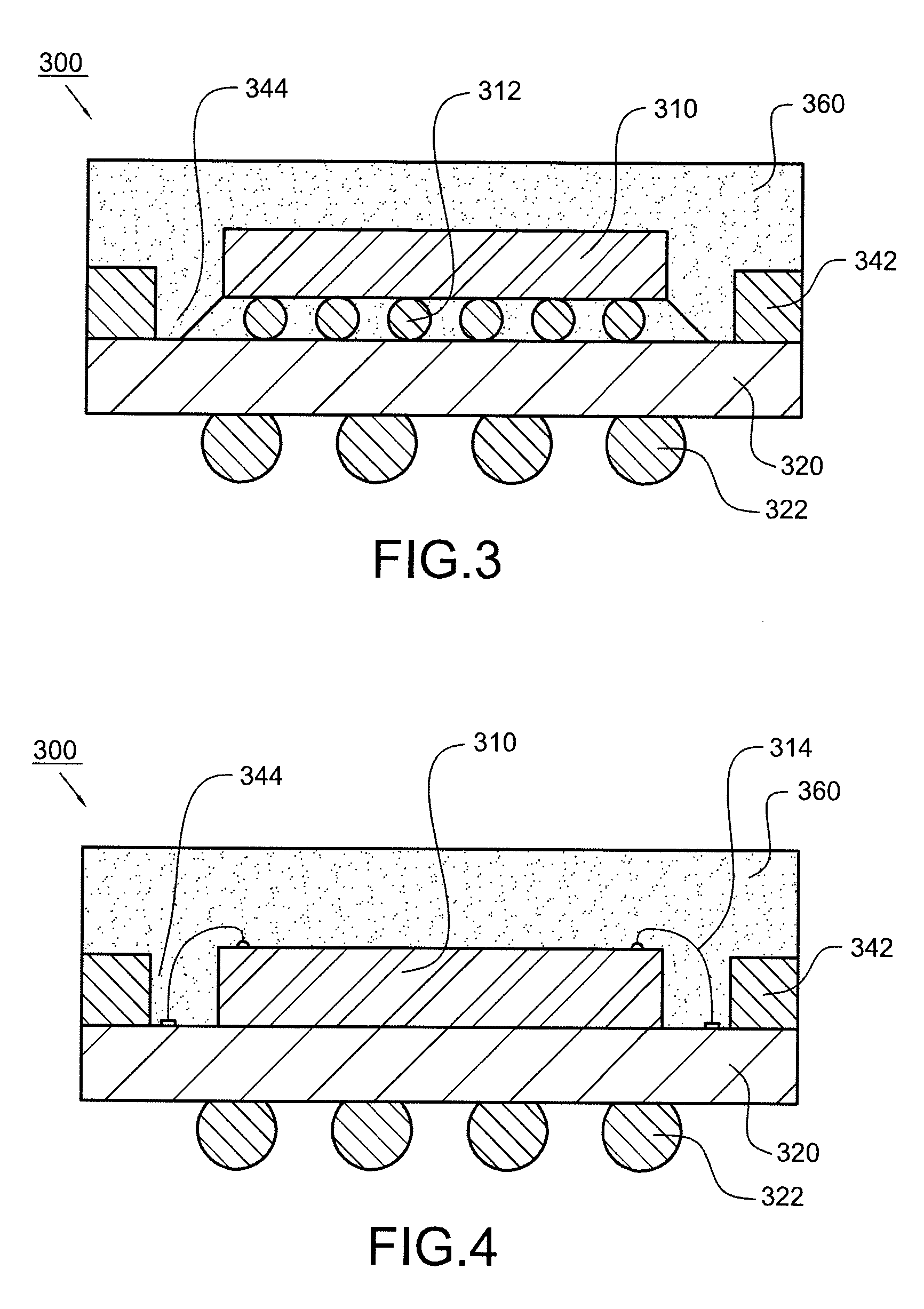

Semiconductor package and method for manufacturing the same

ActiveUS20090289339A1Decrease process stepReduce processing stepsSemiconductor/solid-state device detailsSolid-state devicesEngineeringElectrical and Electronics engineering

A semiconductor package includes a carrier, a chip, a stiffener and an encapsulant. The chip is disposed on the carrier. The stiffener is disposed around the chip, directly contacts the carrier, and is mounted on the carrier. The encapsulant is adapted to seal the chip and the stiffener.

Owner:ADVANCED SEMICON ENG INC

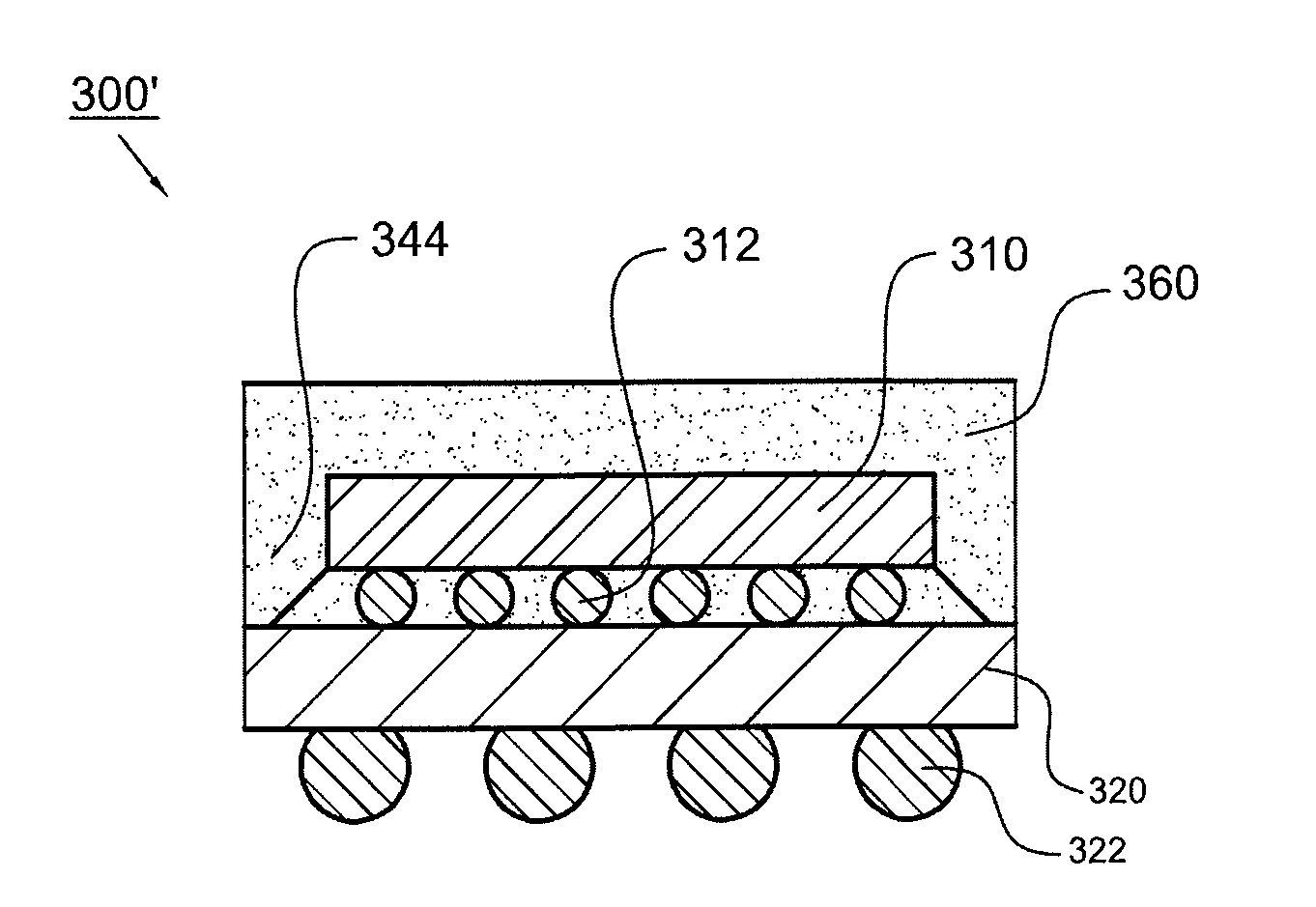

Thermal stress reduction

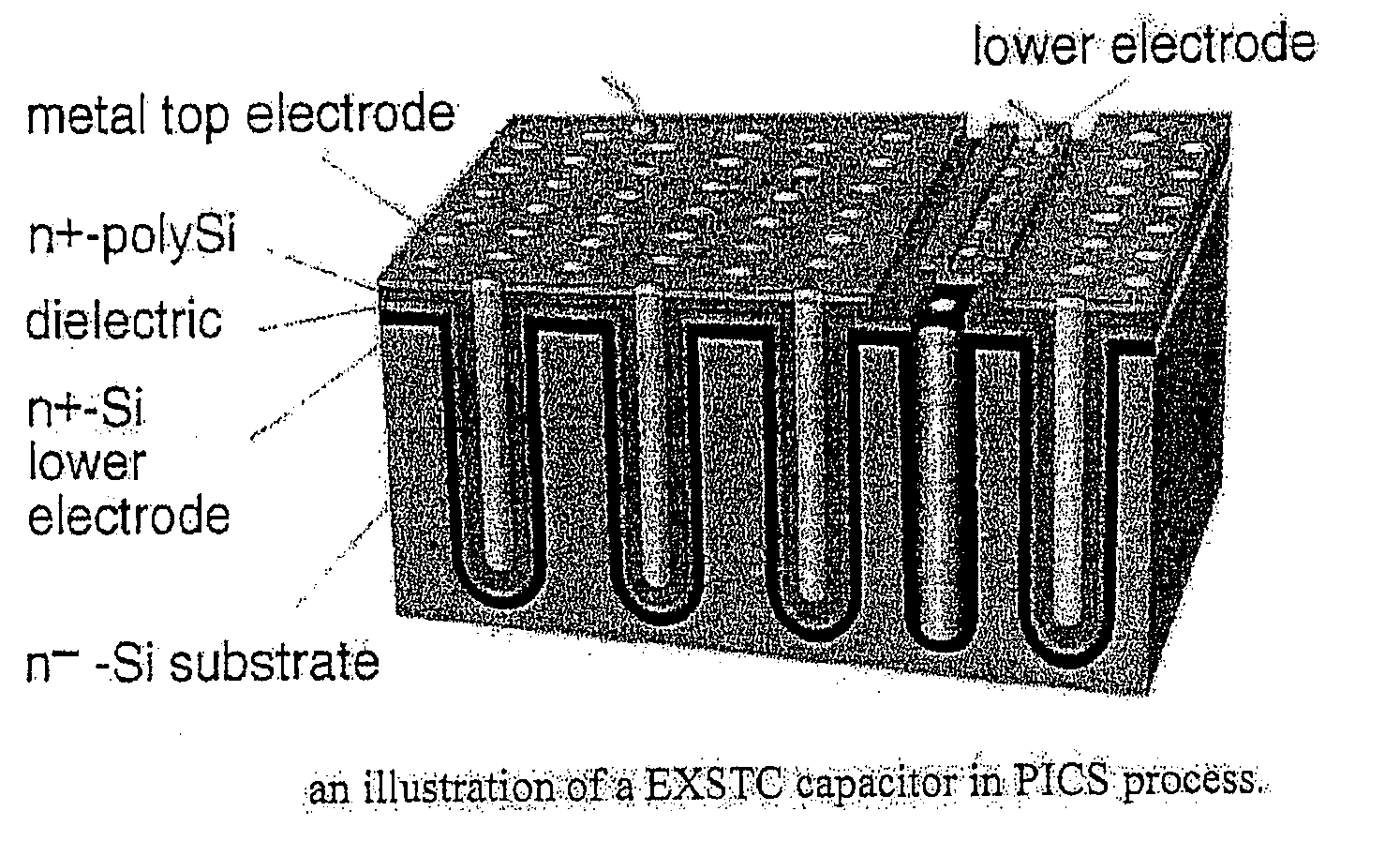

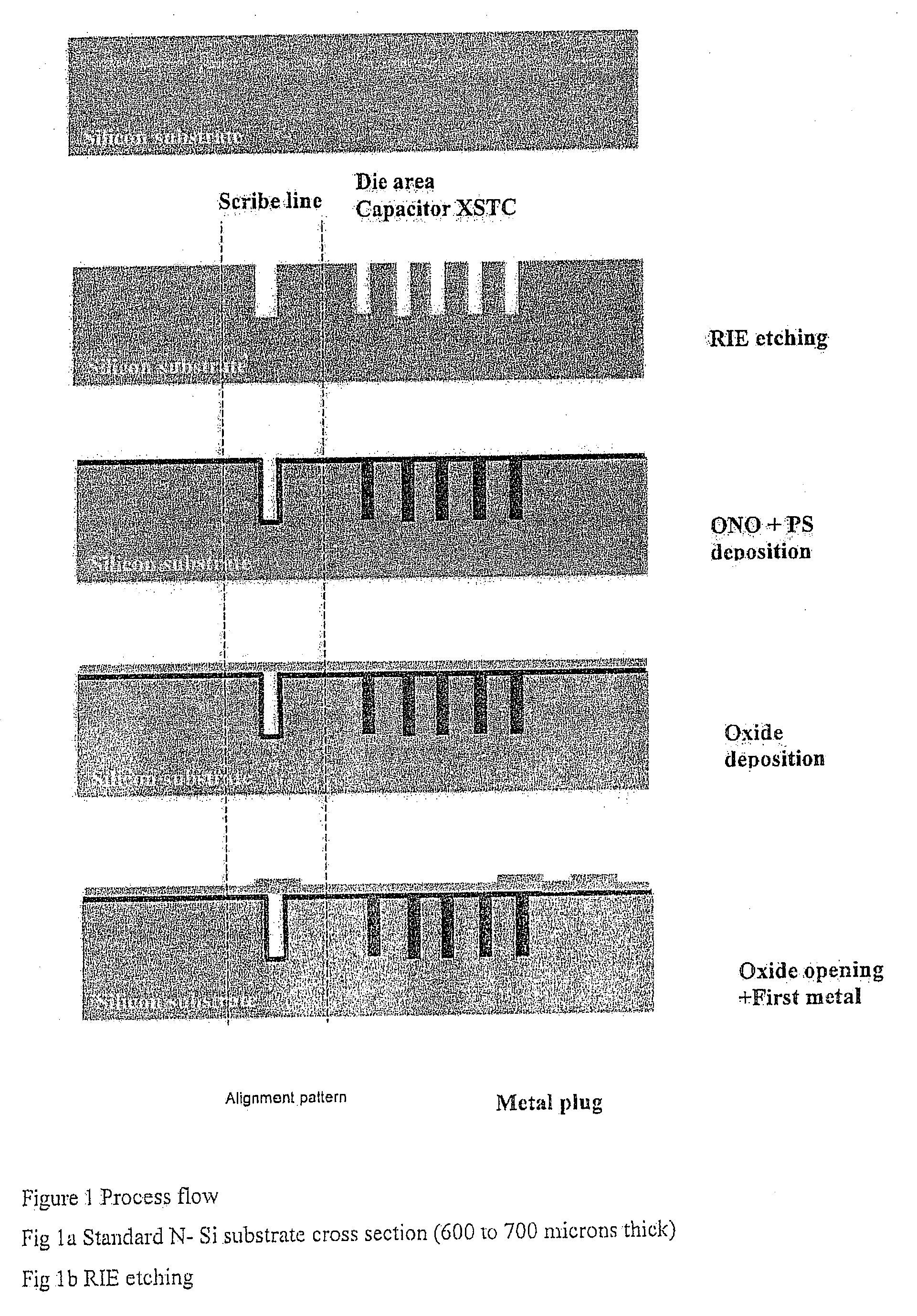

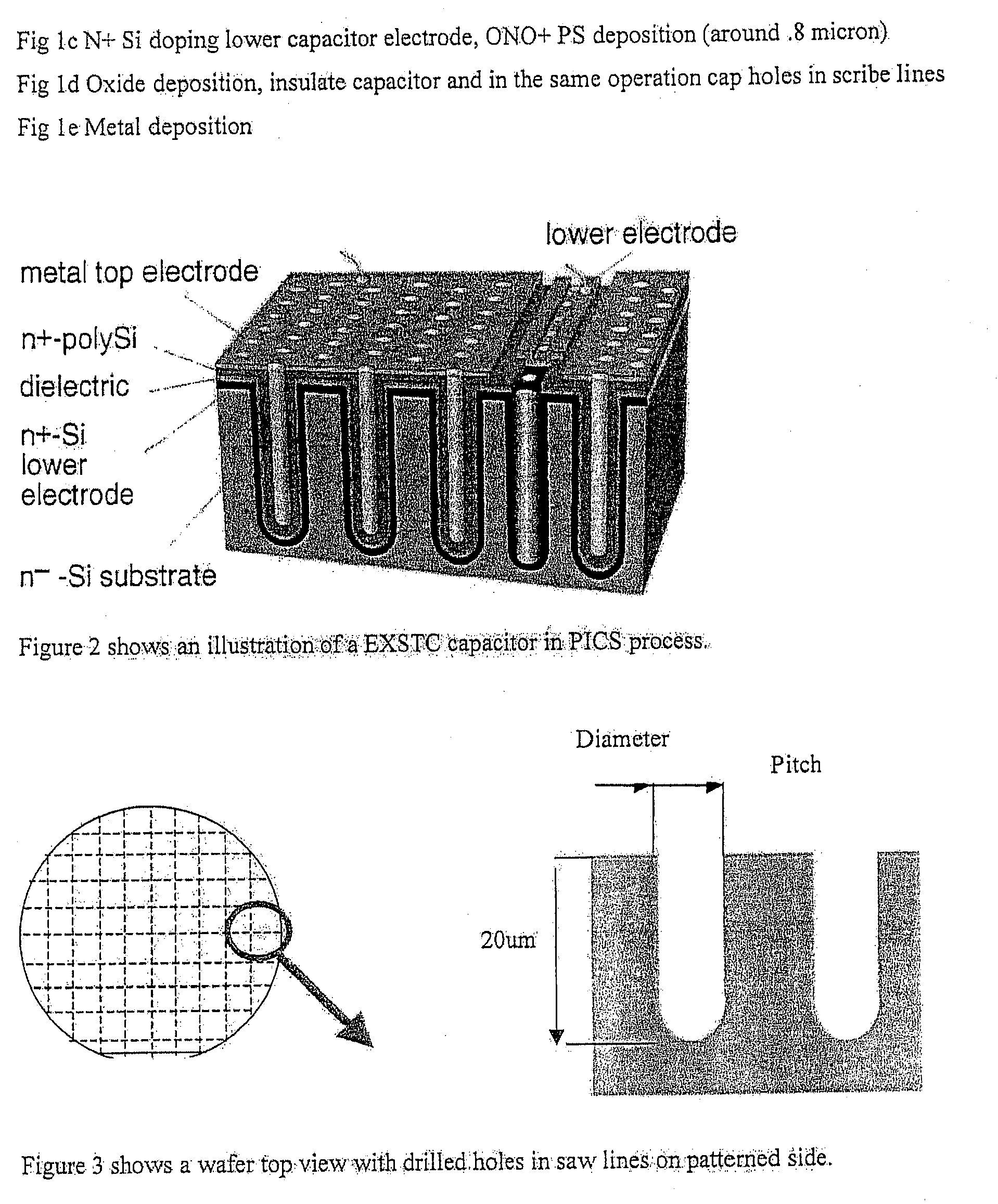

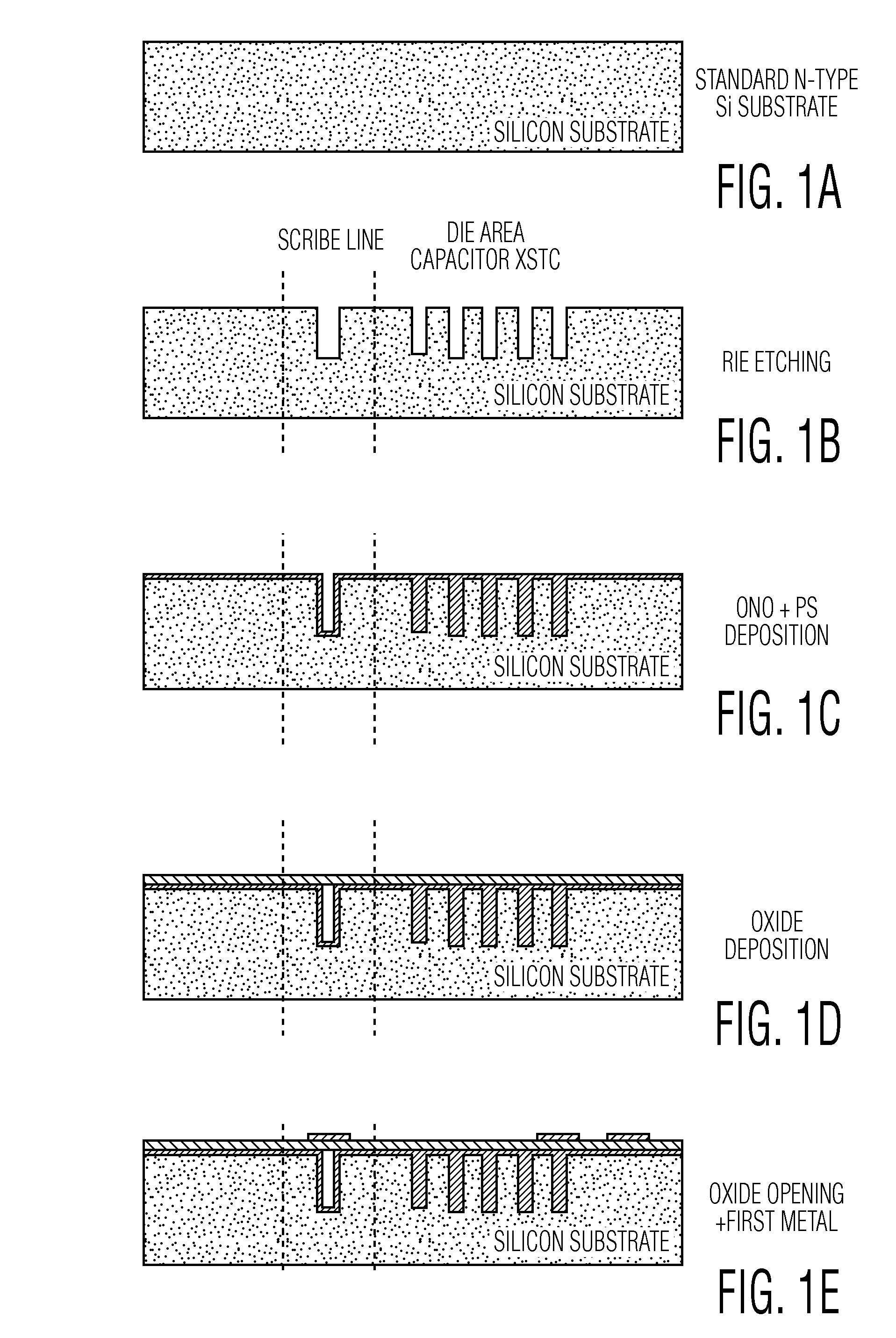

ActiveUS20100258916A1Cost optimizationQuality improvementSemiconductor/solid-state device detailsSolid-state devicesWaferingEngineering physics

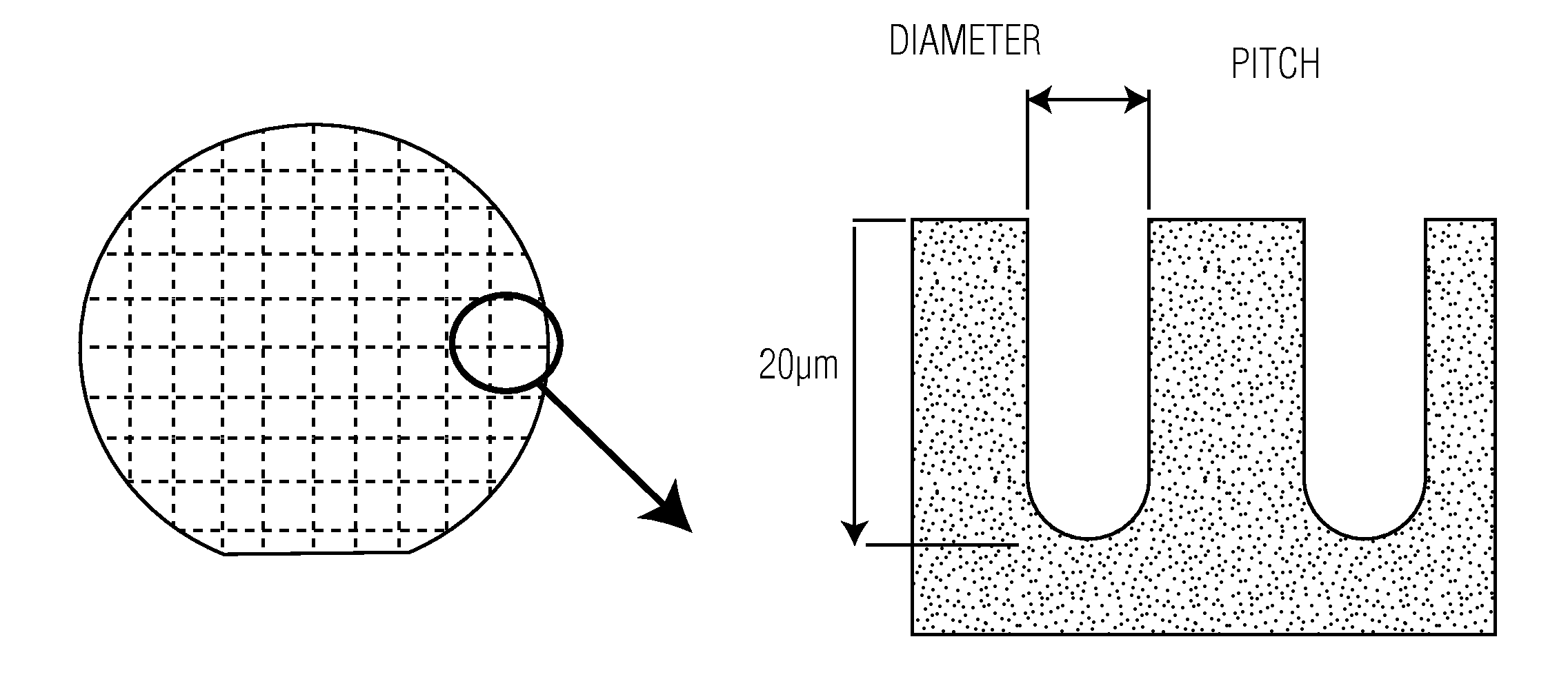

The present invention relates to a method for thermal stress reduction on a wafer, comprising the steps of providing a patterned wafer with saw lanes between adjacent dies, forming thin holes within the silicon substrate, which holes create a dotted groove in the saw lanes, and wherein no second layer on an opposing side of the wafer is formed, a patterned wafer obtained by said method. The forming of the holes is preferably combined with other processing steps or another step to avoid additional operations and manipulations prior to, or after standard wafer processing, and it therefore optimizes fabrication quality and costs. Preferably the holes within the silicon substrate having a depth of more than 3 to 50 μm, preferably from 5-40 μm, like 20 μm.

Owner:NXP BV

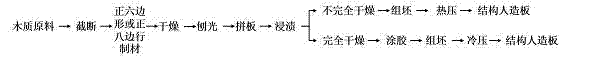

Soaking compression restructuring artificial board and method for producing same

The invention provides a method for producing a high-performance structure artificial board which is produced through utilizing fast-growing small dimension wood or bamboo wood raw materials. The method comprises the steps that the fast-growing wood is sawn into boards to be subjected to dry fixed thickness dressing treatment or the bamboo wood is longitudinally split to be subjected to plasticizing flatten dry fixed thickness dressing treatment, and an adhesive is used to form a fast-growing large board through splicing; the board is soaked in phenolic resin or melamine-formaldehyde resin; the soaked large board is dried until the resin content is 50-80% to obtain a blank; or the soaked large board is dried until the resin is completely solidified and is then coated with the adhesive to obtain the blank; the blank is laminated and assembled to obtain a blank body; and the blank body is subjected to cold pressing or hot pressing to obtain the structure artificial board. The produced artificial board does not need mould proof, anticorrosion, insect prevention and flame retardant treatment, is stable in dimension, can be used as building wood beams, wooden pillars, stairs, cement moldboards, compartments and container bottom boards, decoration materials, furniture materials and the like, and is particularly suitable for outdoor occasions.

Owner:NANJING FORESTRY UNIV

Semiconductor package and method for manufacturing the same

ActiveUS7902650B2Reduce processing stepsHigh mechanical strengthSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageEngineering

A semiconductor package includes a carrier, a chip, a stiffener and an encapsulant. The chip is disposed on the carrier. The stiffener is disposed around the chip, directly contacts the carrier, and is mounted on the carrier. The encapsulant is adapted to seal the chip and the stiffener.

Owner:ADVANCED SEMICON ENG INC

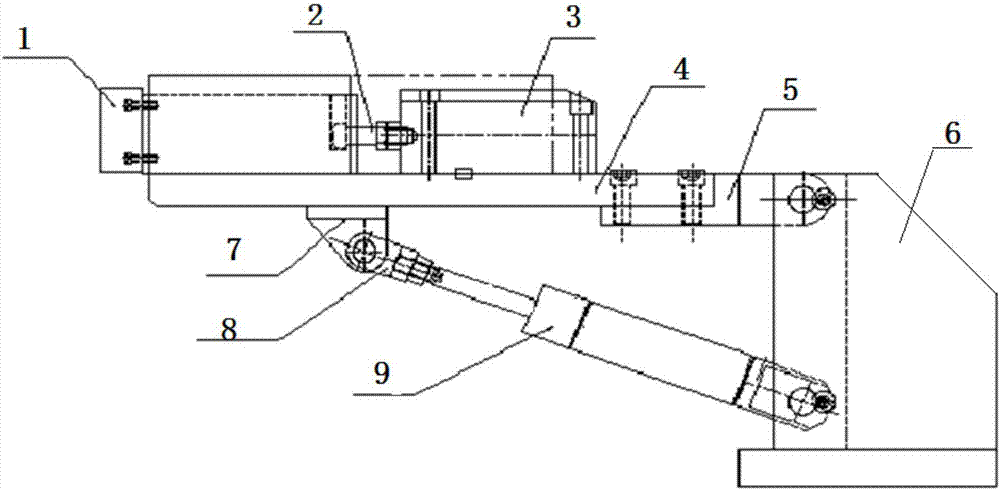

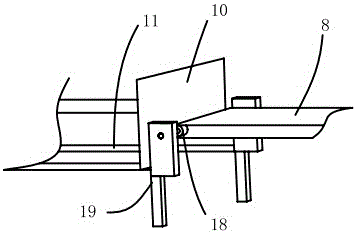

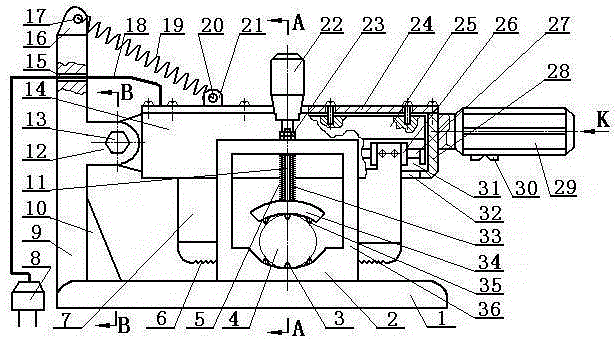

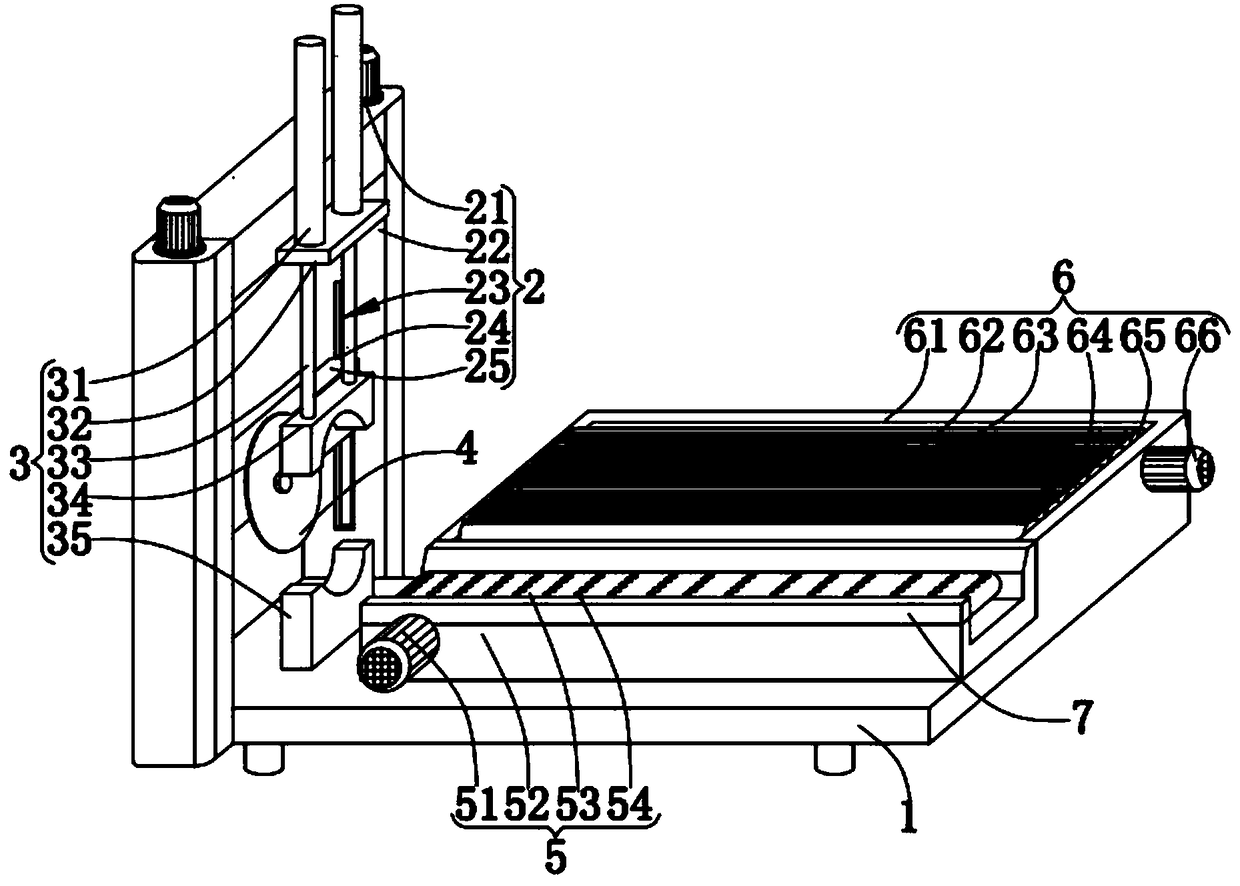

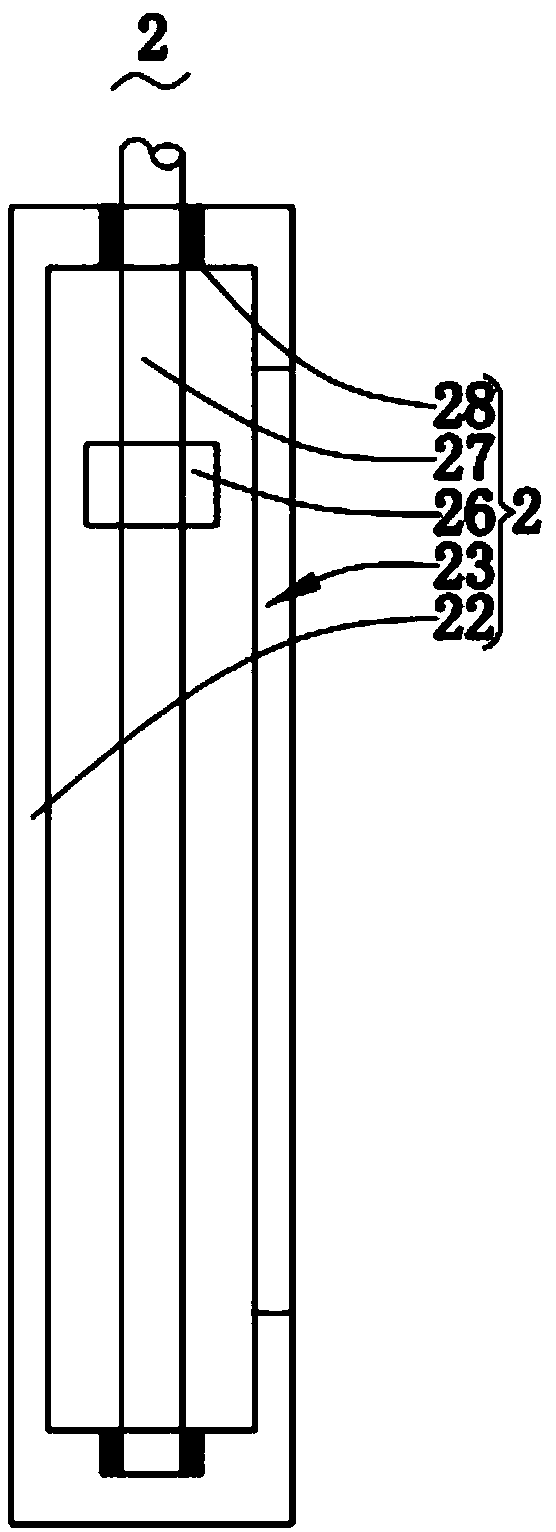

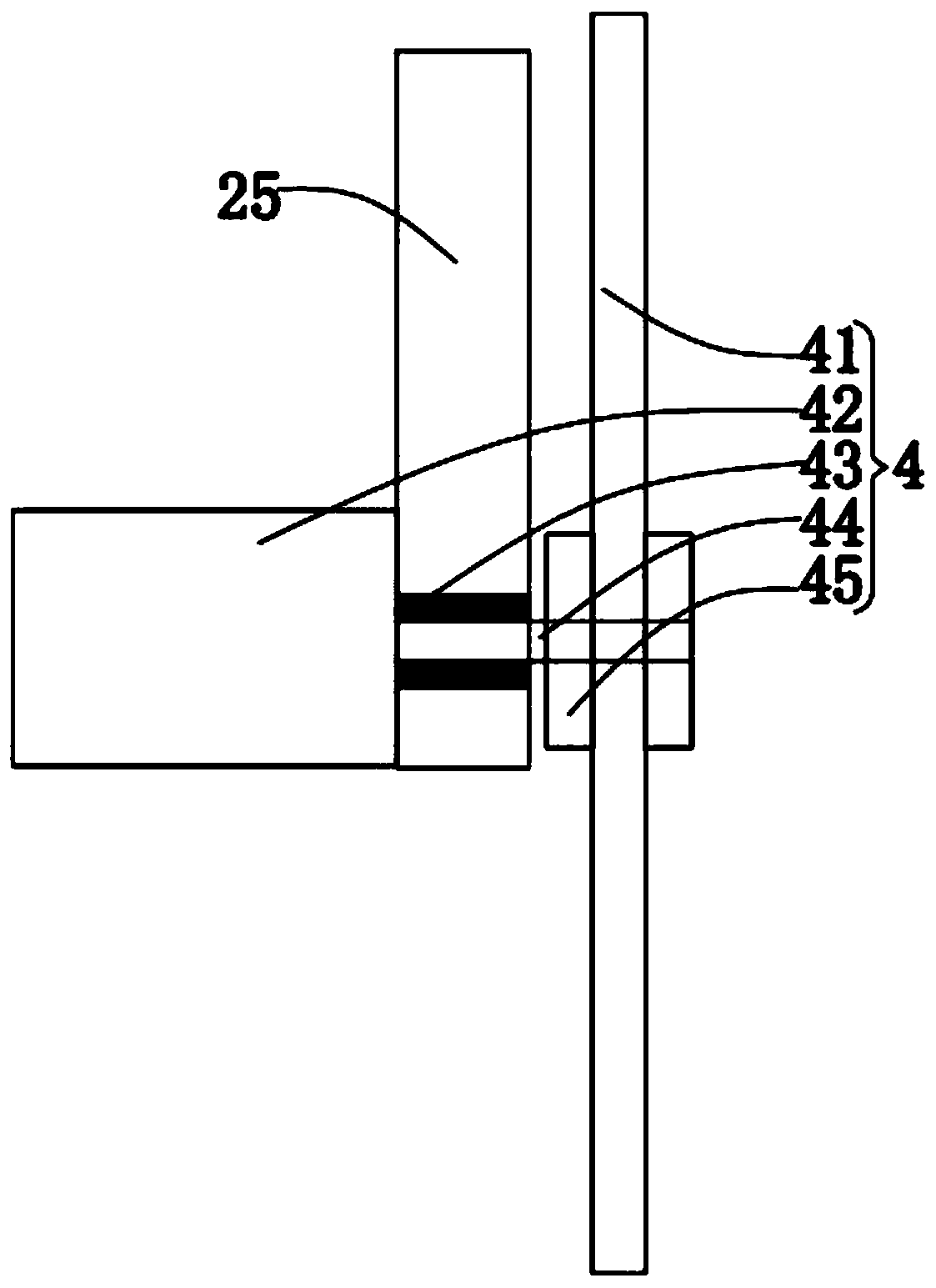

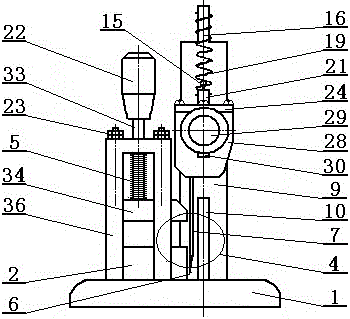

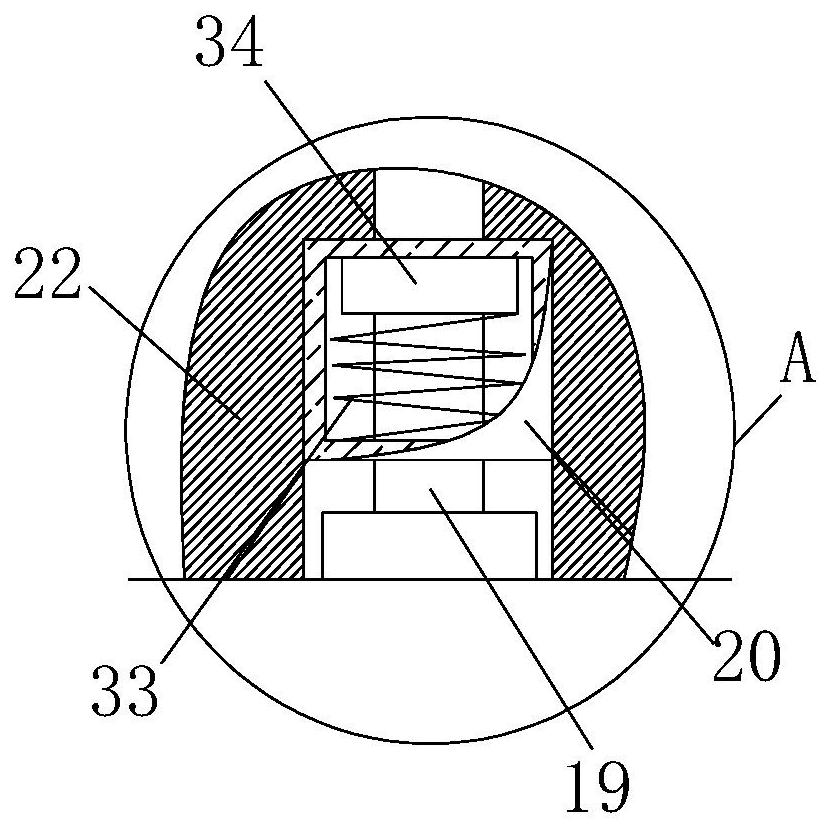

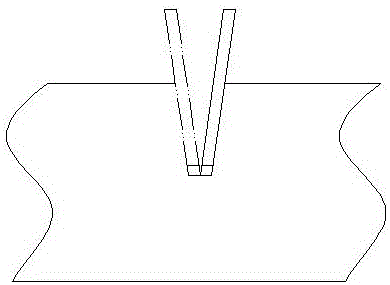

Device for assisting gantry circular sawing machine in cutting steel plate

PendingCN107398591AExtended service lifeReduce wearMetal sawing devicesMetal sawing accessoriesCircular sawSteel plates

The invention discloses a device for assisting a gantry circular sawing machine in cutting a steel plate. The device is arranged at a saw kerf close to the front end of the steel plate and comprises a supporting base, and supporting base is connected with a supporting plate; the supporting plate is provided with a wedge mechanism capable of being wedged into a steel plate sawing gap, the tail end of the wedge mechanism is connected with a propelling mechanism, and the propelling mechanism is arranged on the supporting plate; the supporting plate is connected with a lifting mechanism, one end of the lifting mechanism is connected with the supporting plate, and the other end of the lifting mechanism is connected with the supporting base; one end of the supporting plate can ascend and descend relative to the supporting base under the action of the lifting mechanism. The device for assisting the gantry circular sawing machine in cutting the steel plate can be wedged into the saw kerf in the steel plate sawing process, the width of the saw kerf is increased, and a saw blade is prevented from being extruded by materials on side edges of the saw kerf. By means of the device, steel plate sawing can be easier, the abrasion of the surface of the saw blade is reduced, the service life of the saw blade is prolonged, and the sawing efficiency is improved.

Owner:江苏宁兴恒力智能设备有限公司

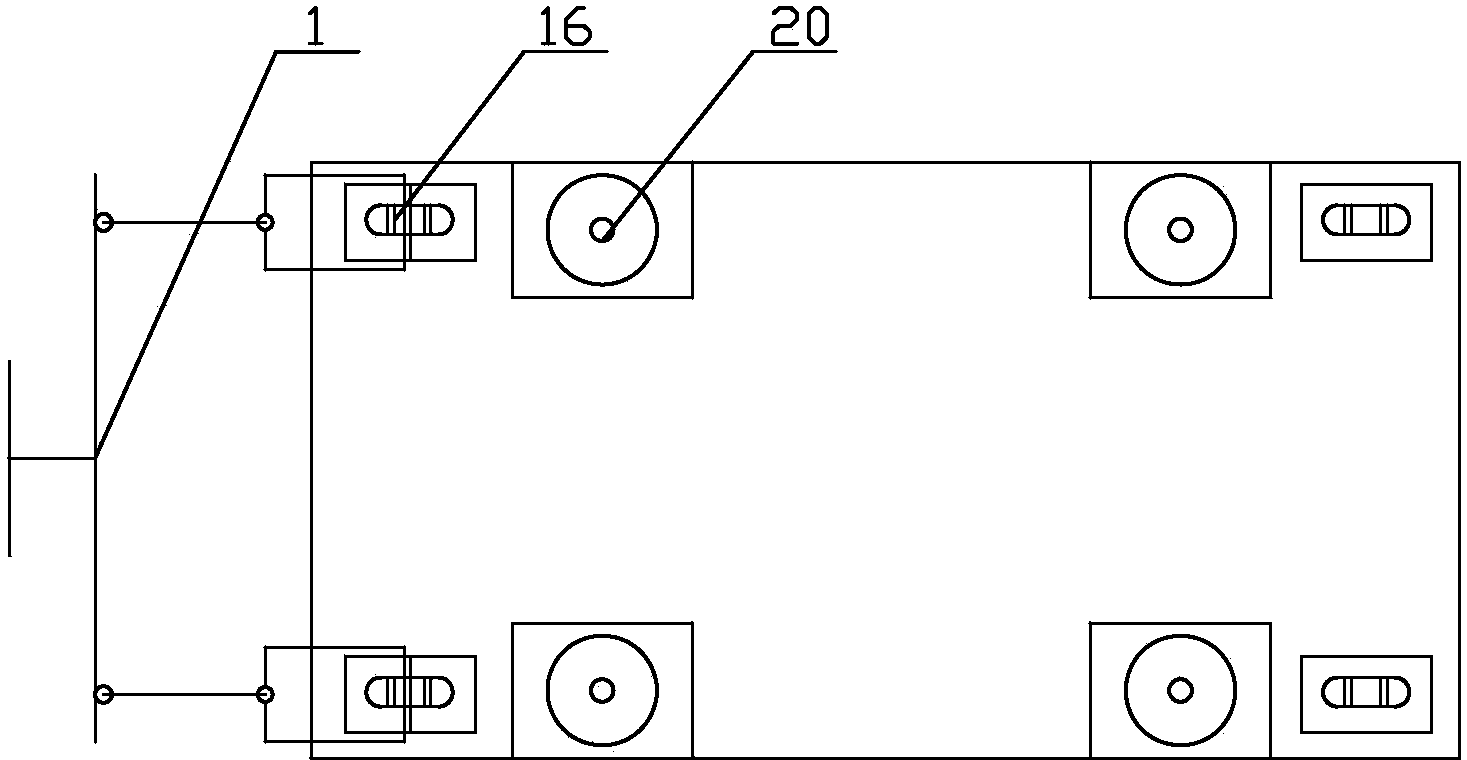

Automatic advancing type bamboo chopstick shear gauge

ActiveCN106078969AImprove sustainable use timeImprove the lubrication effectCane mechanical workingCircular sawsButt jointEngineering

The invention discloses an automatic advancing type bamboo chopstick shear gauge. The automatic advancing type bamboo chopstick shear gauge comprises a machine base, multiple sawing units which are arranged on the machine base and used for sawing raw materials, a feeding device and a dust removing device. Each sawing unit comprises a support, a supporting beam connected to the support, a rotating shaft and a sawing piece connected with the rotating shaft. The feeding device comprises a feeding plate arranged in front of the sawing units and a material storage groove formed in the tail end of the feeding plate. The feeding plate is fixed to the machine base through a supporting frame. The feeding plate is provided with matched notches opposite to the sawing pieces. A transmission device is assembled on the feeding device. The feeding plate can be used for automatically conveying bamboo chopsticks, and the bamboo chopsticks slide into the material storage groove. A guide rail is erected on the material storage groove. The guide rail is connected with a top plate in a sliding manner. A push piece is arranged on the back face of the top plate and is used for pushing the top plate to slide on the guide rail. The top plate is in butt joint with the feeding plate. According to the automatic advancing type bamboo chopstick shear gauge, the bamboo chopsticks with a fixed length can be sawn due to the arrangement of the top plate, the uniformity is high, and equipment can rotate without resistance.

Owner:安吉天友机械科技有限公司

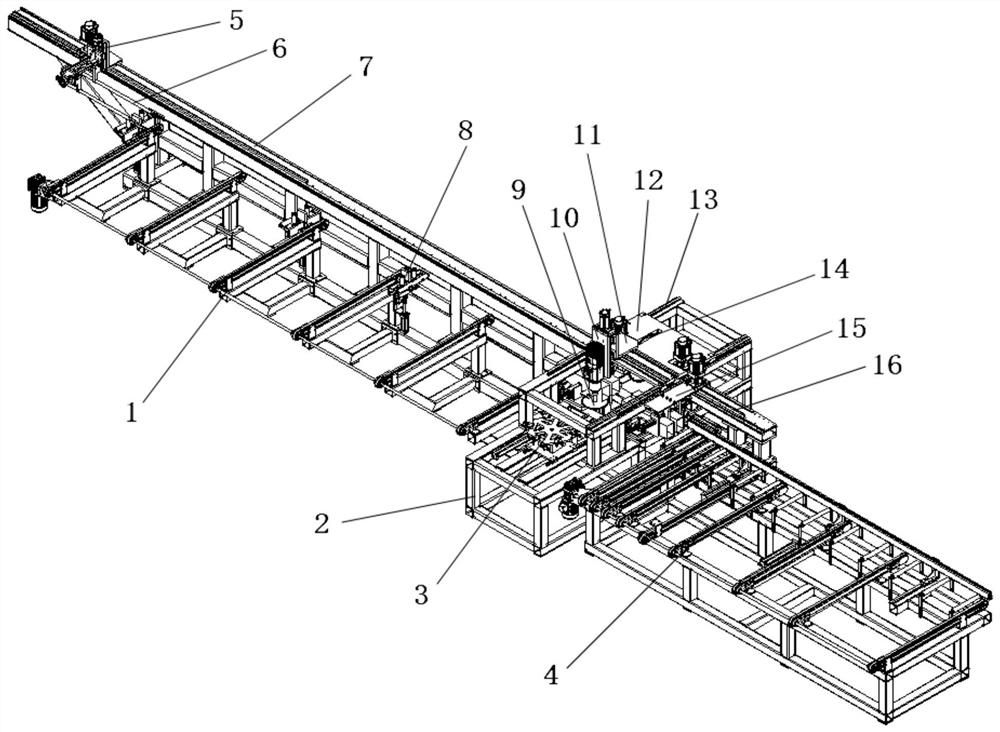

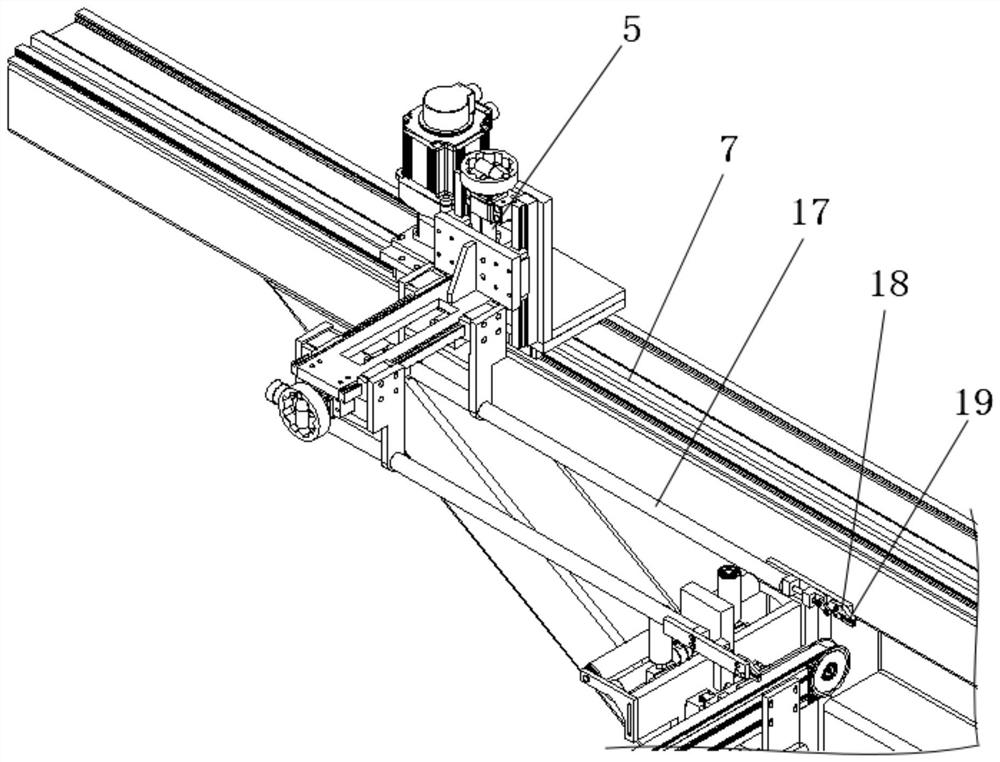

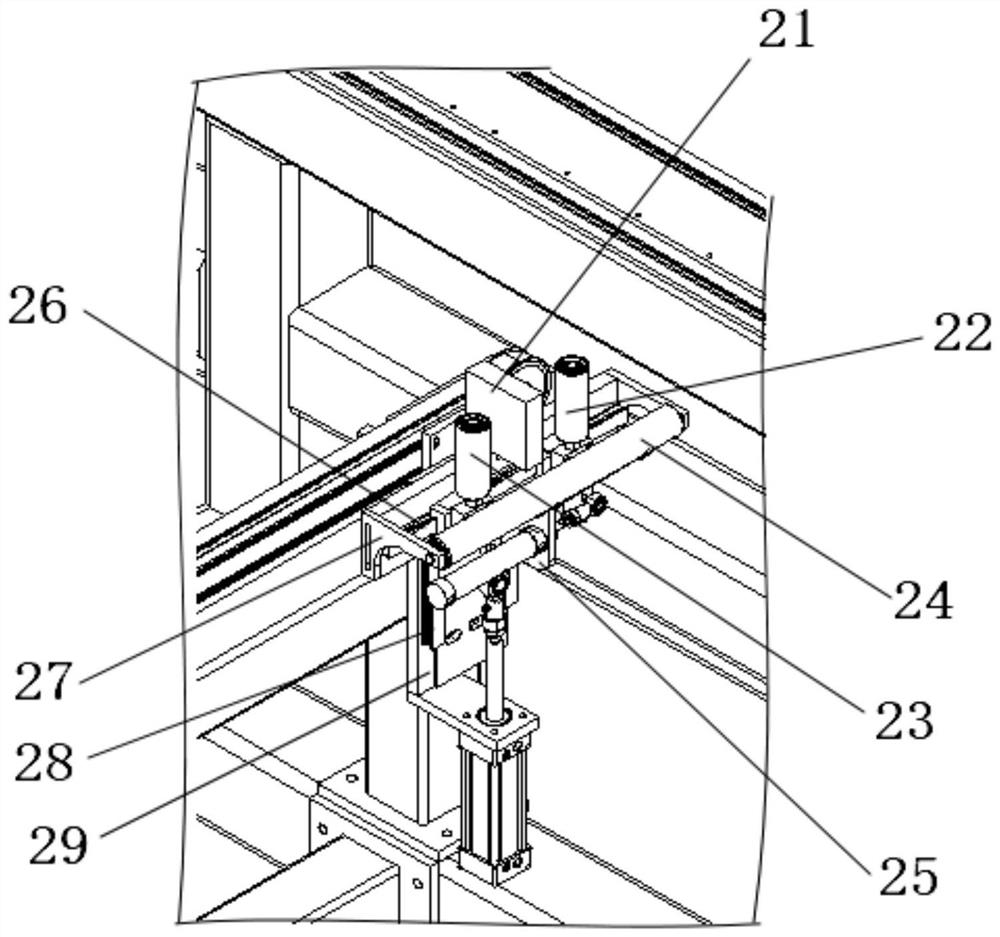

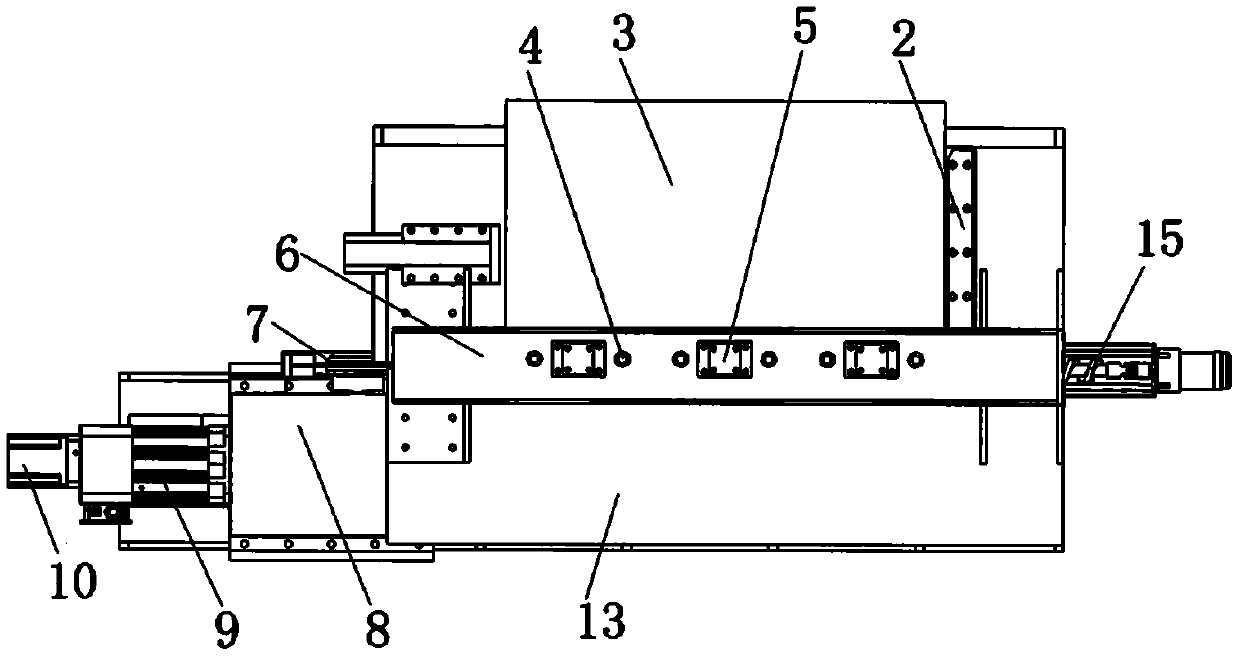

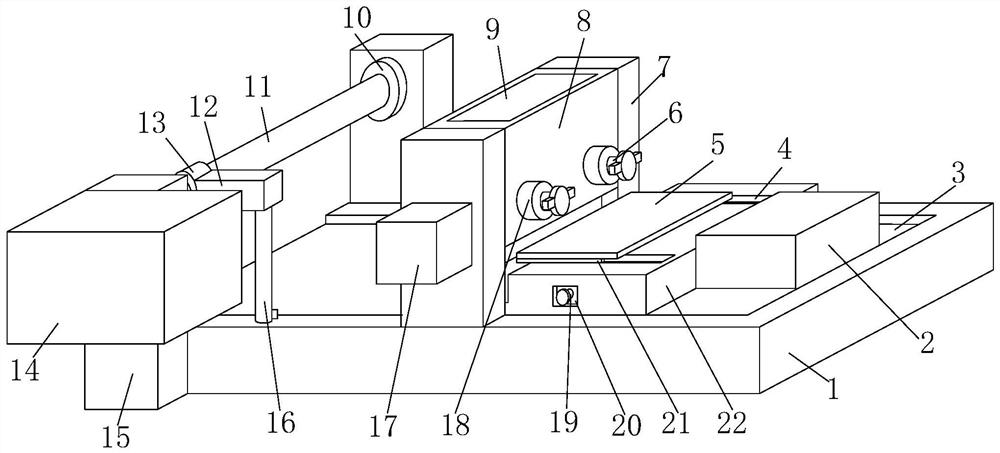

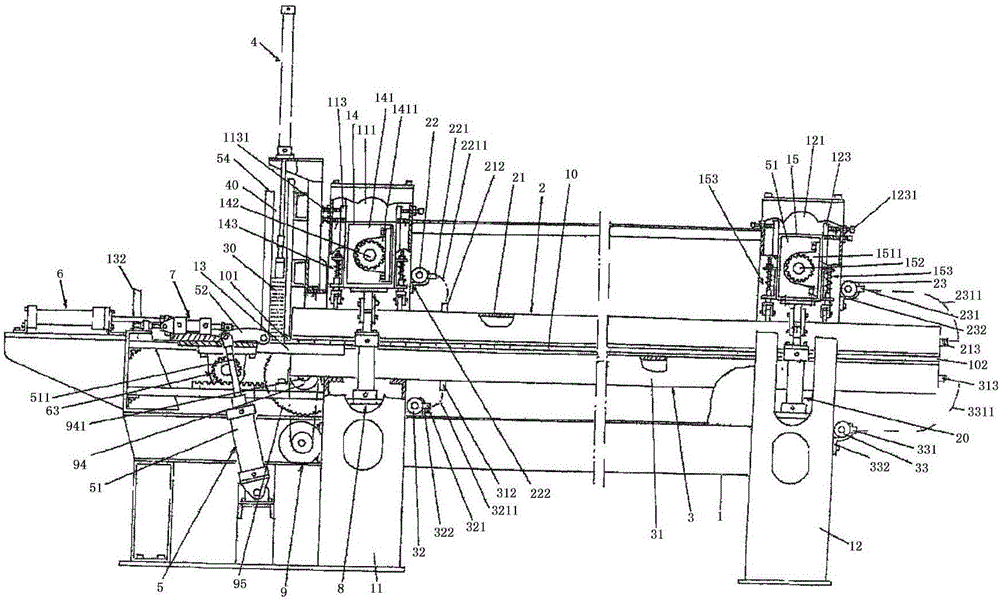

Sawing and milling system and method

ActiveCN112658684APrecise positioningPromote sportsOther manufacturing equipments/toolsMachining systemEnd milling

The invention provides a sawing and milling system and method. According to the scheme, a clamping guide mechanism and a pushing mechanism capable of pushing a sectional material to a milling device are arranged on one side of the discharging end of a sectional material feeding and conveying device, the milling device comprises an integrated machine head support, a support guide rail, a sawing assembly and an end milling assembly, the sawing assembly and the end milling assembly are installed on the integrated machine head support and driven by the integrated machine head support to move in the X direction at the same time, the end milling assembly can also move in the Y direction and the Z direction, a cutter disc rail is arranged on one side of the end milling assembly, a rotary cutter disc is installed on the cutter disc rail and can move in the X direction along the cutter disc rail, and the rotary cutter disc can move to the position of the end milling assembly for cutter replacement. Meanwhile, two sectional materials are machined, automatic tool changing can be achieved, the efficiency is high, and the integration degree is high.

Owner:山东鑫迈德数控设备有限公司

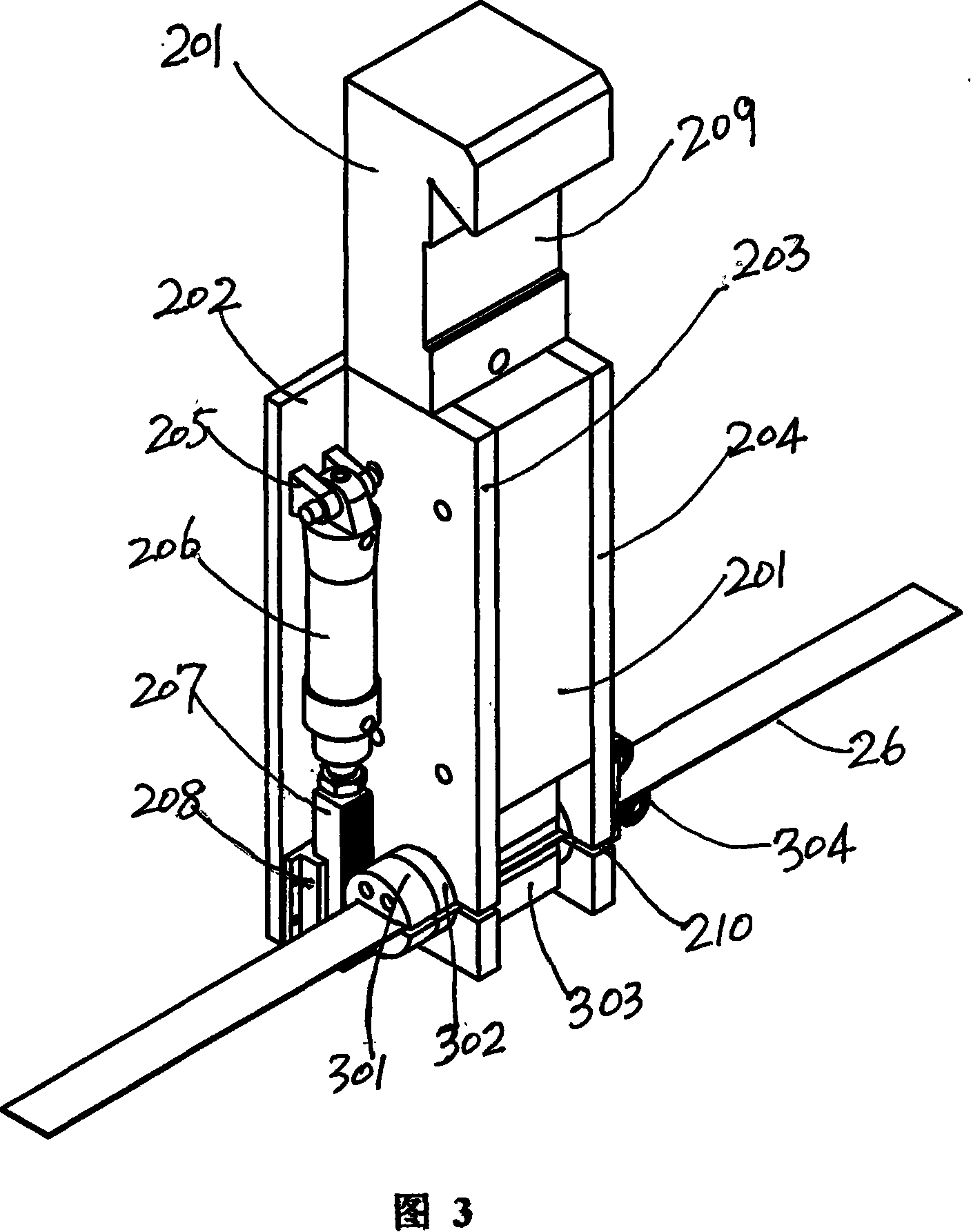

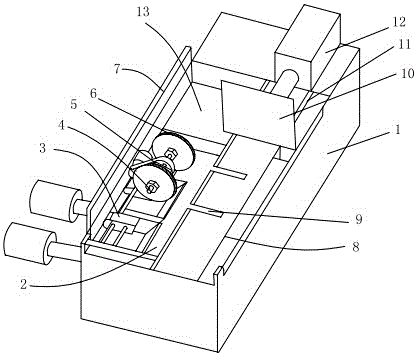

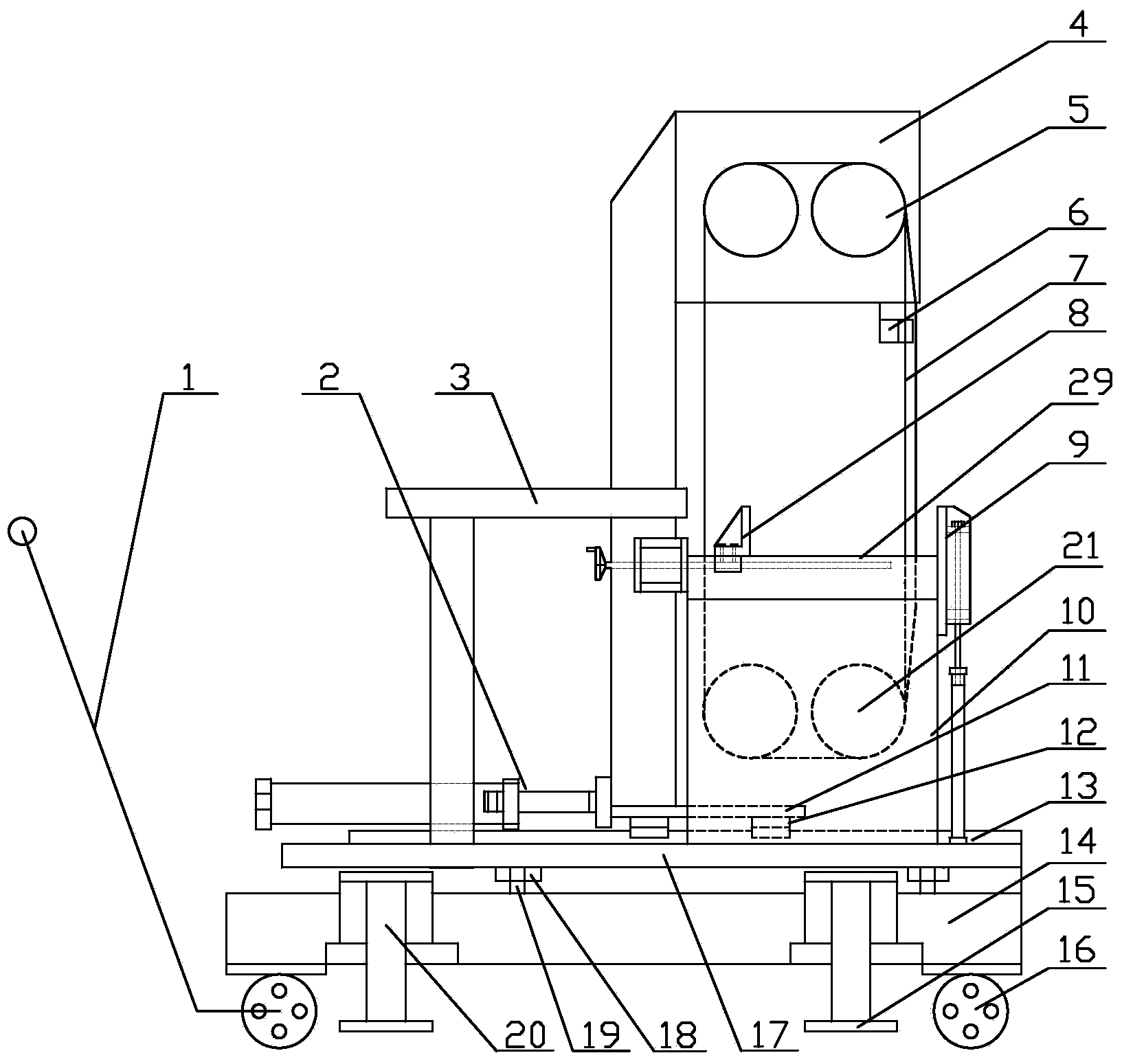

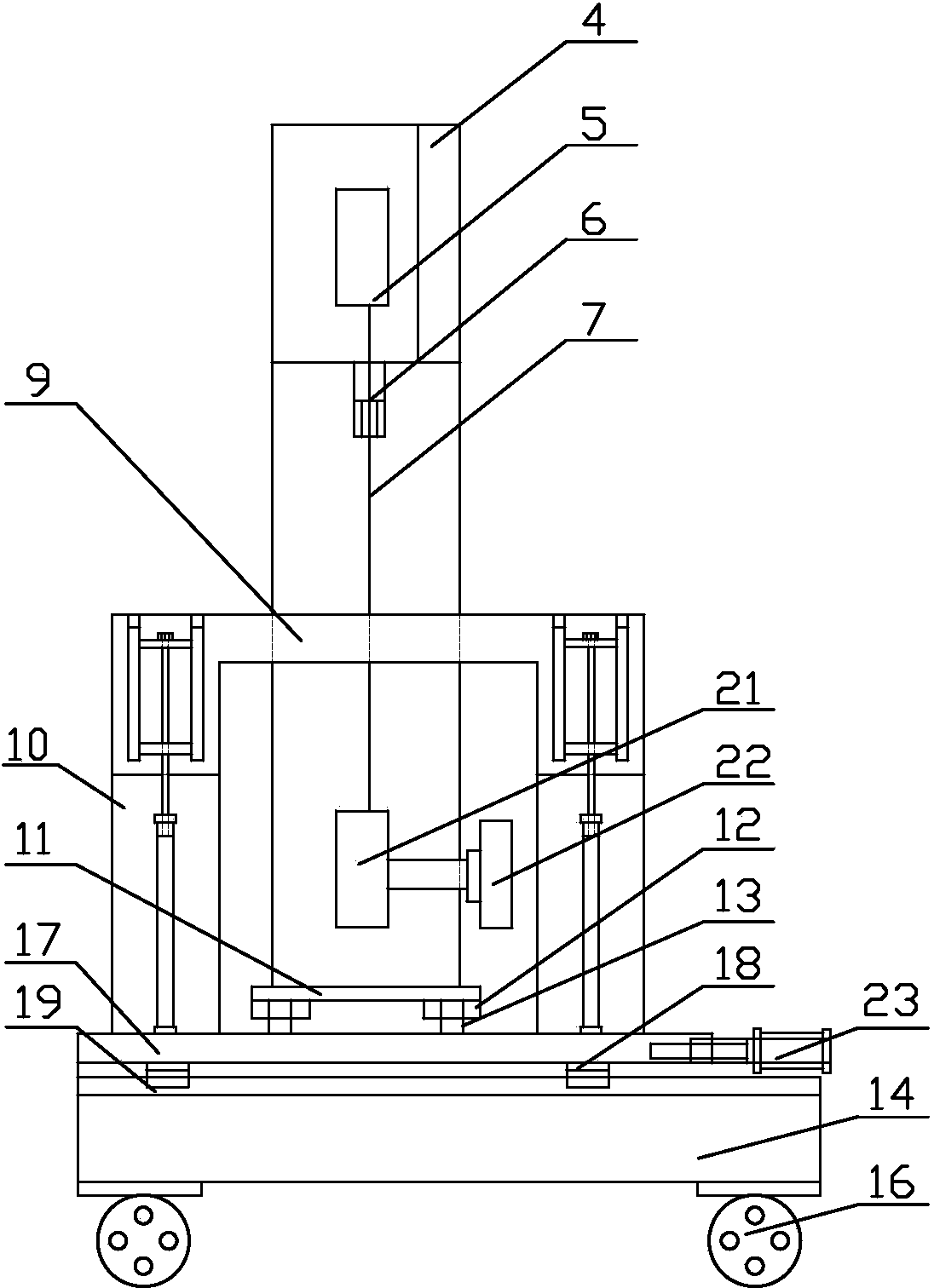

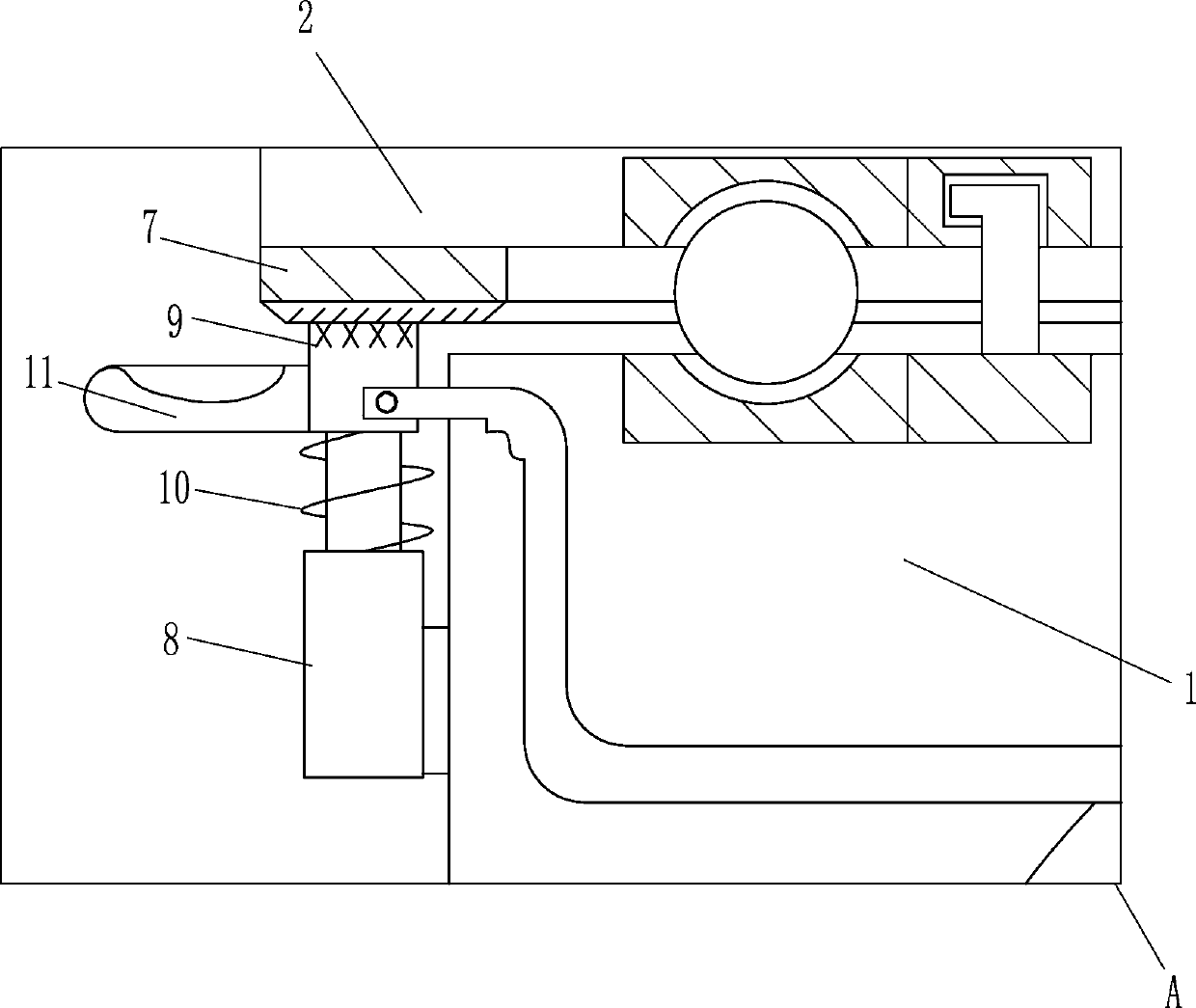

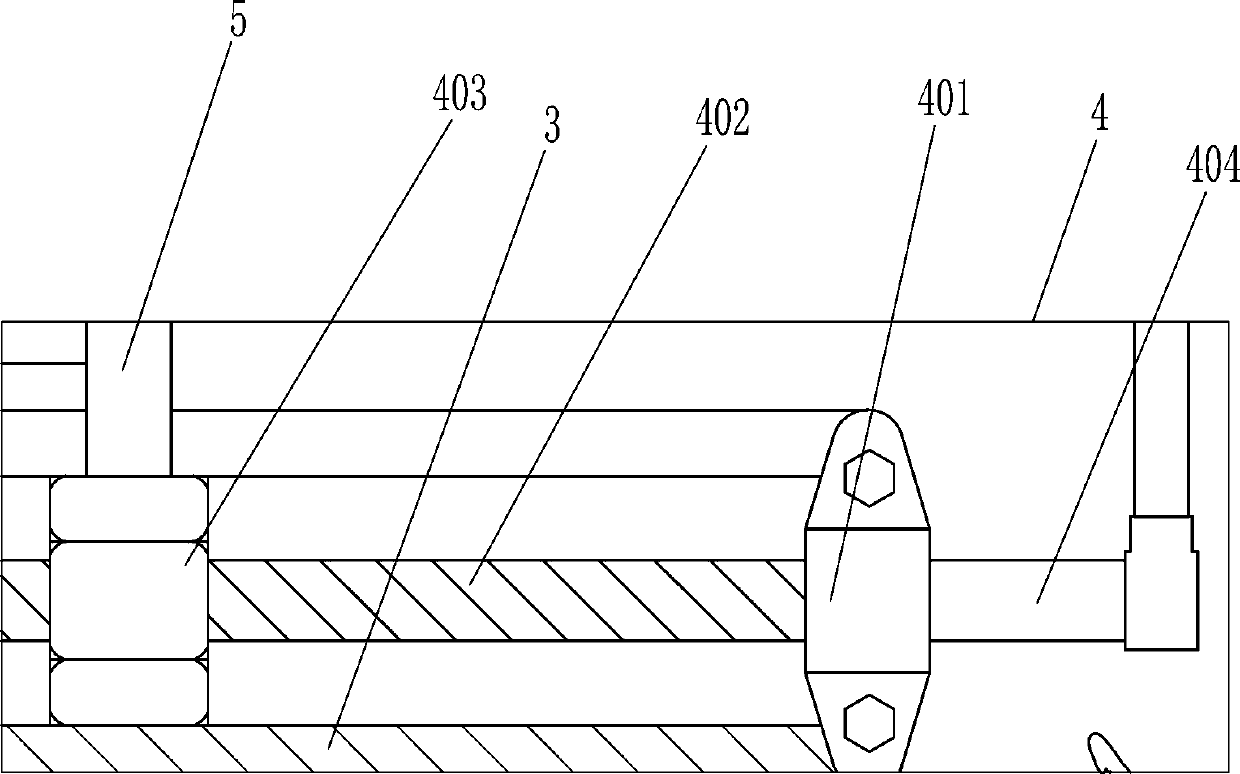

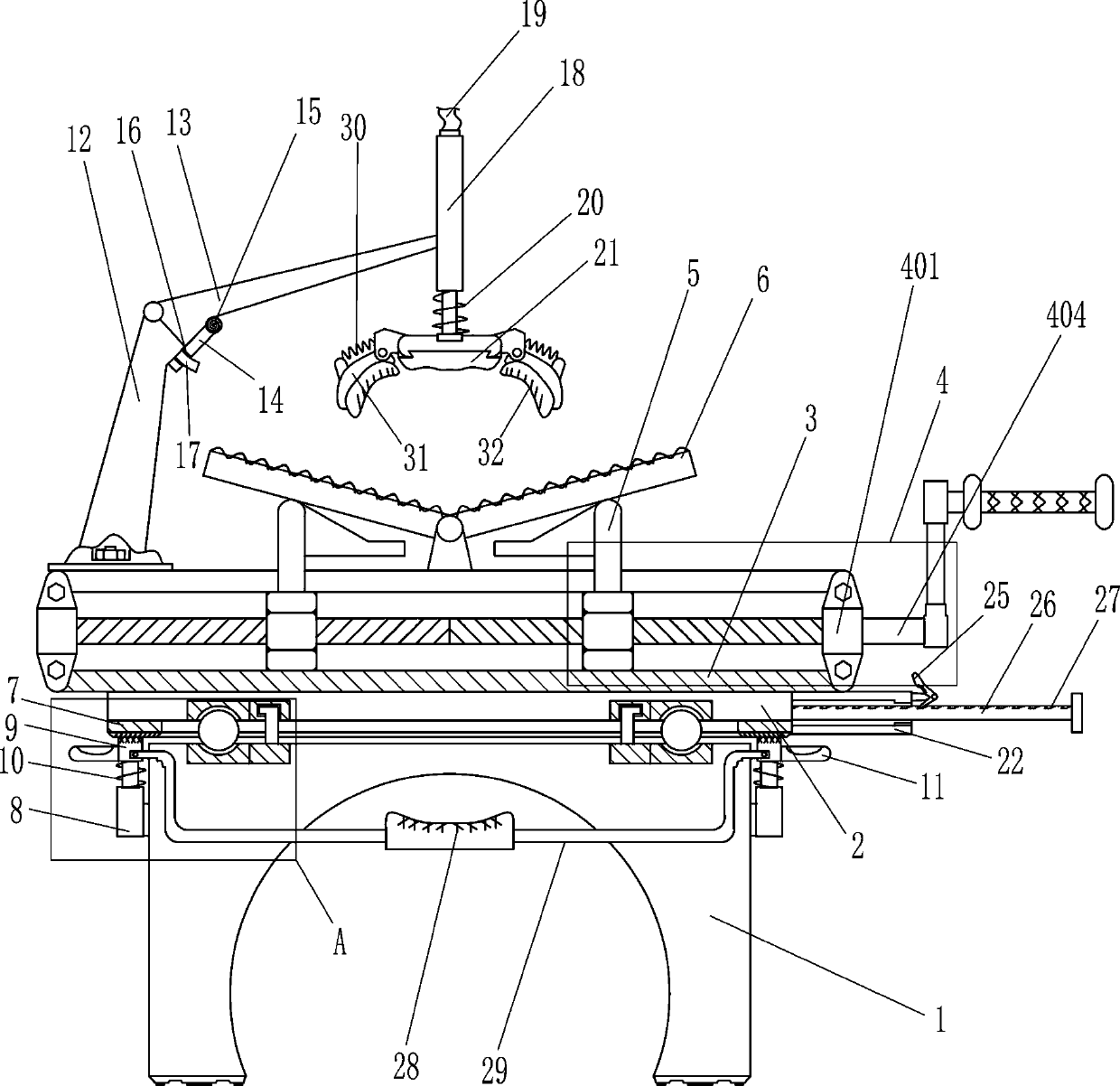

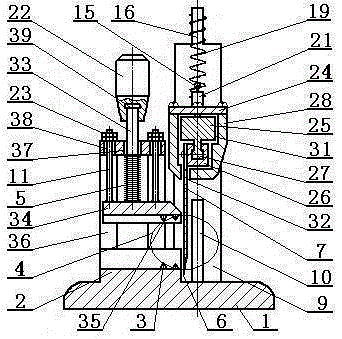

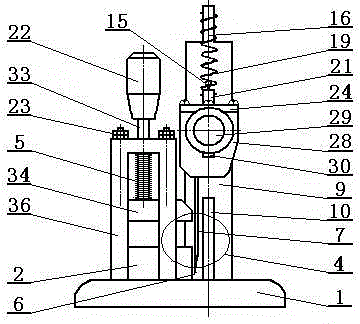

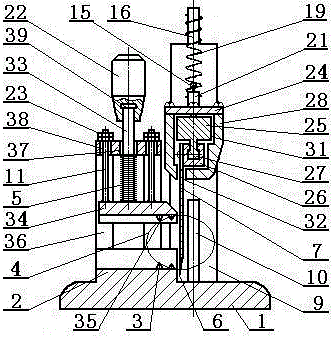

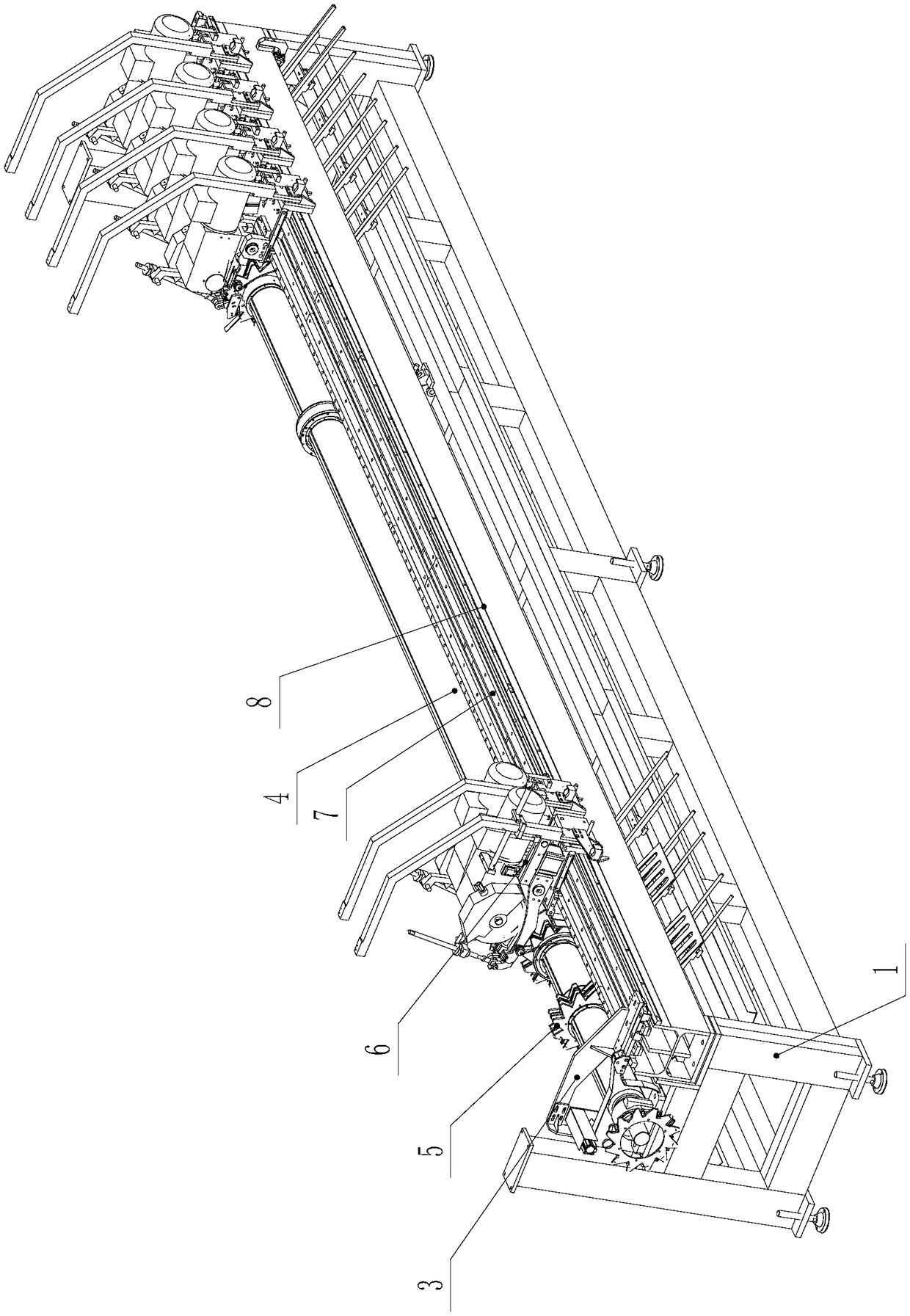

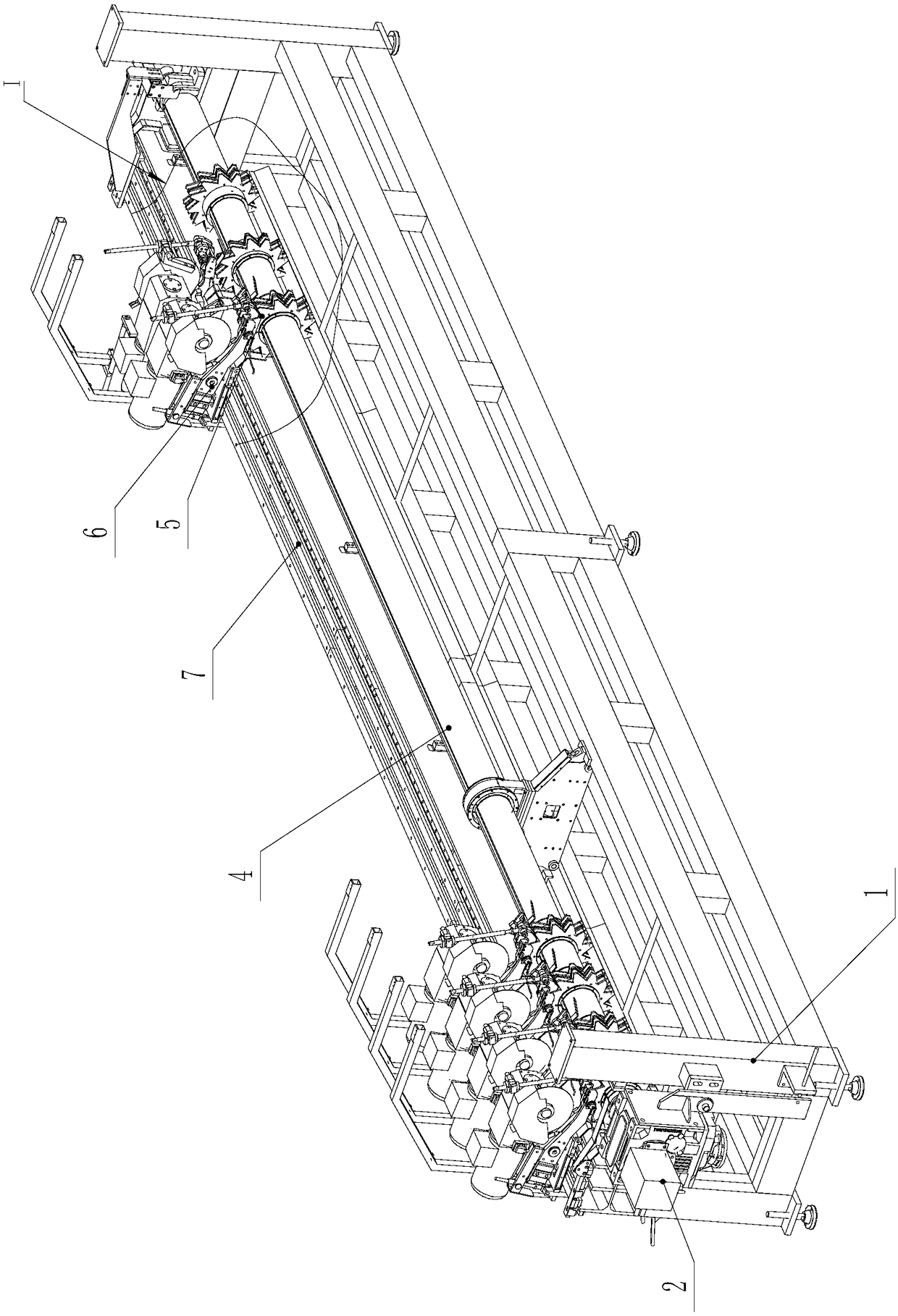

Vertical sawing machine

InactiveCN103521838AExtend your lifeSolve the problem of holding a sawMetal sawing devicesPositioning apparatusEngineeringMechanical engineering

The invention relates to sawing equipment of vertical cutting, in particular to a vertical sawing machine. The vertical sawing machine comprises a base, a machine body and a saw frame, wherein walking wheels are fixedly arranged below the base, and a whole lifting oil cylinder is arranged on the base. A workpiece clamping device is arranged on the upper portion of the machine body, the machine body is arranged on a second plate, the second plate is arranged on the upper portion of the base, a first plate is arranged on the upper portion of the second plate, the saw frame is arranged on the first plate, a front and back movement device of the first plate is arranged between the first plate and the second plate, and a left and right movement device of the second plate is arranged between the second plate and the base; a diving wheel and a driven wheel are arranged on the saw frame, and saw blades are wound on the driving wheel and the driven wheel. The vertical sawing machine solves the problem caused when a saw is taken by a person for sawing, due to the fact that the saw blades can be twisted for a certain angle, the service life of the saw blades can be prolonged, and production efficiency is improved. Besides, a jaw has the lifting function, and a workpiece can be placed on the jaw conveniently.

Owner:JINAN TONGJI MACHINERY

Cement pouring template pressing equipment

ActiveCN109760147AAvoid injuryPrevent slipping outGripping devicesClamping devicesRubber ringEngineering

the invention relates to pressing equipment, in particular to cement pouring template pressing equipment. The cement pouring template pressing equipment can support and stabilize the template well, can prevent workers from being injured, and can change a sawing angle conveniently and quickly. According to the technical scheme, the cement pouring template pressing equipment comprises a base, a mounting plate, a sliding frame, a moving mechanism, moving rods, placing plates, an annular rubber ring and the like, wherein the mounting plate is rotationally connected to the top of the base, the sliding frame is connected to the top of the mounting plate, the moving mechanism is arranged in the sliding frame, a part of the moving mechanism is connected with the two moving rods, and the moving rods penetrate through the top of the sliding frame in a sliding mode. According to the equipment, the opening angle of the placing plates on the left side and the right side are adjusted by workers according to the shape of a template to adapt to different shapes of templates well; and a first push rod can be pressed down to rotate the mounting plate to enable the template to rotate, the saw cuttingangle can be changed as required, and saw cutting is more convenient and rapid..

Owner:CHINA RAILWAY CONSTR ENG GROUP +1

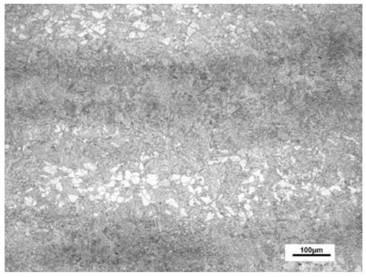

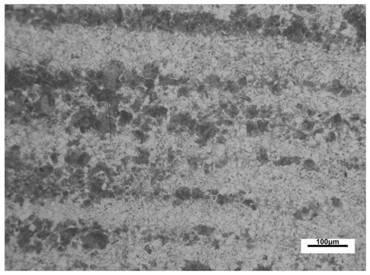

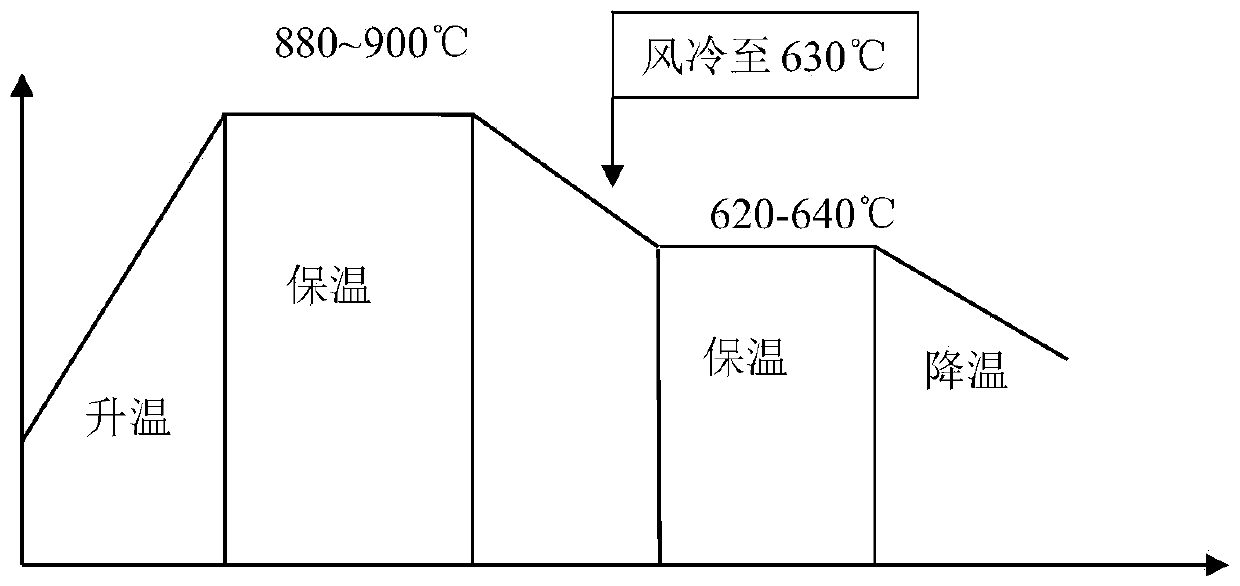

Heat treatment method for 18CrNiMo7-6 steel

PendingCN111518996APrevent annealingImprove plasticityFurnace typesHeat treatment furnacesIsothermal annealingIngot

The invention discloses a heat treatment method for 18CrNiMo7-6 steel. The method is used for carrying out annealing treatment on a round bar forged by an 18CrNiMo7-6 steel ingot; and in the annealingtreatment, the temperature of the round bar is increased to a first heat preservation temperature and heat preservation is carried out at the first heat preservation temperature, then air cooling iscarried out until a second heat preservation temperature is achieved and heat preservation is carried out at the second heat preservation temperature, and finally cooling is carried out, wherein the first heat preservation temperature is larger than or equal to 800 DEG C, and the second heat preservation temperature is 620-650 DEG C. According to the method, the cooling speed and the heat preservation temperature in isothermal annealing are controlled, so that the 18CrNiMo7-6 steel with ferrite and flaky pearlite structures is obtained, the steel has moderate hardness, the steel is convenientto machine, be subjected to blanking and saw, the cutter sticking phenomenon is avoided, and the yield is increased.

Owner:DAYE SPECIAL STEEL CO LTD

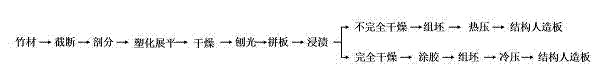

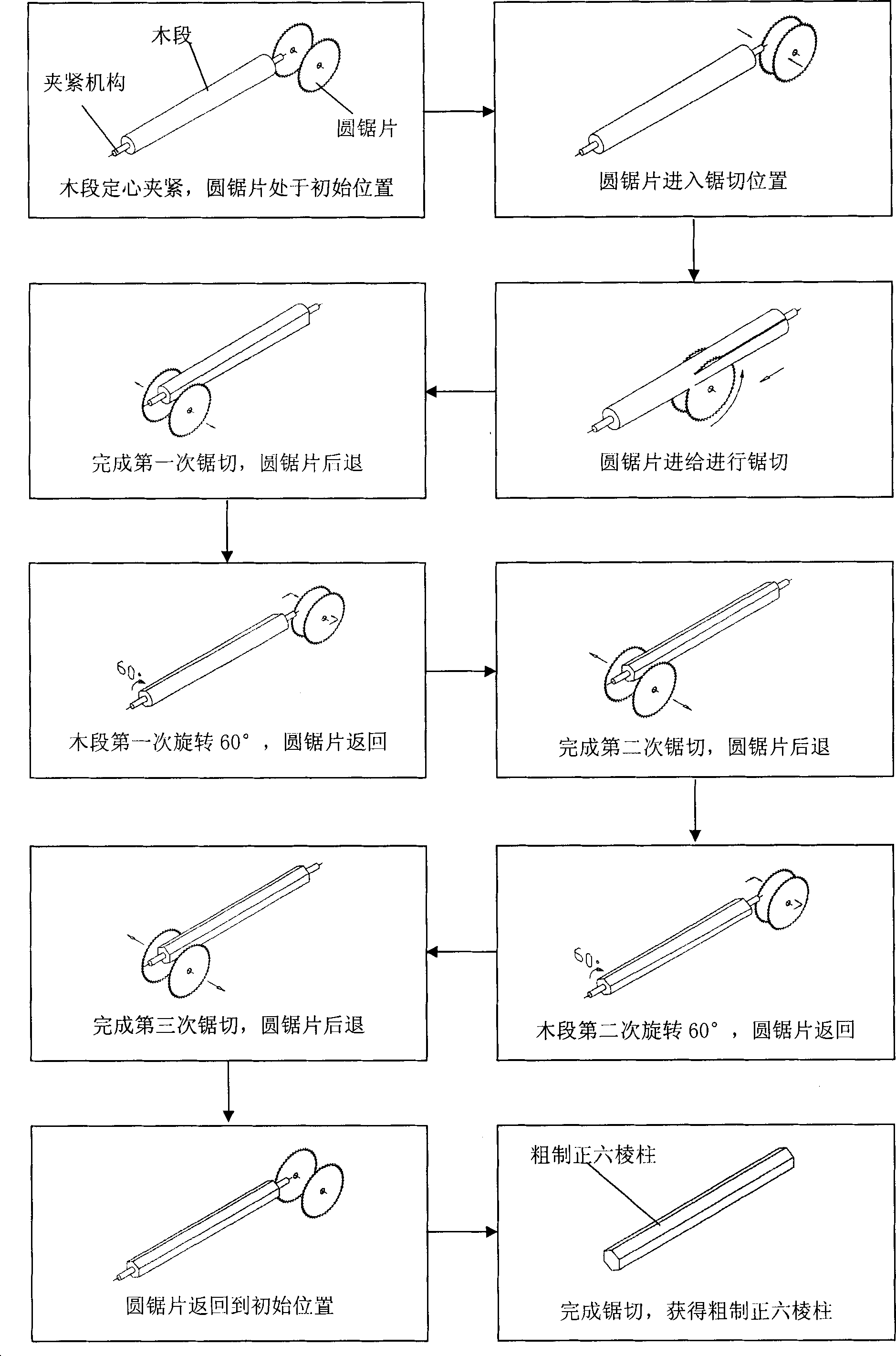

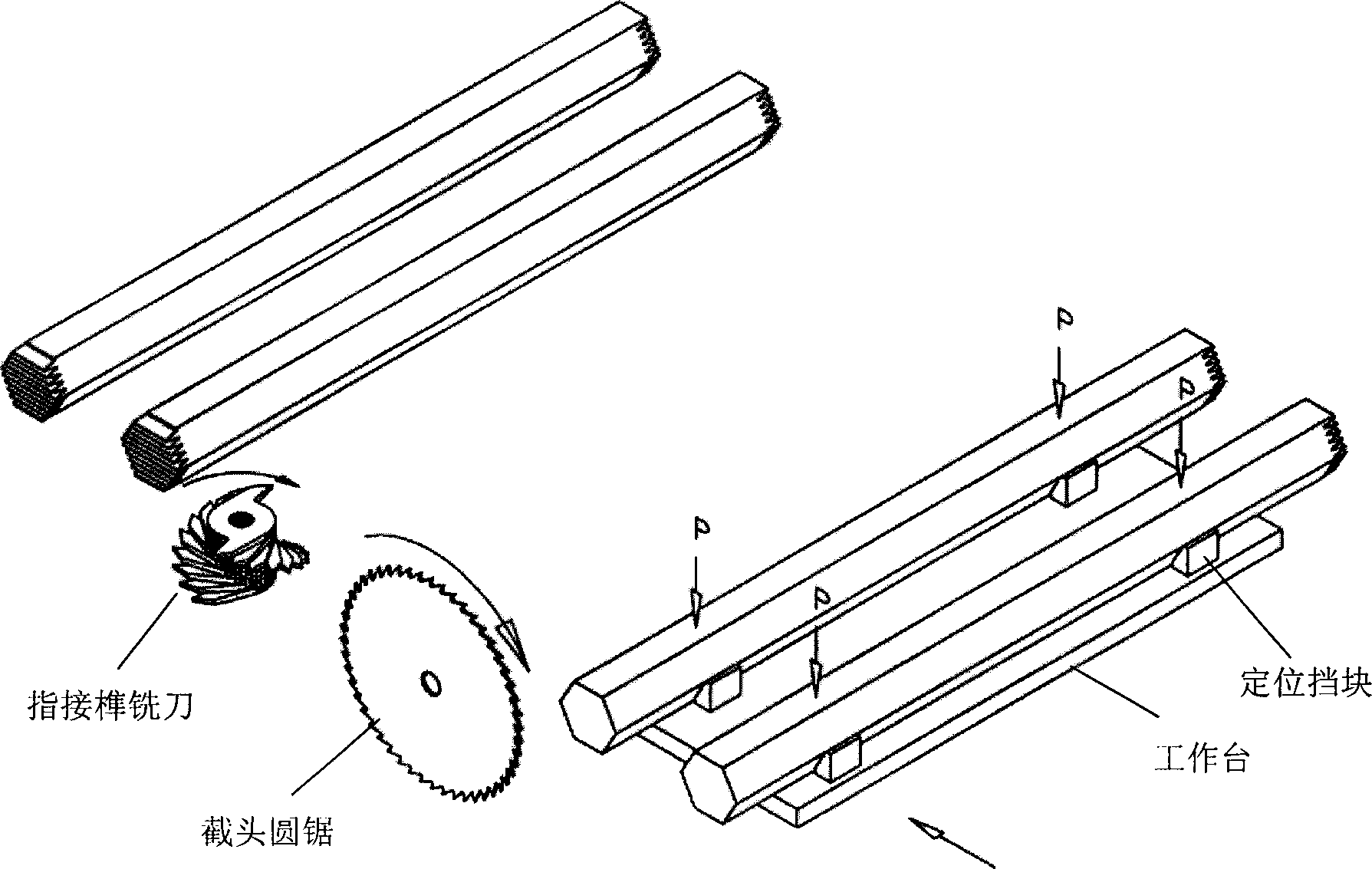

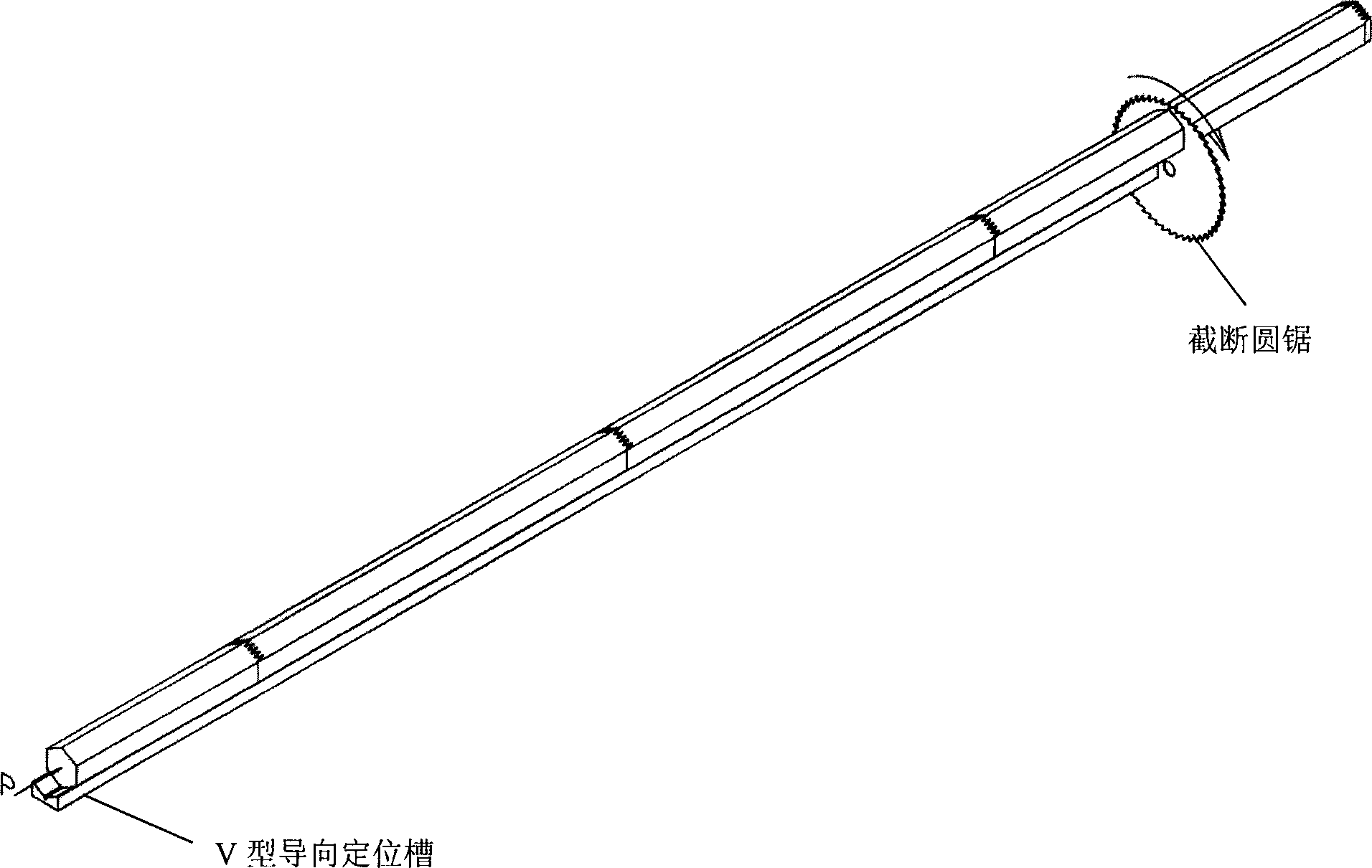

Method for preparing large-size sheet by using small-diameter wood

ActiveCN103341890BIncrease profitReduce curvatureWood veneer joiningWood mortising machinesFinger jointEngineering

The invention discloses a method for preparing a large-size sheet by using small-diameter wood. The method comprises the steps of: cutting small-diameter wood with a diameter of 6-11cm into wood sections with lengths of 1m, grouping into 5 groups according to the diameter of the small head and the 10mm difference, and drying until the water content is 12 percent; sawing the wood sections into rough regular hexagonal prisms, inscribed circles of bottom surfaces of which are 46mm, 56mm, 66mm, 76mm and 86mm, extending through a finger joint tenon and cutting according to the specification, milling into refine regular hexagonal prisms, inscribed circles of bottom surfaces of which are 40mm, 50mm, 60mm, 70mm and 80mm; symmetrically splitting the regular hexagonal prisms into quadraprisms through the maximum diagonal plane; symmetrically splitting the regular hexagonal prisms into pentagonal prisms through a plane vertical to the side surfaces of the hexagonal prisms; and selecting the quantities of the refine regular hexagonal prisms, and the pentagonal prisms and the quadraprisms, thereby obtaining a rectangular large-section glued wood beam through coating, assembling and bidirectional-pressurizing, and sawing into the large-size sheet with the thickness of 5-20mm. According to the method, the utilization rate and the use value of the small-diameter wood are improved.

Owner:江西兴创木业有限责任公司

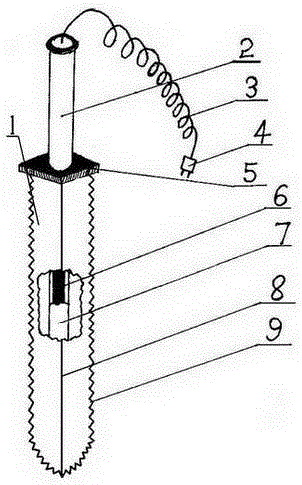

Defroster of refrigerator

InactiveCN106679294AEasy sawingEasy to manufactureLighting and heating apparatusDefrostingElectricityFrost

The invention provides a defroster of a refrigerator. The defroster mainly comprises a small knife body, a heating plate and a conducting wire, and is characterized in that the small knife body comprises a knife handle, a knife handle support, a knife back and a knife blade. One long strip-shaped heating plate is installed in the interlayer of the knife back; two insulating plates are separately adhered to the double surfaces of the heating plate so that the small knife body is uncharged; and the knife handle and the knife handle support are both made of a nonconductive insulating material. The heating plate is connected with one conducting wire; the conducting wire penetrates out of the center of the knife handle; the other end of the conducting wire is connected with a plug; after the plug is supplied with power, the heating plate is powered on and starts to heat to make sure that the small knife body is heated to the temperature of about 200 DEG C, and then defrosting is started. The edge of the small knife body is saw-toothed; with the addition of certain heat, the small knife body is capable of rapidly cutting off frozen frost on the inner wall of the refrigerator, so the defroster is capable of saving efforts, also convenient, also simple to manufacture, low in cost and easy to promote and popularize.

Owner:兰金隆

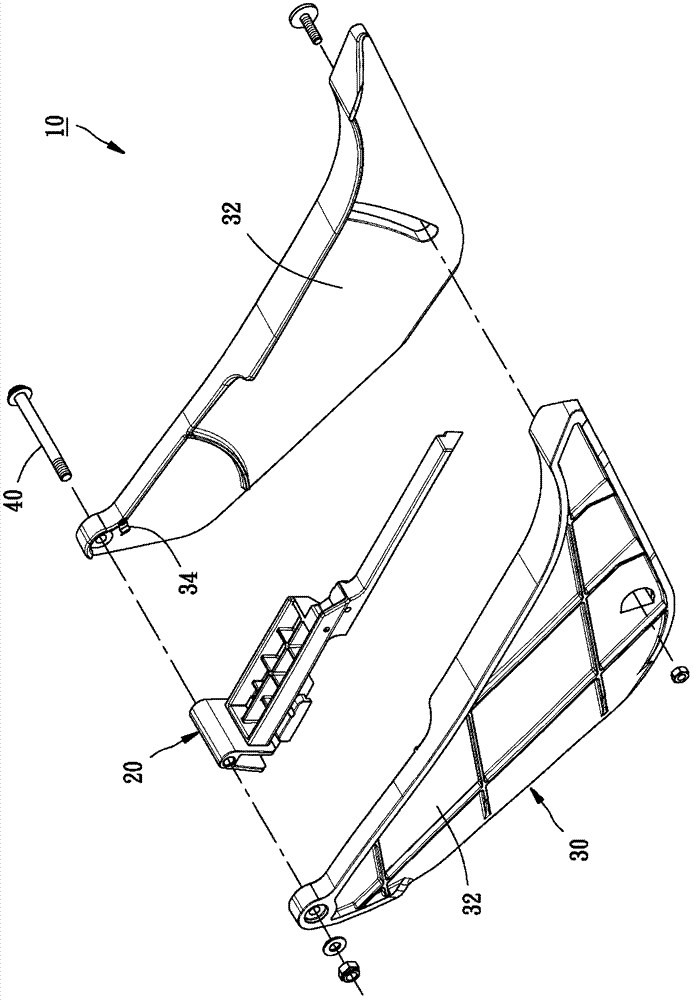

Saw blade protective cover device of table saw

InactiveCN102773558AEasy sawingMetal sawing accessoriesMaintainance and safety accessoriesEngineering

Owner:REXON IND CORP LTD

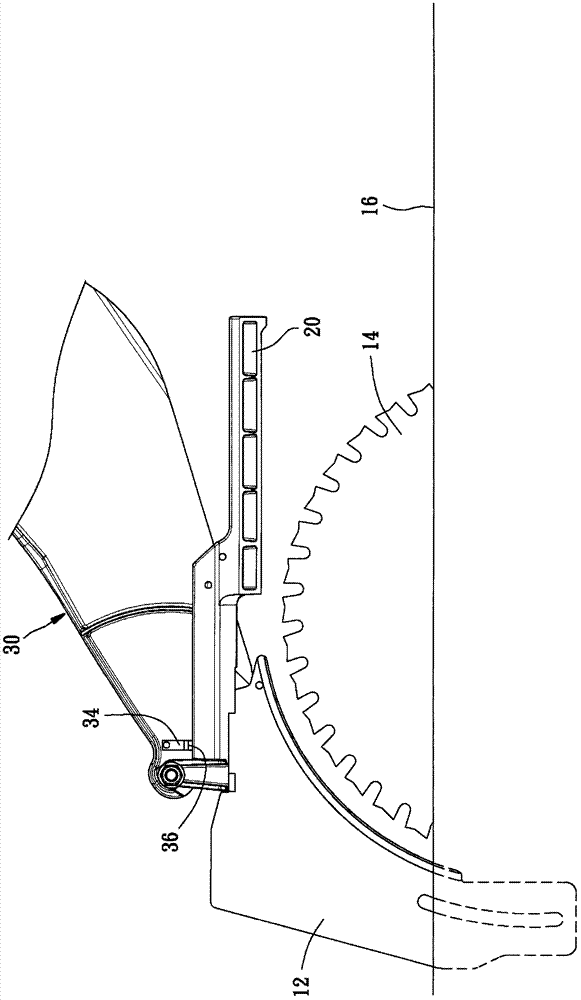

Household scissors-type sawing tool for passion fruit

The invention discloses a household shears-type sawing tool for a passion fruit. The household scissors-type sawing tool comprises an upper half shearing part, a lower half shearing part and a rivet, wherein an upward-concave upper arc-shaped shearing edge is arranged at the lower end of the upper half shearing part; upper sawing teeth which are uniformly distributed are arranged at the lower end of the upper arc-shaped shearing edge; the extending length of the upper toothed bulges is 2-4 mm; an upper long-strip cutting edge is arranged at the upper end of the upper half shearing part; an downward-concave lower arc-shaped shearing edge is arranged at the upper end of the lower half shearing part; lower sawing teeth which are uniformly distributed are arranged at the upper end of the lower arc-shaped shearing edge; the extending length of the lower toothed bulges is 2-4 mm; a lower long-strip cutting edge is arranged at the lower end of the lower half shearing part; a lower shears handle is arranged at the lower right end of the upper half shearing part; an upper shears handle is arranged at the upper right end of the lower half shearing part; the upper half shearing part and the lower half shearing part are oppositely assembled and riveted together through the rivet; and under the action of external force, the upper half shearing part and the lower half shearing part can be opened or closed. Not only can the household shears-type sawing tool be used for sawing off the passion fruit easily and the juice of passion fruit be prevented from outflowing, but also the household shears-type sawing tool is simple in structure, low in cost, convenient to clean, and sanitary.

Owner:吴凰

Electric cut-open knife for passion fruit

The invention discloses an electric cut-open knife for passion fruit. The electric cut-open knife is mainly characterized in that a lower clamping plate is arranged on the upper portion of a bottom plate of a knife rest, two sets of upward needle tips different in height are arranged at the rear end of an upward concave arc surface of the lower clamping plate along the arc surface, and the four corners of the lower clamping plate are connected with the lower ends of four support feet of a support; a first round through hole is formed in the center of a rectangular flat plate on the upper portion of the support; a pull rod is arranged in the first round through hole, and after the lower portion of the pull rod is sleeved with a compression spring, the pull rod is perpendicularly welded together with an upward convex arc top face of an upper clamping plate; an annular shoulder is arranged on the upper portion of the pull rod, and the upper portion of the pull rod and a handle are integrated through injection molding; two sets of downward needle tips different in height are arranged at the rear end of a downward concave arc surface of the upper clamping plate along the arc surface, and the downward concave arc surface of the upper clamping plate is opposite and parallel to the upward concave arc surface of the lower clamping plate; a knife body is composed of a blade, a plug, a wire, a fixing plate, a single-phase alternating current linear motor, a knife holder, a knife handle and a switch. The passion fruit can be cut open simply, conveniently and easily through the electric cut-open knife.

Owner:张芙蓉

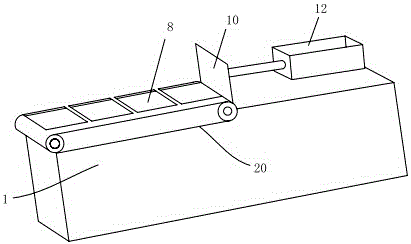

High-speed numerical-control circular sawing machine

InactiveCN111451574AClamp firmlyStable without vibrationMetal sawing devicesMetal sawing toolsCircular discBall screw

The invention discloses a high-speed numerical-control circular sawing machine which comprises a sawing machine frame, a sawing machine fixing base, a workpiece clamping mechanism and a main shaft feeding mechanism. The workpiece clamping mechanism is arranged at the upper portion of the sawing machine frame. The main shaft feeding mechanism is arranged at the upper portion of the sawing machine fixing base. A ball screw controlled by a drive motor to be operated is arranged between the sawing machine frame and the sawing machine fixing base. The workpiece clamping mechanism comprises oil cylinders, a pressing plate, a discharging plate and a positioning reference block, and the workpiece clamping mechanism is installed on a steel part portal frame. The main shaft feeding mechanism comprises a speed reducer, a gearbox, a saw blade, a saw head sliding base and an output main shaft. The three evenly-distributed oil cylinders are arranged on an oil cylinder portal frame. The pressing plate is controlled by the pressure of the oil cylinders to act on the workpiece, so that the pressure acting on the workpiece is evenly distributed. The workpiece is clamped firmly, and it is ensured that the sawed workpiece is stable and does not vibrate.

Owner:DONGGUAN GOODA MASCH MFG CO LTD

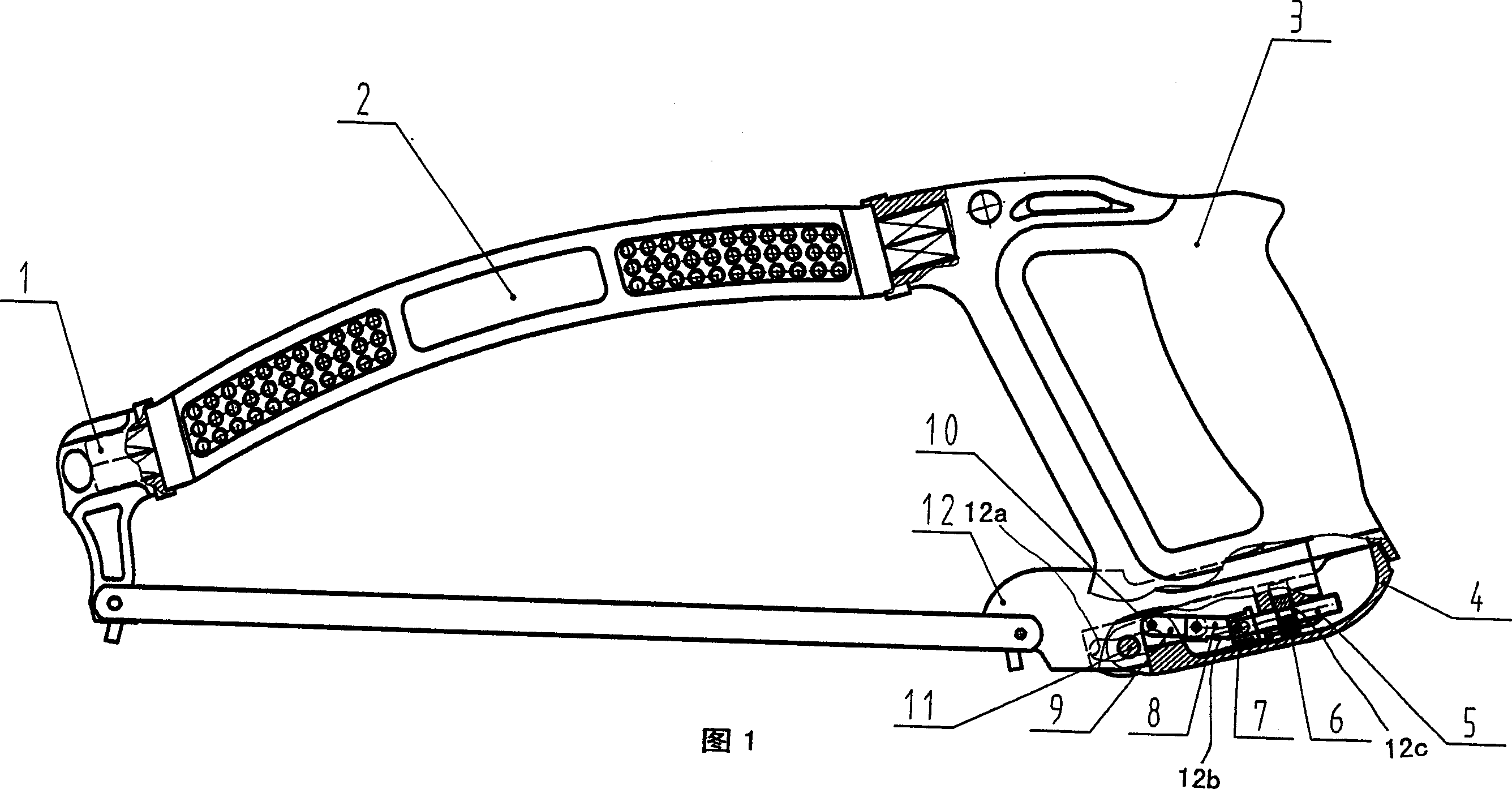

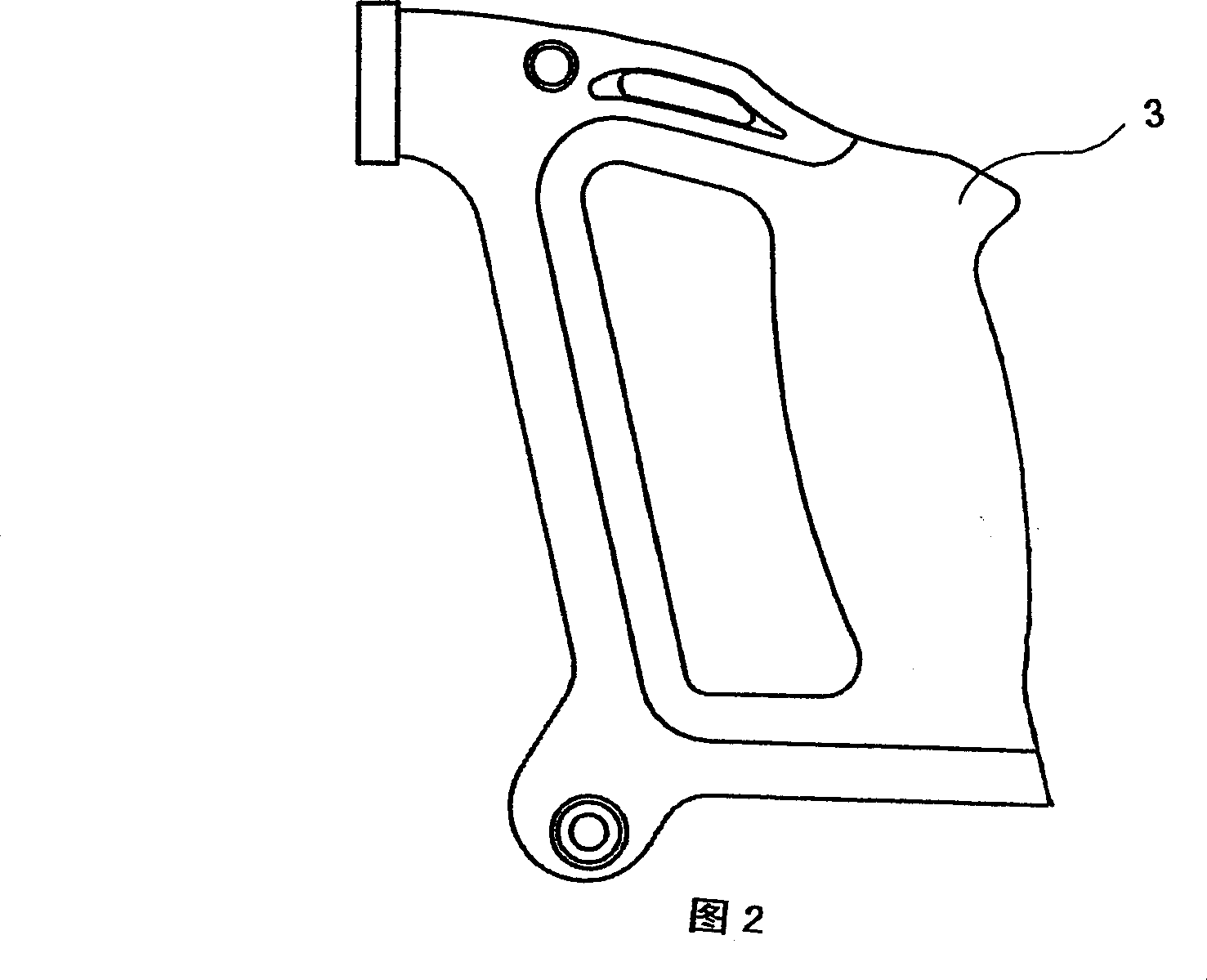

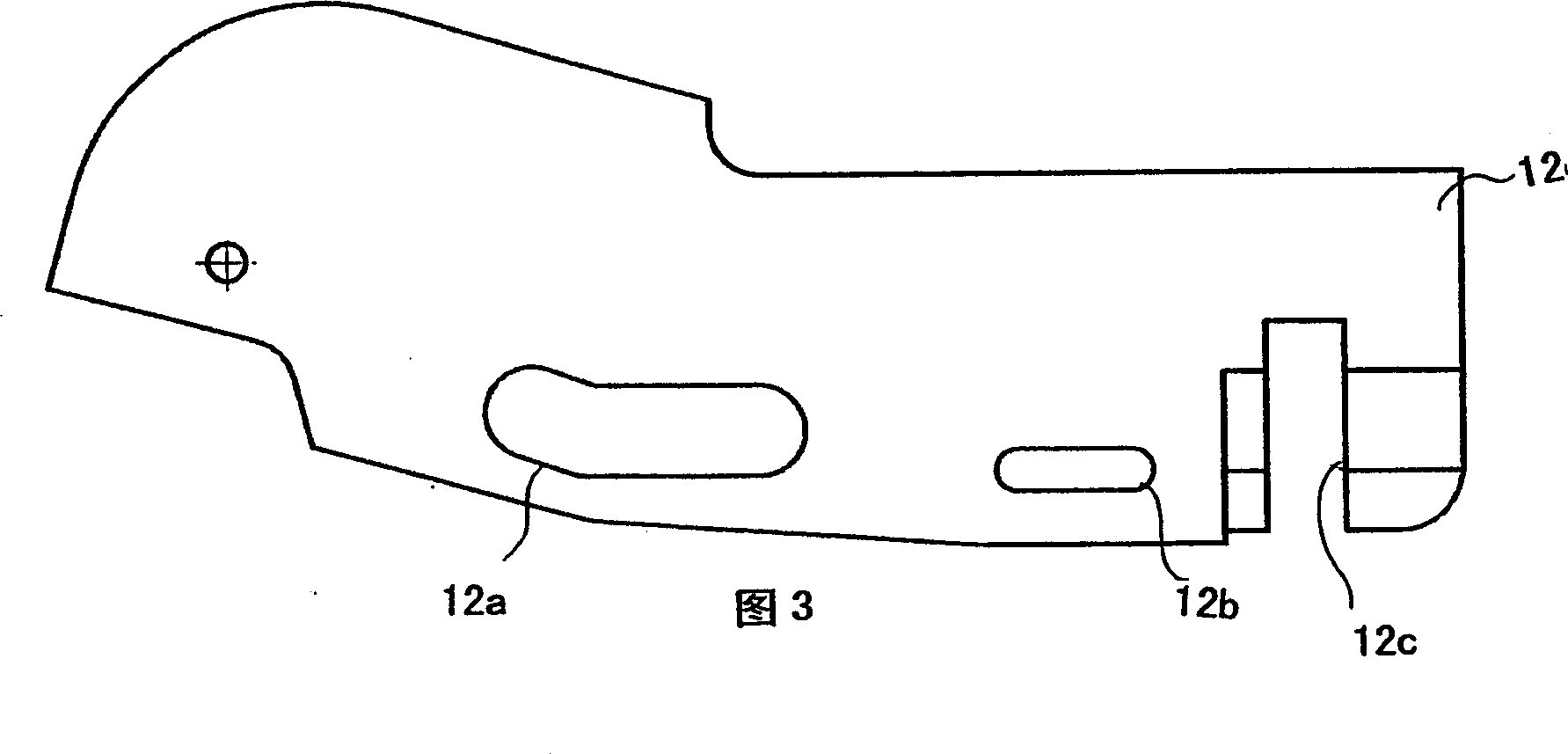

Sawing height instantly adjustable handsaw

InactiveCN100349681CSafe and quick replacementEasy sawingMetal sawing devicesEngineeringSupport point

The invention discloses an arm saw with its saw cutting height adjusting instantly, which comprises the arm saw frame that is formed by the antecurvature, the bending girder, the handle, the rocking cover and the backwardcurvature. The antecurvature and the backwardcurvature through their pull nails to equip the saw blades; the slot-heads at the two ends of the bending girder can be embedded in the slot holes on the antecurvature and the backwardcurvature; through the circumvolving of the slot-head adjust the height and direction of the saw cutting; as encountering the dead angle and the limitation of the height, the invention can also work. The backwardcurvature is at the inner side of the rocking cover, and the handle, the rocking cover and the backwardcurvature are equipped the active frame to fast load and unload the saw blade; the active node frame comprises the front, the back connecting boards and the active bolt to change the saw blade in time. The rocking cover through the revolving of the main supporting point and the transition of the side supporting point controls the precise displacement of the backwardcurvature.

Owner:舟山春蕾锯业有限公司

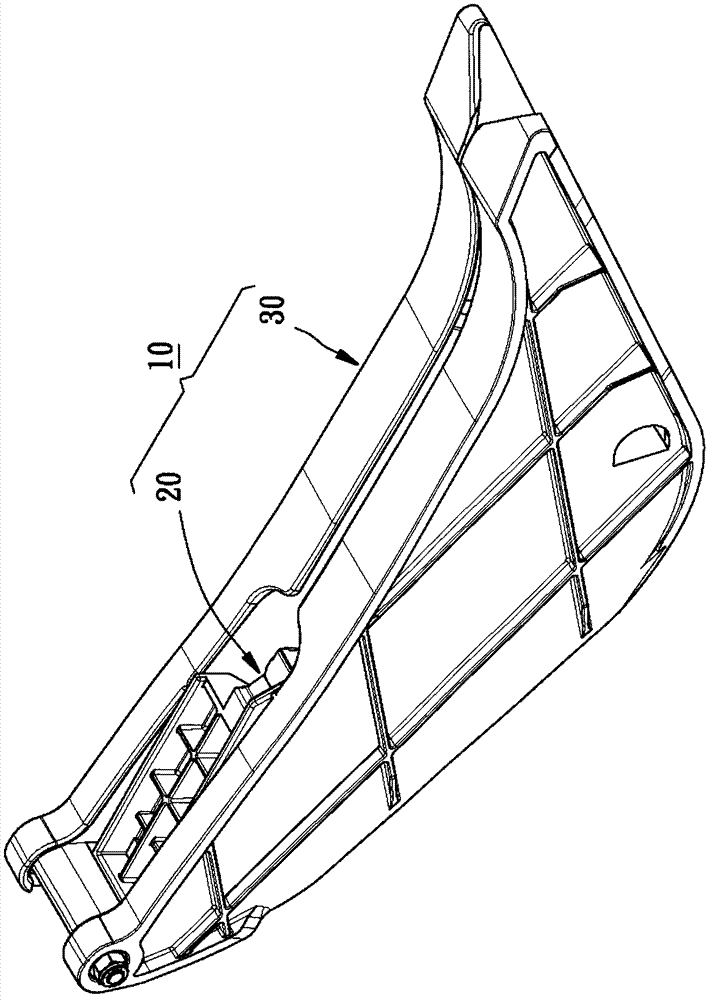

Automobile pipe cutting device

PendingCN109332805AGuaranteed to move forwardShorten the timeMetal sawing devicesEngineeringMachining

The invention relates to the field of automobile pipe machining devices, in particular to an automobile pipe cutting device. The automobile pipe cutting device comprises a base, a lifting structure, afixing structure, a sawing structure, a first feeding structure, a second feeding structure and a guiding structure; and the first feeding structure is arranged at the top end of the base. Through work of the first feeding structure, an automobile pipe rolling into the first feeding structure can be automatically conveyed to the right bottom end of the sawing structure, manual pushing is not needed, the time and labor are saved, continuous sawing can be achieved, and the work efficiency is improved; through the guiding effect of the guiding structure, it can be ensured that the pipe moves forward normally, and the jamming phenomenon can be avoided; and the second feeding structure is arranged at one end of the first feeding structure, through arrangement of the second feeding structure, the pipe can enter the first feeding structure in an automatic rolling-in mode, the time and labor are saved, the work efficiency is improved, and the continuity of sawing work can be achieved.

Owner:邢箫

Thermal stress reduction

ActiveUS8928121B2Cost optimizationQuality improvementTransistorSemiconductor/solid-state device detailsEngineeringStress reduction

The present invention relates to a method for thermal stress reduction on a wafer, comprising the steps of providing a patterned wafer with saw lanes between adjacent dies, forming thin holes within the silicon substrate, which holes create a dotted groove in the saw lanes, and wherein no second layer on an opposing side of the wafer is formed, a patterned wafer obtained by said method. The forming of the holes is preferably combined with other processing steps or another step to avoid additional operations and manipulations prior to, or after standard wafer processing, and it therefore optimizes fabrication quality and costs. Preferably the holes within the silicon substrate having a depth of more than 3 to 50 μm, preferably from 5-40 μm, like 20 μm.

Owner:NXP BV

Semiconductor package and method for manufacturing the same

InactiveUS20090289338A1Reduce processing stepsHigh mechanical strengthSemiconductor/solid-state device detailsSolid-state devicesSemiconductor package

A semiconductor package includes a carrier, a chip, a stiffener and an encapsulant. The chip is disposed on the carrier. The stiffener is disposed around the chip, directly contacts the carrier, and is mounted on the carrier. The encapsulant is adapted to seal the chip and the stiffener.

Owner:ADVANCED SEMICON ENG INC

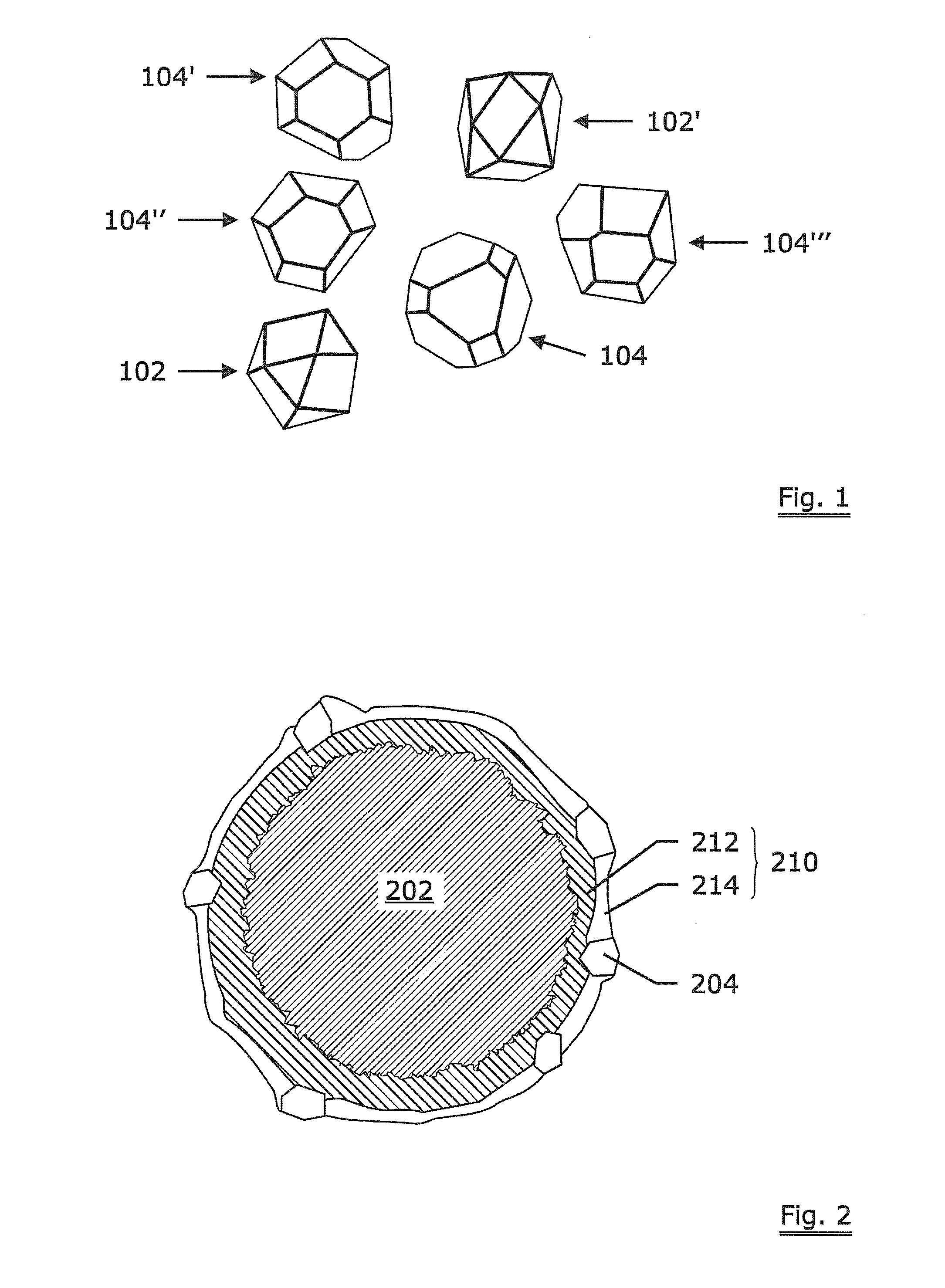

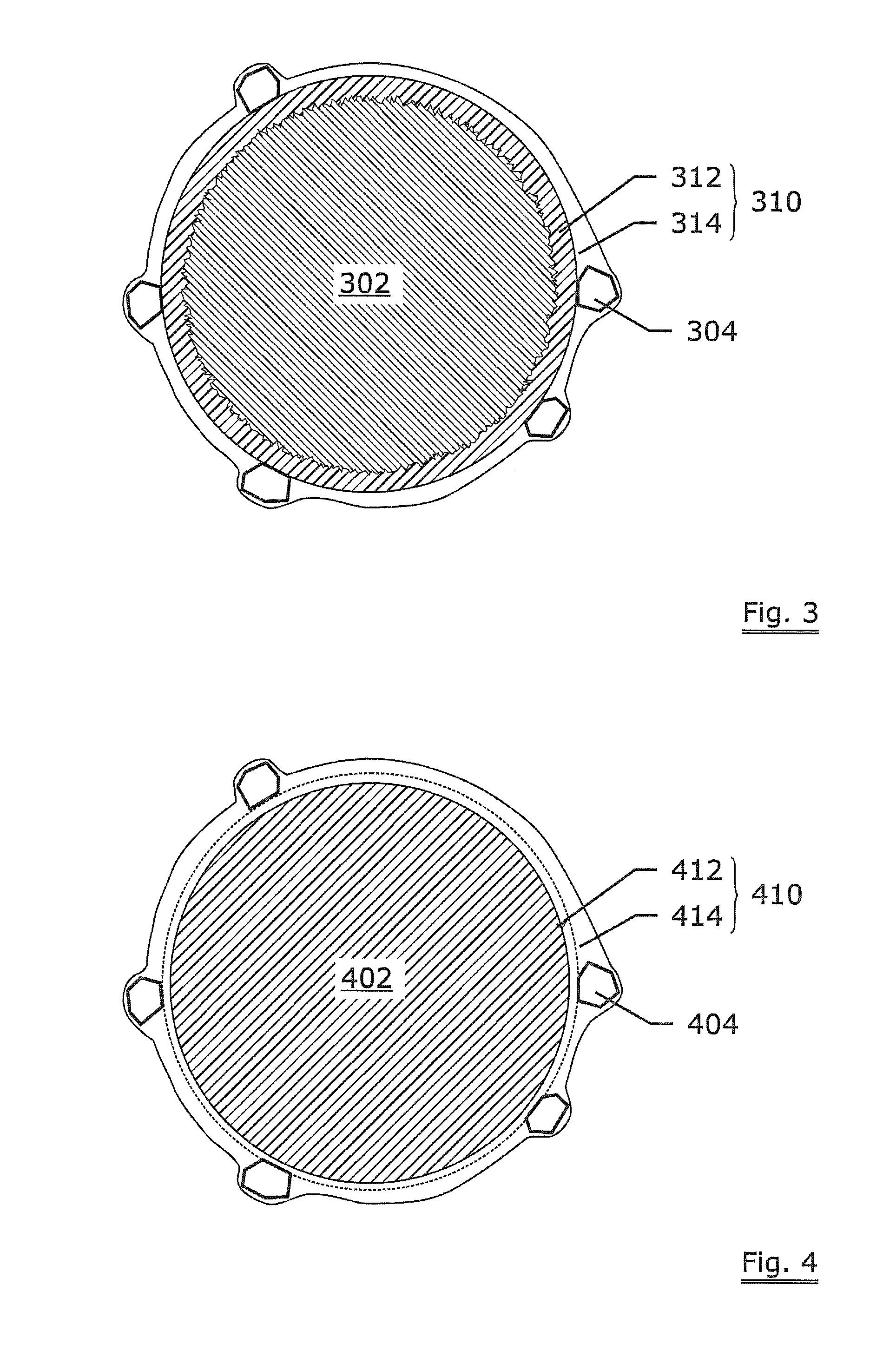

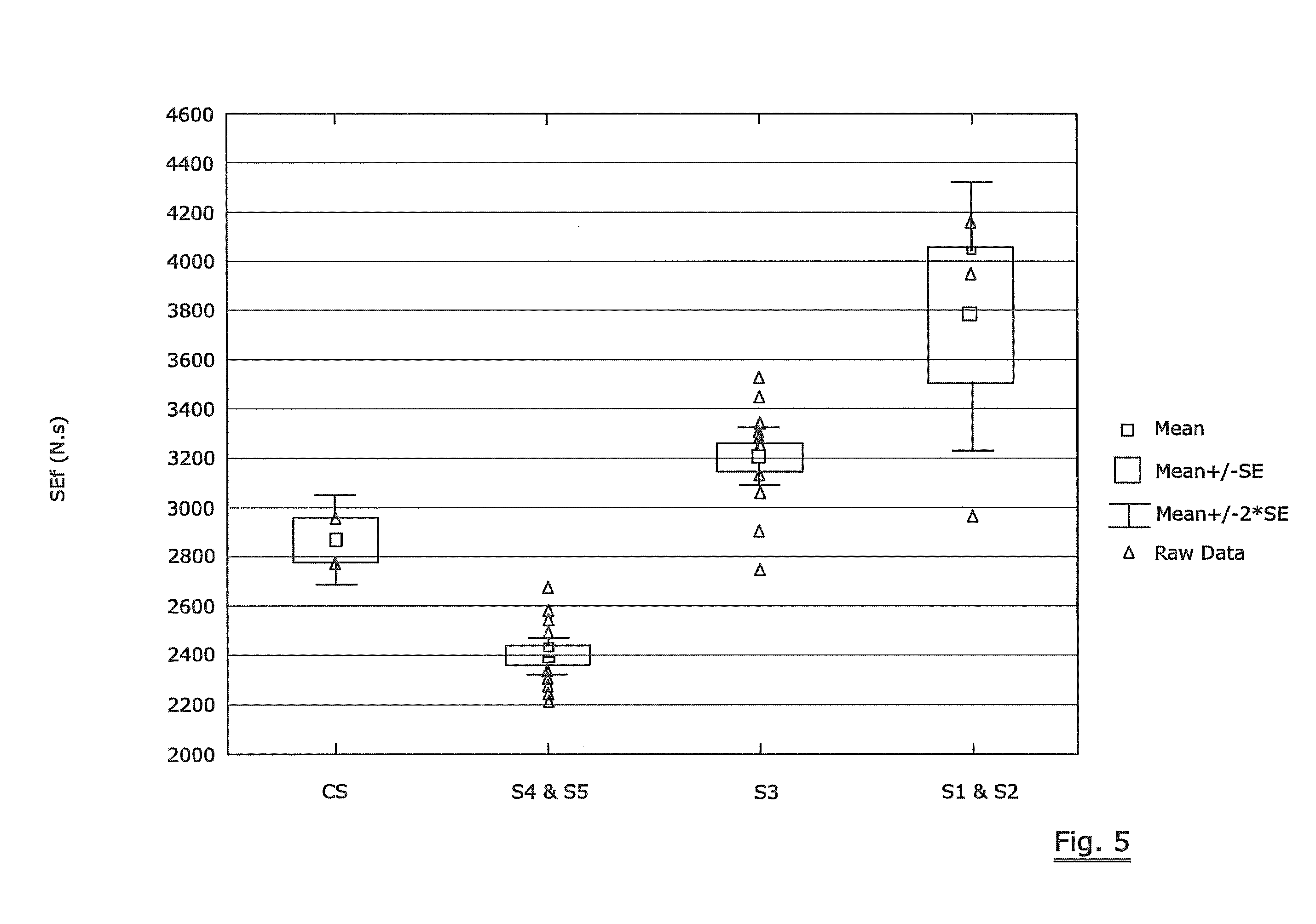

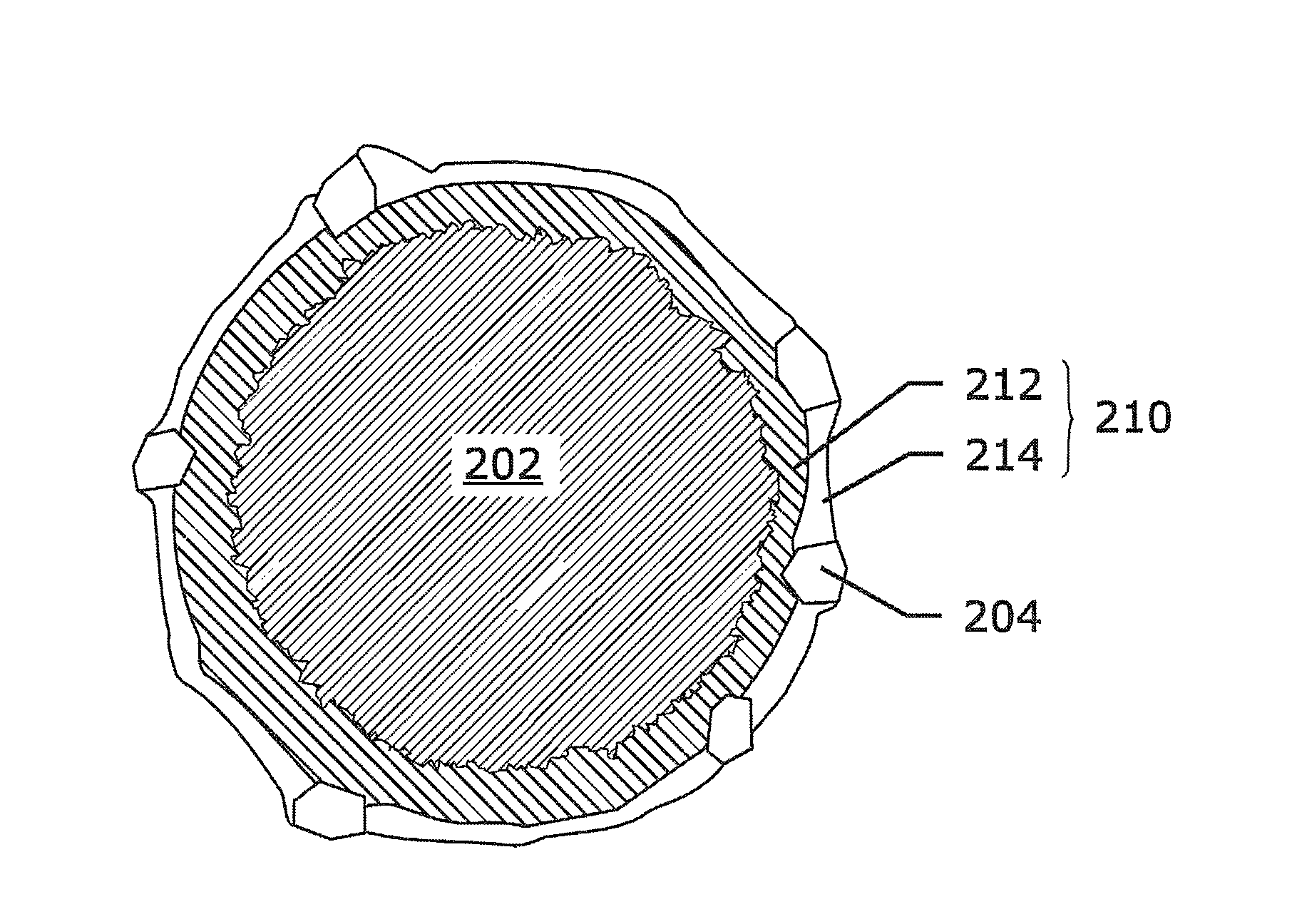

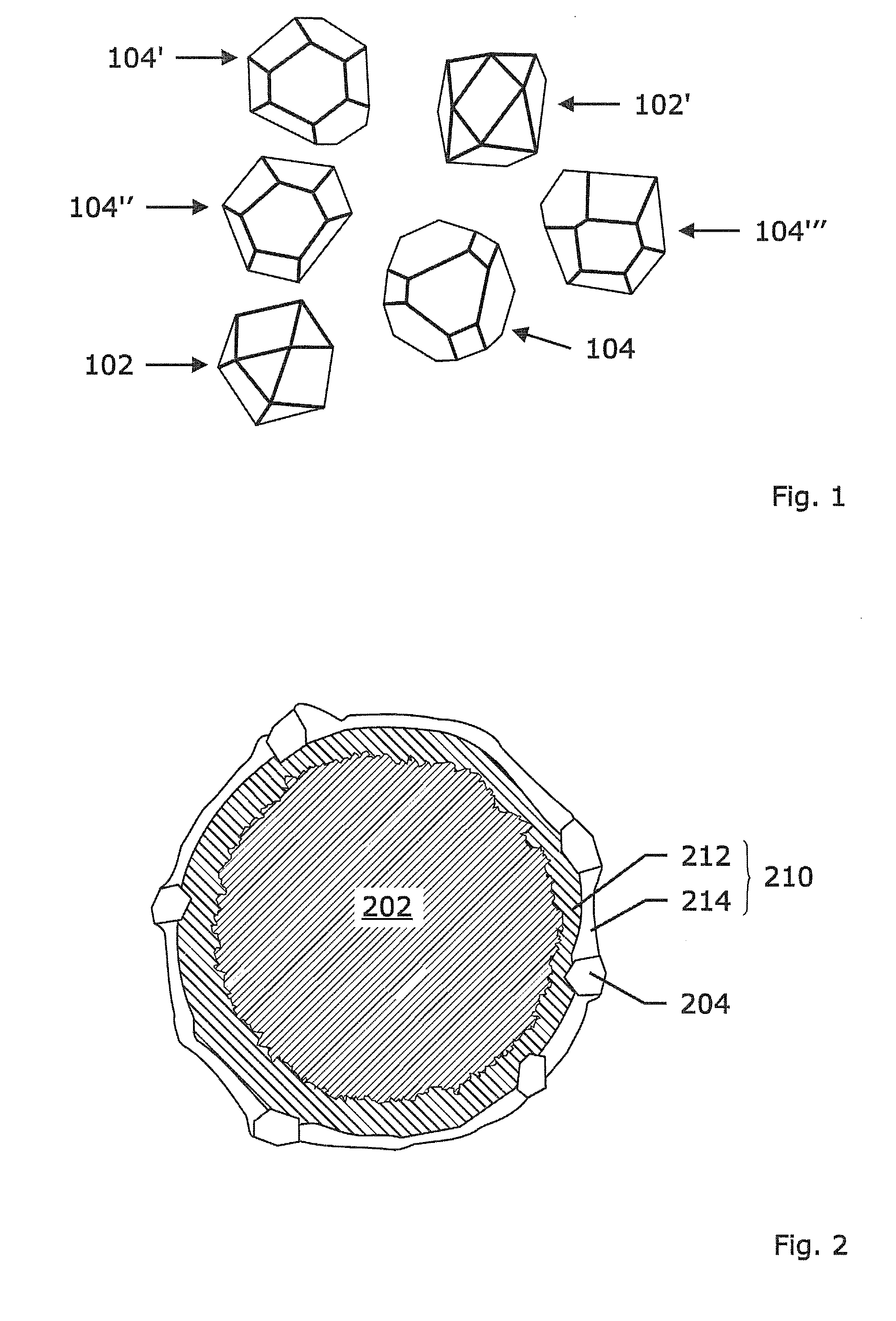

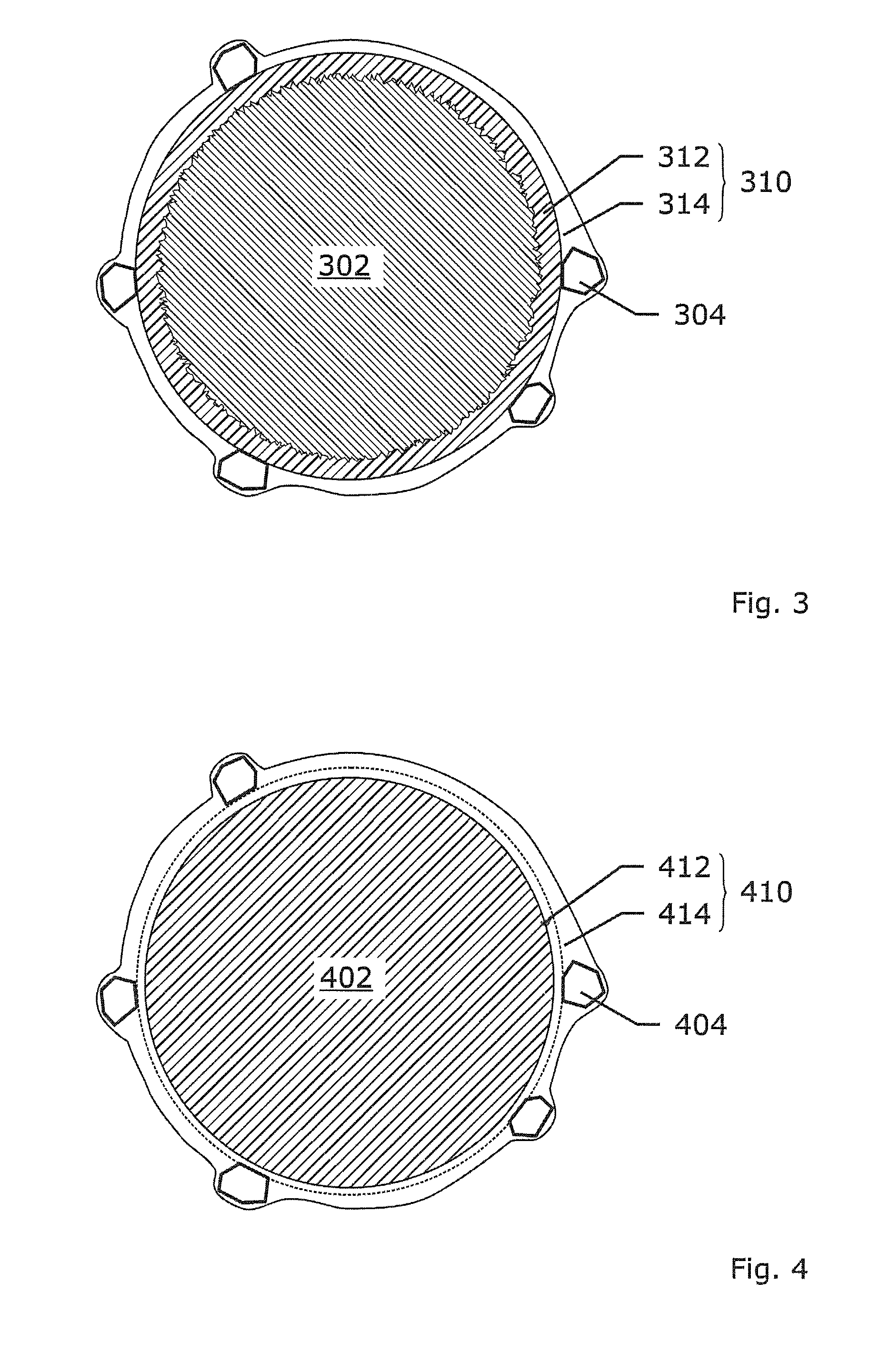

Fixed abrasive sawing wire with cubo-octahedral diamond particles

ActiveUS20150144120A1Easy sawingWeaken energyMetal sawing toolsStone-like material working toolsHigh pressureMetal

The invention a fixed abrasive sawing wire comprising diamond particles held in a metallic retention layer on a steel wire. The steel wire has a diameter less than 300 μιη. More than half of the diamond particles (102, 102′, 104, 104′, 104″, 104′″) have a cubo-octahedral morphology as obtained in the diamond synthesis by high pressure at high temperature. 95% of the diamond particles have a size of 80 pm or less. The diamond particles predominantly show low elongation below or equal to 0.2 and are not obtained by crushing larger diamonds.

Owner:BEKAERT BINJIANG STEEL CORD CO LTD

Refrigerator defrosting knife with serrated edge

InactiveCN103335476AEasy sawingEasy to manufactureLighting and heating apparatusDefrostingFrostEngineering

The invention discloses a refrigerator defrosting knife with a serrated edge, which mainly comprises a small knife body, a heating plate and a conductive wire, and is characterized in that the small knife body comprises a knife handle, a knife handle holder, a knife back and an edge, wherein a strip-shaped heating plate is mounted in the interlayer of the knife back, with two insulating strips respectively on two sides to allow the small knife body not to be electrified; the knife handle and the knife handle holder are made of non-conducting insulating materials; the heating plate is connected with the conductive wire which penetrates out of the knife handle from the center; the other end of the conductive wire is connected with a plug; once the plug is connected with a power, the heating is electrified and heated, and accordingly the temperature of the small knife body rises to about 200 DEG C, and the defrosting can be started. The small knife body adopts a serrated edge can quickly remove the frost on the inner wall of the refrigerator at a certain temperature, so that the purpose of labor saving and convenience are provided. Moreover, the defrosting knife is simple to manufacture, low in cost and easy to popularize.

Owner:陈东彩

Fixed abrasive sawing wire with cubo-octahedral diamond particles

The invention a fixed abrasive sawing wire comprising diamond particles held in a metallic retention layer on a steel wire. The steel wire has a diameter less than 300 μιη. More than half of the diamond particles (102, 102′, 104, 104′, 104″, 104′″) have a cubo-octahedral morphology as obtained in the diamond synthesis by high pressure at high temperature. 95% of the diamond particles have a size of 80 pm or less. The diamond particles predominantly show low elongation below or equal to 0.2 and are not obtained by crushing larger diamonds.

Owner:BEKAERT BINJIANG STEEL CORD CO LTD

An electric cutting knife for passion fruit

The invention discloses an electric cut-open knife for passion fruit. The electric cut-open knife is mainly characterized in that a lower clamping plate is arranged on the upper portion of a bottom plate of a knife rest, two sets of upward needle tips different in height are arranged at the rear end of an upward concave arc surface of the lower clamping plate along the arc surface, and the four corners of the lower clamping plate are connected with the lower ends of four support feet of a support; a first round through hole is formed in the center of a rectangular flat plate on the upper portion of the support; a pull rod is arranged in the first round through hole, and after the lower portion of the pull rod is sleeved with a compression spring, the pull rod is perpendicularly welded together with an upward convex arc top face of an upper clamping plate; an annular shoulder is arranged on the upper portion of the pull rod, and the upper portion of the pull rod and a handle are integrated through injection molding; two sets of downward needle tips different in height are arranged at the rear end of a downward concave arc surface of the upper clamping plate along the arc surface, and the downward concave arc surface of the upper clamping plate is opposite and parallel to the upward concave arc surface of the lower clamping plate; a knife body is composed of a blade, a plug, a wire, a fixing plate, a single-phase alternating current linear motor, a knife holder, a knife handle and a switch. The passion fruit can be cut open simply, conveniently and easily through the electric cut-open knife.

Owner:张芙蓉

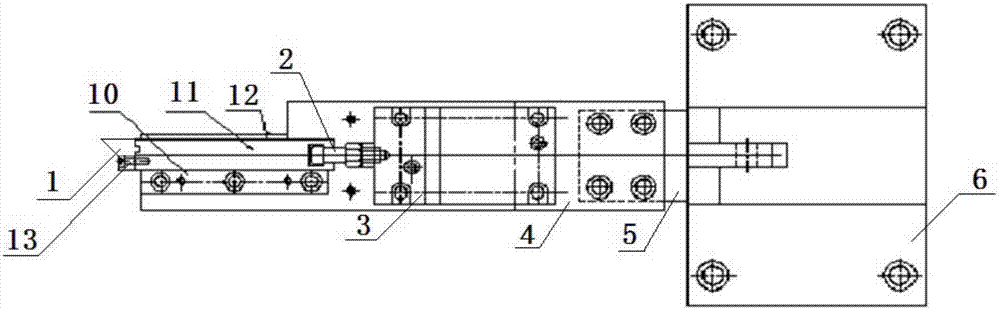

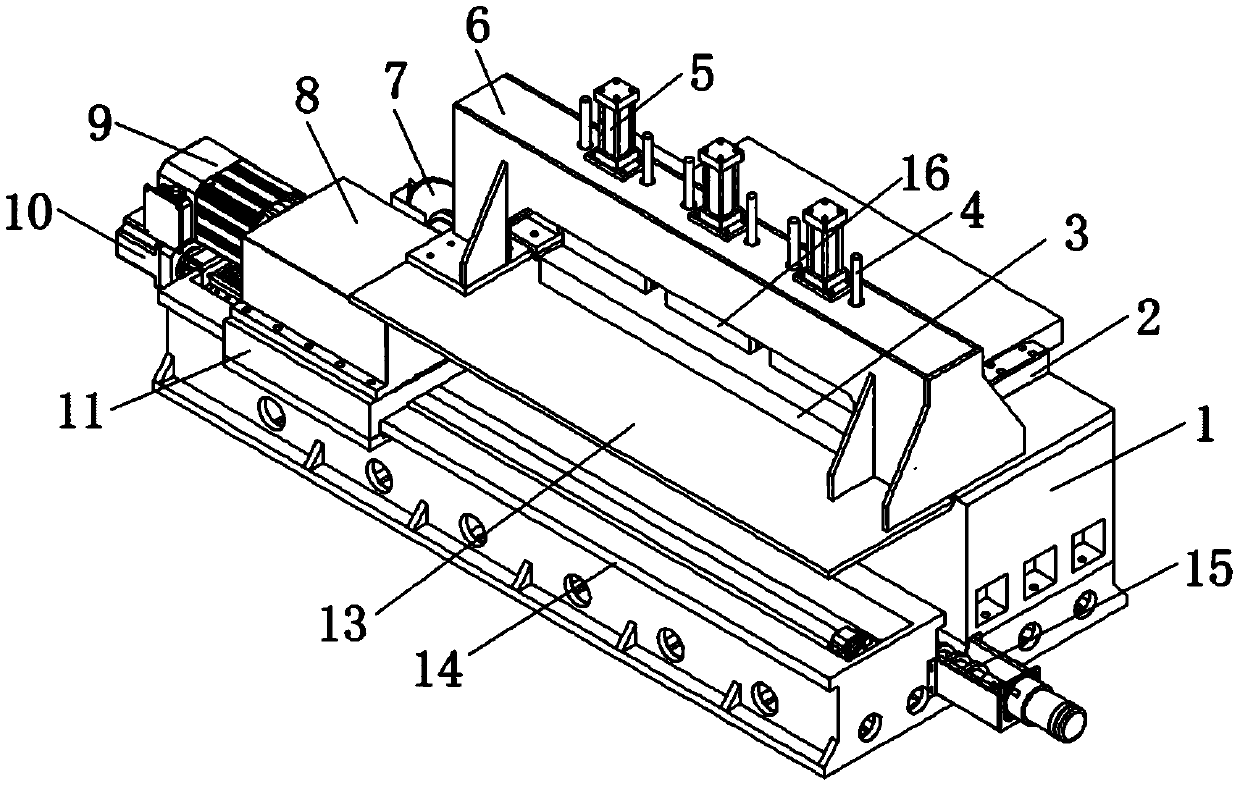

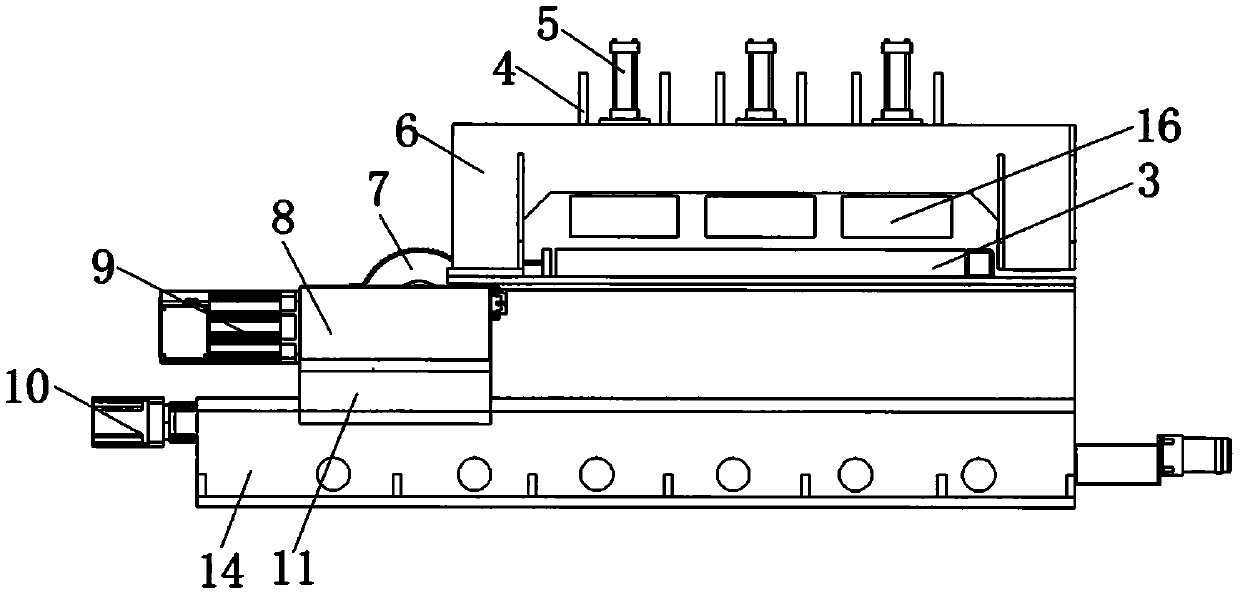

Rapid feeding device based on sawing machine machining and feeding method thereof

PendingCN113458838AImprove work efficiencyEasy to adjustMetal working apparatusPush outManufacturing engineering

The invention relates to the technical field of sawing machines, in particular to a rapid feeding device based on sawing machine machining and a feeding method thereof. The technical problems to be solved by the invention are that that in the prior art, a feeding function is not achieved, a plurality of bars cannot be pushed at a time, and the working efficiency is greatly reduced. In order to solve the technical problem, the rapid feeding device based on sawing machine machining and an adjusting method are provided, and a discharging mechanism, a pushing mechanism, a feeding mechanism and the feeding method are included. The width of a discharging opening is changed by pushing an adjusting plate, the width of a pushing opening is changed through a sliding plate, and multiple bars can be selected to be pushed at a time, so that the flexibility is achieved; the multiple bars can be pushed at a time, the working efficiency is greatly improved, and the adjusting method is simple; by means of the feeding mechanism, the bars can be pushed out little by little, a sawing machine can conveniently conduct sawing and other machining, and the feeding mechanism and a single-chip microcomputer module are matched so that more intelligence can be achieved.

Owner:王皓

Method capable of prolonging service life of fitter's tool

InactiveCN106270766APromote sheddingReduce frictional heatMetal sawing devicesFiling/rasping toolsHardnessEngineering

The invention discloses a method capable of prolonging service life of a fitter's tool. The method is characterized by including: alternately using two side faces of the fitter's tool when the fitter's tool is used for working. Compared with the prior art, the sawing method has the advantages that one side not being used for sawing is equivalent to normalizing, so that heat generated by friction can be reduced, and existence of a martensite matrix of a saw blade is ensured (in other words, hardness of the saw blade is ensured unchanged constantly or precipitation time of middle carbon of martensite is prolonged); saw dust is enabled to be crisp and prone to shedding, and a cut material is enabled to be crisp, so that cutting is better facilitated. By the filing method, one side not being used for filing is equivalent to normalizing, so that heat generated by friction can be reduced, and existence of a martensite matrix of saw teeth is ensured (in other words, hardness of the saw teeth is ensured unchanged constantly or precipitation time of middle carbon of martensite is prolonged); file dust is enabled to be crisp and prone to shedding, and a filed material is enabled to be crisp, so that filing is better facilitated.

Owner:张民生

Automatic plate splicing machine having lateral material ejecting function

ActiveCN106239650AIncrease exerciseLow movement resistanceOther plywood/veneer working apparatusPlywood pressesWood processorEngineering

The invention discloses an automatic plate splicing machine having a lateral material ejecting function and belongs to the technical field of wood processing machinery. The automatic plate splicing machine comprises a rack, an upper heating mechanism, a lower heating mechanism, a plate material pressing mechanism, a material turning mechanism and a material pushing mechanism and is characterized in that the material pushing mechanism comprises a pair of material pushing plate acting cylinders, material pushing plates and a pair of material pushing plate synchronizing devices. In a pair of rack left columns, a plate material end ejecting acting cylinder is arranged on one rack left column on the rear side of the left end of the rack and located at the position corresponding to the rear end of a plate material cavity, and the material ejecting acting cylinder column of the plate material end ejecting acting cylinder faces the plate material cavity. It is guaranteed that the plate materials in the plate material cavity are pushed into a plate material inlet port of a plate material moving channel under a balanced acting force one by one, the motion resistances of material pushing plates are decreased, the material pushing plates are protected, and the energy consumption of the pair of material pushing plate acting cylinders is reduced. The irregular ends of the plate materials located at the plate material cavity in an overlapped state can be regular to facilitate sawing executed by a sawing mechanism only to the ends, wood resources are saved, and the quality of whole spliced plate sheets is guaranteed.

Owner:无锡苏惠信息技术服务有限公司

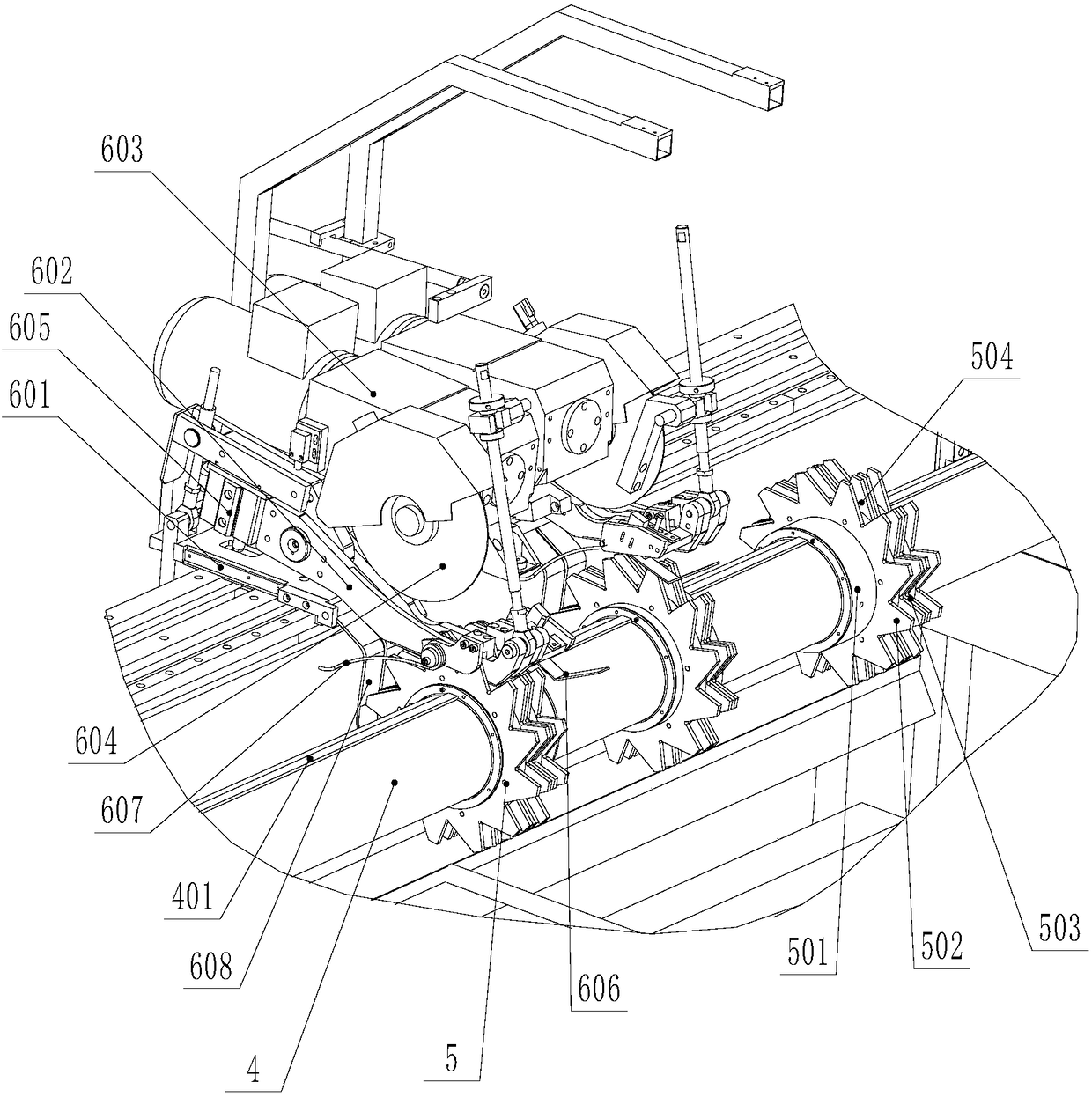

A sawing host of a pipe multi-head sawing machine

The invention discloses a saw-cutting mainframe of a multi-head saw-cutting machine for a tube. The saw-cutting mainframe comprises a rack, wherein a plurality of saw-cutting heads are installed on the rack, each saw-cutting head comprises a base installed on the rack, a support is installed on the base, a power box is installed on the support, a saw blade is installed on an output shaft of the power box, the position of the saw blade is corresponding to the position of a shifting gear group installed on a rotatable feeding spindle, a feeding gap for facilitating the saw blade to enter is arranged in the shifting gear group, and the depth of the feeding gap is greater than the tube diameter of the tube; and the length of each saw blade stretching in the corresponding feeding gap is greater than the tube diameter of the tube, and a compression device for compressing the tube shifted by the corresponding shifting gear group is arranged on the corresponding base. The saw-cutting mainframe is capable of carrying out rotary feeding saw-cutting by cooperating with the shifting gear groups, thus the saw-cutting efficiency is increased.

Owner:SUZHOU KINKALTECK MACHINERY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com